flak monkey

|

| posted on 17/3/19 at 04:58 PM |

|

|

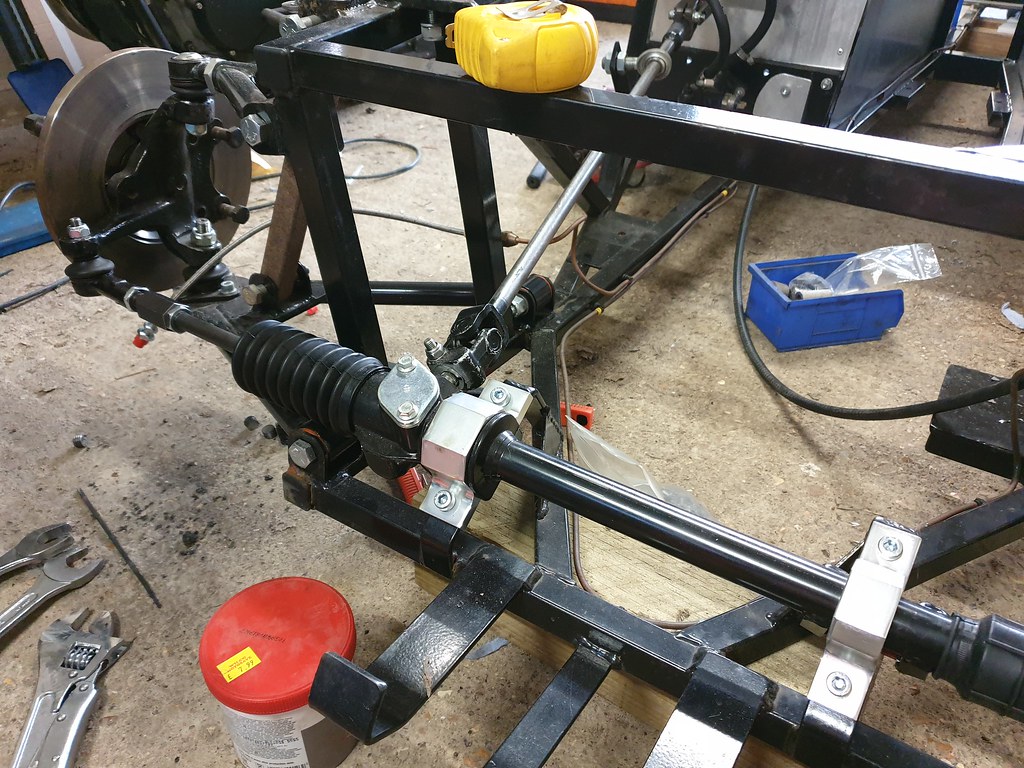

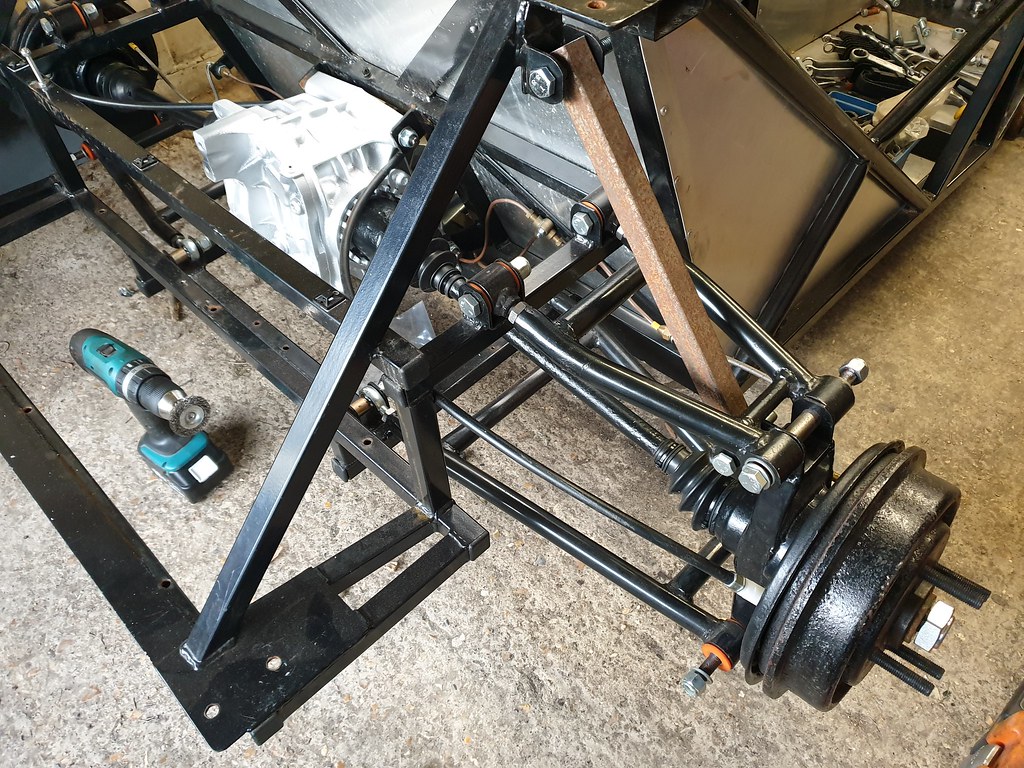

Me and Sophie have had a pretty productive day today. A lot of faffing around to get the suspension on the car and roughly set up. I need to make some

extensions for the rack and modify the standard track rods as the Avon is a stupid width at the front.

Also had to make some spacers for the lower rear wishbones - the book dimension of 80mm for their position appears to be incorrect. We've set

them as far forward as they will go for now.

Much complexity, be interesting to see how it handles as there is a lot of adjustabilty in the back suspension and none in the front. Time will

tell.

Fitted the new 2.9 turn steering rack - had to modify the packers than came with the clamps as even those weren't the right size, nothing is

simple. Column all bolted up easily though.

Removed the master cylinder, cleaned it up and painted it as it was rusty having been fitted bare. Re-routed the rear brake line and fitted proper

p-clips rather than the plastic snap in clips in a couple of places.

Differential fitted without much drama.

Still a few modifications to do to some of the existing work, but nothing major, mostly tidying up and doing a few things to my own taste.

The next thing is to get the rear brake drums and back plates cleaned up and fitted

Sera

http://www.motosera.com

|

|

|

|

|

G13BLocost

|

| posted on 17/3/19 at 06:34 PM |

|

|

I like this car, it looks dead simple to work on and should be good fun.

How are you finding building the Pinto? I've never dug into an iron block+head engine before.

My Locost blog: ogilvietacing.com

|

|

|

flak monkey

|

