Mk1 MX5/Eunos Duratec Swap

flak monkey - 21/4/20 at 07:37 PM

Because I need another project.... obviously....

We have a really solid, rust free Mk1 MX5 which I have been doing a few bits on over the past couple of years. Was originally planning to stick a

turbo on it and call it done, but everyone does it and I have a bit of a dislike of turbos in sports cars.

So I had an idea to swap what is effectively a Mk3 on drivetrain into it - 2.0 duratec, 6 speed box etc. It's certainly not a common swap and

there doesn't seem much info about it on the web.

I plan on running it on Megasquirt and bike throttle bodies. Relatively basic build with 210hp spec cams which should be enough to have some fun in

the twisties.

I picked up a very cheap 2004 Duratec from just up the road - £100 as it had been partly stripped and then sat in the corner of a workshop for a few

years. Was worth a punt.

Stripped it down this weekend - bores and bearings were all immaculate with the exception of a bit too much crank endfloat for my liking. So I decided

to put a set of new main and HD rod bearings in and will be fitting ARP bolts to the stock rods. I don't need to rev it more than about 7250rpm

anyway.

Washed the block down, brushed out all the galleries, cleaned and measured the crank, rods, bores etc and all is good. No signs of wear on the

pistons.

Deburred everything on the block and main cradle too since these motors are full of sharp edges and unfinished stuff from the factory, drives me

nuts.

Cleaned everything up and am just starting to put it all together again. Once the short block is built I'll strip the head and clean that up

properly.

