Rob Allison

|

| posted on 11/4/13 at 08:09 PM |

|

|

You can use the VTEC switch if you wanted to. But its full closed loop control thats needed. It can't just use PMW output as the oil pressure

changes will alter the cams timing position. The closed loom is needed to ensure the timing is kept where you want it. Much like idle control.

I think the cam runs 4 sensor lobes for this purpose.

There is not a lot of information on the ford system as they like to keep things to themselfs. But a lot of the SVT engine run it now to beat the

emissions

|

|

|

|

|

ManuFromParis

|

| posted on 11/4/13 at 10:55 PM |

|

|

You mean the command to the solenoid is a not a command to set the cams in a specific position but just a command to increase or lower the oil

pressure and the sensor is needed to stop the command when cams are in wanted position ?

If I'm right, it's then a little more complicated than i thought...

Question is : is the mid-revs torque gain worth the trouble when high-revs power is the main purpose ?

|

|

|

scutter

|

| posted on 11/4/13 at 11:14 PM |

|

|

rolling road 05/08/10

VVc

Check out the difference in these graphs, both done at the same rolling road. The multi-colour one has the vvc working.

Whilst the one without vvc has the most bhp the vvc lines rae both high for a given rpm and the torque line gives a nice kick whenit comes in.

ATB Dan

[Edited on 11/4/13 by scutter]

The less I worked, the more i liked it.

|

|

|

ManuFromParis

|

| posted on 11/4/13 at 11:28 PM |

|

|

Ok, you convinced me : I'd definitly want the best of both curves !!!

With maybe a smoother power curve @ 2750rpm for my tires to last a little longer...

[Edited on 11/4/2013 by ManuFromParis]

|

|

|

scutter

|

| posted on 11/4/13 at 11:52 PM |

|

|

The kick is where the solenoid kicks in, it could be softened with ign timing, the tyres only break traction in the wet.

Atb Dan

The less I worked, the more i liked it.

|

|

|

ManuFromParis

|

| posted on 12/4/13 at 12:44 AM |

|

|

Found this video explaining how cam timing works on a simillar engine (1.6 with both intake and exhaust cams variable)

http://www.youtube.com/watch?v=f8uJktVbbd8

Clearer to me now that it might be tricky to mimic a full control, even with a phase sensor.

Video title found in this topic :

http://www.turbosport.co.uk/showthread.php?t=137130

[Edited on 12/4/2013 by ManuFromParis]

|

|

|

ManuFromParis

|

| posted on 12/4/13 at 09:07 AM |

|

|

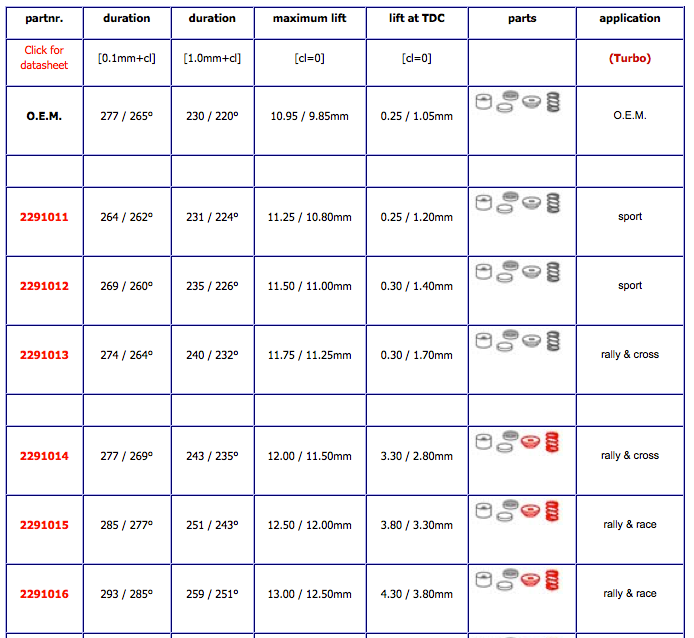

I have a question : On this catalog for ST170 cams, the durations for EOM cams are pretty long, compared to those I knew better of the silvertop :

277° for EOM ST170 Vs 262° for Sport-R Silvertop, both @ 0,1mm lift

http://www.catcams.co.uk/acatalog/Ford_ST170.html

I'd think that the duration would have been shorter because of the overlap at full advance.

