mr henderson

|

| posted on 3/12/09 at 11:57 AM |

|

|

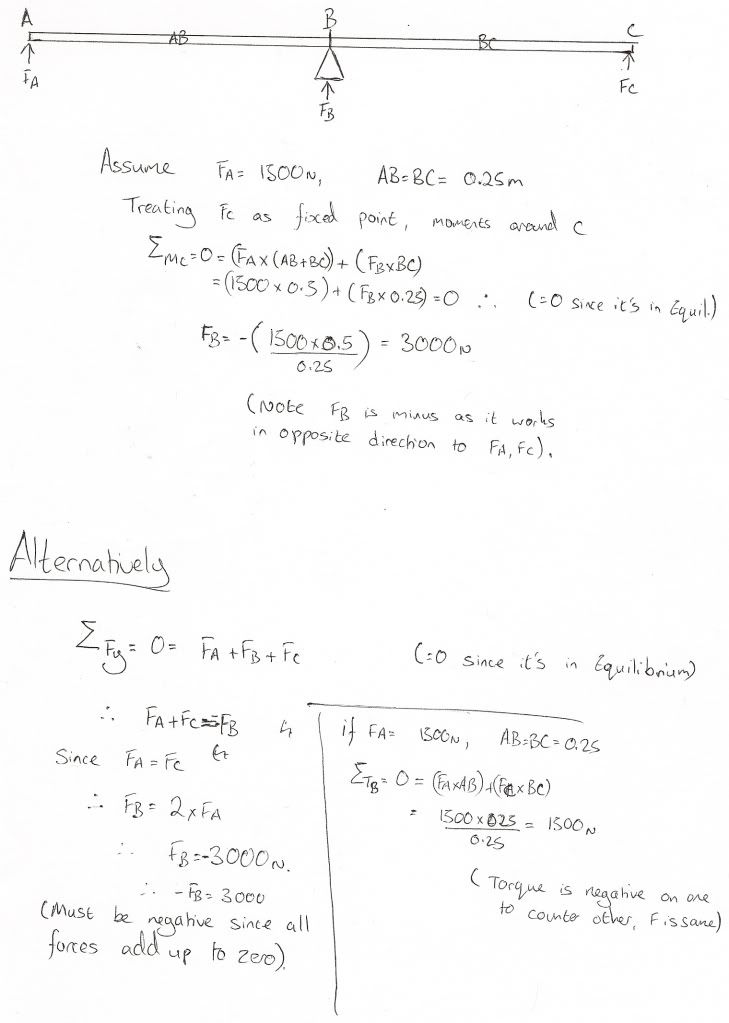

Engineer's input required, rocker suspension

I've attached a sketch of the way I think the forces involved in a rocker suspension work on the chassis. The assumptions are that the sprung

weight of the corner is 150kg, and that the pivot on the rocker (point X) is in the middle.

Have I got this right?

|

|

|

|

|

tegwin

|

| posted on 3/12/09 at 12:11 PM |

|

|

What about the lateral (left/right) forces? That top pivot will be hit with a lot of lateral force!

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

MikeCapon

|

| posted on 3/12/09 at 12:13 PM |

|

|

Hi Mr H. My view in my flued up state is the following.

Point Y. As it's a 1:1 ratio 150kgs in equal 150 kgs out so agreed.

Point X. Disagree here. Effectively the cars weight is all sitting on this pivot so it's 150 kg for me.

ETA. Doh.. Of course the rocker is effectively a 2:1 lever thus doubling the force to 300 kg. Matt, you were right and I was wrong.

Cheers,

Mike

[Edited on 3/12/09 by MikeCapon]

|

|

|

matt_gsxr

|

| posted on 3/12/09 at 12:14 PM |

|

|

I'm no chassis engineer, just a physicist but.

If the rocker is equal length then...

The chassis is pushing up at Y with 150kg force (yuck I know I should use N). In the same way that the rocker at the other end is being pushed up by

the wheel.

Therefore the rocker at X is being pulled away from the chassis with a 300kg (3000N force).

I hope that makes some sense. You can think of it by thinking what would happen if you took out a bolt (where would it go).

