Chassis Rail - Bend or Weld?

scootz - 15/8/17 at 04:14 PM

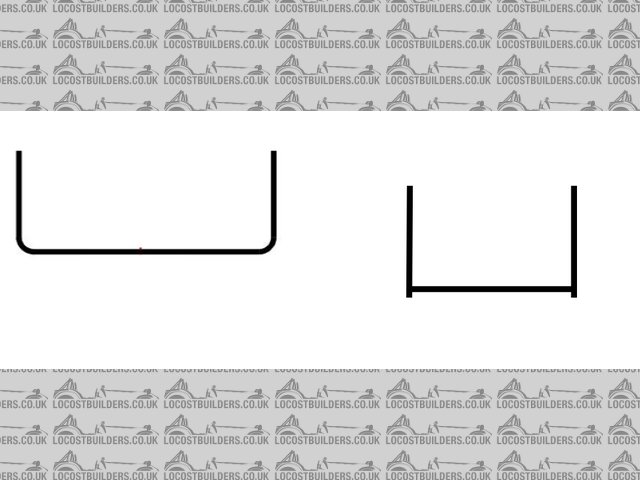

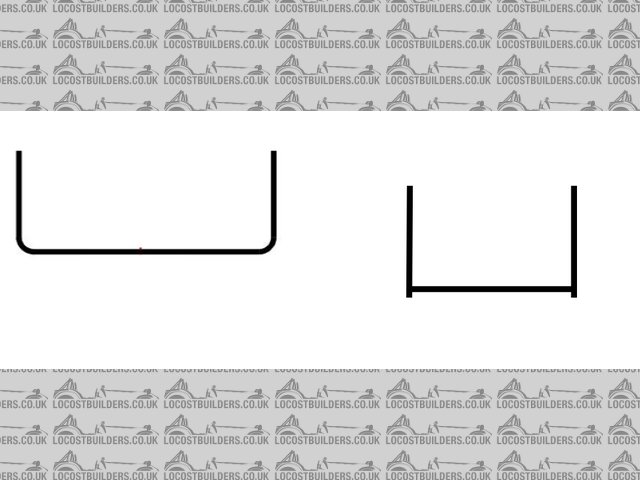

If you assume that we're looking down from above onto the top chassis rail a the rear of a car (and also assume that there's an identical

one below it).

The material is round tube.

Which would be considered the 'stronger'. The single length with 2 bends as per the illustration on the left. Or cut into 3 pieces, the

central piece notched at both ends, and all welded together as per the illustration to the right?

Cheers

jossey - 15/8/17 at 05:31 PM

I suspect a weld would be stronger

ReMan - 15/8/17 at 05:51 PM

My guess the bend would be stronger, but the weld more rigid

scootz - 15/8/17 at 06:14 PM

Thanks chaps.

907 - 15/8/17 at 10:00 PM

I'd vote bend, as there are no stress raisers.

Paul G

mcerd1 - 16/8/17 at 06:01 AM

quote:

Originally posted by 907

I'd vote bend, as there are no stress raisers.

You mean apart from the residual stresses from the bending

907 - 16/8/17 at 07:57 AM

Bending stresses are reduced by over bending a couple of degrees or so, then easing the bend back to the required degree.

The experienced metal worker can "feel" the bend "settle" to where it wants to remain.

The elongated crystal structure in a cold formed bend is the same as highly regarded CDS tube. Effectively work hardening and results in a higher

tensile strength.

Stress raisers are another can of worms entirely.

Sudden changes in crystal structure, from small equal crystals to the columnar and grain growth crystals found in welds;

or sudden changes in material thickness, nicks, undercut etc;

or sudden directional changes of the fabricated shape.

I hope this explains my previous (shorter) post.

Paul G

scootz - 16/8/17 at 08:15 AM

Thanks guys.

It's 2" OD tube with 1.6mm wall thickness?

Are we just talking fine margins between the 2 here? If so, then I will proceed with the cut, notch and weld as it's something I can do myself.

chillis - 16/8/17 at 09:37 AM

What loads are to be put through the two structures.

Bending will cause the tube to be thinner in section on the 'long' side of the bend but a weld could result in failure of the metal adjacent

to it because of the changes in structure of the metal.

TBH you pays yer money and takes yer choice.

mcerd1 - 16/8/17 at 10:26 AM

quote:

Originally posted by 907

.....I hope this explains my previous (shorter) post.

Paul G

Yes and I don't disagree with you - I was only saying that bending has its issues too

the severity of issues with either method will be largely determined by the material being used and its weldability and cold work hardening behaviour

(just for an example you'd probably weld a 6082 alloy and bend a 1050)

With small tubes I suspect the biggest problem with bending will come from the local deformation at the bend (look at your average cheepo office

furniture with all the insides of the bends collapsed inwards) possibly followed by a stiff spot in the frame caused by local work hardening (think

about were those cheepo chairs often break)

but welding brings its own issues, mostly just the usual cracking next to the welds that folk have had issues with in loads of chassis before now

(harder/more brittle weld material and/or stiff points in the frame and other stress raisers....)

so neither option is perfect, but you can do things to improve either design - at the end of the day the type of material and ease of fabrication will

be the deciders

(I'm assuming your just using something like S355 tubes rather than CDS? these structural steels are designed to weld pretty easily)

[Edited on 16/8/2017 by mcerd1]

907 - 16/8/17 at 11:25 AM

If you can't bend, but have the facilities to weld, then assuming they are available in the material your using

you could buy in the 90 bends and weld them to straight tube lengths.

Just a thought.

iant88 - 16/8/17 at 11:45 AM

"It's 2" OD tube with 1.6mm wall thickness? "

That is a bit thin to bend at that diameter.

Also, I'd rather braze it than weld it

scootz - 16/8/17 at 12:50 PM

quote:

Originally posted by mcerd1

quote:

Originally posted by 907

.....I hope this explains my previous (shorter) post.

Paul G

Yes and I don't disagree with you - I was only saying that bending has its issues too

the severity of issues with either method will be largely determined by the material being used and its weldability and cold work hardening behaviour

(just for an example you'd probably weld a 6082 alloy and bend a 1050)

With small tubes I suspect the biggest problem with bending will come from the local deformation at the bend (look at your average cheepo office

furniture with all the insides of the bends collapsed inwards) possibly followed by a stiff spot in the frame caused by local work hardening (think

about were those cheepo chairs often break)

but welding brings its own issues, mostly just the usual cracking next to the welds that folk have had issues with in loads of chassis before now

(harder/more brittle weld material and/or stiff points in the frame and other stress raisers....)

so neither option is perfect, but you can do things to improve either design - at the end of the day the type of material and ease of fabrication will

be the deciders

(I'm assuming your just using something like S355 tubes rather than CDS? these structural steels are designed to weld pretty easily)

T45 Robert

iant88 - 16/8/17 at 03:09 PM

Are you using Tig or Mig ? I still think it'd be better brazed (or should I say bronze welded )

scootz - 16/8/17 at 04:38 PM

Tigged with either A31 or A32 flller