| posted on 17/3/19 at 07:04 PM |

|

|

quote:

Originally posted by G13BLocost

I like this car, it looks dead simple to work on and should be good fun.

How are you finding building the Pinto? I've never dug into an iron block+head engine before.

I've built a few pintos now. Dead easy to work on.

But in all honesty the duratec and chevy engines I've worked with haven't been that bad either.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 22/3/19 at 04:34 PM |

|

|

Been a busy few evenings cleaning and repainting parts ready to fit. Also went to see the guys at Tiger to pick up brake lines and rack extensions

etc.

Some of the parts that I collected with the kit needed a repaint having been sat around for a while. All simple stuff, but worthwhile at this

stage.

I also got the new CV boots fitted to the drive shafts, the old ones were shot and these stretch ones were fun to fit with the cone. Really messy

job!

This weekend I intend to get the car rolling, although I do need to find a new driveshaft nut for the LH side as both times I have bought one they

have been incorrect

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 29/3/19 at 06:52 PM |

|

|

Lots of stuff happening but I have been a bit tardy taking photos of progress. Need to sort some shocks.

Front end is more or less assembled, rack modified, wheel alignment is done. Have also stripped and repainted the calipers, new pistons and seals to

go in tomorrow.

Rear end is also assembled. Need to torque up the rear hub nuts and adjust the brakes a bit before doing the rear wheel alignment

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 8/4/19 at 12:51 PM |

|

|

I have quite busy, but again a bit bad at taking photos....