Matt

|

|

|

Dangle_kt

|

| posted on 3/12/09 at 12:21 PM |

|

|

quote:

Originally posted by matt_gsxr

You can think of it by thinking what would happen if you took out a bolt (where would it go).

Matt

what, into an old roses tin along with about 50 other bolts I can't find when I need them?

|

|

|

liam.mccaffrey

|

| posted on 3/12/09 at 12:43 PM |

|

|

Assuming the corner weight is 150kg taking moments about the inner upper connection tells you with a 1:1 ratio the middle pivot must be twice the

150kg.

Matt is right

[Edited on 3/12/09 by liam.mccaffrey]

[Edited on 3/12/09 by liam.mccaffrey]

Build Blog

Build Photo Album

|

|

|

Liam

|

| posted on 3/12/09 at 12:45 PM |

|

|

I had to work all this out for my design and if I recall (a long time ago!) matt-gsxr is correct. The pivot sees the corner weight plus the

reaction from the spring, i.e. corner weight x rocker ratio (only 1 in your 1:1 example) trying to pull it off the chassis. In other words a rocker

pivot has a hard life! Even more so if you have something more than a 1:1 ratio on the rocker as I do - i.e. shorter length inboard.

Liam

|

|

|

hughpinder

|

| posted on 3/12/09 at 12:50 PM |

|

|

I'm with matt_gsxr on this one.

Hugh

|

|

|

rachaeljf

|

| posted on 3/12/09 at 12:59 PM |

|

|

^^^

What he said

The fulcrum reaction equals the sum of the two end reactions. 150 + 150 = 300 I believe.

Cheers R

|

|

|

mr henderson

|

| posted on 3/12/09 at 01:16 PM |

|

|

Thanks for that chaps, makes very good sense.

|

|

|

aitch

|

| posted on 3/12/09 at 01:54 PM |

|

|

and of course these are only static loads

if the inboard section is shorter then the loads are higher (wouldnt it??)

e.g if the inboard section is half the length the leverage is halved, therefore the spring and dampner assembly would be under a 300kg static load and

the pivot 450kg static load.. ??

this seems right in my head

aitch

|

|

|

britishtrident

|

| posted on 3/12/09 at 05:45 PM |

|

|

Also be aware of the very high bending moment exerted by the lower end of the spring-damper unit on lower member.

[Edited on 3/12/09 by britishtrident]

|

|

|

Benonymous

|

| posted on 8/12/09 at 11:44 PM |

|

|

This probably explains why most inboard shock absorbers are connected to the suspension via a pushrod and a bellcrank. In Staniforths book I noticed

the rocker/wishbone set ups would create these very significant loads and have the disadvantage of being difficult to alter or adjust in some ways.

|

|

|

MikeRJ

|

| posted on 9/12/09 at 01:43 AM |

|

|

quote:

Originally posted by Benonymous

This probably explains why most inboard shock absorbers are connected to the suspension via a pushrod and a bellcrank.

The loading on bellcrank and pivots can be very high as well.

|

|

|

aitch

|

| posted on 9/12/09 at 07:56 AM |

|

|

and more connections linkages and pivots in a bell crank design, but it is more adjustable by its nature and more options to position of the spring

dampner assembly

aitch

[Edited on 9/12/09 by aitch]

|

|

|

kb58

|

| posted on 9/12/09 at 02:42 PM |

|

|

There's something wrong with this picture; since the car isn't moving, the total forces must total to zero.

There's 150kg pushing the outer end of the rocker upward, and since the rocker's balanced (not rotating), it means there's also

150kg upward force acting on the inboard end. Therefore, there's 150kg downward force on the bottom of the spring, so there's 150kg net

upward force on the rocker-arm pivot, not 75kg.

[Edited on 12/9/09 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

mr henderson

|

| posted on 9/12/09 at 04:02 PM |

|

|

quote:

Originally posted by kb58

There's something wrong with this picture; since the car isn't moving, the total forces must total to zero.

There's 150kg pushing the outer end of the rocker upward, and since the rocker's balanced (not rotating), it means there's also

150kg upward force acting on the inboard end. Therefore, there's 150kg downward force on the bottom of the spring, so there's 150kg net

upward force on the rocker-arm pivot, not 75kg.

