snapper

|

| posted on 22/4/17 at 06:36 AM |

|

|

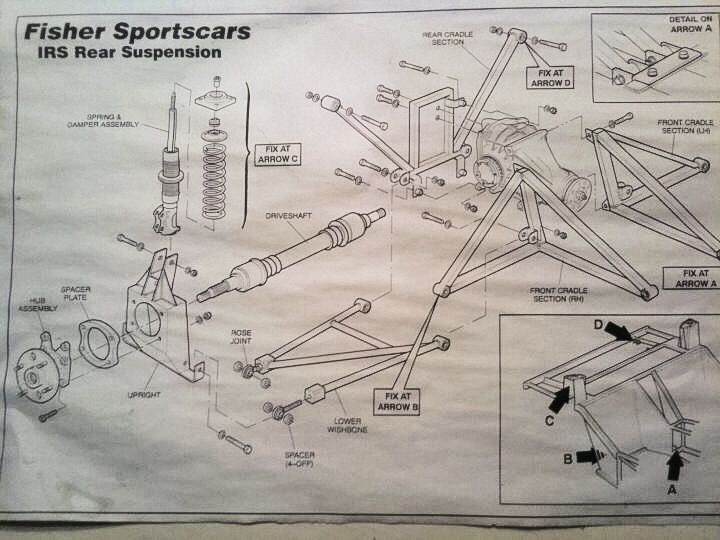

Convert live axle Fury to IRS

I found this and it looks like a bolt on conversion.

This interests me as I have a Quaife ATB in a Sierra diff on another car.

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

|

|

Schrodinger

|

| posted on 22/4/17 at 08:25 AM |

|

|

that looks interesting, could use that in my stylus.

Keith

Aviemore

|

|

|

owelly

|

| posted on 22/4/17 at 01:38 PM |

|

|

I made a de-dion that bolts into the trailing arm mounts of a live axle and picks up on the coil over top mounts. The whole lump rolls in and out like

a subframe.

http://www.ppcmag.co.uk

|

|

|

jeffw

|

| posted on 22/4/17 at 03:13 PM |

|

|

And did it handle better than the Live Axle?

|

|

|

FuryRebuild

|

| posted on 22/4/17 at 03:31 PM |

|

|

That is exactly my setup.

Mine is now modified with a training link - the rear is very stuck and planted. I even have the old spas off of it somewhere.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

Schrodinger

|

| posted on 23/4/17 at 07:30 AM |

|

|

Is that available or do you have to fabricate?

If fabricate are any dims available?

Keith

Aviemore

|

|

|

FuryRebuild

|

| posted on 23/4/17 at 07:46 AM |

|

|

Fabricate. Mark Fisher abandoned it as not cost-effective. They went to a double-wishbone setup instead. He did state that the geometry was better on

this setup.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

Ugg10

|

| posted on 23/4/17 at 08:22 AM |

|

|

I (then sold to Mazie on here) had a similar IRS setup on my fury direct from the factory, bought 2000. As already said, mark moved to double wishbone

as it was easier/cheaper to make. Marks view was that the IRS was not really that much quicker on the track but slightly more forgiving on the road

but really not much in it, availability of parts probably drove the change.

If fabricating I would try and introduce an mx5 Torsen diff and hubs, more available.

[Edited on 23/4/17 by Ugg10]

[Edited on 23/4/17 by Ugg10]

---------------------------------------------------------------

1968 Ford Anglia 105e, 1.7 Zetec SE, Mk2 Escort Workd Cup front end, 5 link rear

Build Blog - http://Anglia1968.weebly.com

|

|

|

FuryRebuild

|

| posted on 23/4/17 at 09:43 AM |

|

|

I had a big off in mine at Harewood and bent a lot at the back (including trashing a wishbone). A mentor of mine who builds champion cars and

who's son was national grass-track champion was always skeptical about the lower wishbone mounting. Under hard acceleration, the wishbone will

pivot on what are essentially quite weak brackets, and this upsets the geometry.

He convinced me to replace the wishbones with turnbuckles and add a trailing link. It utterly transformed the car. Now under hard accelerations

(including cornering) these torsional loads are totally negated by the trailing link to the chassis. I found at harewood that I went from a quite

snappy rear-end to something that was unstickable. It was actually a little scary because suddenly I wasn't sure when the rear would go, or how

fast. I then had to start working on front-wheel grip to reset the balance of the car.

The second advantage of going to turn-buckles rather than wishbones was pure setup time. On spherical bearings on the wishbones, I found it took most

of the day to set the geometry whereas with a turn-buckle, it was just a matter of undoing the bolts and giving it a gentle twist.

The final advangage was around spares - co-incidentally the length of each turnbuckle was the same as the sensible spot to put the trailing link. So

it meant that I could carry a spare link that would do either for side. Finally, each turnbuckle is quite cheap to make.

So, I think this IRS (I have no experience of the double-wishbone) had huge potential and all it took was a trailing link to sort out the flex in the

brackets.

For what it's worth, the entire rear suspension is currently off the car and due to go on quite soon, so if you want to see it laid out in all

its glory, give me a call. I don't mind if you want to take measurements or even get busy with the hot-glue and make a jig. My only request

would be to not damage the flashy powder-coat I've had applied.

If you're thinking of having a crack at it, I have the spax from the front and rear that are just sat there. The rear shock is a golf McPherson

strut item, I think. I'd sooner give them away than put them in the scrap bin.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|