The car is actually now on it's wheels - the front wheel alignment is done, and I still need to do the rears, a job for one evening this week

(and a lot of swearing I expect....)

The engine block, rods and new pistons are at the machine shop. Block is being bored and decked, pistons being fitted to the rods (later wide beam

ones). It should be ready for collection next week at some point. At the same time I will be dropping off the cylinder head to be machined for

44.4/38.1 valves and have hardened seats put in. Also skimmed to raise the compression.

Before dropping it off I decided to get the bulk of the porting done on it. Mainly hogging all the material out of the exhaust ports and cleaning up

the guides. Once it's back then I will do the final tidy up and smoothing work. The 4 exhaust ports are done - took around 3 hours - thankful

for my big 3ph compressor and die grinder.

I have also made a start on modifying the sump and have moved the filler neck on the rocker cover. Those are both going to the blasters later this

week and will then be ready to finish off.

Marking out for porting - 35mm high and 29.5mm wide

Comparison of original and new port sizes

New port - sides are actually parallel - measurements maintained throughout the port - no material removed from port floor

Smoothed guide - length is maintained but the guide is streamlined

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 22/4/19 at 06:32 PM |

|

|

Picked up the block, pistons and rods from the machine shop last week. The block has been bored/honed 0.5mm oversize and the top face machine 0.5mm to

bring the piston crown flush with the deck face. New pistons have been fitted to the later wide beam injection rods too.

Sophie spent today cleaning the outside of the block and painting it, also had the modified rocker cover blasted last week so that got a coat of paint

today too.

All painted with epoxy primer followed by 2k black and clear.

The rocker cover has some finishing touches to complete yet, those will have to wait until next weekend.

I still need to finish the porting work on the head before it's dropped off at the machine shop for big valves and a skim.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 16/5/19 at 06:21 PM |

|

|

Another long break from updates... still been plodding on with things though.

Fitted new rings to the pistons - after finding out the brand new Hepolite set I bought had a huge gap - just over 2mm - even though its fresh bore

and the rings were packaged for the correct size. Now fitted with Mahle ones which are spot on.

So the rotating assembly is sorted.

Modified the distributor tonight, just need to assemble it. Turned off the main body and modified the shaft. Machined up a cap to press on, just need

to clean it up and assemble it. Will be running megajolt so no need for the dizzy other than as an oil pump.

Sera

http://www.motosera.com

|

|

|

big_wasa

|

| posted on 16/5/19 at 07:05 PM |

|

|

Who did you use for your rebore ?

Cheers.

|

|

|

flak monkey

|

| posted on 16/5/19 at 07:28 PM |

|

|

Cambs rebores.

Nothing wrong with their machining job. The hepolite rings are just junk.

Sera

http://www.motosera.com

|

|

|

big_wasa

|

| posted on 17/5/19 at 09:22 AM |

|

|

I only ask as I am planning on forging the bottom end and just curious on local firms.

Cheers

|

|

|

flak monkey

|

| posted on 17/5/19 at 09:40 AM |

|

|

Cambs rebores http://www.cambridge-rebores.co.uk/ are excellent. I've used them for machining work on all the engines I've built

Sera

http://www.motosera.com

|

|

|

mcerd1

|

| posted on 17/5/19 at 11:05 AM |

|

|

Looking good - In fact some bits of that engine are looking very similar to mine, only you've done it infinitely faster than me

What are you planning for the carb's and cam on this one ?

your dizzy / oil pump drive looks almost identical to the one that the guys at H&H knocked up for me (I was going to do it myself, but it was part

of deal)

Probably overkill but I'm going to take another old dizzy (hall effect EFI one) and strip it down without the gear on it to make an oil pump

priming tool of some kind...

quote:

Originally posted by flak monkey

The rocker cover has some finishing touches to complete yet, those will have to wait until next weekend.

