interior aluminum trim

jabbahutt - 12/3/07 at 11:36 AM

Hi

Started the interior last night, unpacked the ali extrusion provided by MK and need some clarification

All the extrusion is the same type, an angle type with curved outer edges. Looking at other builders photos this doesn't seem to be the same.

Looking at it I'm wondering how I'm meant to bend this type of extrusion for the top edges of the tran tunnel and the sides especially the

rear curved edge of the side panel.

Have I got this completely wrong or have most of you opted for a different extrusion type as it's easier to work with?

As ever thanks for your time and assistance

tim windmill - 12/3/07 at 11:47 AM

it sounds like the stuff we got from mk. its easy to bend to shape and fit the tunnel and panels etc

nick205 - 12/3/07 at 11:49 AM

I used an ally extrusion from B&Q which is meant for edging flooring (I think). It's approx 25mm wide with a curved lip along one edge and a

ridged face. It's dead easy to cut and bend along the tunnel and round the rear curve of the side panel. It wasn't too dear either!

whitestu - 12/3/07 at 01:54 PM

I used the MK stuff - easy to bend as already suggested and all the same.

Stu

bodger - 12/3/07 at 06:00 PM

That's what I've got. Steve at MK just said to take it easy bend a bit at a time & it'll be OK.

D.A.Z - 12/3/07 at 07:26 PM

mine was made with a timber template,shaped like a (n) looking from the end, then covered with a hard vynal,you can see what i mean in archive.

Daz

jabbahutt - 13/3/07 at 11:59 AM

still a bit baffled I'm afraid. Had a go at bending the provided extrusion and it's very difficult with it being an angled extrusion as

opposed to a length of strip which bens really easily.

I can't imagine how to create the bend along the top of the transmission tunnel where it goes up under the dash.

Whats the technique for creating this bend as an example as it quite a gentle bend? do you use the chassis to assist/press against and act as a

template?

ReMan - 13/3/07 at 09:44 PM

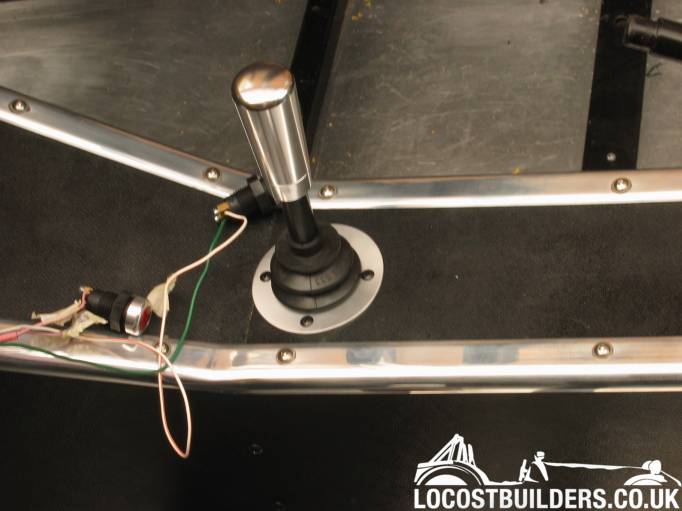

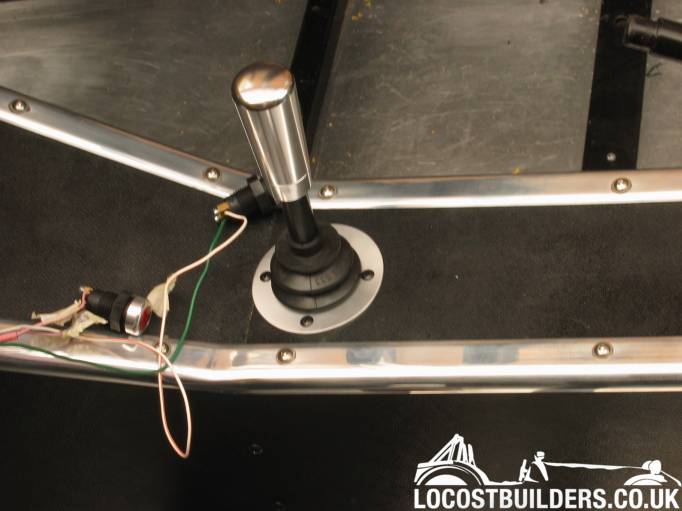

I had no special skills and managed to cobble these up from strips, had to nick it to get it to bend sharply by the wheelarch, but on the tunnel it

was just a case of leaning on it over a sharp edge and a bit of tapping with a soft hammer.

The curves over the arches were started for me by MAC!, but I still did a bit of work, again leaning on it over a wheel and hiting it with a hammer

till it fitted, then holding it real tight whist it was drilled and rivetted

[Edited on 13/3/07 by ReMan]