The others seem to think that it's 300kg at that point, and I would have to say their explanation sounds good to me. Could you elaborate as to

why you believe that it is 150kg?

|

|

|

kb58

|

| posted on 9/12/09 at 04:28 PM |

|

|

I think the problem, maybe with my own opinion, is what the frame of reference is. I'm trying to look at just the frame - no tire - in order to

remove the confusion of an external reference.

I'll revisit this later when I have more time... maybe I need to pull out my statics book...

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

Liam

|

| posted on 9/12/09 at 05:13 PM |

|

|

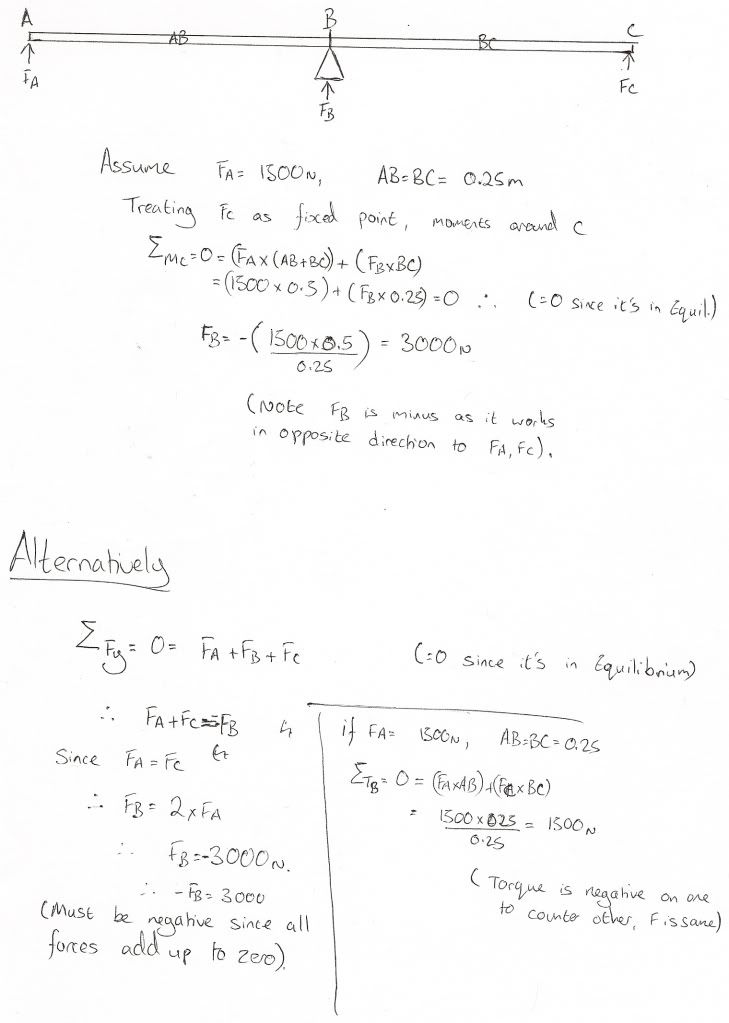

In a nutshell, you can consider that the 300kg pushing the rocker pivot upwards, is resisted by the 150kg spring force plus the 150kg corner weight

pusing downwards.

|

|

|

Badger_McLetcher

|

| posted on 9/12/09 at 06:23 PM |

|

|

The way I see it:

If disfunction is a function, then I must be some kind of genius.

|

|

|

aitch

|

| posted on 9/12/09 at 06:31 PM |

|

|

quote:

Originally posted by Badger_McLetcher

The way I see it:

cant argue with that

way i see it if the load is 150kg acting upwards on the arm then the oposing force of shock with the same leverage has to be the same 150kg acting

upwards on the arm,providing a total 300kg upward force that requires a 300kg downward force on the pivot point...

aitch

[Edited on 9/12/09 by aitch]

|

|

|

boggle

|

| posted on 9/12/09 at 09:57 PM |

|

|

wow....this is just like being back at college doing my H.N.D.

have you considered a single large damper mounted horizontal?

[Edited on 9/12/09 by boggle]

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|