Originally posted by Doctor Derek Doctors

The last jobs I managed were the rear suspension brackets, namely the rocker mounts and the inboard shock mounts:

NOTE from Admin: This thread has been split out from here due to

it going way off topic. Whilst there is an obvious element of bickering between two parties I feel there is also some relevant technical discussion

and hence I am letting this thread run on it's own merit for now. Please all contributors keep this factual and on topic or risk the thread being

locked/deleted.

quote:

Originally posted by Doctor Derek Doctors

The last jobs I managed were the rear suspension brackets, namely the rocker mounts and the inboard shock mounts:

quote:

Originally posted by Sam_68

You might want to think carefully about the arrangement of those rocker mounts.

OK.

You haven't run into any problems of rapid wear on the rod ends, due to limited rotation?

Personally, I usually use angular contact ball bearings (cheaper than rod ends, lower friction, wear better, look neater), but if you're happy

with a plain bearing surface, then DU bearings/bushes are at least as effective as rod ends/spherical bearings; lighter, neater and much

cheaper, so replacement as a short-life service item is rather more palatable.

I used the system for 4 years on one car, the rod ends never needed replacing and were still going strong.

There are other bearings which work in a more optimal way but you have to figure in the cost/time/skill in making the rockers and mounts to take

roller bearings which is a lot greater than the rod end system and with this being a budget home build car that is more of a concern.

Its a home build so if someone wants to do something different thats completely upto them as well, I'll even do the design work.

Hae you got any pictures of you Supercharged Duratec Comercail project? I would be interested in having a look.

[Edited on 4/1/16 by Doctor Derek Doctors]

quote:

Originally posted by Doctor Derek Doctors

There are other bearings which work in a more optimal way but you have to figure in the cost/time/skill in making the rockers and mounts to take roller bearings which is a lot greater than the rod end system and with this being a budget home build car that is more of a concern.

quote:

Originally posted by Sam_68

quote:

Originally posted by Doctor Derek Doctors

There are other bearings which work in a more optimal way but you have to figure in the cost/time/skill in making the rockers and mounts to take roller bearings which is a lot greater than the rod end system and with this being a budget home build car that is more of a concern.

Yes, angular contact or taper roller bearings are a little more involved in terms of the rocker design, but DU bearings are much simpler and cheaper than your rod end arrangement (and neater, and more rigid), if you design them right.

It seems an odd and inappropriate use of rod ends, to me, but if you're happy with it....

quote:

Originally posted by Doctor Derek Doctors

Hae you got any pictures of you Supercharged Duratec Comercail project? I would be interested in having a look.

quote:

Originally posted by Sam_68

quote:

Originally posted by Doctor Derek Doctors

Hae you got any pictures of you Supercharged Duratec Comercail project? I would be interested in having a look.

Sorry, missed this!

Not that I'm allowed to release at the moment, I'm afraid. We're under construction with two prototype chassis at present (one for the supercharged, one for base spec N/A MZR/Duratec), the S/C engine is built and ready for installation and I'm in the process of finalising the body design and other details, but the guy who's running the project is absolutely insistent that he wants prototypes fully finished and thoroughly tested before we break cover... too many projects lose credibility and fail as a result of exposing their protracted development to public view, we feel.

If everything runs to plan, look out for us at next year's Autosports show.

Maybe.

Again, I'm not allowed to disclose. You probably wouldn't have heard of them anyway - they are newly formed to produce the car I'm

working on, though the owner's background includes a previous race prep/development company.

