coyoteboy

|

| posted on 24/5/13 at 12:10 PM |

|

|

Audi V8 timing belt job

So my donor engine needs a belt change (doesn't but it's worth doing now as I need to change the water pump). Tools for the job are ~£400

alone and basically comprise a bunch of locking devices to hold all 4 cams in place with the crank (cams have a single pulley and are linked at the

opposite end with a chain so it's no more difficult than a 16v head in essence). I'm thinking I can do it the way I've done pretty

much all of my cars - bodge a few locking tools together, matchmark the cams and crank locations, take care and rotate it by hand a few cycles to

ensure it lines up.

Anyone any experience with the ABZ engine timing belt job that can highlight any potential issues?

|

|

|

|

|

loggyboy

|

| posted on 24/5/13 at 12:18 PM |

|

|

These will be interference fit pulleys, meaning home made locking devices will need to be spot on, not just close enought to ensure it doesnt turn

half a turn like you could in the old days when the pulleys were keyed to the cam/crank. We are talking less than a degrees accuracy required.

Even with 2 camshaft engines its easy to get wrong. I did 2 clio 172s a recently and you tentsion the belt fully, but keep the pulley bolts loose, so

the position of the belt is irrelvent to the position of the cams/crank. then when the belts all tenstioned, you torque up the pulley bolts.

For something as complex as V8 you will need to get it right.

Mistral Motorsport

|

|

|

coyoteboy

|

| posted on 24/5/13 at 12:29 PM |

|

|

Hmm it's just the crank pulley that I'll be taking off but I haven't checked if it's an friction fit type or keyed, I must

admit. I will have to dig in more detail but I think the tools are a tool to lock the two cam pulleys together, a set to lock each pair of cams

together (not really needed if the front set are locked but probably used for things like seal replacements if removing the front pulleys, so used in

the standard procedure).

It's the crank that'll be an issue if not keyed then. I think the official crank locker is a tooth holder on the flywheel - not a problem

to fab with the box off and no clutch fitted, but I hate keyless pulleys - they almost always take 2 attempts to get right IME!

Edit: Crank pulley is apparently keyed on the RS6 - slightly different engine but same era:

[Edited on 24/5/13 by coyoteboy]

[Edited on 24/5/13 by coyoteboy]

|

|

|

loggyboy

|

| posted on 24/5/13 at 01:15 PM |

|

|

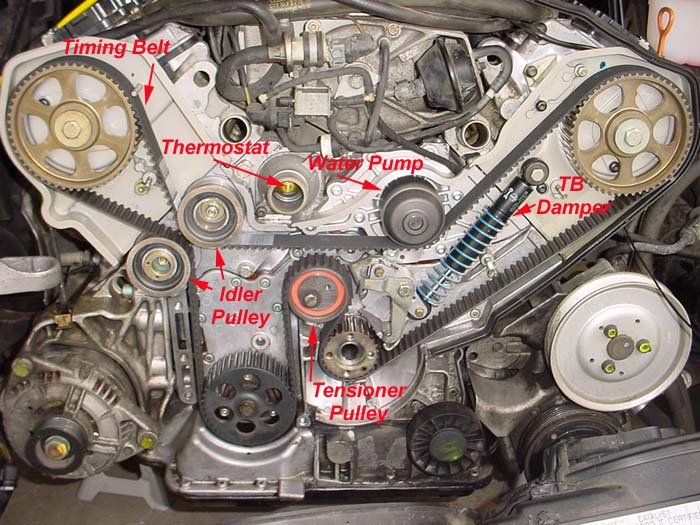

Crank might be keyed but cams arent:

http://www.audipages.com/Tech_Articles/enginemechanical/tbreplace0.html

Mistral Motorsport

|

|

|

britishtrident

|

| posted on 24/5/13 at 02:22 PM |

|

|

There is certainly a key on the pulley in the picture.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

chrism

|

| posted on 24/5/13 at 04:20 PM |

|

|

Would it not be easier/cheaper getting an Audi specialist to do it. If the engines out and you can take it to them, it would save a significant amount

of labour cost as I believe most of the labour cost is removing everything to get access to the front of the engine and then putting it all back

again.

May cost a fair amount less than just buying the tools for the fitting labour.

----------------------------

A little hard work never killed anyone, but why take the risk!

-----------------------------

|

|

|

Simon

|

| posted on 24/5/13 at 05:11 PM |

|

|

quote:

Originally posted by chrism

Would it not be easier/cheaper getting an Audi specialist to do it. If the engines out and you can take it to them, it would save a significant amount

of labour cost as I believe most of the labour cost is removing everything to get access to the front of the engine and then putting it all back

again.

May cost a fair amount less than just buying the tools for the fitting labour.

My thoughts exactly. Audi will probably be scheduled so even though you've 95% of the work, they'll still want 100%, but non franchised

might come up with sensible price, plus if they screw it up, you've got some comeback.

ATB

Simon

|

|

|

coyoteboy

|

| posted on 24/5/13 at 05:36 PM |

|

|

Can't easily transport it anywhere (no suitable vehicle) and I have no means of checking/correcting any job they do if they cock it up and I

can't run the engine for 6 months, at which point I have no comeback. I never use garages, ever. Seen too many expensive botch jobs, I'd

rather do a cheap botch job and only have myself to blame (never had a problem before, don't expect any with careful research).

Maybe if I could find a friendly specialist who would pop in on his way home and do it in my garage I might be tempted, but even so it's going

to cost more than the engine is worth if I'm to offer them a fair return on their time.

quote:

Crank might be keyed but cams arent: http://www.audipages.com/Tech_Articles/enginemechanical/tbreplace0.html

I'll have to assess the belt pattern and tensioning but I think everything between the cams is static, so providing I don't remove any of

the pulleys (there's no need to) I don't need to worry about anything - matchmarks and tooth counting will work fine as it always has.

