scootz

|

| posted on 13/8/12 at 04:49 PM |

|

|

Front Wheel Drive Cars...

I understand that FWD cars with offset diffs are prone to torque steer. Is this purely because of the unequal length driveshafts?

If so, is there any way to neutralise the unwanted handling characteristics? Weight / balance the shorter shaft to the longer one?

Cheers!

It's Evolution Baby!

|

|

|

|

|

loggyboy

|

| posted on 13/8/12 at 04:59 PM |

|

|

Equal length shafts can help, my clio 172 and 197 had them and it wasn't as bad as my red topped Nova that didn't.

Mistral Motorsport

|

|

|

v8kid

|

| posted on 13/8/12 at 05:09 PM |

|

|

Sometimes they make the longer shaft fatter i.e. stiffer so it winds up the same amount. Hence if done properly should eliminate problem.

Cheers!

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

zilspeed

|

| posted on 13/8/12 at 05:15 PM |

|

|

quote:

Originally posted by scootz

I understand that FWD cars with offset diffs are prone to torque steer. Is this purely because of the unequal length driveshafts?

If so, is there any way to neutralise the unwanted handling characteristics? Weight / balance the shorter shaft to the longer one?

Cheers!

It's even there in RWD cars too.

This gives me a chance to show some pics I found which demonstrate good design (of that aspect) in bike engined racing cars.

Ordinarily, the offset sprocket can lead to unequal shaft lengths - the easy way of doing things.

Here's the Stohr F1000 which uses a final drive case which results in equal length drive shafts.

Equal length drive shafts

The car in the avatar was also painstakingly designed to incorporate equal length drive shafts.

|

|

|

MikeRJ

|

| posted on 13/8/12 at 05:25 PM |

|

|

quote:

Originally posted by v8kid

Sometimes they make the longer shaft fatter i.e. stiffer so it winds up the same amount. Hence if done properly should eliminate problem.

Cheers!

I don't believe "wind up" has anything to do with it, because with a conventional diff the torque in each driveshaft is always

balanced so although one driveshaft may twist more the same level of torque is being delivered to each wheel. Driveshaft angle is more important

however, and unequal length driveshafts typical give unequal angles. IME the biggest contributor of all is suspension geometry, both static settings

and the amount by which everything moves under load.

|

|

|

v8kid

|

| posted on 13/8/12 at 07:22 PM |

|

|

quote:

Originally posted by MikeRJ

quote:

Originally posted by v8kid

Sometimes they make the longer shaft fatter i.e. stiffer so it winds up the same amount. Hence if done properly should eliminate problem.

Cheers!

I don't believe "wind up" has anything to do with it, because with a conventional diff the torque in each driveshaft is always

balanced so although one driveshaft may twist more the same level of torque is being delivered to each wheel. Driveshaft angle is more important

however, and unequal length driveshafts typical give unequal angles. IME the biggest contributor of all is suspension geometry, both static settings

and the amount by which everything moves under load.

You could well be right that the angularity plays a small part but I think the torsional rigidity effect would be larger.

Thinking about what happens - its not a steady difference in twisting, the wheels are gripping and letting go and then gripping again. In this uneven

grip the energy stored in the twisting of the driveshaft would be significant. When it lets go it releases a burst of torque and when it grips it

absorbs the torque. So the drive is alternating between sides of the car pulling it one way and then the other. If the suspension is really badly

designed the frequency of this twisting pulsation would match the suspension frequency and then it would really dart about. IMHO

Even in the "steady state" why is a longer screwdriver more effective than a short one? Stored energy in the torsion is my bet

As Zil says though easier for us to take the effort to have equal driveshafts.

Cheers!

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

britishtrident

|

| posted on 13/8/12 at 07:28 PM |

|

|

Torque steer is due to unequal angles of the drive shafts in relation the outer CV joints.

A turning moment about the steering axis is created internally by torque reactions within the cv joints.

Equal length drive shafts are fitted on more powerful and upmarket models to ensure the drive shafts enter the CV joints at as near equal

angles as possible.

