Mr C

|

| posted on 21/11/11 at 09:06 AM |

|

|

Mid Engined Gear Linkage Problem

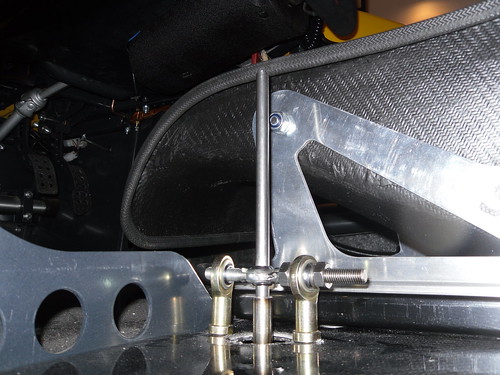

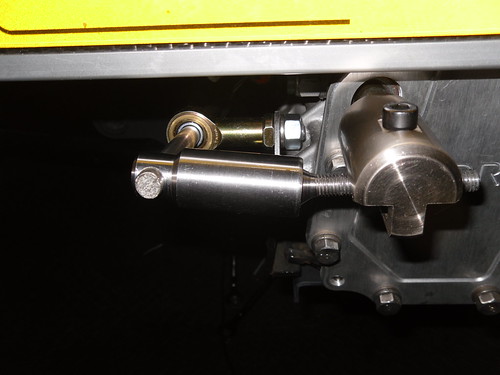

I'm attempting to design and make my own gearchange mechanism. Its for a subaru gearbox converted into a mid engined configuration. I've

currently got as far as the set up shown in the images, albeit the homemade parts have been replaced with machined components. The current problem is

the pattern is "upside down" 2nd is where 1st should be and 3rd is where 4th should be. Although I can live with this, I am worried that a

wrongly selected gear, resulting in engine damage may occur. So I'm looking for suggestions, thoughts etc, to get the pattern right. Cable

change mechanisms do not seem to work well with this box so is not an option. I would prefer to use existing mounting holes etc and the mechanism has

to be simple and robust.

I'm hoping I've missed something blindingly simple and hope to be enlightened

[Edited on 21/11/11 by Mr C]

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

|

|

liam.mccaffrey

|

| posted on 21/11/11 at 09:25 AM |

|

|

I have a very similar problem in that I had considered modifying my gear change unit like you have. I think however I am going to risk it though and

and turn the volvo gear change unit around and have new control cables made. this will mean my gears will be upside down for a volvo 850. My box was

cable operated all along however.

Build Blog

Build Photo Album

|

|

|

rdodger

|

| posted on 21/11/11 at 09:33 AM |

|

|

Could you consider using the mechanism from a mid/rear engined car?

On my GTM Libra I used an Elise mechanism when I got rid of the rod change. It does use cable though.

911 could be an option too.

Failing that have you looked at the Ultima rod change?

|

|

|

jack_t

|

| posted on 21/11/11 at 09:55 AM |

|

|

Hello matey

i have been following this on your blog, i may have a solution to your problem u2u me your email and ill send u a diagram of what you will have to do

|

|

|

russbost

|

| posted on 21/11/11 at 10:07 AM |

|

|

Surely it is simply a matter of changing the relatinship of the pivot & operating rod? At present you have pivot at centre & operating rod

below, if you move the operating rod to above the pivot everything will work "backwards" therefore making it the right way round for your

installation.

Seems, very straightforward unless I am missing something entirely?

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

liam.mccaffrey

|

| posted on 21/11/11 at 10:14 AM |

|

|

Where might i find a link to your blog.

quote:

Originally posted by jack_t

Hello matey

i have been following this on your blog, i may have a solution to your problem u2u me your email and ill send u a diagram of what you will have to do

Build Blog

Build Photo Album

|

|

|

jack_t

|

| posted on 21/11/11 at 10:19 AM |

|

|

quote:

Originally posted by liam.mccaffrey

Where might i find a link to your blog.

quote:

Originally posted by jack_t

Hello matey

i have been following this on your blog, i may have a solution to your problem u2u me your email and ill send u a diagram of what you will have to do

the rod that comes out beneath the car also rotates so the gear stick end needs to stay in that configuration its the gearbox end that needs to change

|

|

|

stevebubs

|

| posted on 21/11/11 at 11:20 AM |

|

|

As above - surely it's just a case of shifting a pivot point either at the front or back of the car?

|

|

|

Mr C

|

| posted on 21/11/11 at 11:23 AM |

|

|

Thanks all for such a rapid and helpful response, amazing.

