Not a locost, an MG, but still low cost

Trev Borg - 10/8/09 at 05:49 PM

I have already posted this in the body work bit, but it realy belongs here.

The torsion stiffness of the MGF is not great

MGF Torsional Stiffness: 7100Nm/degree

BMW Z3 Torsional Stiffness: 5600Nm/degree

MX-5 (mk1) Torsional Stiffness: 6000Nm/degree (approx)

MGTF Torsional Stiffness: 8500Nm/degree (est.)

BMW Z4M Torsional Stiffness: 14500Nm/degree

and I would like to remove the windscreen, which adds a fair chuck the it.

So, if I get rid on the screen, how can I make up for the loss in stiffness (insert gag here), and also increase it?

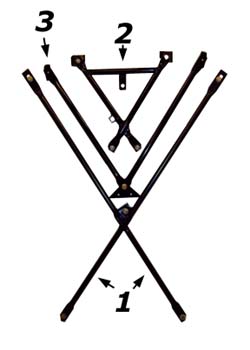

As it will be maily for the track, I want to fit a rollover bar, and I have already got a set of TF body braces to fit

Linky to webpage

So, how do i add strength?

Where would be the best place to add some bracing?

Humbug - 10/8/09 at 06:30 PM

The MGF isn't that bad... even your linky page says "Stiffest roadster in its class at launch - and surprisingly remains competitive

even now".

Re your question, without any engineering qualifications mind  , I would have thought if you remove the screen hoop (yellow) you should replace it

with something that joins the at the same points, say some roll bar tubing with small bends at each end welded to the top of the A posts? Imagine the

bar at the front of a roller coaster car. Then you could fill in the gap from where the bottom of windscreen glass used to be to the top of the new

bar with an aeroscreen of some sort. Then put a braced roll bar at the back.

, I would have thought if you remove the screen hoop (yellow) you should replace it

with something that joins the at the same points, say some roll bar tubing with small bends at each end welded to the top of the A posts? Imagine the

bar at the front of a roller coaster car. Then you could fill in the gap from where the bottom of windscreen glass used to be to the top of the new

bar with an aeroscreen of some sort. Then put a braced roll bar at the back.

...or, braced roll bar at the back joined to the top of the existing screen frame?

Rescued attachment mgf_body_in_white IDEAS.jpg

garyo - 10/8/09 at 06:54 PM

Weld the doors shut.

Trev Borg - 10/8/09 at 07:34 PM

I have no problem with welding the door shut, not sure how much that would help.

I was thinking that the strengthening piece that goes under the dash could be made stronger, with some bracing pieces across to the place where the

screen was.

speedyxjs - 10/8/09 at 08:11 PM

quote:

Originally posted by garyo

Weld the doors shut.

Not quite weld the doors shut but how about some kind of side protection bars in place of the doors then the door skin welded on the outside? Grind

the welds down and paint and i think with an aeroscreen would look very sleek

Trev Borg - 10/8/09 at 08:38 PM

I'm liking that avatar.

thats the kinda thing

my rough scetch.

Gonna give it some thought.

I am in no ruch

speedyxjs - 10/8/09 at 08:48 PM

quote:

Originally posted by Trev Borg

I'm liking that avatar.

Thanks. I didnt make the connection between it and this post untill you said

MikeR - 10/8/09 at 08:54 PM

do you need the passenger seat?

Just thinking a petty strut would help, or even petty strut to the top of the dash structure that you're going to make.

(id make the aero screen out of steel to make it into a stressed member to replicate some of the strength of the windscreen)

Humbug - 10/8/09 at 09:22 PM

There are some more ideas on your linked website here

e.g.

MikeRJ - 10/8/09 at 09:40 PM

I suspect the windscreen contributes very little to the stiffness of the MGF since it's not tied into a roof. Just like a locost, the big empty

cockpit area will likely be the limiting factor.

Also not sure why you consider the standard torsional stiffness is "not great" when it beats it's competitors of the era by a decent

margin?

iank - 10/8/09 at 09:54 PM

To put it in perspective a RonC book locost was calculated to be somewhere between 1200 to 1400 ftlbs/degree (1600-1900 Nm/degree) by cymtricks.