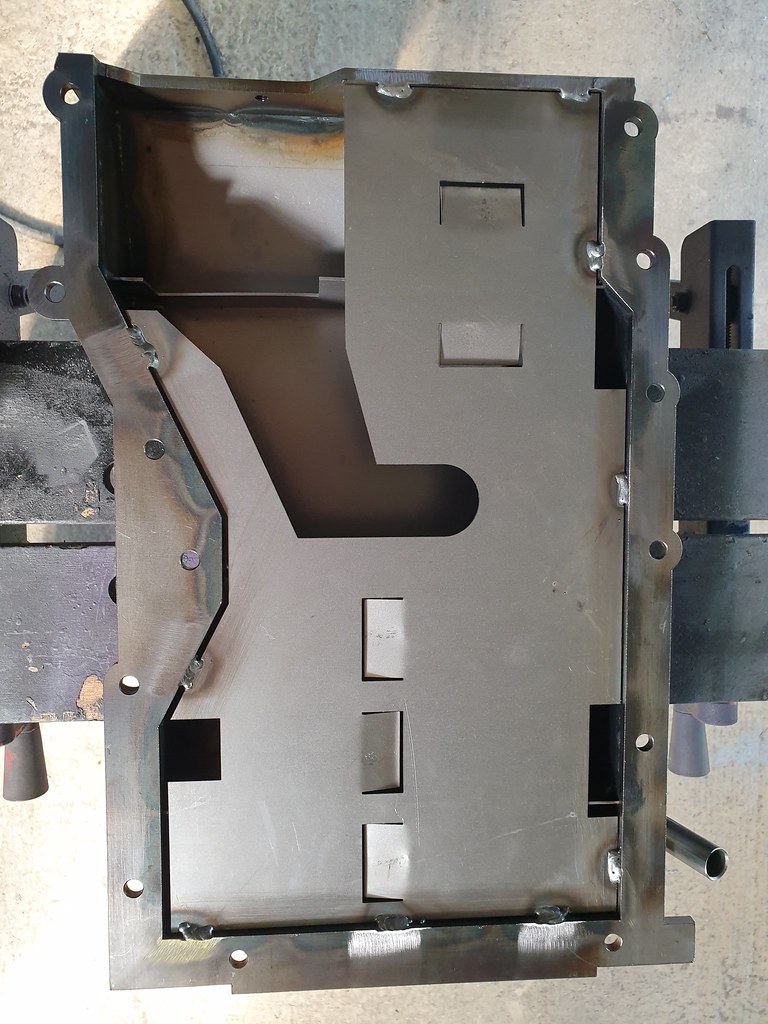

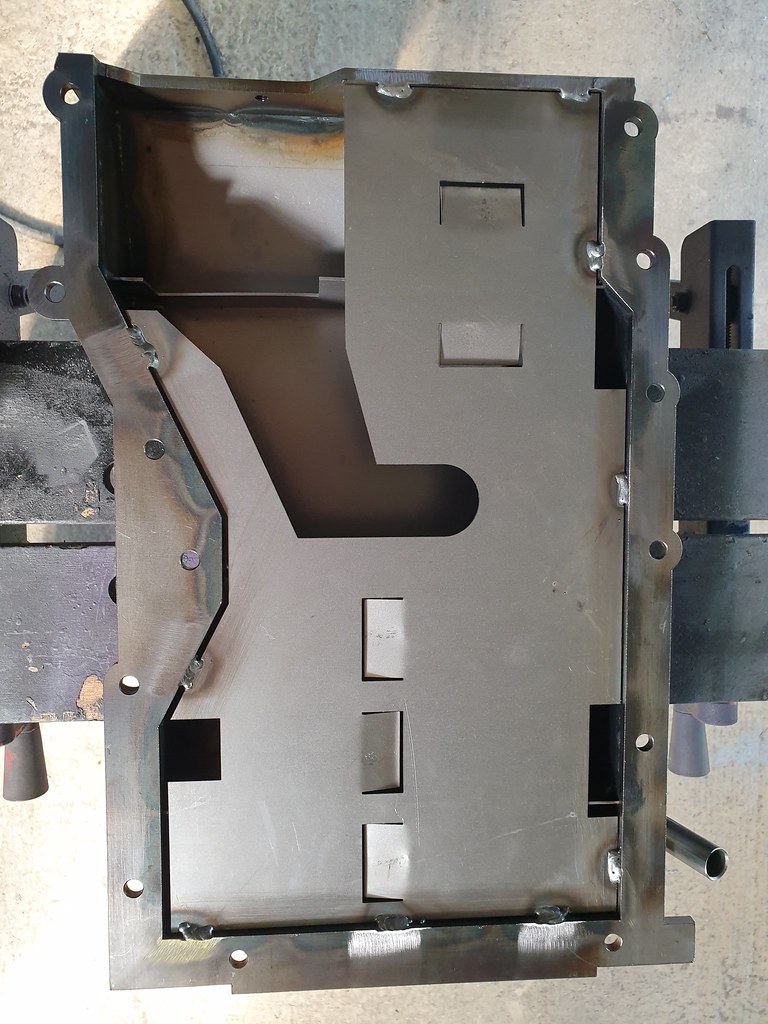

Oh and I'll be making one of my sumps for it too.

roadrunner - 21/4/20 at 11:38 PM

Looking good Flak.

snapper - 22/4/20 at 06:43 AM

Second photo, sensor in the middle of the block, is that a knock sensor?

flak monkey - 22/4/20 at 06:46 AM

quote:

Originally posted by snapper

Second photo, sensor in the middle of the block, is that a knock sensor?

Yes, standard spot for them on the duratec

wylliezx9r - 22/4/20 at 08:06 AM

Awesome project and IMO much better than adding a turbo to the old lump.

Golfedrocks - 22/4/20 at 12:16 PM

Great work, will be good to see the progress.

SJ - 22/4/20 at 12:37 PM

Where do you find the time!

flak monkey - 23/4/20 at 06:09 PM

Not sure I know where I find the time to be honest! Even with the current global chaos work is just as busy as ever...

I finished assembling the bottom end with new bearings and ARP rod bolts so thats now bagged up, waiting for the head and sump. I'm waiting for

my local laser cutters to get back to me, but I'll be ordering a few kits for the sumps and some inlet flanges while I'm there.

Ordered an MS2 kit from DIY Autotune in the USA last Friday, it arrived Monday... great service by those guys as always. Probably the 10th system

I've had from them, and they are always bang on.