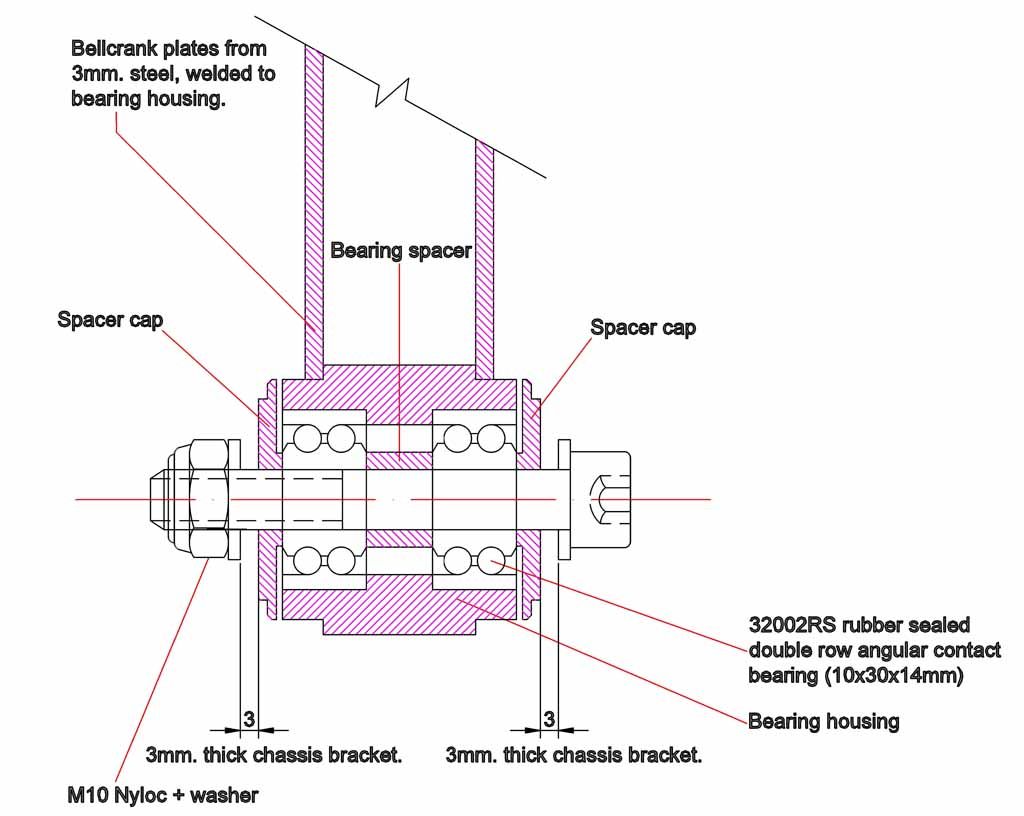

For what it's worth, this is an extract of my rocker assembly (quickly doctored to omit/change certain details for confidentiality, which means

that the 'spacer caps' are a bit of a redundant red herring - you could just use plain washers to space the bearings out from the chassis

mounting brackets, if you wished).

As you suggest, the need for a machined housing makes the rocker for angular contact bearings a bit more expensive (though the flip side is that the

bearings are cheaper than decent quality rod ends, and they perform better having less friction). But as I said, if budget/simplicity is that

critical, I'd be looking at DU bushes, if I were you.

quote:

Originally posted by Sam_68

Again, I'm not allowed to disclose. You probably wouldn't have heard of them anyway

quote:

Originally posted by Doctor Derek Doctors

I might have done. I've signed plenty of water tight NDA's but none that said that I couldnt disclose the company name.

quote:

Originally posted by Sam_68

And what about contracts of employment that prohibit you from discussing the company and its projects on public forums?

quote:

Originally posted by Sam_68Not that I'm allowed to release at the moment, I'm afraid. We're under construction with two prototype chassis at present (one for the supercharged, one for base spec N/A MZR/Duratec), the S/C engine is built and ready for installation and I'm in the process of finalising the body design and other details, but the guy who's running the project is absolutely insistent that he wants prototypes fully finished and thoroughly tested before we break cover... too many projects lose credibility and fail as a result of exposing their protracted development to public view, we feel

quote:

Originally posted by Doctor Derek Doctors

But you are discussing it on a public forum already.

quote:

Originally posted by Doctor Derek Doctors

Anyway, doesn't matter really.

What day are you at Autosport with the car? I'll come and have a natter.

" - but if we make it, I dare say I'll be

there for the duration, roped in to answer any techy questions. I have firm assurances that I won't have to wear a spandex miniskirt and drape

myself over the car, though, you'll be pleased to learn.

" - but if we make it, I dare say I'll be

there for the duration, roped in to answer any techy questions. I have firm assurances that I won't have to wear a spandex miniskirt and drape

myself over the car, though, you'll be pleased to learn. That pic above of the rocker cross section shows a lack of understanding of how these things are actually made and implemented in a modern race car.

Amateurish, to say the least. A pair of double row bearings???.Nobody would do that would they? Seriously??

Cheers,

Nev.

[Edited on 22/1/16 by Neville Jones]

Needle rollers are the usual solution in race cars, of course, but they have limited life (they flat-spot easily) and good quality items are not

cheap. The Nadella RAX series Needle Roller/Thrust Combination Bearing is a particularly nifty solution, but they're about £100 a pop. Probably

not the best solution in an ultra-budget car, and certainly not for a road car that must be expected to do substantial mileage with minimal

maintenance.

But what do you think of Dr Derek's rose joint solution - would you do it that way, or if not, how would you do it? If everybody else is

wrong, why don't you contribute something positive by telling us how to do it right?

[Edited on 20/1/16 by Sam_68]

OK! I think that's enough  Lets not ruin another very interesting thread with yet another bout of dick waving

Lets not ruin another very interesting thread with yet another bout of dick waving

quote:

Originally posted by Sam_68

But what do you think of Dr Derek's rose joint solution - would you do it that way, or if not, how would you do it? If everybody else is wrong, why don't you contribute something positive by telling us how to do it right?

quote:

Originally posted by Neville Jones

..a more thought out total solution, and more in line with current thinking.

It's certainly not my place to offer solutions to the experts, but I can look at these things with an old engineers viewpoint.

It would have been far easier for both of you to keep your opinions to yourselves instead of ruining callans thread,in which he's worked really

hard.

Same old stuff from the pair of you

My comments on the design of the rocker pivot were merely to suggest possibly superior (and cheaper) alternatives, in the interests of being helpful;

I did consciously try to temper my comments to avoid seeming too critical.

