Yazza54

|

| posted on 14/12/10 at 05:17 PM |

|

|

Flatshifts

I've been looking at flatshifts for my R1 5PW Fury. Not the ram type ones... just a coil kill. Would be interested to know what other people are

running? I still want the paddles to operate mechanically.. just with a coil kill when I pull the paddle.

I've seen a couple of boxes that do the coil kill... but they don't come with a trigger switch. Then when I've looked into the

inline switches thatgo in the linkage rods they cost twice what the bloody coil kill electronic box costs!!!!

Ideas/Suggestions/Opinions welcome

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

|

|

MakeEverything

|

| posted on 14/12/10 at 05:38 PM |

|

|

Cant you make a switch system on the paddles using reed switches or microswitches through a relay?

Kindest Regards,

Richard.

...You can make it foolProof, but youll never make it Idiot Proof!...

|

|

|

RazMan

|

| posted on 14/12/10 at 05:39 PM |

|

|

I have often wondered about these kits and I would imagine the point where the switch is activated (top or bottom of the paddle travel) would be

critical if you are going to avoid a lot of crunching noises.

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Yazza54

|

| posted on 14/12/10 at 05:57 PM |

|

|

The proper switches are in line in the linkage and either react to a push or pull... these are about £200 alone! Then the box controls the coils and

the kill times etc is another £200 again!

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

Rocket_Rabbit

|

| posted on 14/12/10 at 06:50 PM |

|

|

quote:

Originally posted by Yazza54

The proper switches are in line in the linkage and either react to a push or pull... these are about £200 alone! Then the box controls the coils and

the kill times etc is another £200 again!

Are they?

I'm sure you can get a full solenoid flatshift auto-blipper for under £400.

|

|

|

PAUL FISHER

|

| posted on 14/12/10 at 08:15 PM |

|

|

The best ones Ive used are either the Pingle or the Klicktronic, both with steering wheel electronic push buttons for up and down shifts, I had the

Flatshifter pro on one of my Indys a couple of years ago, great for up shifts, but the autoblip down shift was a bit poor, but since then they have

brought out the Flatshifter Max, could be what you are looking for.

http://www.flatshifter.com/

|

|

|

Yazza54

|

| posted on 23/12/10 at 11:49 AM |

|

|

Bought a translogic system. British superbike recommended, got it for a good price and the switch is tiny, looks very well made. With limited space in

the linkage this is the only one that would work. Will post pics later...

P.s retails about 380 Inc vat, got it off eBay for 320 posted recorded..he's got 4 left. Came this morn, very pleased.

It's plug and play to the coils, needs ground and ignition live which are easy enough to do. Figured out how it'll fit to the linkage and

did a little CAD drawing so my dads engineer friend can make the adapters (linkage is m5 but shift switch is m6), has a map switch for the dash too

for different kill times.

Got to keep busy when winter stops play

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

noc231073

|

| posted on 24/12/10 at 02:25 PM |

|

|

anyone fit the flatshift pro system how does the vacum work???

|

|

|

PAUL FISHER

|

| posted on 24/12/10 at 05:14 PM |

|

|

U2U sent

|

|

|

Yazza54

|

| posted on 24/12/10 at 08:01 PM |

|

|

I didn't take a pic as I got carried away and just fitted it all :p

Just waiting on the adapters now for the sensor and I'll stick some pics up of how it all fits in etc. After looking at all the kits this is the

best packaged in terms on sensor size and fitment I could find. It's a very well finished product in terms of the loom, switches, sensor etc...

looks like good value, if it works as well as it should I'll be made up.

It's this one..

http://www.translogicuk.com/quickshifter-system-2.htm

Vid of one on a sidecar...

http://www.youtube.com/watch?v=u7gCGJ8ncgw

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

Yazza54

|

| posted on 30/12/10 at 01:50 PM |

|

|

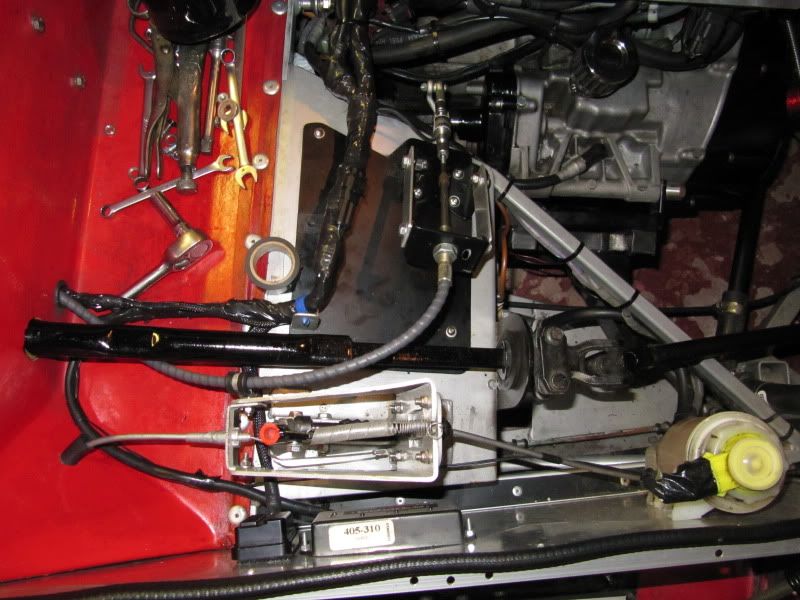

Fitted now..