A few of the usual mods, rad fan relay output, PWM idle valve and 2 spark outputs. Although this time I have built an external igniter module using 2

BIP373's to see if there is any difference in the amount of noise on signals by having those high current drivers outside the MS case itself.

I picked up a bargain set of early R1 throttle bodies - these are the ones which also have vac slides in them - the thought behind these was to smooth

part throttle response, I'm interested to see how this works in a car and whether it improves MAP signal at low throttle openings as I prefer to

use MAP for load rather than TPS. They might be crap, but you don't know if you don't try these things. And I've been around the block

enough times now to have the inclination to follow roads less travelled.

This is what they looked like when they turned up.

Interestingly they have a wax stat attached which controls air bleed valves in each body - this appears to act like an air bypass for warm up, much

the same as an IAC would on true EFI. I'm not planning to retain it since they are (according to some google research) quite temperamental and

prone to seizing up. I'll be removing it and going down the electronic IAC route as usual with EFI.

I am planning to retain the injectors in the Duratec head, and for reference the ones fitted to the current 2.5l engine in the Mazda are around

300cc/min and super cheap (I got a set for $75USD shipped). These will work great for an engine with throttle bodies and 210hp spec cams. This leaves

the holes in the throttle bodies which I might use as the air bypass for the IAC, currently undecided. I'll make a new fuel rail for the Duratec

since I have a length of blank in the workshop, that way I can use the return system and add an external FPR.

Anyway, this is what they look like stripped of everything I'm not going to use. I will split them and re-space them to suit the Duratec inlet

spacing.

I also have an alternator here from a Mazda 6 - bolts straight up, but it should be controlled by the ECU using a PWM signal to the D terminal to

control the regulator.

After a lot of research it seems that the PWM signal is ~1.3v at peak. With 0% duty cycle giving 0v output and 100% duty being ~18v output. I'm

planning to have a bit of a play around to see if I can trick it into charging at a constant ~14v like a normal alternator by building an external

regulator system. Why? Because I can and it will cost me nothing... if it doesn't work then the alternator goes in the scrap and I'll get a

little denso unit instead.

ettore bugatti - 23/4/20 at 08:54 PM

Racing beat makes a very nice exhaust manifold for the NC, well worth trying to fit that in.

Im surprised this swap is not more common.

snapper - 24/4/20 at 05:26 AM

Didnít take long did it !?!

I was going to follow your build closely on my build and you go and buy a build it yourself Megasquirt and do all that fancy stuff with the

drivers.

I already have a Denso alternator, light flywheel, AP clutch kit and bellhousing for Type 9 so was considering a V6 Type 9 with longer 1st.

I will u2u for detail about where you got the injectors from if you donít mind?

flak monkey - 24/4/20 at 07:43 AM

quote:

Originally posted by snapper

Didnít take long did it !?!

I was going to follow your build closely on my build and you go and buy a build it yourself Megasquirt and do all that fancy stuff with the

drivers.

I already have a Denso alternator, light flywheel, AP clutch kit and bellhousing for Type 9 so was considering a V6 Type 9 with longer 1st.

I will u2u for detail about where you got the injectors from if you donít mind?

Doesn't take me long once I get started

The V6 box has the longer input shaft if I recall? No big deal as they make bellhousings for it, as long as you have the right one. When I put the

Duratec in my GTS I put a BGH gear kit in it with a longer first and uprated layshaft bearings.

I got the injectors from Injector Planet

https://injectorplanet.com?ref:ODE5ODYuNTguODE2MTIuVA

The part number is 0280158156

sebastiaan - 24/4/20 at 10:16 AM

That alternator.... Bonus points for using the boost control PWM output from the megasquirt and cut the dutycyle to zero at TPS>90%!

flak monkey - 26/4/20 at 04:31 PM

Done a little bit more over the weekend, although have mostly been on gardening duties!

Stripped all the valves from the head, washed it down, checked it all over and reassembled with the standard valves and springs etc with some new stem

seals for good measure.

Got it bolted back down to the block with new standard bolts.