My blog is Scoobystorm

The design is based on what I've seen on Ultimas and also a GD setup. The gearbox is originally rod and doesn't like cable particulary

because of 5th and reverse being internally strongly spring loaded.

As Jack stated, the rod needs to rotate

Thanks again all.

Mike

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

MikeRJ

|

| posted on 21/11/11 at 12:26 PM |

|

|

quote:

Originally posted by russbost

Surely it is simply a matter of changing the relatinship of the pivot & operating rod? At present you have pivot at centre & operating rod

below, if you move the operating rod to above the pivot everything will work "backwards" therefore making it the right way round for your

installation.

Seems, very straightforward unless I am missing something entirely?

It depends on the OP's interpretation of "upside down". If 1st is where 2nd should be, and both 1st and second are to the right of

3rd and 4th then this will work. If 1st and 2nd are correctly located to the left of 3rd and 4th, then changing the pivot will fix one problem and

introduce another. i.e. does only the push/pull motion need to be reversed, or does both push/pull and rotation of the operating rod need to be

reversed?

|

|

|

Mr C

|

| posted on 21/11/11 at 12:41 PM |

|

|

quote:

Originally posted by MikeRJ

quote:

Originally posted by russbost

Surely it is simply a matter of changing the relatinship of the pivot & operating rod? At present you have pivot at centre & operating rod

below, if you move the operating rod to above the pivot everything will work "backwards" therefore making it the right way round for your

installation.

Seems, very straightforward unless I am missing something entirely?

It depends on the OP's interpretation of "upside down". If 1st is where 2nd should be, and both 1st and second are to the right of

3rd and 4th then this will work. If 1st and 2nd are correctly located to the left of 3rd and 4th, then changing the pivot will fix one problem and

introduce another. i.e. does only the push/pull motion need to be reversed, or does both push/pull and rotation of the operating rod need to be

reversed?

Thanks for highlighting this, I did find it difficult to describe succintly, the push pull needs to be reversed, the rotation is currently correct.

current gear pattern

2 4 R

1 3 5

standard pattern

1 3 5

2 4 R

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

Mr C

|

| posted on 21/11/11 at 01:06 PM |

|

|

Jack, U2U sent, thanks, Mike

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

russbost

|

| posted on 21/11/11 at 01:49 PM |

|

|

From the above gear pattern a simple swap of the operating rod/pivot position will do the job.

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

MikeRJ

|

| posted on 21/11/11 at 04:44 PM |

|

|

quote:

Originally posted by russbost

From the above gear pattern a simple swap of the operating rod/pivot position will do the job.

I still don't understand how moving the pivot will reverse only the push/pull and not the rotation? Could you do a quick sketch?

At the moment, standing at the rear end of the car and looking forwards, moving the gear lever left will turn the operating rod clockwise i.e. the rod

turns in the opposite direction to the gearlever pivot. Pushing the gearlever forward will move the operating rod backwards. The rotation must be

preserved whilst the push/pull motion reversed.

I can't see a simple solution to this without adding additional linkages.

|

|

|

Mr C

|

| posted on 21/11/11 at 05:34 PM |

|

|

quote:

Originally posted by MikeRJ

quote:

Originally posted by russbost

From the above gear pattern a simple swap of the operating rod/pivot position will do the job.

I still don't understand how moving the pivot will reverse only the push/pull and not the rotation? Could you do a quick sketch?

At the moment, standing at the rear end of the car and looking forwards, moving the gear lever left will turn the operating rod clockwise i.e. the rod

turns in the opposite direction to the gearlever pivot. Pushing the gearlever forward will move the operating rod backwards. The rotation must be

preserved whilst the push/pull motion reversed.

I can't see a simple solution to this without adding additional linkages.

The linkage moves in the way described and the left right rotation needs to remain the same whilst reversing the push pull operation. The difficulty

is keeping the rotation working whilst doing this as Mike states. I was hoping there would be a simple linkage someone might come up with that I could

add.