If the driveshaft lengths (and ride height) are equal left to right then the torque steer generated within the left and right CV joints should

cancel each other out.

[Edited on 13/8/12 by britishtrident]

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

iank

|

| posted on 13/8/12 at 07:32 PM |

|

|

There are kits available for the classic mini which do the same as Zil's design with the fwd gearbox/diff.

http://www.minisport.com/mini-spare-parts/info_C_MAD005.html

[Edited on 13/8/12 by iank]

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

scootz

|

| posted on 13/8/12 at 07:54 PM |

|

|

Cheers all!

Onto my next Q... say you had a rearward facing gearbox output shaft 11cm to the right of a vehicles centre line and you wanted to connect it to a

centrally positioned diff flange using as short a prop as possible. Theoretically, how little distance could you be looking at between the

two?

I suppose another way of asking the same Q is, how acute an angle can you run with a typical CV joint?

It's Evolution Baby!

|

|

|

britishtrident

|

| posted on 13/8/12 at 08:12 PM |

|

|

They will operate up about 40 degrees for steering but for continuous running I would use not much over 20 degrees .

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

scootz

|

| posted on 13/8/12 at 08:16 PM |

|

|

Ta!

It's Evolution Baby!

|

|

|

zilspeed

|

| posted on 13/8/12 at 08:17 PM |

|

|

quote:

Originally posted by scootz

Cheers all!

Onto my next Q... say you had a rearward facing gearbox output shaft 11cm to the right of a vehicles centre line and you wanted to connect it to a

centrally positioned diff flange using as short a prop as possible. Theoretically, how little distance could you be looking at between the

two?

I suppose another way of asking the same Q is, how acute an angle can you run with a typical CV joint?

]]

None of this is hypothetical though, is it ?

|

|

|

scootz

|

| posted on 13/8/12 at 08:20 PM |

|

|

quote:

Originally posted by zilspeed

None of this is hypothetical though, is it ?

My tiny mind is wandering... again!!!

It's Evolution Baby!

|

|

|

chillis

|

| posted on 13/8/12 at 08:41 PM |

|

|

Torque steer of false wheel drive cars is the price to be paid for having a differential/drive on the same axle as the steering wheels. Equalising the

driveshaft lengths helps but its still much more than can be found with real wheel drive cars. Move the FWD engine/trans to the rear so the steering

wheels arn't on the same axle - simples.

|

|

|

MikeRJ

|

| posted on 14/8/12 at 08:41 AM |

|

|

quote:

Originally posted by v8kid

You could well be right that the angularity plays a small part but I think the torsional rigidity effect would be larger.

Thinking about what happens - its not a steady difference in twisting, the wheels are gripping and letting go and then gripping again. In this uneven

grip the energy stored in the twisting of the driveshaft would be significant. When it lets go it releases a burst of torque and when it grips it

absorbs the torque. So the drive is alternating between sides of the car pulling it one way and then the other. If the suspension is really badly

designed the frequency of this twisting pulsation would match the suspension frequency and then it would really dart about. IMHO

Even in the "steady state" why is a longer screwdriver more effective than a short one? Stored energy in the torsion is my bet

As Zil says though easier for us to take the effort to have equal driveshafts.

Cheers!

Doesn't matter if steady state or not, the torque delivered to both wheels will be the same with an open diff. If energy stored in the

driveshafts is the problem, then equal length driveshafts of the same diameter would be just as bad, as total energy stored is the same. To look at

it a different way, the energy stored in the longer driveshaft doesn't just affect the wheel it's directly connected to, the diff balances

the torque between the two wheels.

This is also why an LSD tends to make torque steer worse, the torque split between the wheels is no longer balanced under all conditions.

A longer screwdriver is no more effective for doing up screws than a shorter one with the same size handle etc. A long springy screwdriver shaft

would make the screwdriver pretty useless.

