j_mcvic

|

| posted on 8/3/16 at 10:59 AM |

|

|

2 poster ramp 3 phase to single phase motor change!

Hi Everyone,

I recently bought a Tecalemit Twintec MK5 from an ex Renault dealership. The problem is that it has a 3 phase motor just now.

Im planning on putting it into my unit which currently only has a 6Kva single phase genrator for power.

When I bought the ramp the guy had 2 identicle ones for sale, one with a 3ph 2.2Kw motor and the one that I bought which was a 3Kw 3ph motor so Im

looking to change the motor for a single phase 3Kw motor. Ive read a load of things and forums about changing the motor but Im still not sure what im

needing.

I think I need a 3Kw single phase 4 pole capacitor start capacitor run motor - Can someone confirm this for me?

Also, what happens with the current control box on the ramp just now? Im assuming that this gets removed completely and replaced with a single 3

position switch which will give me up, off and down? Again can this be confirmed?

There are limit switches built into the ramp just now but im not worried about these working

Ramp:

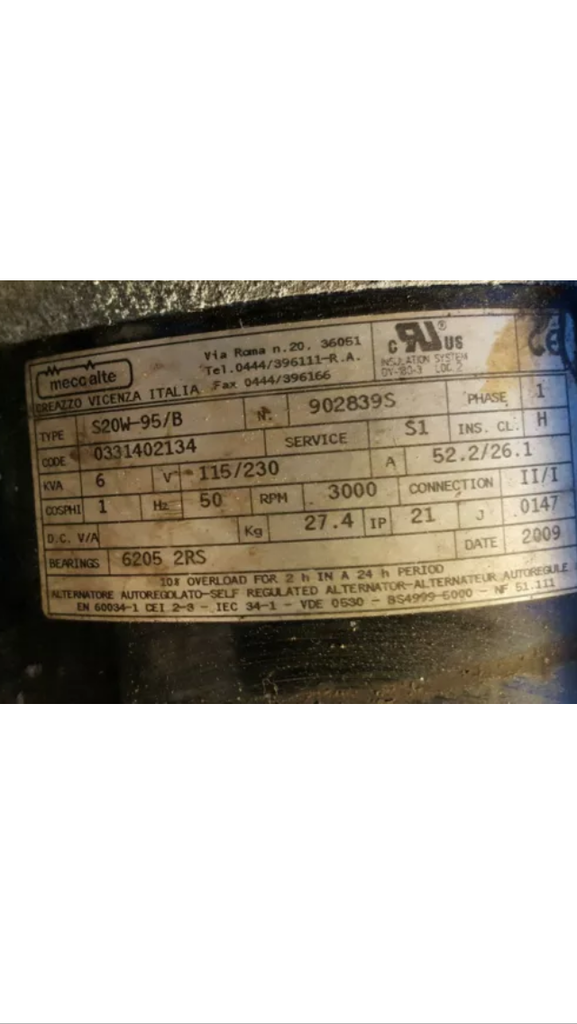

Plate on motor:

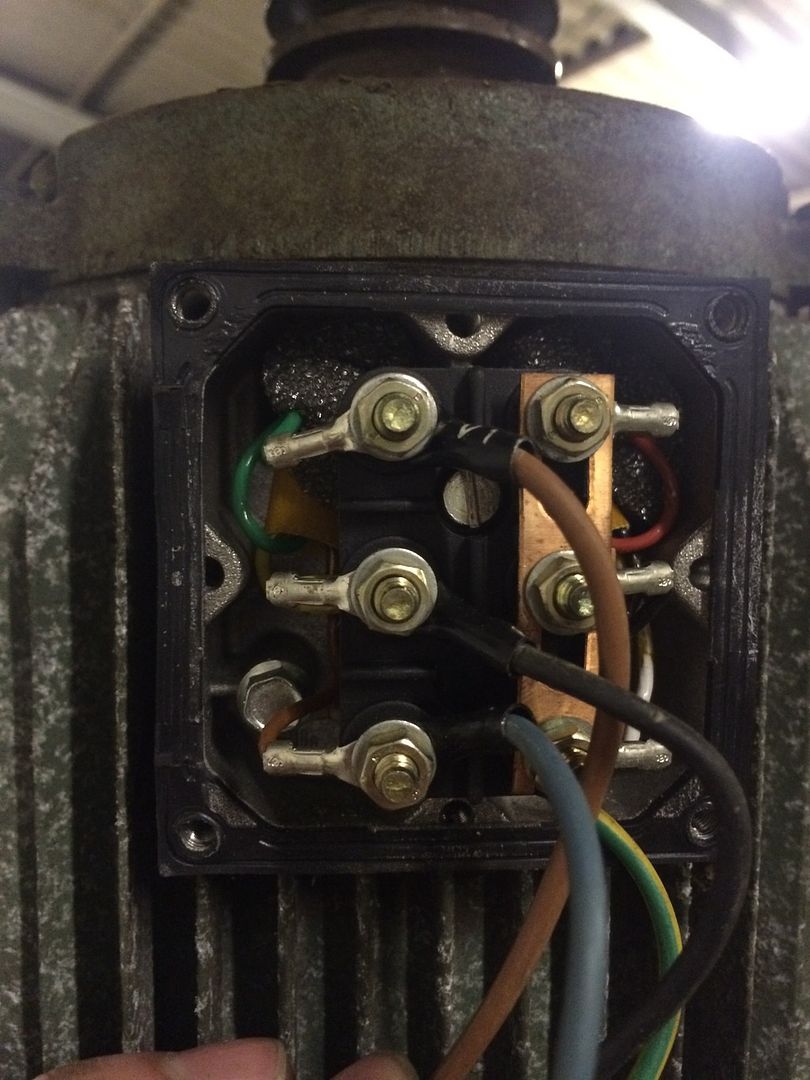

Motor Wiring:

Control box wiring:

Control switch wiring:

Generator plate:

Any help and links to what I need would be much appreciated.

Thanks

Jamie

|

|

|

|

|

hizzi

|

| posted on 8/3/16 at 11:55 AM |

|

|

i would be tecalmet do a single phase version,mlook them up or phone see if you can get a spec

|

|

|

Dick

|

| posted on 8/3/16 at 12:19 PM |

|

|

You will need a 3kw motor with the same rpm from the plate it seems to have been a 1400 rpm so yes what you are saying in your post is what you meed.

You will also need the control for this as the one you show is for 3 ph may be best to see if you can find a second hand one as the cost of both item

wont be cheap.

|

|

|

llionellis

|

| posted on 8/3/16 at 12:28 PM |

|

|

There's a 4KW single to three phase inverter on ebay for £200.00 I think I would look into that option.

|

|

|

yngndrw

|

| posted on 8/3/16 at 12:38 PM |

|

|

There are a couple of additional considerations.

1) The direction of three phase motors is dictated by the waveform of the power supply and they are easily reversed by swapping any two of the phases.

Single phase motors are started using a start capacitor in a given direction and are more difficult to reverse. (See:

https://woodgears.ca/motors/reversing.html)

2) As mentioned in point #1, a starting capacitor is used to start a single phase motor rotating in the correct direction. You need to be careful that

the motor you get is suitable for being started and stopped as much as you'd want to for a two post lift.

You should defiantly consider using a single phase to three phase converter instead. (A rotary converter, or possibly even changing your generator for

a three phase generator.)

There is an old thread on the matter here:

http://www.locostbuilders.co.uk/viewthread.php?tid=175257

For the record, I would not advise bypassing the limit switches. They are there for a reason and you should ensure they still work after you have made

your changes. This is not the sort of thing that you should take shortcuts on.

[Edited on 8/3/16 by yngndrw]

|

|

|

David Jenkins

|

| posted on 8/3/16 at 01:48 PM |

|

|

You may well find that a single-phase motor will be physically larger than the three-phase one, for a given power (the three-phase doesn't have

the great big start winding). Also, single-phase motors can overheat if they are started too often in a short period.

I'd also go for a converter, if you can get a decent quality one at a suitable price (at least you won't need variable speed!).

|

|

|

owelly

|

| posted on 8/3/16 at 05:49 PM |

|

|

Another consideration would be to reduce the size of the pulley on the motor/increase the one on the drive and use a smaller motor. It would make the

job slower but you may find a cheaper motor.

http://www.ppcmag.co.uk

|

|

|

rash12

|

| posted on 8/3/16 at 06:14 PM |

|

|

speak to these people they will supply all you need and very helpful i used them for my conversion 110513297638 ebay

|

|

|

dilley

|

| posted on 8/3/16 at 08:36 PM |

|

|

You can use a capacitor as a bullshit 3rd phase.

|

|

|

j_mcvic

|

| posted on 8/3/16 at 09:00 PM |

|

|

Hi everyone,

Thanks for all the information its pretty much what I was expecting. I did think about going down the inverter route however I think I'm going

to go for the new motor and control box from the company Rash12 has dealt with.