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

russbost

|

| posted on 21/11/11 at 05:48 PM |

|

|

Now in fairness I did say "Seems, very straightforward unless I am missing something entirely?" which I was!

Sorry, should have looked more closely at the pics, I was asssuming it was a twin rod system & you'd only pictured part of it, I

didn't look at the third pic where it's more obvious!

I would therefore have to agree that without splitting the 2 motions I can't see an easy way of doing it.

Is this in an SDR storm? Actually doesn't matter whether it is or not as they use that engine & box IIRC, how do they get around the

problem, presumably they aren't selling kits where you finish up with a backwards gearshift, so they must have found a way around it???

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

v8kid

|

| posted on 21/11/11 at 06:12 PM |

|

|

If you make the pivot point for your gearstick the bottom set of balljoints and have the actuation rod coming from the top set of balljoints when you

push the stick forwards the actuation rod will go forwards instead of backwards.

Or am I missing something too?

Cheers!

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

Mr C

|

| posted on 21/11/11 at 06:47 PM |

|

|

quote:

Originally posted by russbost

Now in fairness I did say "Seems, very straightforward unless I am missing something entirely?" which I was!

Sorry, should have looked more closely at the pics, I was asssuming it was a twin rod system & you'd only pictured part of it, I

didn't look at the third pic where it's more obvious!

I would therefore have to agree that without splitting the 2 motions I can't see an easy way of doing it.

Is this in an SDR storm? Actually doesn't matter whether it is or not as they use that engine & box IIRC, how do they get around the

problem, presumably they aren't selling kits where you finish up with a backwards gearshift, so they must have found a way around it???

Hi Russ

Yes it is a V-Storm, The SDR gear change isn't production ready as such. Simon is currently working on a dash mounted cable gear change

mechanism and has been for a while. The demo car was not brilliant, being vague at best and the most recent write up in this months CKC was even less

complimentary. I'm not convinced it will be a satisfactory mechanism, coupled with the long wait (22 months from date of order) I've

decided to cut my losses and do my own thing.

The other option is the mechanism developed by Saker but its untidy looking and probably similar in quality to the one Simon's developing,

indeed I understand they now use sequential boxes.

I've thought about modifying the gearchange to do this and will do a rough drawing albeit in powerpoint as I haven't a clue with CAD etc

and would appreciate some feedback, if I get it done in a little while I'll post it shortly.

I'm not an engineer, actually a nurse by trade and this being my first build, appreciate any ideas no matter how small or insignificant they may

be. as this is my last major hurdle to getting this thing on the road.

Thanks again all.

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

Mr C

|

| posted on 21/11/11 at 06:50 PM |

|

|

quote:

Originally posted by v8kid

If you make the pivot point for your gearstick the bottom set of balljoints and have the actuation rod coming from the top set of balljoints when you

push the stick forwards the actuation rod will go forwards instead of backwards.

Or am I missing something too?

Cheers!

Thanks for your response

You would loose the rotation required for the gear change also the ball joints are rod ends so will not allow for the type of movement if I have

understood your suggestion.

Mike

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

fluidslvr

|

| posted on 21/11/11 at 07:37 PM |

|

|

this any help to you??

http://www.youtube.com/watch?v=RJZiZfE_IoE&feature=related

http://mkmidi.blogspot.com

|

|

|

russbost

|

| posted on 21/11/11 at 07:42 PM |

|

|

Mike

2 suggestions, first would it be possible to split the gearchange into 2 x rods, with one doing the rotation & the other doing the fore/aft

motion. Can't be 100% certain looking at your setup from the pics but it looks as tho' you may be able to keep the lower rod to control

the rotating motion (which is in the correct plane as it is) tho' you would have to incorporate some sort of "slide" at the rear end

to stop from controlling the longitudinal motion & add an upper rod which would do the fore aft?