[Edited on 22/1/16 by Sam_68]

quote:

Originally posted by daniel mason

It would have been far easier for both of you to keep your opinions to yourselves instead of ruining callans thread,in which he's worked really hard.

Same old stuff from the pair of you

Martin, and others, I'm not fazed by the legal threats, I've said nothing that can't be shown true. Check your own houses are in order

first.

To keep on topic...

I've got he opinions of a couple of genuine card carrying shirt wearing F1 engineers to guide me, one of whom is currently involved in designing

the suspension for customer GT Supercar builds.

Cheers,

Nev.

[Edited on 22/1/16 by Neville Jones]

Jesus! Neither of you seem to get it do you?

My apologies.

Sorry, 40inches... I really am - and as I said, I will delete all off-topic posts and comments of mine when this matter (which has been referred to

the site administrator) has been resolved.

In the meanwhile, quite apart form the fact that Nev/Rod/Rob/Syd is deliberately stalking/trolling me at every opportunity, he has now progressed to

making statements which are outright lies, and as such are both libelous and defamatory.

For the sake of my employer, this is simply not something I can tolerate.

If enough people report the posts hopefully the management will let the "Gibbs" axe fall on both of them (or the one of them - I do have my

suspicions!)

Back on topic, do you have a date when the pans are going to be made available, I fancy building one of these as a side project to the Herald

restoration!

Thanks,

Shaun

I've just taken the time to search the bearings and do the numbers for Dereks little 600cc car.

Front corner weights will be about 110kg's max for an all up of 450kg's. (I'll keep forces and weights in kg's, so the majority of

readers can understand readily, although in engineering calcs these should be Newtons) I'll round out some of the numbers for simplicity.

If we assume a wishbone length of 500mm, and a pushrod angle of 40 degrees to the horizontal then the pushrod will have a compression load of about

170 kg's. We double this for shock loads, so 340kg's. This is the push on the rocker. We have to make an assumption on the rocker ratio, as

this affects the load on the rocker central pivot. At 1:1, this gives a load at the rocker pivot of about 960kg's, with the coilover load and

reaction added.

The pushrod moves up and down relative to the rocker, so an assumption of the angle again has to be made. Say 5 degrees. This is to estimate the side

thrust loads on the rocker. But, the load acting at this angle is the pushrod 340 kg's. so, about 30 kgs. (The coilover stays coplanar with the

rocker.)

A needle roller to do the job will cost about £5~£6. a pair of thrust bearings will be about the same again, then about £4 for a proper needle inner.

So, about £16 for the bearings.

The 32002RS bearings are £18+ on the i'net, and a couple of £'s cheaper if you get the metal shielded items Two of these per rocker then

costs at least £32.

Then you've got the extra work to make the bearing sections, which is straightforward for the needle, with a straight bore and a couple of

circlips; not quite so for the double double angular contact bearings.

I've been through this design exercise a number of times, and keep coming up with the same end result, taking into account material costs and

labour.

Then there's the added complexity of the double bearing setup, and not to mention the added weight of the bigger housing for the double double

bearings and the bearings themselves.

For his purpose, Dereks sphericals with maybe the thrusts top and bottom will do the job satisfactorily, with good lubrication. And do it in a light

and economical, cost effective manner.

The numbers above for loads are quick and approximate but shouldn't far off.

Cheers,

Nev.

The DU bearings I recommended for Derek's application (budget, low-mileage race) are typically about £0.70 each, from memory. You can get them as

plain bushes, top-hat bushes, or thrust washers. Their wear and friction is comparable with spherical bearings, but they're not suitable for any

application in which you need to accommodate some mis-alignment (which you don't with a rocker pivot)

Throw 'em away after each hillclimb run, if you like, and your bank account probably still won't notice the difference. They're also

much lighter, much neater and much simpler than any other solution.

As previously stated, needle rollers are the usual solution for race cars, but they tend to have limited life: the individual needles flatten and so

flat-spot the bearing under the localised loads and limited range of rotation you get with a rocker. Fine for a race car, where you can rely on the

components being 'lifed' and regularly checked, but not so clever for a road car, where 'servicing' in most people's mind

consists of an oil and filter change every 12K miles. Decent quality needle rollers - like decent quality rod ends - also tend to be rather

more expensive. Hence for road-gong applications I prefer something with service qualities closer to those you'd expect for a wheel bearing.

For what it's worth, if I was going to use sphericals, I'd use a pair in the form of, erm, spherical bearings (rather than rod ends), housed

in the rocker rather than mounted to the chassis (so that the chassis mounts could just be a pair of tabs like normal wishbone mounts, with a bolt

though the rocker assembly. Slightly increases the inertia of the rocker assembly, but looks a damned sight neater than 'free-standing' rod

ends fixed to the chassis.

You pays yer money, and you takes yer choice, but the optimal solution depends on application.

quote:

Originally posted by Sam_68

The DU bearings I recommended