While that can be increased considerably with his proposed mods the MGF as it stands is 2-3 times stiffer out of the box.

Trev Borg - 10/8/09 at 10:01 PM

Thats a good point, well made.

I will definately give the scren some thought.

I really do like the red concept car thingy. Just a little too gay for my liking, but it still gives me the horn

Trev Borg - 10/8/09 at 10:26 PM

the mgtf has bars across the lower part of the front subframe, and across the the rear engine compartment, and a strengthed piece under the dash.

I have already aquired these bits.

they also have solid subframe mounts instead of rubbery ones.

MikeR - 10/8/09 at 10:55 PM

i think the screen could help somewhat - but i've no idea how much.

If you've got a very rigid square thing and you add it to the top of an open structure + mount it over a small distance, say 6 to 12". It

will add some strength.

MikeRJ - 11/8/09 at 07:54 AM

quote:

Originally posted by MikeR

i think the screen could help somewhat - but i've no idea how much.

If you've got a very rigid square thing and you add it to the top of an open structure + mount it over a small distance, say 6 to 12". It

will add some strength.

It's not bolted to an open structure though, it's effectively going across the bulkhead, which is an already stiff part of the car.

Obviously without a screen and it's pillars you lose whatever (probably minimal) roll over protection they provide

Trev, at least some of the TF add-ons are likely to be saftey related, i.e. cross bracing the subframes would prevent them lozenging in an accident

and would help to maintain suspension geometry under heavy loading, but they are so spindly that they would provide a negligible improvement in

torsional rigidity.

The TF got a 4 star NCAP rating which is pretty impressive for a design originally launched (as the F) in 1995.

Trev Borg - 11/8/09 at 10:26 PM

I kinda figured that, but they are supposed to do a job.

webby

I got the info from the above site.

What I need is someone who knows their stuff to tell me that I can get rid of the screen, and can mke the chassis more ridged, by added a braced

rollover bar at the back, and some cross bracing from A to B, around the front dash area.

Been thinking about the torsion strength thing today while at work.

Would doing things like, fully welding subframes (as apposed to them just being welded in places) add ant ridgidity?

Or things like removing door skins, and bonding riveting panels over?

Just thoughts these tho, as I'm cluesless as to what really makes the chassis ridged.

Would I be right in thinking the main problem area in the car would be the door area?

MikeR - 11/8/09 at 10:37 PM

Are you going to have a passenger?

If not, petty strut it.

make a balsa model and you'll soon realise you lose a lot of strength in open areas.

If you're going to do the doors, weld both sides so you have a tall box rigidly added to the structure not a thin sheet of metal. Should be a big

improvement.

The point i was making about hte screen is that if you solidly weld in a 6" member across the open space it will beef it up a lot. I was gessing

hte screen structure would be solid (ish) and the load as it meets the car would be over a few inches. If you replace that with something you

won't be losing out too much.

(I've no idea what the scuttle is made out of so this could be worthless idea).

Ninehigh - 14/8/09 at 03:19 PM

quote:

Originally posted by Trev Borg

Just a little too gay for my liking, but it still gives me the horn

What does that say about you then

Full roll cage?

Trev Borg - 14/8/09 at 05:53 PM

eeeerrrm got me there

, I would have thought if you remove the screen hoop (yellow) you should replace it

with something that joins the at the same points, say some roll bar tubing with small bends at each end welded to the top of the A posts? Imagine the

bar at the front of a roller coaster car. Then you could fill in the gap from where the bottom of windscreen glass used to be to the top of the new

bar with an aeroscreen of some sort. Then put a braced roll bar at the back.

, I would have thought if you remove the screen hoop (yellow) you should replace it

with something that joins the at the same points, say some roll bar tubing with small bends at each end welded to the top of the A posts? Imagine the

bar at the front of a roller coaster car. Then you could fill in the gap from where the bottom of windscreen glass used to be to the top of the new

bar with an aeroscreen of some sort. Then put a braced roll bar at the back.