Made a blanking plate for the EGR too from a bit of 4mm aluminium offcut

Found a bit of fuel rail extrusion when I was clearing my workshop for moving a few month back, glad I kept it. The stock Duratec fuel rail

doesn't have a return, and they look like poo, so I made a new one. Luckily I spent a weekend organising my new workshop a couple of weeks back,

and I found all my special drills for doing the fuel rails. Just need the new injectors to turn up now...

rusty nuts - 26/4/20 at 07:40 PM

Why only half the valves?

sebastiaan - 27/4/20 at 06:02 AM

quote:

Originally posted by flak monkey

I picked up a bargain set of early R1 throttle bodies - these are the ones which also have vac slides in them - the thought behind these was to smooth

part throttle response, I'm interested to see how this works in a car and whether it improves MAP signal at low throttle openings as I prefer to

use MAP for load rather than TPS. They might be crap, but you don't know if you don't try these things. And I've been around the block

enough times now to have the inclination to follow roads less travelled.

Hi Flak,

In the interest of science and having nothing better to do, I ran a MAP line from the R6 (38mm) ITB's to the megasquirt yesterdays. My engine

idles at 60kPa, so probably a bit too high to properly run speed-density. This is a bone-stock Alfa 2 liter "Nord". so YMMV.

flak monkey - 27/4/20 at 08:31 AM

quote:

Originally posted by rusty nuts

Why only half the valves?

They are all there, angle of the photo makes it look like half are missing

quote:

Originally posted by sebastiaan

Hi Flak,

In the interest of science and having nothing better to do, I ran a MAP line from the R6 (38mm) ITB's to the megasquirt yesterdays. My engine

idles at 60kPa, so probably a bit too high to properly run speed-density. This is a bone-stock Alfa 2 liter "Nord". so YMMV.

Interesting, thanks

peter030371 - 27/4/20 at 10:50 AM

quote:

Originally posted by flak monkey

Stripped all the valves from the head, washed it down, checked it all over and reassembled with the standard valves and springs etc with some new stem

seals for good measure.

How did you clean the head? I guess you are adding a very mild cam which is the same route I am taking with my new head but at what point would you

consider a head skim is needed for a mild cam?

flak monkey - 27/4/20 at 11:26 AM

quote:

Originally posted by peter030371

quote:

Originally posted by flak monkey

Stripped all the valves from the head, washed it down, checked it all over and reassembled with the standard valves and springs etc with some new stem

seals for good measure.

How did you clean the head? I guess you are adding a very mild cam which is the same route I am taking with my new head but at what point would you

consider a head skim is needed for a mild cam?

The same way I clean all my engine parts.... a big tray full of kerosene and some hard work with a scrubbing brush or brass wire brush and bottle

brushes and a rifle cleaning kit for oil galleries  . Kerosene is great at dissolving the gum which holds oil and carbon deposits on to all the parts

- it's also a bit less flammable/volatile than petrol, but still comes with a health warning!

. Kerosene is great at dissolving the gum which holds oil and carbon deposits on to all the parts

- it's also a bit less flammable/volatile than petrol, but still comes with a health warning!

I'm going to fit a set of Raceline 210hp cams when I have the money available.

You are limited to how much you can skim the head on a Duratec, otherwise the front cover doesn't fit any more. I wouldn't consider taking

more than a clean up skim off the head (0.25mm), but normally it's not needed unless the head is warped. If you need to up the compression, the

only option is aftermarket pistons, and it gets expensive, really fast!

peter030371 - 27/4/20 at 11:41 AM

quote:

Originally posted by flak monkey

The same way I clean all my engine parts.... a big tray full of kerosene and some hard work with a scrubbing brush or brass wire brush and bottle

brushes and a rifle cleaning kit for oil galleries  . Kerosene is great at dissolving the gum which holds oil and carbon deposits on to all the parts

- it's also a bit less flammable/volatile than petrol, but still comes with a health warning!

. Kerosene is great at dissolving the gum which holds oil and carbon deposits on to all the parts

- it's also a bit less flammable/volatile than petrol, but still comes with a health warning!

I'm going to fit a set of Raceline 210hp cams when I have the money available.

