tcr

|

| posted on 6/7/12 at 09:33 AM |

|

|

locking off brake bias bar

just been reading this and was wondering how you have done it ? ...........pics would be helpful

Note 5: Bias bars and other mechanical adjusting devices fitted to twin master cylinders must be rendered inoperable by mechanical means

MK MIDI ZX10R

http://www.facebook.com/media/set/?set=a.4393256076054.2182513.1427988207&type=1&l=64c91c3c17

why isnt anything simple!!!

torquetune.co.uk

nrpexhausts.co.uk

|

|

|

|

|

loggyboy

|

| posted on 6/7/12 at 11:31 AM |

|

|

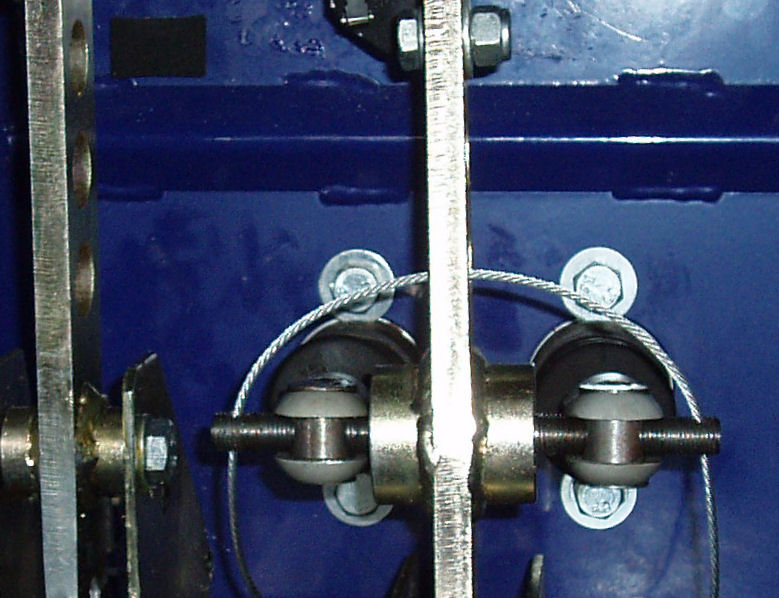

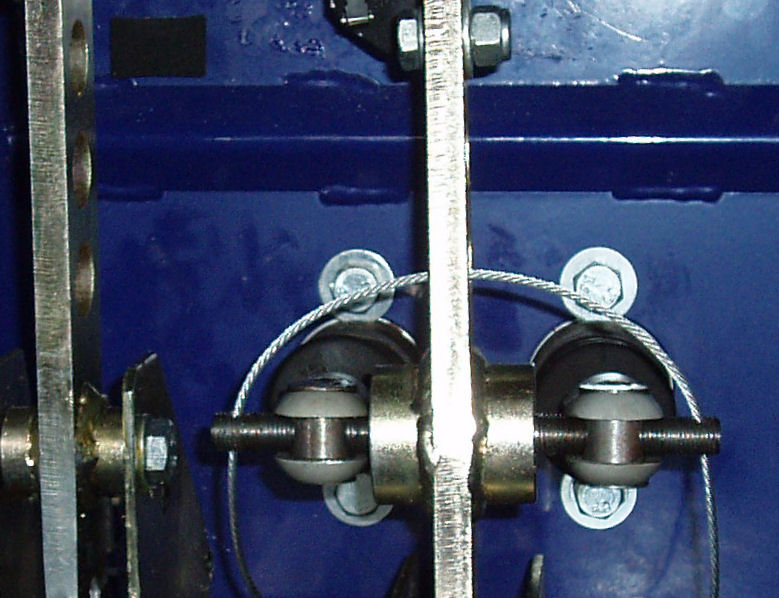

Google image search revealed these 2 options:

Mistral Motorsport

|

|

|

tcr

|

| posted on 6/7/12 at 11:39 AM |

|

|

thanks

MK MIDI ZX10R

http://www.facebook.com/media/set/?set=a.4393256076054.2182513.1427988207&type=1&l=64c91c3c17

why isnt anything simple!!!

torquetune.co.uk

nrpexhausts.co.uk

|

|

|

fluidslvr

|

| posted on 6/7/12 at 05:34 PM |

|

|

nylocs with locking wire..

http://mkmidi.blogspot.com

|

|

|

tcr

|

| posted on 9/7/12 at 09:53 AM |

|

|

have you got the lock wire wrapped around something else like on the 2nd pic ?

MK MIDI ZX10R

http://www.facebook.com/media/set/?set=a.4393256076054.2182513.1427988207&type=1&l=64c91c3c17

why isnt anything simple!!!

torquetune.co.uk

nrpexhausts.co.uk

|

|

|

loggyboy

|

| posted on 9/7/12 at 10:04 AM |

|

|

quote:

Originally posted by tcr

have you got the lock wire wrapped around something else like on the 2nd pic ?

Effectively it being through the nut is the 'something else'

Mistral Motorsport

|

|

|

Lightning

|

| posted on 9/7/12 at 10:13 AM |

|

|

i welded a bit of studding to a nut and screwed the nut onto the end of the bias bar. Did this both ends. It looked like the nuts were welded to the

bar. They accidently unscrewed and fell off after the test.