[Edited on 14/8/12 by MikeRJ]

|

|

|

v8kid

|

| posted on 14/8/12 at 09:06 AM |

|

|

Doesn't matter if steady state or not, the torque delivered to both wheels will be the same with an open diff. If energy stored in the

driveshafts is the problem, then equal length driveshafts of the same diameter would be just as bad, as total energy stored is the same. To look at

it a different way, the energy stored in the longer driveshaft doesn't just affect the wheel it's directly connected to, the diff balances

the torque between the two wheels.

This is also why an LSD tends to make torque steer worse, the torque split between the wheels is no longer balanced under all conditions.

A longer screwdriver is no more effective for doing up screws than a shorter one with the same size handle etc. A long springy screwdriver shaft

would make the screwdriver pretty useless.

[Edited on 14/8/12 by MikeRJ]

Mike,

Good arguement however you are assuming that the diff sees the wheels - but it does not.

As far as the diff is concerned nothing else exists other than the driveshaft inner end. So the diff provides 50% power to each driveshaft. One

driveshaft absorbs 15% more power than the other due to it winding up. So that wheel sees 15% less power and the other wheel spins first. And so it

occilates to and fro. The diff most emphatically does not divide the power between the wheels it divides it betweel the driveshafts which modifiy the

power to the wheels dynamically and the steady state picture is very different from the dynamic picture.

Why do you reckon manufacturers make the longer driveshaft a bigger diameter (hence stiffer) ?

Your experience of screwdrivers must be different to mine  Ask another old time joiner and I'll bet you get the same answer as mine. Ask another old time joiner and I'll bet you get the same answer as mine.

Cheers!

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

chillis

|

| posted on 14/8/12 at 09:21 AM |

|

|

quote:

Originally posted by v8kid

Doesn't matter if steady state or not, the torque delivered to both wheels will be the same with an open diff. If energy stored in the

driveshafts is the problem, then equal length driveshafts of the same diameter would be just as bad, as total energy stored is the same. To look at

it a different way, the energy stored in the longer driveshaft doesn't just affect the wheel it's directly connected to, the diff balances

the torque between the two wheels.

This is also why an LSD tends to make torque steer worse, the torque split between the wheels is no longer balanced under all conditions.

A longer screwdriver is no more effective for doing up screws than a shorter one with the same size handle etc. A long springy screwdriver shaft

would make the screwdriver pretty useless.

[Edited on 14/8/12 by MikeRJ]

Mike,

Good arguement however you are assuming that the diff sees the wheels - but it does not.

As far as the diff is concerned nothing else exists other than the driveshaft inner end. So the diff provides 50% power to each driveshaft. One

driveshaft absorbs 15% more power than the other due to it winding up. So that wheel sees 15% less power and the other wheel spins first. And so it

occilates to and fro. The diff most emphatically does not divide the power between the wheels it divides it betweel the driveshafts which modifiy the

power to the wheels dynamically and the steady state picture is very different from the dynamic picture.

Why do you reckon manufacturers make the longer driveshaft a bigger diameter (hence stiffer) ?

Your experience of screwdrivers must be different to mine  Ask another old time joiner and I'll bet you get the same answer as mine. Ask another old time joiner and I'll bet you get the same answer as mine.

Cheers!

This is only true where the front wheels are both pointing exactly ahead, as soon as the steering wheel is turned even slightly then the diff favours

one side more than the other, this then feeds itself and the steering wheel feels as though its being tugged out of your grip.

|

|

|

v8kid

|

| posted on 14/8/12 at 10:39 AM |

|

|

Yup I agree

Cheers!

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

britishtrident

|

| posted on 14/8/12 at 10:45 AM |

|

|

First of the reason why longer shafts are a larger diameter is to change the critical vibration frequencies of the shaft. In any event even on

a car with equal length outer drive shafts the total length of drive shaft going to one wheel will be longer as it will comprise the

length of the inner shaft + the length of outer shaft.

Secondly Newton's laws state that every reaction has an equal and opposite reaction, this applies equally to torques. A torque applied

at one end of a shaft must be resisted by an equal but opposite at the other end.

An everyday situation the gives very simple model of torque steer is using a universal joint on the end of a socket set extension.

When torque is applied the socket will tend to twist off the nut. The severity of the twisting off effect is governed by the size of the angle

the extension bar makes with the universal joint not the length of the extension bar.