Another question about what was the main subject of this topic : giving up the VCT.

As the VCT EOM pulley seems to have a spring and a locking mecanism to get the intake camshaft back to "full retard" position, which

appears to be 145° @ crankshaft EOM, and considering the optimal "fixed" timing would be around 108-110° @ crankshaft, wouldn't it

be much simplier to rotate the whole thing, introducing an offset at the intake pulley ?

(Solenoid not active, of course)

If I'm not mistaken, the pulley has 40 teeth, so one tooth offset would be 9°, which in cranksaft timing would be 18° because the crank goes

twice faster.

It would mean that introducing a "two teeth" offset would advance the fixed intake camshaft of 36°, the Full lift would then be 145 - 36 =

109° !!!

Am I right ?

[Edited on 12/4/2013 by ManuFromParis]

|

|

|

silky16v

|

| posted on 12/4/13 at 10:08 AM |

|

|

quote:

As the VCT EOM pulley seems to have a spring and a locking mecanism to get the intake camshaft back to "full retard" position, which

appears to be 145° @ crankshaft EOM, and considering the optimal "fixed" timing would be around 108-110° @ crankshaft, wouldn't it

be much simplier to rotate the whole thing, introducing an offset at the intake pulley ? (Solenoid not active, of course) If I'm not mistaken,

the pulley has 40 teeth, so one tooth offset would be 9°, which in cranksaft timing would be 18° because the crank goes twice faster. It would mean

that introducing a "two teeth" offset would advance the fixed intake camshaft of 36°, the Full lift would then be 145 - 36 = 109° !!! Am I

right ?

The VCT pulley doesn't have a locking mechanism, it alters via oil pressure, you need a fixed vernier to set the timing at a static state

The full retard position is 85° when setting the camshaft timing with the timing bar it you altered the timing by 2 teeth this will take you to 85 +

36 = 121° which isn't ideal

you could however use a normal zetec pulley on the inlet (drilled out to 12mm) and the VCT delete spacer and with a cam timing wheel dial in the

correct ° without the need for a Vernier, but for the cost of vernier its just not worth all the hassle in my eyes.

The way i see this whole thread is to have a cheap 180bhp+ engine

1. ST170 engine = £300 - £500 (with injectors and inlet)

2. VCT delete kit & vernier = £100 - £120

3. Bike throttle bodies = £100+

4. 4 branch & exhaust = £350+

5. standard zetec fuel rail = £10+ (as the ST doesn't have a return line)

6. fuel pump & regulator = £100 - £150

7. odd and ends £100+

8. whatever custom ecu your using = £250+

it can be done cheaper if using Carbs, but i prefer injection

The loss of low down torque from removing the VCT just isn't an issue in my eyes, my car is so much nicer to drive now than before, like a kit

car engine should be.

If i was fitting the engine into a non 7 style car i would consider the VCT again, but in something that weights around 500kg it just isn't

needed,

obviously this is my person feeling on the VCT, this just might not be whatever one's else needs might be

best thing is to try both and see what you prefer

|

|

|

ManuFromParis

|

| posted on 12/4/13 at 11:24 AM |

|

|

quote:

The full retard position is 85° when setting the camshaft timing with the timing bar it you altered the timing by 2 teeth this will take you to

85 + 36 = 121° which isn't ideal

Allright, my mistake.

Not such a good idea then, especially if there is no locking mecanism as shown in the 1600 double VCT video.

Thanks for the reply.

|

|

|

Rob Allison

|

| posted on 12/4/13 at 01:18 PM |

|

|

The problem with the standard vct pulley is that they can fail. They rattle and don't hold a fixed position. Best off they the delete kit and

standard pulley

|

|

|

ManuFromParis

|

| posted on 15/4/13 at 10:07 AM |

|

|

quote:

Originally posted by Rob Allison

Thats not how the ST VVT works. Its a pulsed solenoid which is used to alter the oil supply pressure. This then moves the vvt pulley from it

none pressure filled retarded position. Its not related to revs. The ECU uses a closed loop system with a cam phase sensor to check where the cam

timing is in relation to the crank.

If you just put 12volts onto the solenoid it will go from 85degs full lift to 145 degs full lift. The position which gives the best power is inbetween

them. Thats why only correct control of the VVT will allow good power and the benifit of the inlet VVT.