Steve

|

|

|

BobM

|

| posted on 9/7/12 at 10:20 AM |

|

|

quote:

Originally posted by Lightning

i welded a bit of studding to a nut and screwed the nut onto the end of the bias bar. Did this both ends. It looked like the nuts were welded to the

bar. They accidently unscrewed and fell off after the test.

... but just hope the tester doesn't have a spanner to test it

Not very Locost but very BEC

|

|

|

tcr

|

| posted on 9/7/12 at 10:22 AM |

|

|

ha ha there's a possibility that might happen to mine too

MK MIDI ZX10R

http://www.facebook.com/media/set/?set=a.4393256076054.2182513.1427988207&type=1&l=64c91c3c17

why isnt anything simple!!!

torquetune.co.uk

nrpexhausts.co.uk

|

|

|

eddie99

|

| posted on 9/7/12 at 10:51 AM |

|

|

quote:

Originally posted by Lightning

i welded a bit of studding to a nut and screwed the nut onto the end of the bias bar. Did this both ends. It looked like the nuts were welded to the

bar. They accidently unscrewed and fell off after the test.

Neat

http://www.elitemotorsporteng.co.uk/

Twitter: @Elitemotoreng

Facebook: http://www.facebook.com/pages/Elite-Motorsport-Engineering/153409081394323

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

blakep82

|

| posted on 9/7/12 at 10:52 AM |

|

|

interesting ideas!

i like the one with the wire rope thing looped round. might use that one myself. problem with my nbias bar is there's no access to it once its

in for drilling the nuts, or welding,

2 holes drilled in the ends of the bar, wire rope through, and looped around the pedal (checking it won't catch anything) might be the best way

for me! it will allow movement, but less that a quarter turn really.

screwing studding on the end, erm, clever, but dangerous if you get caught! lol

this one is the one i like

here's a question though, what is it they're actually checking it for? is it to stop people adjusting it and doing it wrong? in which case

any locking efforts can be undone easily

or to stop the bar screwing itself in and out under vibration? in which case, surely 2 nyloc nuts would do? or some sort of split pins or something

[Edited on 9/7/12 by blakep82]

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

adithorp

|

| posted on 9/7/12 at 12:12 PM |

|

|

As I understand it, the locking doesn't have to be perminent anymore (had to be welded when IVA first introduced). Now just has to prevent it

moving accidentaly and have the correctly worded sticker to say not to adjust.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

tcr

|

| posted on 9/7/12 at 07:10 PM |

|

|

who sells the warning decal?

MK MIDI ZX10R

http://www.facebook.com/media/set/?set=a.4393256076054.2182513.1427988207&type=1&l=64c91c3c17

why isnt anything simple!!!

torquetune.co.uk

nrpexhausts.co.uk

|

|

|

JekRankin

|

| posted on 9/7/12 at 07:12 PM |

|

|

Would a nyloc nut at either end do the trick? They'd be nigh on impossible to remove without tools.

[Edited on 9/7/12 by JekRankin]

|

|

|

loggyboy

|

| posted on 9/7/12 at 10:55 PM |

|

|

quote:

Originally posted by JekRankin

Would a nyloc nut at either end do the trick? They'd be nigh on impossible to remove without tools.

[Edited on 9/7/12 by JekRankin]

No, the intention is to stop people from adjusting them, not to stop them from coming 'loose'.

Mistral Motorsport

|

|

|

blakep82

|

| posted on 9/7/12 at 11:42 PM |

|

|

quote:

Originally posted by loggyboy

quote:

Originally posted by JekRankin

Would a nyloc nut at either end do the trick? They'd be nigh on impossible to remove without tools.

[Edited on 9/7/12 by JekRankin]

No, the intention is to stop people from adjusting them, not to stop them from coming 'loose'.

thats the thing that confuses me though, because anyone capable of building a car, and using some method of locking the bias bar, surely is capable of

removing that and adjusting it in a few minutes?

i'd have thought that nylocs are as hard (if not harder) to remove as lock wire, only nylocs are easier to fit!

the wire rope one is probably still the one i'd got for, but how do you join the ends together suitably? didn't see anything to show how

they'd done it (or even if it passed IVA!)

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

loggyboy

|

| posted on 10/7/12 at 06:53 AM |

|

|

yes, it is a bit of a strange rule, but i believe they intend it to discourage adjustment, more for possible future owners. they know people are

going to remove them, otherwise they would have kept the welding rule. I suspect its a lot of back covering and box ticking.

Mistral Motorsport

|

|

|

JekRankin

|

| posted on 10/7/12 at 08:19 AM |

|

|

In the end I decided to drill and roll pin mine because that seems to be the accepted solution for IVA. I still think the use of Nylocs might be

better in some respects, because it still prevents anyone from casually adjusting it without tools, but doesn't require holes to be drilled in

the bias bar.

|

|

|

BobM

|

| posted on 11/7/12 at 09:24 AM |

|

|

I spoke to the IVA tester before tackling my bias bar. He was of the view that he expected to see locknuts with roll pins plus a warning label. So

that's what I did and he was happy.

Not very Locost but very BEC

|

|

|