White plugs are from the flatshift, the plugs from your loom plug into the flatshifter loom and then back to the coils. Dead easy to figure out.

Yellow switch on the dash controls base kill time, slowest is 70 millisecs, then 60 then 50. The other parameters are set by the sensor and flatshift

ecu, dependant on gear, revs etc.

Pressure sensor inline in the linkage, this one is a push sensor but pull ones are available too.

All in all very pleased. Shifts very smooth and feels a lot kinder on the gearbox, can definitely tell the difference when you change the kill times

too, faster but more harsh. The slowest setting is still very fast and is perfect for road/touring.

[Edited on 30/12/10 by Yazza54]

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

neo2

|

| posted on 30/12/10 at 09:43 PM |

|

|

Hi im liking the look of these now you have done the homework on them been looking for a while for my GSXR indy, im also in the middle of fitting the

paddle shifter to mine but its going to be using micro switches in the padals and a electronic soleniod at the lever end, i am retaining the interior

manual lever too for both options, just deciding which type to go for like yours or the type where the pressure switch is on the lever on the engine

itself, would you go for the same one again or choose different etc..

|

|

|

Yazza54

|

| posted on 30/12/10 at 10:30 PM |

|

|

I wouldn't change it, I'd rather have the sensor in the linkage right on the shift lever. Can't get any better placing than that,

coincidentally that was the only place I had enough room to fit it anyway. There wasn't enough room to fit it behind the paddle, but I'm

glad because it made me think of a better way. All I had to do was re route my shift cable around the steering column and make two 100mm brackets to

give room for the sensor arrangement. Also to fit the sensor I had 2 adapters machined up (did a CAD drawing for the little adapters), because my

linkage is M5 but the sensor thread is M6. Works perfect.

It's all perfectly rigid on the linkage and feels great through the paddle. The sensor works by push on mine and is solid on downshift. Though

being a sensor it's solid on upshift anyway, it's not like a switch..i.e you can't feel any movement if you press the sensor by

hand. Besides being a bit of a performance mod it just generally feels easier on the gearbox and nicer to drive.

[Edited on 30/12/10 by Yazza54]

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

neo2

|

| posted on 3/1/11 at 10:09 PM |

|

|

Nice mod that im thinking i want one mine has electric solenoid working the shift lever on the engine through paddles operated by switches instead of

cable, but ive still got the full lever in as well, as back up in case of solenoid failure..

|

|

|

Yazza54

|

| posted on 3/1/11 at 10:13 PM |

|

|

quote:

Originally posted by neo2

Nice mod that im thinking i want one mine has electric solenoid working the shift lever on the engine through paddles operated by switches instead of

cable, but ive still got the full lever in as well, as back up in case of solenoid failure..

But no flatshift? So you still have to lift off when you pull the paddle which operates the switch?

Same principle if so.. you'll end up with a fully semi auto flatshift. As the solenoid pushing on the gear lever will work the pressure sensor.

Whereas mine is still manual as it's a cable to the paddle, albeit with full throttle upshift.

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

neo2

|

| posted on 4/1/11 at 08:34 PM |

|

|

Yeah thats right i still have to lift off throttle and then click paddle etc

|

|

|

Yazza54

|

| posted on 4/1/11 at 09:02 PM |

|

|

Well that'll work on the same principle. This one doesn't do downshift though I.e no auto blipper.

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

matt_gsxr

|

| posted on 4/1/11 at 10:22 PM |

|

|

Yazza,

You might want to triangulate your bracket, at the moment its only the clamping of the bolts that is stopping it rotating. When it goes rotate it

might knacker your cable.

Matt

|

|

|

Yazza54

|

| posted on 5/1/11 at 01:06 PM |

|

|

It was never triangulated before though? Just bolted direct to the brackets. It's totally rigid. I guess it'd be easy enough to make two

ally L shaped brackets to meet them in the middle though.

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|

adithorp

|

| posted on 5/1/11 at 01:36 PM |

|

|

The bolts are probably man enough for the job as the pull is pretty much in line. If it's not in line though any movement will effectively alter

the cable length on the other hand.

I'd not put a lot a faith in Matt when it comes to cable pulls anyway...  I'llleave him to explain why. I'llleave him to explain why.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

RazMan

|

| posted on 5/1/11 at 05:19 PM |

|

|

That really is a neat little system - do you have a link for the pressure switches? I think they might come in handy for a future project.

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Yazza54

|

| posted on 5/1/11 at 05:37 PM |

|

|

http://www.translogicuk.com/quickshifter-system-2.htm

I bought mine brand new off eBay for 60 or so quid less than the list price posted, so it's worth checking on there too. Remember that there are

two different types of sensor... Push and pull depending on the direction your gearlever works on upshift. Also there's two versions.. GP and

Linear. Mines the gp which is best at either the paddle end or gear box end. I'd say gearbox end is always better. The linear is longer and

looks harder to fit, I think it's for going in the middle of the linkage on a bike.

Part no of mine is TLS-QS2GPPUSH

I did a CAD drawing for the m5/m6 adapters I had made to fit the sensor in the linkage too if anyone decides to use this system and needs it.

I'm unhappy cos I eat and I eat cos I'm unhappy

|

|

|