You are limited to how much you can skim the head on a Duratec, otherwise the front cover doesn't fit any more. I wouldn't consider taking

more than a clean up skim off the head (0.25mm), but normally it's not needed unless the head is warped. If you need to up the compression, the

only option is aftermarket pistons, and it gets expensive, really fast!

I've not tried cleaning the head yet, other things to sort out first, but I have a range of brushes so just need to get some kerosene

Was only thinking of a 'clean up skim' if needed after the clean.

flak monkey - 30/4/20 at 09:17 AM

Slowly making some progress.

Made a couple of odd little plenum things - one for MAP signal to the ECU and the other as the IAC distribution to each throttle body, but I might do

something else for the IAC, I haven't decided yet.

Intake manifold arrived yesterday afternoon, so I managed to get the throttle bodies re-spaced and offered up for test fitting.

flak monkey - 1/5/20 at 05:32 PM

Change of heart on the alternator. The original one would have been in the way of the steering column and would just make it difficult to get the

exhaust out of the 'wrong side'.

Picked up a cheap Daihatsu Denso 80amp unit and set about making some brackets for it this afternoon. Belt routing should work ok, though not with a

bit of rope

It's all a complete mock up for now.

Abe - 1/5/20 at 05:58 PM

Man alive you blow me away with what you know and can do. Superb 👌👌👌

SJ - 1/5/20 at 07:25 PM

What's the top pulley driving?

flak monkey - 1/5/20 at 07:27 PM

quote:

Originally posted by SJ

What's the top pulley driving?

Power steering pump.

Planning to retain PS on the MX5

flak monkey - 3/5/20 at 05:40 PM

Done a bit more, but slowed down a bit.

One of the trickier things with the early R1 throttle bodies is getting a filter to fit. The backplates won't bolt straight up as the vac slide

spring covers are in the way. So my plan was to mod Pipercross PX500 filter and backplate onto them. I cut a new plate from some 1.5mm aluminium. 45mm

silicone hose pushed through tight fitting holes in the plate lets it clear everything. I'm just waiting for the trumpets to arrive which will be

pushed into the open ends and will serve to lock it all together.

The flywheel also turned up - standard NC MX5

sebastiaan - 4/5/20 at 01:07 PM

quote:

Originally posted by flak monkey

Slowly making some progress.

Made a couple of odd little plenum things - one for MAP signal to the ECU and the other as the IAC distribution to each throttle body, but I might do

something else for the IAC, I haven't decided yet.

Intake manifold arrived yesterday afternoon, so I managed to get the throttle bodies re-spaced and offered up for test fitting.

Great work. Careful though; mounted like that you may or may not be able to still balance the ITB's. I've them mounted the other way

'round and in my application it would be impossible to get to the balancing screws.

flak monkey - 4/5/20 at 01:18 PM

quote:

Originally posted by sebastiaan

Great work. Careful though; mounted like that you may or may not be able to still balance the ITB's. I've them mounted the other way

'round and in my application it would be impossible to get to the balancing screws.

Accessible from underneath, same as usual

Abe - 4/5/20 at 07:47 PM

Good stuff!!

flak monkey - 7/5/20 at 01:35 PM

Did some welding.... hopefully it will fit and clear everything... if not, then I'll be modifying it!

peter030371 - 11/5/20 at 12:35 PM

Hi Sera, sorry another question if you don't mind

I stripped my head at the weekend and I can't decide if my valve stems/and or guides are worn or not (never stripped any head like this before).

I can't find any data online but do you know what is acceptable if I measure the valve stems (I think they are 5.48mm new)?

rusty nuts - 11/5/20 at 01:29 PM

Valve guide/stem wear is normally checked by putting the valve in the guide and holding it off the seat check the sideways movement

peter030371 - 11/5/20 at 01:38 PM

quote:

Originally posted by rusty nuts

Valve guide/stem wear is normally checked by putting the valve in the guide and holding it off the seat check the sideways movement

Which makes perfect sense as the valve stem and guide are working together but what is 'acceptable' sideways movement? From what I have read

its seems down to experience but I have none