...I was just looking to do the same mod on my rocker just the other day and struggling to find a bit of tube the right size

[Edited on 17/5/2019 by mcerd1]

-

|

|

|

flak monkey

|

| posted on 6/10/19 at 03:07 PM |

|

|

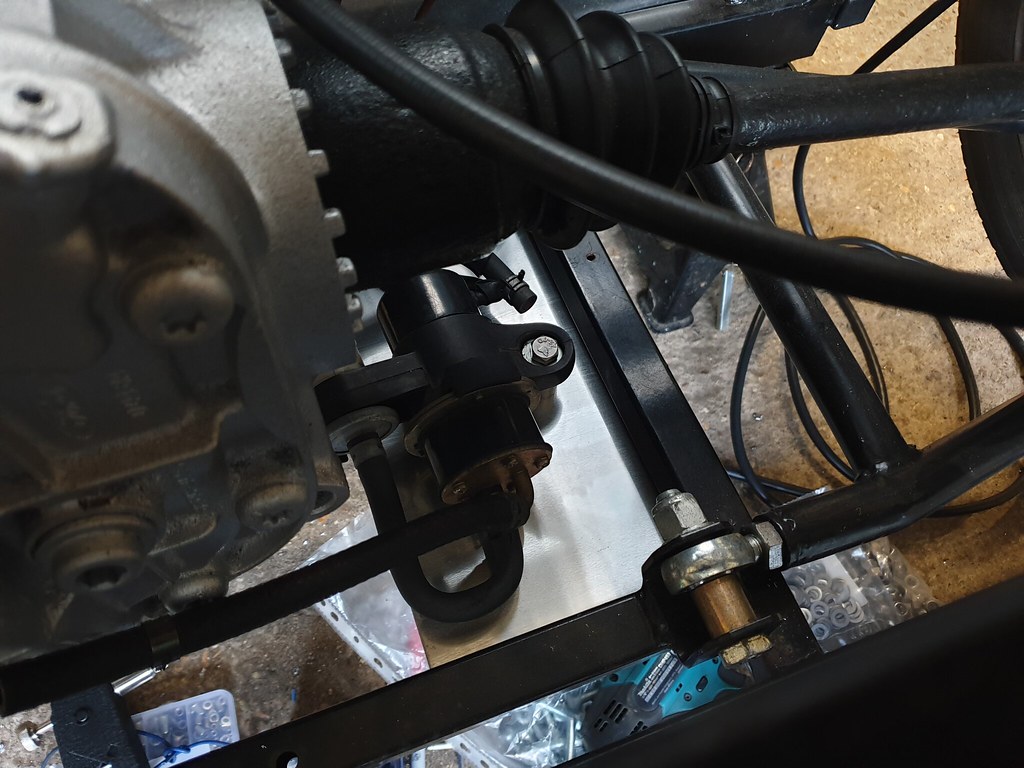

Been really lax with updates on this - mostly as a lot of things aren't photo worthy, especially in my messy garage....

In short:

The suspension is all fully assembled including wheel alignment and a set of shiny new adjustable Gaz shocks.

Wiring loom made and installed - yet to be tested, but it's all there and mostly tidied up as much as possible prior to fitting the body

work.

Dropped in the gearbox and a spare block/head just for mocking things up and checking clearances. Everything looks OK.

Brakes are bled and the handbrake is hooked up.

Next major things are to get the roll bar and fuel tank fitted, along with the fuel pump (R1 to suit the carbs) before finally buying a bodywork

set.

Sera

http://www.motosera.com

|

|

|

big_wasa

|

| posted on 6/10/19 at 03:20 PM |

|

|

Iíve got a starter motor left over if you need one.

|

|

|

flak monkey

|

| posted on 7/10/19 at 01:14 PM |

|

|

quote:

Originally posted by big_wasa

Iíve got a starter motor left over if you need one.

That would be very helpful! I'll U2U you....

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 13/10/19 at 06:32 PM |

|

|

Shelled out some cash and bought a new tank and roll bar from Tiger yesterday. Mostly got them fitted today - make some brackets up for the tank. Just

need to get some rose joints for the roll cage stays and paint the tank mounts.

