CraigJ

|

| posted on 5/7/07 at 06:32 PM |

|

|

Locost Chain diff

Right i thought i put a small "how to" on building a sierra based chain diff. I wold like to say i take no responsibility or liability for

any diffs that are built by anyone following these instructions. My current diff is yet untested as my car will not be complete until late september

early october.

Right first you need a rear diff from a ford sierra. I used one from a 1.8 and its a non-lsd diff. The diff needs to be drained of its oil and then

the rear removed. once open you need to remove the 2 small cir-clips from the inside edges of the shafts, these can then be removed. A large C-spanner

or a hammer and chisel are then needed to remove the large rings on each side of the dff. Once these are off the diff unit can then be removed from

the casing. The diff unit then needs to be stripped of its old bearings and drive sprocket/gear. you should b left with a unit looking like this

One side can be welded up right away

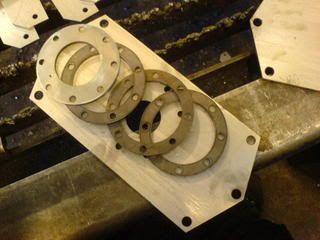

You now need 2 bearings which are sealed. They are 40mm bore, 80mm OD and 18mm wide like these Fag ones

Right the short shafts need to be taken down a mm or 2 as they are 41.3mm in diameter. This can be done on a metal lathe by an engineering firm for

very little cost. If you take in the diff and bearings they can make them fit.

You now need some why of mounting the diff. I have done this by making a housings out of meal see pic

with bearing inside

This first attempt was made from 5mm s/s and 6mm mild steel rings with a 2mm end piece. These have now been replaced with 8mm ali and 6mm ali rings to

keep the weight down a bit.

The complete unit will look somthing like this

s/s and mild one

I have now redone this with ali (just need to fit the ali rings.

Sprockets ali and mild steel

I have all the diamentions needed to make the parts which i will post up tomorrow.

All together this has cost-

diff 50 pound

Bearings 15 pounds each

nuts bolts 10 pounds

The ali, s/s, mild steel parts will differ in cost but expect to pay up to 50 pounds for them to be laser cut or done by water jet. would advise water

jet for the ali as laser leaves burrs on thicker ali. (im a laser profiler and belive me its a pain to get 5mm+ ali to cut east without burrs.

This isnt the best guide but if it helps some people save a few houndred quid its worht it lol. If i have missed something off just let me know, or if

you have any questions please ask. I may build a few of these to sell later this year once it has been tested but not before.

A pic of it in the chassis

S/s 1. as you can notice the bottom of the diff mounting has been modified and made slimmer for more clearence.

|

|

|

|

|

MikeR

|

| posted on 5/7/07 at 07:02 PM |

|

|

daft question,

how do you keep the oil in the diff & how do you get enough in there?

|

|

|

CraigJ

|

| posted on 5/7/07 at 07:21 PM |

|

|

The side that has'nt been welded up yet will have a bleed nipple fitted or a simple nut/bolt fitted to it so it can be filled with grease

instead of oil.

|

|

|

MikeRJ

|

| posted on 5/7/07 at 07:27 PM |

|

|

Ingenious bearning mounts!

I think you may need to seal the driveshaft flanges into the diff somehow, or I reckon oil could leak out here.

|

|

|

CraigJ

|

| posted on 5/7/07 at 07:38 PM |

|

|

will be packed with grease not oil but i have been thnking of trying some O-rings of some sort just incase. Its still an ongoing project and i wont

know for sure ho well it works untill i get a chance to test it.

|

|

|

CraigJ

|

| posted on 5/7/07 at 07:40 PM |

|

|

double post.

[Edited on 5/7/07 by CraigJ]

|

|

|

COREdevelopments

|

| posted on 5/7/07 at 08:10 PM |

|

|

hey, i like that! a neat idea, well done you, also notice you use gt85! that is the best smelling lube out there!! mmmmm

|

|

|

minitici

|

| posted on 6/7/07 at 07:32 AM |

|

|

In one of your pics, it looks like you have welded the bearing to the spigot of the diff. Loctite bearing fit may have been more appropriate

|

|

|

Hammerhead

|

| posted on 6/7/07 at 09:46 AM |

|

|

this guy made a nice one too.

http://www.c42.mride.se/chaindrive.html

|

|

|

CraigJ

|

| posted on 6/7/07 at 02:24 PM |

|

|

quote:

Originally posted by minitici

In one of your pics, it looks like you have welded the bearing to the spigot of the diff. Loctite bearing fit may have been more appropriate

Yes i have put a couple of welds on it. When i took it down i went a tad too far, so the bearing was just spinning so a few small weld tacks did the

job. The diff spins very freely and has no friction from any of the parts.

|

|

|

NS Dev

|

| posted on 11/7/07 at 11:23 AM |

|

|

that's the setup most of the autograssers use (the ones that use a diff at all), except they generally use a plate type lsd unit, often escort,

with the holes in the housing plated over.

The issue is, as was mentioned, oil/grease leakage out from the side gears round the driveshafts.

I have seen some with oil seals fitted here and some just use o-rings as you propose, but they only have to do a handful of miles.

I'll be interested to see whether or not the grease will leak from yours, if it doesn't that is great news as it saves a lot of hassle not

having to fit the seals.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

cloudy

|

| posted on 28/7/07 at 04:18 PM |

|

|

Any plans on the tensioning of the diff+chain?

|

|

|