goodall

|

| posted on 16/3/07 at 05:35 PM |

|

|

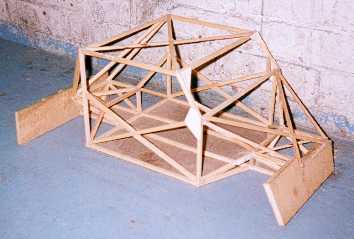

hardtop chassis design

any one see any major problems with this quick design?

i got the cad of the gts locost build site which i then opened in pro desktop but decided be far simpler to draw the bits on in paint   tried my

best to make it was done in prodesktop tho tried my

best to make it was done in prodesktop tho

[Edited on 16/3/07 by goodall]

Rescued attachment hardtop chassis.JPG

|

|

|

|

|

goodall

|

| posted on 16/3/07 at 06:32 PM |

|

|

i see what you mean but i like the seven shape with the long bonnet and the relatively short cabin, its what attracts me to it

|

|

|

goodall

|

| posted on 16/3/07 at 07:03 PM |

|

|

tweeked the design a wee bit more

Rescued attachment hardtop chassis.JPG

|

|

|

jlparsons

|

| posted on 16/3/07 at 07:25 PM |

|

|

Have been planning something very similar myself - a-pillars as you've drawn connected to the rollbar with a )( shaped backbone. Having

a-pillars rather than just channel to hold the glass would be pretty much a full roll cage - much safer, perhaps a fair bit stiffer too? The

detachable lid with doors attached would just be fibreglass and perspex and would then fit over the top if i ever got round to making it.

Looks good to me!

Any resemblance to real persons, living or dead is purely coincidental. Some assembly required. Batteries not included. Contents may settle during

shipment. Use only as directed. No other warranty expressed or implied. Do not use while operating a motor vehicle or heavy equipment. Subject to

approval, terms and conditions apply. Apply only to affected area. For recreational use only. All models over 18 years of age. No user-serviceable

parts inside. Subject to change. As seen on TV. One size fits all. May contain nuts. Slippery when wet. For office use only. Edited for television.

Keep cool; process promptly.

|

|

|

JB

|

| posted on 17/3/07 at 07:07 AM |

|

|

Chassis Design

You need to optimise for torsional rigidity and the easiest way to do that is to build a wooden model and twist it in your hands.

What you will quickly realise is that you need to triangulate especially across the engine bay. You will also realise that the windscreen opening is a

weak spot and the A pillars at the base of the windscreen.

|

|

|

Doug68

|

| posted on 17/3/07 at 11:02 AM |

|

|

If you going to do a BEC that doesn't have to look like a 7 then shove the engine in the back and do away with prop shaft live axle rubbish.

Look at this over on the middy section for example there are other people

traveling the same road as you.

JB - The frame look the dogs.

I'm planning on bonding the windscreen to 20mm SHS welded inside the the front roll tube - 'A' pillar frame as per modern car

methods this'll stiffen up the area nicely. Unless of course I've got the math wrong in which case I'll have a broken windscreen,

we shall see.

|

|

|