Mudchute

|

| posted on 24/4/15 at 02:53 PM |

|

|

A new build - mx5/Sierra rear end question.

Hi everyone,

I've been given permission to commence a Haynes locost build so I've been planning which of the variations to go for.

I want to use an mx5 and go for an sdv build but the rear end is bothering me. I've seen the excellent Saturn cars mx5 guide and will follow

that however I don't want to use the mx5 rear dampers which I believe it does. For adjustability I'd rather use a damper the same as the

front but can't find a design that allows this.

Can anyone help or point me in the correct direction?

Thank you guys

Gavin

|

|

|

|

|

Slimy38

|

| posted on 24/4/15 at 03:14 PM |

|

|

Nope, no MX5 dampers used in any MX5 design I've seen, they're standard seven type dampers. It uses the upright from the mx5, and needs a

short top wishbone to accommodate the rear diff arms, but that's about it for customization?

|

|

|

mikeb

|

| posted on 24/4/15 at 03:29 PM |

|

|

mounting the diff seems to be the biggest headache.

|

|

|

Mudchute

|

| posted on 24/4/15 at 03:33 PM |

|

|

Ah, I've not been able to find a pic of an assembled Saturn/Haynes rear suspension assembly hence the confusion.

Is the short top arm a problem? Does it compromise the suspension action/geometry in any way?

|

|

|

ianhurley20

|

| posted on 24/4/15 at 03:48 PM |

|

|

One compromise which is the way I have built mine is a standard Haynes using Sierra rear end with Mazda engine box and other bits.

|

|

|

Mudchute

|

| posted on 24/4/15 at 03:51 PM |

|

|

Were you able to retain the Mazda rear hub or brakes?

|

|

|

garyt

|

| posted on 24/4/15 at 05:22 PM |

|

|

Hi. I have used the saturn plans for my build. If you look thru my photo archive you can see how the mx5 diff is used fitted. If you look for the

talon build it uses a diffcover to fo away with the mx5 diff arms and as such the 2 are very fifferent. My build uses the mx5 uprights hubs brakes etc

there are a few anomalies to be aware of. The shorter rear upper wishbone doesnt appear to effect anything . I had craig at plazcut (no connection) to

do the plates for me and he now lists them. If you need any clarification on anything dont be afraid to ask and ill do my best to answer. Measure.

Take a picture.

Feel free to browse my photo archive or see my buil thread its in the chassis section..... lol... maybe the mods can move it to the haynes section

Anyway welcome and good luck

Gary

remember we are not mad just creatively insane !!!!!

|

|

|

garyt

|

| posted on 24/4/15 at 06:03 PM |

|

|

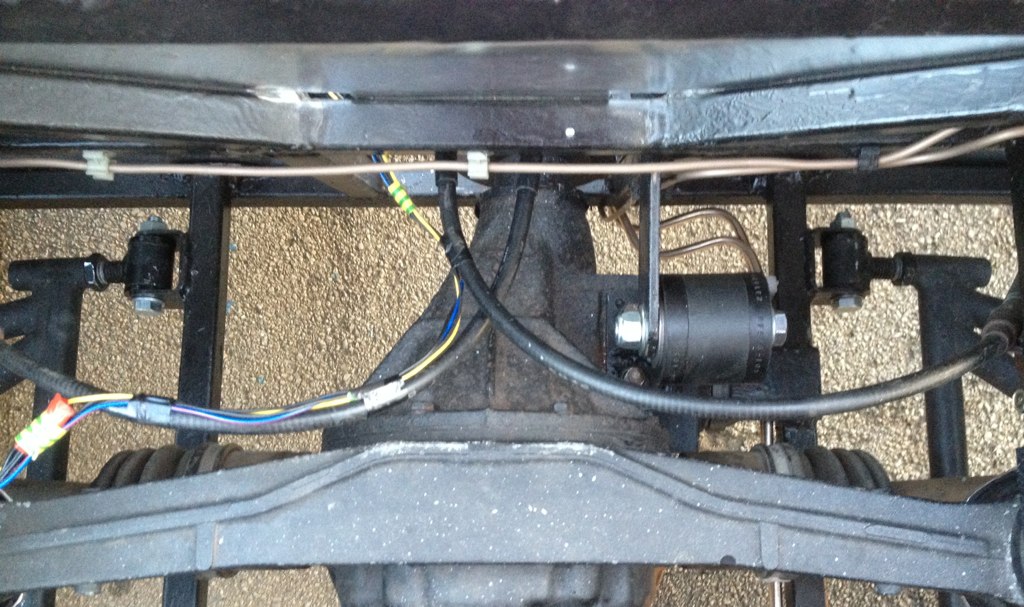

here is a pic of the diff mounted

[img]

Description

[/img]

remember we are not mad just creatively insane !!!!!

|

|

|

Mudchute

|

| posted on 24/4/15 at 06:12 PM |

|

|

Thanks Gary, it's useful to see the Saturn rear built up.