Torque Steer can actually be demonstrated by jacking up a fwd car with both driven wheels clear of the deck. Take all sensible safety

precautions set the steering wheel straight ahead and start the engine.

Put the car in gear and increase the RPM, if the car has unequal length outer shafts there will be a pronounced kick of the steering wheel to full

lock. This won't happen on a car with equal lengths shafts.

Torque steer is caused by the relative position of the ball bearings that transmit the forces between the spider of the CV joint and the outer

part of the CV joint.

[Edited on 14/8/12 by britishtrident]

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

mcerd1

|

| posted on 14/8/12 at 03:55 PM |

|

|

^^ that all makes sense to me (I think)

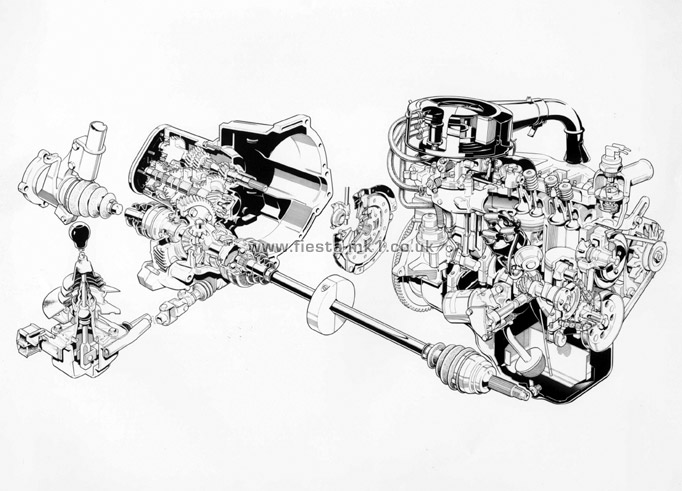

so can anyone explain what the big weight clamped round the longer shaft on my old mk1 fiesta ?

I could never work out what that was meant to be doing......

also I take it a FWD car with a large scrub radius is just exaggerating any torque steer that happens to be there already ?? (or have a I missed

something ?  ) )

i.e. why ford and the likes have been banging on about it on the new RS etc....

-

|

|

|

britishtrident

|

| posted on 14/8/12 at 04:11 PM |

|

|

The big weight on the drive shaft is a vibration damper to alter the resonant frequency of the drive shaft, more up market fwd cars use a

vibration damper with a rubber insert which is more effective over a wider spread of frequencies.

Scrub radius effects the "tug" and kick back through the steering but isn't really anything to do with torquesteer.

[Edited on 14/8/12 by britishtrident]

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

gazza285

|

| posted on 14/8/12 at 07:15 PM |

|

|

If equal length, same material spec drive shafts, and running at the same angles help to eliminate torque steer, how come my Cloverleaf Sprint was so

bad?

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

mcerd1

|

| posted on 14/8/12 at 07:57 PM |

|

|

quote:

Originally posted by britishtrident

The big weight on the drive shaft is a vibration damper to alter the resonant frequency of the drive shaft, more up market fwd cars use a

vibration damper with a rubber insert which is more effective over a wider spread of frequencies.

I wondered about that, but dismissed it as I didn't think a bog standard 1979 fiesta new the meaning of the word 'refinement' :lol:

-

|

|

|

scootz

|

| posted on 17/8/12 at 09:09 PM |

|

|

Soooo... for arguments sake (of course  )... )...

Would it be advantageous to machine a spacer to extend one diff output flange (say 10cm) to allow for equal length / angled shafts?

It's Evolution Baby!

|

|

|

whitestu

|

| posted on 11/1/13 at 11:03 AM |

|

|

quote:

If equal length, same material spec drive shafts, and running at the same angles help to eliminate torque steer, how come my Cloverleaf Sprint was so

bad?

I was about to make that point! Alfasuds, Sprints and 33s all had equal lenght shafts and the larger engined models have dreadful torque steer.

It's much more to do with suspension geometry than drive shaft design.

Stu

|

|

|