Thank you all for your input!

|

|

|

mark chandler

|

| posted on 8/3/16 at 10:16 PM |

|

|

My zippo had a 3 phase 2.5hp motor, think it was 1,200 rpm which I replaced with a single phase 3hp motor, 1,400 rpm.

Took a bit of working out with the relays to put in a reverse as you need to cross a couple of wires, for my lathe which has a similar loading I used

a reverse switch and on/off switch which was much easier.

Anyway the 3hp motor burnt out after 3 years, it did struggle so I now run a 4hp motor and made smaller toothed wheel, it is very good now although

you do need a 32amp feed, in hindsight a big three phase to single phase box would have ultimately saved me money as I could have then run a three

phase supply for lift, lathe and pillar drill instead of fiddling with each one to get to single phase.

Dropping a capacitor onto the existing motor to make up the third phase will not work, the start load is just to high.

Regards Mark

|

|

|

nick205

|

| posted on 9/3/16 at 10:58 AM |

|

|

Can't help with the motor, but that looks a great thing to have. I'd most like to have the space (height) for one

|

|

|

j_mcvic

|

| posted on 9/3/16 at 02:30 PM |

|

|

Hello again everyone....

So i've looked into both options (Motor change & Inverter) and neither have come back with good results at all!

First I contacted SW motors and fans... They came back to me very quickly and said it wouldn't be something they can supply. Try contacting

Transwave.

So I contacted Transwave and they came back and said they can supply an inverter but it would be £702!

I know its probably not as easy as im thinking (Very limited electrical knowledge) but can I not just have a 3Kw single phase 4 pole motor and a 3 way

switch (up, off, down)?

So a motor like this:

SINGLE PHASE 240V ELECTRIC MOTOR 0.18KW TO 4KW 1400RPM 2800RPM 2 POLE 4 POLE

And a switch like this:

Electric motor Reversing Switch single or 3 phase 32amp 4 Pole Lathe car lift

Or a switch like this:

GARAGE DOOR ROLLER SHUTTER SWITCH PUSH BUTTON CONTROL PUSHBUTTON NP2-B324

Again any help would be appreciated as I dont want to have the shell out £700 for an inverter if I can change the motor for around half that!!

Thanks

Jamie

|

|

|

obfripper

|

| posted on 9/3/16 at 08:39 PM |

|

|

The limiting factor in your setup will be your generator.

It is capable of 25a current and 10% overload, the motor will require 5-10 times the running current to start, with a vehicle on the ramp half way up

it will be at the higher end of the starting current.

At best that limits you to a 5a running current which will be a 1.5hp motor.

This is not a problem, as if you use a 8 pole motor, it will have 3/4 of the torque of the existing motor but half the speed, which should just allow

the motor to be useable, and could be geared down further if neccesary.

A 6 or 4 pole motor will require the gearing to be altered accordingly so the torque will be sufficient to be useable.

With the switchgear, you are likely to need an industrial electrician / decent wiring schematic to work this out, the tecalemit wiring looks far more

complicated than any 2 poster that i've used, most manafacturers use mechanical limit stops and chain break stop mechanisms that just disable

the control switch.

It should be possible with the components already there to run single phase and keep the safety mechanisms and limit stops without any more

components.

If you are going to try running from a 240v 3ph inverter, you will need to rewire the motor from star to delta, there may be instructions in the lid

for the motor, i don't know if the switchgear will need rewiring as well, i suspect it may do, going by the sticker inside the cover they did

offer a model with this setup so a wiring schematic may exist from tecalemit for this purpose.

A 415v 3ph inverter is far more expensive (i suspect this is what transwave quoted you for), but would not need any wiring changes.

With either inverter type the overload current rating will determine if it is capable of starting the motor, and whether the overload current is drawn

from inbuilt capacitors or directly from your supply - if it is direct from your supply it is unlikely that your generator/inverter combination will

be capable of starting the present motor, and trying so might damage the generator or inverter.