Hey Rob,

I'm confused with your post and I just to try to understand how it works :

Do you have information about the signal sent to the solenoid and how it works ?

What do you mean by "pulsed solenoid" ?

Is this the kind of mecanism ?

http://www.tlxtech.com/understanding-solenoids/theory-operation/pwm-solenoid-theory

[Edited on 15/4/2013 by ManuFromParis]

|

|

|

Rob Allison

|

| posted on 15/4/13 at 01:17 PM |

|

|

It's PMW. Pulse width modulated.

It's a 12volt signal which is switched at a vairing frequency. I don't have any details as there is little info about it. If someone has a

current Autodata It may be listed on there

|

|

|

ManuFromParis

|

| posted on 15/4/13 at 04:55 PM |

|

|

quote:

The loss of low down torque from removing the VCT just isn't an issue in my eyes, my car is so much nicer to drive now than before, like a kit

car engine should be.

If i was fitting the engine into a non 7 style car i would consider the VCT again, but in something that weights around 500kg it just isn't

needed,

obviously this is my person feeling on the VCT, this just might not be whatever one's else needs might be

best thing is to try both and see what you prefer

I totally agree with you but the more I read about Variable Valves, the more it would make sense (to me) that a road oriented car, even as a Se7en,

should benefit a lot from this feature.

Most of the car builders want their engine tuned for maximum power and setup the engine for this purpose, but eventually the car is mostly used on

roads where the use of the 4500-6500 RPM range is actually pretty occasional.

The car might as well be used on occasional fun track days (no race) where this race engine setup makes a lot of sense, but only with some chassis and

engine racing options to prevent damages and preserve car and engine (Geometry setup, ARB, sport shocks and calipers, oil cooler, race cams, etc...)

that kitcars don't really have, most of the time. So the benefit of the Race Setup is not really enjoyable without risking damages.

What I mean is that the Fixed Cams Timing compromise, which is "High Revs Power Oriented", is in contradiction with a high percentage of

the engine use, in most cases.

I'm not sure I may change the timing setup from my Kent FZ1802R Cams in SilverTop before and after every fun trackday I go to, but actually I

think I might, because I looove torque, more than power for a road use anyway !

So I'm considering advancing the intake a little on the Zetec (10° ?), just to feel the kind of change one could expect with a VCT on that kind

of engine. What do you think ? Should I try to advance a little more ?

[Edited on 15/4/2013 by ManuFromParis]

|

|

|

ManuFromParis

|

| posted on 15/4/13 at 05:03 PM |

|

|

quote:

Originally posted by Rob Allison

It's PMW. Pulse width modulated.

It's a 12volt signal which is switched at a vairing frequency. I don't have any details as there is little info about it. If someone has a

current Autodata It may be listed on there

Reading the TlxTech article mentionned above and watching the Ford video, I wouldn't be surprised it would indeed work that way.

What is weird though, is that very few Engine Management Units have a Variable Valve management feature and when they have, only the Honda Vtec and

the Rover VVC are options.

That said, I asked Emerald if they had plans about the ST170 and here is the (very fresh) answer I got this afternoon :

quote:

Hi Emmanuel,

we are currently looking for an ST170 engine/car that we can run on the dyno/rolling road for a few days.

We may buy an engine/car if necessary.

Best regards, Karl

|

|

|

Rob Allison

|

| posted on 15/4/13 at 05:47 PM |

|

|

Don't try and adjust the silver or blacktop engines cam timing by much with out checking valve clearance. They don't have the valve

pockets the st has.

|

|

|

ManuFromParis

|

| posted on 15/4/13 at 05:58 PM |

|

|

Ok, thanks

|

|

|

cjellwood

|

posted on 16/10/17 at 08:52 PM posted on 16/10/17 at 08:52 PM |

|

|

ST170 VVT Delete

Hi,

Recently my VCT solenoid snapped in half while replacing it and the VVT pulley was messing around so I decided to go for a VVT delete. So far I have

deleted the oil flow and running the car like that pending delivery of the new pulleys which arrived today. The car runs like a 1.6 and is very

economical like this running at full retarded I presume?

This week I need to give my mechanic instructions on how to time the new pulleys after fitting but neither of us know a dicky about it. The car is

standard all round , just the new pulleys (oh and a stage 2 head to make things interesting). Since having the engine rebuilt recently I am yet to

see what the new head has to offer due to the VVT issues.