Choices, the tmxr kit is tempting. It'll certainly make life easier. I'll go have a think and report back.

|

|

|

Stot

|

| posted on 24/4/15 at 06:21 PM |

|

|

The diff issue is mainly the mounting of the nose. The Saturn plans suggest a rubber mounting but that soon gets torn up in use as when you apply

torque to the diff the nose wants to pull up, especially if you are using rubber wing bushes too. A few of us have solid mounted the whole diff now

and touch wood no problems on mine so far, I'm putting ~200hp through a 1.6 diff. Its also why Talon is offering his replacement diff casing

which solid mounts like the Sierra build. mounted mine with solid bushes and solid nose mount. Proper sized bolts were used eventually..

Only thing I would say is that I can 'feel' the diff when theres engine braking taking place but I don't think it would be any more

or less than a Sierra build which is solid mounted also.

Cheers

Stot

[Edited on 24/4/15 by Stot]

|

|

|

Slimy38

|

| posted on 24/4/15 at 06:39 PM |

|

|

I went for Talon's cover, it mounts really well. And it means you can revert to the standard Sierra sized wishbones and put the geometry back to

the original. Not that I'm saying the short arms are bad, but I have to be honest it didn't sit well with me. Combine that with what Stot

said about mounting the standard diff and the solution from Talon just makes a whole lot of sense.

This is the cover as it arrived, and fitted in place of the standard cover;

These are the mounting lugs, they're actually the Sierra diff plates chopped up!! (waste not, want not)

Painted and fitted;

And another view. Note the cage, it's from the original Haynes design so the wishbones will have the same bracket points;

[Edited on 24/4/15 by Slimy38]

|

|

|

ianhurley20

|

| posted on 24/4/15 at 07:56 PM |

|

|

quote:

Originally posted by Mudchute

Were you able to retain the Mazda rear hub or brakes?

I didn't try to and used standard hubs and sierra drums. If I were doing it all again it would be Phils TMXR design with his diff cover.

I hope Phil is okay because he has a number of domestic and health issues at the moment that may make that choice difficult.

|

|

|

Mudchute

|

| posted on 24/4/15 at 08:44 PM |

|

|

The tmxr setup looks very appealing. I think I'm gonna go with that.

I'm picking up an 8x4 table Monday, a 'boardroom meeting' table that's very heavy and very sid not to mention completely flat.

That'll be the build table!

Hopefully I win an auction on a welder soon as well. The ball is rolling!

|

|

|

garyt

|

| posted on 25/4/15 at 06:17 AM |

|

|

Thats it started now then . Keep it going and remember we are all here as n when required there is a huge wealth of knolage on here for advice and

inspirarion. Good luck Gary

remember we are not mad just creatively insane !!!!!

|

|

|

garyt

|

| posted on 25/4/15 at 06:24 AM |

|

|

As mentioned above Phil at talon is a great guy and has a vary good reputation . I would contact him sooner rather than later to get a lead time /

order your chassis / pack etc. As im not sure how long you would have to wait as they are not "on the shelf" sort o speak

Gary

remember we are not mad just creatively insane !!!!!

|

|

|

Mudchute

|

| posted on 25/4/15 at 07:16 AM |

|

|

Thanks Gary,

I'm very excited about the build, patience will be my enemy however money will keep that in check!

I've been thinking more about chassis options. As I want to do as much for myself as possible I'd like to cut and chamfer the chassis

tubes myself (I have suitable tooling and a milling machine to generate accurate angles) so I've been thinking I could copy the saturn plans for

the front end and mx5 specific fittings (steering column etc) but build a book rear end and mount the diff with the Talon diff cover. Talon also make

suspension arms to fit mx5 uprights into a standard chassis which if used should tie the whole lot together.