I have a 1960's bradbury liftmaster that is running on a capacitor box that provides a phantom phase, it is on a 45a supply which is only just

sufficent to start the 3hp motor halfway up with a car on, the previous owner ran it from a 10kva generator and it would only lift from the floor, it

just hummed if you tried from halfway up.

Dave

|

|

|

mark chandler

|

| posted on 9/3/16 at 10:57 PM |

|

|

Your generator will limit you to something like this

Single Phase 1.5kw Motor and Worm Gearbox 140rpm output 25mm Hollow Bore 74Nm then a bit of fabrication to fit. then a bit of fabrication to fit.

It will take 9 times as long to lift the car fully, maybe 4 minutes but has the torque you need (much quicker than trolley jacks and blocks to get it

2' high anyway)

The switch you have shown will be fine and very easy to wire, you can use the relays, first one supplies the high current power, second one is wired

straight, third puts in the cross to reverse direction and use the field windings to ensure that both straight and reverse cannot be run together and

manage the safety switches at a low current.

|

|

|

j_mcvic

|

| posted on 5/4/16 at 09:23 PM |

|

|

Hi everyone!

Got a bit of an update on this! Got myself a 2.2kw 4 pole motor and have hooked it up to the ramp and have wired some new switch gear to get it to run

both directions. So was pretty happy with that. Tested it with one side of the ramp up and it ran it in both directions. Put the other side of the

ramp up and added the arms and it worked up to about 3/4 way and back down no bother. So I was pretty happy.... But then the issue started!

I put my car on it and it started to lift, it lifted to about 1 foot and then the motor just slowed down and stopped. There was no change in pitch

from the generator so I don't really know where to go from here. I'm going to do some tests on the switches as they are only rated to 10a

so they could of burnt out. Does anyone have any suggestion - does it sound like a motor problem or a generator problem?

Thanks

Jamie

|

|

|

mark chandler

|

| posted on 5/4/16 at 09:41 PM |

|

|

Sounds like the spindles have worn, as you lift the load increases until it stalls the motor.

Have a look at the start and run capacitors to see if they are fried, you should also have a throw out switch at the fan end which disengages the

start capacitor once up to speed, as the motor stalls this should switch in and give it a boost so have a look to see if the contacts are working

correctly here as well.

The oilers on my spindles are shot so I run some ep90 oil on the before lifting anything which makes a lot of difference, I,m surprised it lifted the

car at all with a little motor like that.

|

|

|

hizzi

|

| posted on 6/4/16 at 07:03 AM |

|

|

how big is the generator to run that?

|

|

|

j_mcvic

|

| posted on 6/4/16 at 07:24 AM |

|

|

I'll give the capacitors a check when I next out.

The generator is a 6kva generator - a picture of the plate is in the first post with all the details on it.

|

|

|

j_mcvic

|

| posted on 9/4/16 at 09:54 PM |

|

|

The problem is the start capacitor is fried!

What would of caused this and what would the solution be? Is it a possibility that the motor hasn't got up to speed enough to throw the

centrifugal switch out and change from the start capacitor to the run capacitor?

|

|

|

mark chandler

|

| posted on 10/4/16 at 02:28 AM |

|

|

The run capacitor is always in, the start capacitor boosts this at low speeds and start.

Blown as it has struggled to get up to speed or been held when not moving, bigger motor or smaller gear on the motor to reduce the torque required.

I made a smaller gear for my lift which made a lot of difference as does getting the spindles liberally coated in ep90 oil (not high pressure grease).

|

|

|

rusty nuts

|

| posted on 10/4/16 at 06:37 AM |

|

|

Can't help with the electrics but have been using various two poster lifts for 40 years and would suggest checking the main and the safety

lifting nuts also the spindles for wear before even thinking about using the lift. Check in your local area for company's that rewind electric

motors , they would be an excellent source of advice and any parts . From experience garages don't tend to change lifts without good reason so

I'm always a bit suspicious as to why they are selling them.

|

|

|

mark chandler

|

| posted on 10/4/16 at 08:44 AM |

|

|

^^^^^

I changed the load nuts on mine, another £300 doing this made it run a lot smoother and reduced a lot of the load on the motor (starts

instantlyhowever heavy the car) my safety nuts looked like new so left alone.

Note, I only run my tin top to waist height as the concrete floor is not really suitable, my lift has big feet the extend beyond the arms so it cannot

topple, cheaper lifts rely upon the quality of the concrete.

Hard to run correctly is a sign of wear.

|

|

|