May I ask if there is a good place to start with timing positions other than playing it safe at 0:0 ?

One day I will let the pro's play with it on the rollers to get thebest setting but for now it is a daily use car and I just need a good place

to start. Oh and do we need special tools for this?

In exchange for good info I will come back here with roller data very soon

cheers

Chris

|

|

|

Rob Allison

|

| posted on 22/10/17 at 06:30 PM |

|

|

If you use the standard setup timing by fitting the bar in the cams on the st170. This will set the inlet cam at 85degs. A standard zetec would be at

110 or 112 dregs.

So the inlet can on the st needs to be advanced by about 25degs. I can't remember is its 1 or 2 teeth on the cam pulley. So zeroing an

adjustable pulley at that timing will allow you to swing it about 15 to 20 degrees either way if your getting it tuned.

|

|

|

cjellwood

|

| posted on 22/10/17 at 06:41 PM |

|

|

Thanks! I will be taking the car to a professional tuner but likely they will scratch their head about the ST170 like most do so best I go armed

with some info. The part that worries me is the VVT inlet pulley sits fully retarded as default state. Is this why you set zero at -10 I think it

was to make up for that when setting up with the bar?

|

|

|

Rob Allison

|

| posted on 22/10/17 at 10:14 PM |

|

|

On a zetec the bar will set the cam at 110 or 112 degrees. On the st it will be about 85degrees as the cam is fully retarded.

In normal running the st engine doesn't retard the inlet cam that far retarded apart from when it starts. There is a plot if the cam timing

range against engine load. It surprising how little the cam timing moves against the total it can move

|

|

|

cjellwood

|

| posted on 22/10/17 at 11:26 PM |

|

|

Thanks again! I get the plot now, brain was ticking slow earlier sorry. Just a couple more points if you dont mind sorry...

In your first set of pics where you fitted the pulleys it shows you inlet set to zero. I presume you were able to slide it round to -10 without moving

the belt or cam prior to fastening because you have your own machined spacer? I would need to set my inlet pulley to -10 before fitting and pinning

because I have the solid spacer built into the pulley (pipercam ?)

Also in a later pic you mention advancing 12 degrees but it looks more like 14 degrees on the marks?

My IMRC needs to go too but cant afford TB's so am looking at fixing it to a fixed position permanently. At this moment it is fixed to just over

half way pulled. Would you recommend it ti be fixed at another position?

cheers

Chris

|

|

|

cjellwood

|

| posted on 22/10/17 at 11:43 PM |

|

|

pic of my inlet pulley. The marks are reversed so I assume this is -10 how it should be initially fitted. I am wondering why the 2 x pulley delete

kit that is sold contains the exhaust pulley that does not change from original setting?

|

|

|

big_wasa

|

| posted on 23/10/17 at 02:16 PM |

|

|

I am sure the inlet is two distinct inlet lengths. Long and short. So setting it inbetween is the worst of both.

What ecu are you running ? If oem the ecu will know the imrc andt vvt solenoid are doing nothing and peg the engine back to around that of a blacktop.

|

|

|

cjellwood

|

| posted on 23/10/17 at 02:57 PM |

|

|

quote:

Originally posted by big_wasa

I am sure the inlet is two distinct inlet lengths. Long and short. So setting it inbetween is the worst of both.

What ecu are you running ? If oem the ecu will know the imrc andt vvt solenoid are doing nothing and peg the engine back to around that of a blacktop.

yes just the standard ECU at the moment but I will go aftermarket ECU now if there is a good value box around that is easy to wire up. Having lost

the VCT now I have a redundant VVTPro box if anyone is interested

|

|

|

Rob Allison

|

| posted on 23/10/17 at 08:34 PM |

|

|

quote:

Originally posted by big_wasa

I am sure the inlet is two distinct inlet lengths. Long and short. So setting it inbetween is the worst of both.

What ecu are you running ? If oem the ecu will know the imrc andt vvt solenoid are doing nothing and peg the engine back to around that of a blacktop.

If you are keeping the standard parts inlet and ecu it would be a problem. But as mine is on a k6 ecu with fixed inlet runner length. It fine for

me.

You can't delete the vvt and keep the standard ecu, etc. Or it will hit limp mode

|

|

|