Next job is fuel pump and then will be gettign ready to move house before getting the body set.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 18/10/19 at 04:29 PM |

|

|

Not been doing much this week - had a lot of stuff on for other people and with work. Had planned to drop the cylinder head in at the machine shop but

didn't have time in the end.

I did however get the brackets for the fuel tank painted and refitted, along with the roll bar stay brackets and rose joints fitted.

Made a mounting plate for the fuel pump, just need to improve the mounting of the pump, but I have a plan for that.

I was also impressed by the wheel cleaner I bought, a bit of a scrub and they came up pretty nice. These wheels are just temporary until I can afford

something lightweight and nice. But these will do for the build and the shakedown miles.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 8/11/19 at 04:23 PM |

|

|

Slower progress again at the minute - although I seem to have gained a lot of parts.

Replaced the brake master cylinder and reservoir and the leaks are cured there - thankfully!

Got a pair of seats - really nice new GRP ones from eBay and only £150 for the pair including delivery - they even fit in the chassis (only 400mm

wide) but I do need to make some mounting brackets for them, which isn't a hardship. Will probably make some pads up for them eventually.

Also dropped the cylinder head off at my friendly machine shop who are fitting hardened exhaust valve seats, cutting all the seats for group 1 valves,

fitting bronze guides and skimming the face. I'm expecting a big bill at the end of it! Once it's back I have a little port tidying to

finish off then the engine can finally be built up.

Found someone selling a complete pinto exhaust with headers, collector and silencer, so that's that sorted. Also managed to snag a Bailey Morris

propshaft of the right length which hasn't seen much action.

I finished wiring the rear of the car too - can't do anything more until I have the bodywork which is getting ordered as soon as we have moved

house in a couple of weeks (because I don't have enough to do already!)

The battery also arrived today, so I will start to check out my wiring over the weekend too

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 1/2/20 at 07:01 PM |

|

|

Finally have a proper workshop back again after moving into our dream house in November.

I had the head away at the machine shop and got it back in December. Skimmed to bring the CR up to 11.5:1, bronze valve guides, seats machined for

group 1 valves and hardened seats for the exhaust valves.

Today I finally got around to finishing off the porting and assembling the head with new stainless waisted stem valves, kent springs etc. Felpro thin

head gasket too.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 2/2/20 at 09:01 PM |

|

|

Got a little more done today - was hoping to have the engine pretty much complete, but it seems I need some longer ball studs. Other than that, the

valvetrain geometry looks pretty much spot on. Wipe pattern is right in the middle of the pads on the followers.

Since I couldn't finish that I made a bracket to mount the coil on the back of the head.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 9/2/20 at 04:55 PM |

|

|

Finished the engine assembly this weekend. Degreed the cam and pretty much buttoned everything up.

Made some alternator mounts too for the tiny denso alternator.

Just need to get the flywheel skimmed and then the engine and box are ready to go in.

Sera

http://www.motosera.com

|

|

|

jps

|

| posted on 9/2/20 at 06:12 PM |

|

|

quote:

Originally posted by flak monkey

Is it ok to replace the studs for the manifolds with bolts permanently? The reason I ask is I am using a pinto in my build and have an over rail

exhaust manifold which will need much shorter studs than the original cast manifold. Is a straightforward bolt a suitable alternative?

Great to see the progress btw!

|

|

|

flak monkey

|

| posted on 9/2/20 at 07:49 PM |

|

|

quote:

Originally posted by jps

Is it ok to replace the studs for the manifolds with bolts permanently? The reason I ask is I am using a pinto in my build and have an over rail

exhaust manifold which will need much shorter studs than the original cast manifold. Is a straightforward bolt a suitable alternative?

Great to see the progress btw!

Yep, bolts are fine

Sera

http://www.motosera.com

|

|

|

jacko

|

| posted on 10/2/20 at 08:03 PM |

|

|

Hi Mate long time .

I've only just started to come back on this forum after along time

It's good to see a build with a pinto just a little info the engine mounting stabiliser you have in your photo archives is the one I made and

it worked very well and stopped every thing rocking

Jacko

|

|

|