The other thing I would say is that there is no reason at all why a cable shift should be "wooly" or vague, the original MR2 which is what

I use as a donor for the Furore had a fairly precise shift & even controlling it from a position around 3 feet further forward with longer cables

we still get a precise shift. I would emphasise tho' that for the car shift we pay about £150 for bespoke cables, which, like the originals are

quite beefy. When using a bike engine we just use a teleflex cable, & I've heard of people using teleflex (or morse) cables for car shifts,

but personally I never would. However there are plenty of car cables around, which I would think would be long enough for your application without

needing modification, might be worth thinking about??

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Mr C

|

| posted on 21/11/11 at 08:42 PM |

|

|

Russ thanks for your response, very helpful, potentially I would go to two rods if I can't get one to work and its better than the cable option

in terms of complexity and use. I'll keep this open as an option. One of the challenges is the routing of rods front to back, there are not

many/any options. The other challenge is the 5th/reverse gear which is heavily sprung. This is presenting a challenge for the cable setup according to

Jason at scoobybits(posted on exocars) and adjustment is tricky to say the least.

As well as work well the mechanism is on show at the back of the car so I would like it to look good as well (maybe too many asks on my part

I don't know why the cable system is not working as well as you say it should, perhaps Simon Dickens might be able to shed some more light on

this. If it did work well and was available I would gladly take it in preference to my own lashup

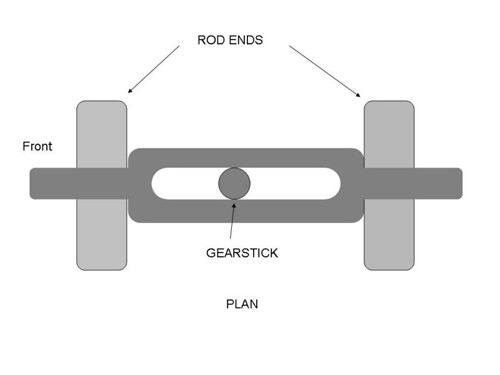

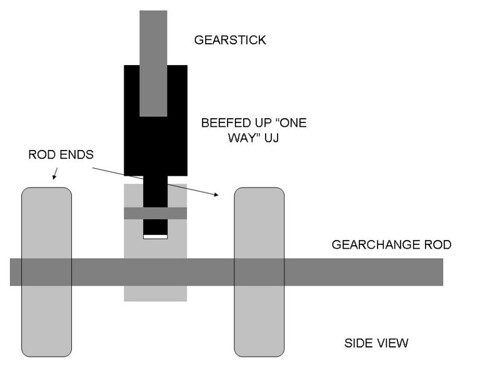

I've come up with the arrangement below hope it makes sense. The UJ at the bottom of the gearstick would have to be modified to give left/right

movement only.

How well would this work given there is no fixed pivot point fore and aft?

jack_t is also thinking about options at the gear box end, thanks Jack, so I'm hopeful we can crack this.

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

Mr C

|

| posted on 21/11/11 at 09:05 PM |

|

|

Russ and all, just done a quick drawing of proposed UJ setup on the end of the gearstick in line with my previous thoughts and suggestions

The back is to the left of the image, hope it makes sense.

Mike

Girl walks into a bar and asks for a double entendre, so the barman gave her one

|

|

|

Alan B

|

| posted on 21/11/11 at 09:11 PM |

|

|

Any help with this of mine....?

It's a hybrid rod/cable system

[img]

gc1

[/img]

|

|

|

russbost

|

| posted on 21/11/11 at 09:13 PM |

|

|

Trying to make quite sure I understand what you have at the moment, between the 2 rod ends in the pic is the lever sitting in a spherical bearing

allowing the lever to pivot both fore/aft & side to side?

If I'm understanding your drawing correctly & I have understood what you had originally then it's possible, if you modify the lower

joint as you suggest, that it could work, but depending on the length above the lower slide thro' the rod ends I think it quite possible it

might "snag" & therefore make the fore/aft shift stick & jam, if you added further support, perhaps another pair of rod ends in

front & behind the 2 you already have I guess that might do the trick, it's one of those things that a little trial & error in practice

is probably necessary to find an optimum setup.

Although all the gears should then be in the right place, the change might still feel a bit strange as you'd be sliding the gearstick fore &

aft instead of the usual action of pivotting it. An interesting conundrum this one!

I would suggest ask Simon what cables he is using as if they are a bit lightweight the problem with that shift may be nothing more than that.

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|