[Edited on 24/5/13 by coyoteboy]

|

|

|

navyseamonkey2011

|

| posted on 24/5/13 at 07:02 PM |

|

|

Home made tools, tipex pen and check everything twice.

job done!! done let the naysayers on forums put you off!

|

|

|

Mark Allanson

|

| posted on 24/5/13 at 07:18 PM |

|

|

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

froggy

|

| posted on 24/5/13 at 07:25 PM |

|

|

Spring loaded dot punch and a spare pair of hands to keep the cams from moving while you nip the pulleys back up . I paint pen the pulleys etc then

dot the cam with the punch near to a cap . The only issue is having enough hands to keep them from moving , only done one but as your engine is out

you can lock the crank up so its not going to move .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

stevegough

|

| posted on 24/5/13 at 07:52 PM |

|

|

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

Luego Locost C20XE.

Build start: October 6th 2008.

IVA passed Jan 28th 2011.

First drive Feb 10th 2011.

First show: Stoneleigh 1st/2nd May 2011.

'Used up' first engine may 3rd 2011!

Back on the road with 2nd engine may 24th

First PASA mad drive 26/7/11

Sold to Mike in Methyr Tydvil 19/03/14

|

|

|

40inches

|

| posted on 24/5/13 at 07:54 PM |

|

|

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

Now that's something to remember for future reference.

|

|

|

40inches

|

| posted on 24/5/13 at 08:00 PM |

|

|

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

Possibly hold the old belt in tension with an "in yer face" cable tie,pulling from across the other side of the engine, Mr Gough

|

|

|

Mark Allanson

|

| posted on 24/5/13 at 08:03 PM |

|

|

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

It is sometimes a bit tight, but a very small amount of slackening of the tensioner(s), without allowing any movement of the belt on the pulley lobes,

will go a very long way.

[Edited on 24/5/13 by Mark Allanson]

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

rdodger

|

| posted on 24/5/13 at 08:07 PM |

|

|

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

Brilliant!

|

|

|

stevegough

|

| posted on 24/5/13 at 08:25 PM |

|

|

quote:

Originally posted by 40inches

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

Possibly hold the old belt in tension with an "in yer face" cable tie,pulling from across the other side of the engine, Mr Gough

Not finding yourself agreeing with me again, are you, yard-and-a-half?

Luego Locost C20XE.

Build start: October 6th 2008.

IVA passed Jan 28th 2011.

First drive Feb 10th 2011.

First show: Stoneleigh 1st/2nd May 2011.

'Used up' first engine may 3rd 2011!

Back on the road with 2nd engine may 24th

First PASA mad drive 26/7/11

Sold to Mike in Methyr Tydvil 19/03/14

|

|

|

coyoteboy

|

| posted on 24/5/13 at 09:54 PM |

|

|

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

|

|

|

froggy

|

| posted on 24/5/13 at 10:10 PM |

|

|

If it's the same code as the one I did which I think was a 40v version you need to tension the belt with the cam pulleys floating . You

can't set the tension between the two pulleys without moving them both if they are still locked to the cams

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

Mark Allanson

|

| posted on 24/5/13 at 10:11 PM |

|

|

quote:

Originally posted by coyoteboy

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

You can! just cable tie the old half a belt to each pulley, release the old water pump, install the new, check that nothing has moved, continue as

described

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

britishtrident

|

| posted on 24/5/13 at 10:52 PM |

|

|

quote:

Originally posted by Mark Allanson

quote:

Originally posted by coyoteboy

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

You can! just cable tie the old half a belt to each pulley, release the old water pump, install the new, check that nothing has moved, continue as

described

MG XPAG and pre-ww2 Morris engines used marks on the chain which lined up marked teeth on the sprockets .

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

coyoteboy

|

| posted on 25/5/13 at 01:52 AM |

|

|

quote:

Originally posted by froggy

If it's the same code as the one I did which I think was a 40v version you need to tension the belt with the cam pulleys floating . You

can't set the tension between the two pulleys without moving them both if they are still locked to the cams

It's not, it's the 32v version, but i still don't see the need to float the cam pulleys if they were set right the first time,

it's just a like for like swap. Assuming a belt with the same number of teeth, tooth to tooth difference won't change and so relative

timing wont change either.

|

|

|

froggy

|

| posted on 25/5/13 at 06:42 AM |

|

|

Your abosolutely right and I'm going to work in a minute to throw all my locking kits in the bin . Your method will work but it won't be

timed 100% . I use a firm that hire kits out for stuff like twin vanos bm s that I don't do regularly .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

harvs

|

| posted on 25/5/13 at 08:58 AM |

|

|

Hi

You should be able to get the new belt in the right position, but when you release the tensioner the relative position between crank and cams will

shift slightly I think (maybe not as much as a whole tooth, but a little none the less). If the cams are floating this movement due to tensioning will

happen before the cams are locked in position, so will be fine. But if the cams aren't loosened first, the timing will likely be a little

out.

I've not experience of this (yet), so don't know how much of an issue the timing being out a little will be, but it's obviously not

ideal.

|

|

|

froggy

|

| posted on 25/5/13 at 09:09 AM |

|

|

It normally shows up as a slightly rough idle or throws up a crank /cam coherence code. Most common one I've seen is the Renault k4m series

engines where people have done belts by paint marks then have issues with idle and stalling on light throttle .

On something with a very long run between the cams you can't get the tension between the two right

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|