Does this ound plausible?

|

|

|

steve-hv8

|

| posted on 25/4/15 at 07:31 AM |

|

|

im following this post with interest as im still thinking about what to do

im going to get in touch with talon and see what lead times are

|

|

|

Slimy38

|

| posted on 25/4/15 at 08:00 AM |

|

|

quote:

Originally posted by Mudchute

Thanks Gary,

I'm very excited about the build, patience will be my enemy however money will keep that in check!

I've been thinking more about chassis options. As I want to do as much for myself as possible I'd like to cut and chamfer the chassis

tubes myself (I have suitable tooling and a milling machine to generate accurate angles) so I've been thinking I could copy the saturn plans for

the front end and mx5 specific fittings (steering column etc) but build a book rear end and mount the diff with the Talon diff cover. Talon also make

suspension arms to fit mx5 uprights into a standard chassis which if used should tie the whole lot together.

Does this ound plausible?

That's pretty much what I did, but I had to be 'creative' with the rear wishbones. Partly because at the time there were no MX5

upright to Haynes chassis options, but partly because I want to keep costs down. You'll find that because a lot of work goes into the wishbones,

they can end up pretty pricey ready made. There's nothing wrong with that but I have more time than money. It took me a good 30+ hours to do my

wishbones, and it saved me a couple of hundred pounds.

|

|

|

Mudchute

|

| posted on 25/4/15 at 09:09 AM |

|

|

Thats good to know, thank you and gives me confidence to attempt more myself.

The wishbones a far off so hopefully between now and then I could establish the correct dimensions. I'm happy to manufacture them myself but

they obviously need to be bang on.

|

|

|

ctwv50

|

| posted on 25/4/15 at 10:27 AM |

|

|

I've poly mounted my diff all round, two volvo engine mounts top and bottom secure the nose and seems to be holding up well but I've not

put any real miles on it as yet just hard launches with fat sticky tyres.

I'll take some pictures when I change the diff sometime this summer.

BUT, if I were to attempt a similar build, which is unlikely, I might try to replicate the westfield rear end but again poly mount the diff ,if it

proves problem free. It'd be a lot of work and you'd have a lot of knock on changes to the standard car but that would be the fun bit.

It'd maybe add a year to the build. lol!

|

|

|

Mudchute

|

| posted on 25/4/15 at 10:43 AM |

|

|

Thats an excellent picture, thank you.

I did have fleeting thoughts about mounting the diff with bushes somehow. It makes a lot of sense and should give the diff/prop/gearbox a slightly

easier time dependent on how well its done.

I straining a the leash to get cracking on this. Tomorrow is going to drag, I need to pick up this table and start mapping it out. I do hope I win the

welder auction too...

|

|

|

ctwv50

|

| posted on 25/4/15 at 11:03 AM |

|

|

Here are some bad images, the first is the first mock up with some standard Volvo engine mounts, the other two are the top and bottom mounts with poly

bushes in and painted. I made these out of metal found in a fabricators scrap bin, a disposable welding gas bottle and any other bits and pieces I had

lying around, hence the rough undesigned look. I intend to redo them using specced material when I change the differential.

|

|

|

Mudchute

|

| posted on 25/4/15 at 11:29 AM |

|

|

They're substantial and must work well.

I was wondering. The big ally 'I beam' mount cast into the diff cover. What if one were to chop that right down, leaving something thats

slightly wider than the diff itself then machine two holes going front to rear of whats left and then fitting a poly bush through them which then

mounts to a chassis bracket?

If that makes sense!

|

|

|

ctwv50

|

| posted on 25/4/15 at 11:48 AM |

|

|

quote:

Originally posted by Mudchute

They're substantial and must work well.

I was wondering. The big ally 'I beam' mount cast into the diff cover. What if one were to chop that right down, leaving something thats

slightly wider than the diff itself then machine two holes going front to rear of whats left and then fitting a poly bush through them which then

mounts to a chassis bracket?

If that makes sense!

GBS Zero do a similiar thing but solid mounted.

http://zachsgbszero.blogspot.co.uk/2013/04/fuel-system-diff-panels-bit-of.html

If it was done in such a way so you could resist the twisting motion then yes go for it.

|

|

|

ctwv50

|

| posted on 25/4/15 at 12:00 PM |

|

|

Actually, having recently taken an mx5 diff apart it occurred to me that you could use slightly longer high strength case bolts and use thick steel

plate shaped and drilled to fit around the cast steel nose to create any kind of mount to any kind of frame or build allowing you to be able to

completely remove the arms from the ali case. Kind of like talons diff case but without the cost.

[Edited on 25/4/15 by ctwv50]

|

|

|