grazzledazzle

|

| posted on 19/4/19 at 05:24 PM |

|

|

Cad work - chassis

Hello,

I have not been around for some time but am planning the next project.

I have a blueprint of a chassis in plan, elevation and a cross section. It is from a 60s sports car and I want to look at making one. I could of

course go the route of scaling / printing it in 2d and using it as template, to start form a fabrication table, but am interested in going about it

in a more technological way, and am looking for someone / a company that can translate the 2d drawings into a 3D cad model, hopefully allowing for

parts to be ordered pre-cut etc. It would hopefully allow a bit of analysis to be done also to see if a few tweaks would help stiffness etc.

So my question is, can anyone do this for me / recommend a company who could?

|

|

|

|

|

richmars

|

| posted on 20/4/19 at 11:09 AM |

|

|

It's not that easy going from 2 to 3d CAD, especially for something complex. It's often easier to start from scratch in 3D. It will be

expensive. Companies pay 」1000's a year for their CAD system so will be looking for a return.

If you have time, maybe learn yourself. Onshape and 3d Fusion are both free for home users. I've done a bit in Onshape and it looks ok.

|

|

|

femster87

|

| posted on 20/4/19 at 12:27 PM |

|

|

When `i use a contractor at work to model complex plants. I pay anything between `」35 - 55/hr

|

|

|

nick205

|

| posted on 20/4/19 at 05:12 PM |

|

|

Used to produce 2D CAD (AutoCAD) then moved to 3D CAD (Solid Edge) at work. From a working perspective 3D CAD is easy enough to master, but the

software isn't cheap.

It was always easier to start in 3D than trying to convert things from 2D to 3D though.

I stepped out of that area in 2004 and now work in sales.

In terms of recommending people or companies to do what your after I can't help, but I'm pretty sure it would be costly. Unless

you're then able to market the result to recoup some expense I'd favour the lower cost method myself.

|

|

|

Sam_68

|

| posted on 20/4/19 at 07:27 PM |

|

|

I'm happy to do it, if you don't get any better offers, provided you're not in a desperate rush.

|

|

|

pigeondave

|

| posted on 10/5/19 at 01:07 PM |

|

|

There was a guy who was on the formula 750 forum, but i cant find the link for it. I'll have a look on my old machine to see if its a

bookmark.

It might have been Faroux Sports Cars, they ahve a twitface page

https://www.facebook.com/pg/Faroux917Krecreation/posts/

They said on one post

Our 3D CAD software connects directly to a laser cutting machine. Using our "Laser Align & Fit' Technology all joints are calculated

by the software in such a way that they fit on their exact location.

This is done by interlocking position helpers (pins and holes) at both ends of the tubes.

|

|

|

choc-ice

|

| posted on 8/7/19 at 09:07 PM |

|

|

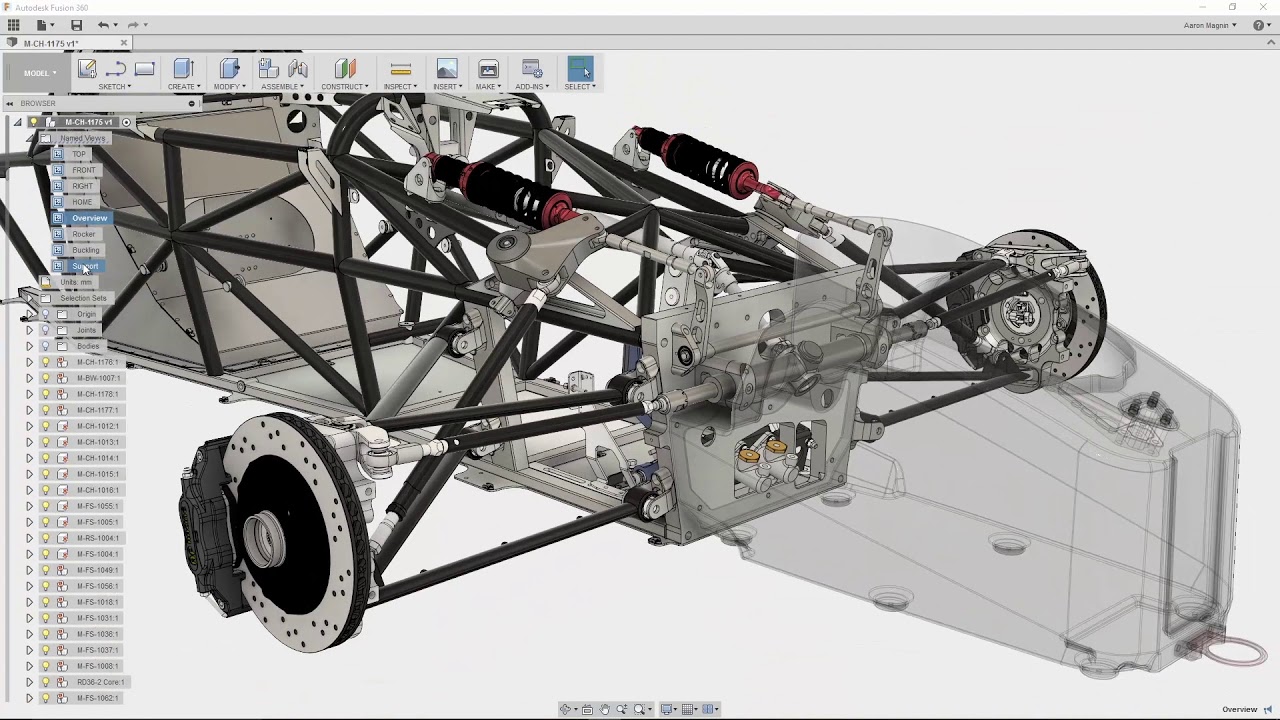

I知 doing something similar with a ladder frame for an MG TV replica, you can see some pictures of the 3D CAD chassis and body

here

As said above, its quite slow work, mainly because you need to keep going back to dimensions that probably don稚 even exist on the 2D drawing.

For the stiffness analysis I値l probably do a comparison between the bare ladder frame and adding things like a transverse crossmember, X crossmember

etc. I知 not sure what the absolute loads will be (or really I知 not sure how accurate they値l be in absolute figures) but a comparison of options

should be ok.

|

|

|

motivforz

|

| posted on 9/7/19 at 07:52 AM |

|

|

I've sent you a U2U.

|

|

|

GWD

|

| posted on 10/7/19 at 02:34 AM |

|

|

I could potentially help you out. Feel free to contact me direct.

|

|

|

DanGT4

|

| posted on 16/9/20 at 03:28 PM |

|

|

Old topic, but this might be of interest to anyone who stumbles upon it.

AutoDesk (the guys who created AutoCAD), now offer their CAD package Fusion 360 for free for personal use.

Download is here: https://www.autodesk.co.uk/products/fusion-360/personal

|

|

|

coyoteboy

|

| posted on 17/9/20 at 04:30 PM |

|

|

^ That's taken some doing, in F360!

|

|

|

HowardB

|

| posted on 18/9/20 at 05:37 AM |

|

|

Worth being aware that the licence terms on free Fusion360 have changed .

linky

So limited use for 3d printing

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

coyoteboy

|

| posted on 18/9/20 at 11:36 AM |

|

|

Yeah, it's kind of demolished the point of it for me - and the price of an annual license is too high for personal use.

They'll find that out with some conversions to paid, but many losses of personal accounts. The restrictions on CAM are not too disabling for a

home user in general, but I do use probing and multi-axis on a home mill, so it's very irritating.

Tricks like this (removal of capability, rather than not adding other capability) are exactly how you kill community support for your software.

|

|

|