Fitting side panels..... couple of questions

Sloan85 - 6/11/12 at 09:20 PM

Do most people cut out individual holes in the side panels for wishbones and steering rack etc. or just cut a large area out for the whole lot?

Does either method have advantages over the other?

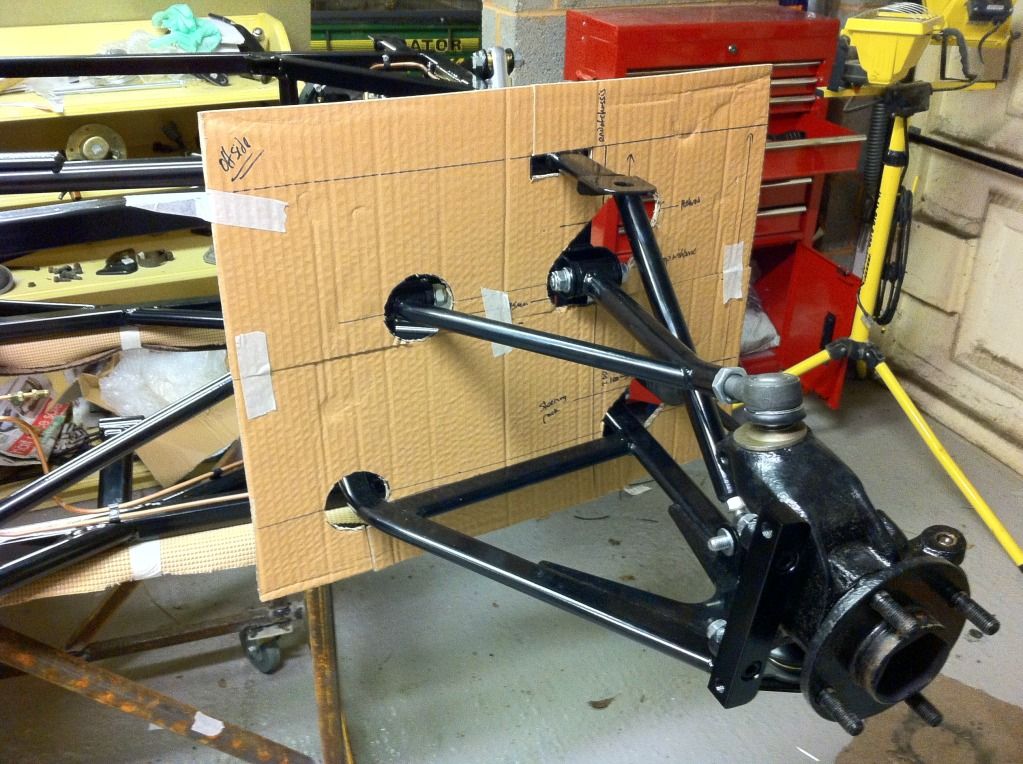

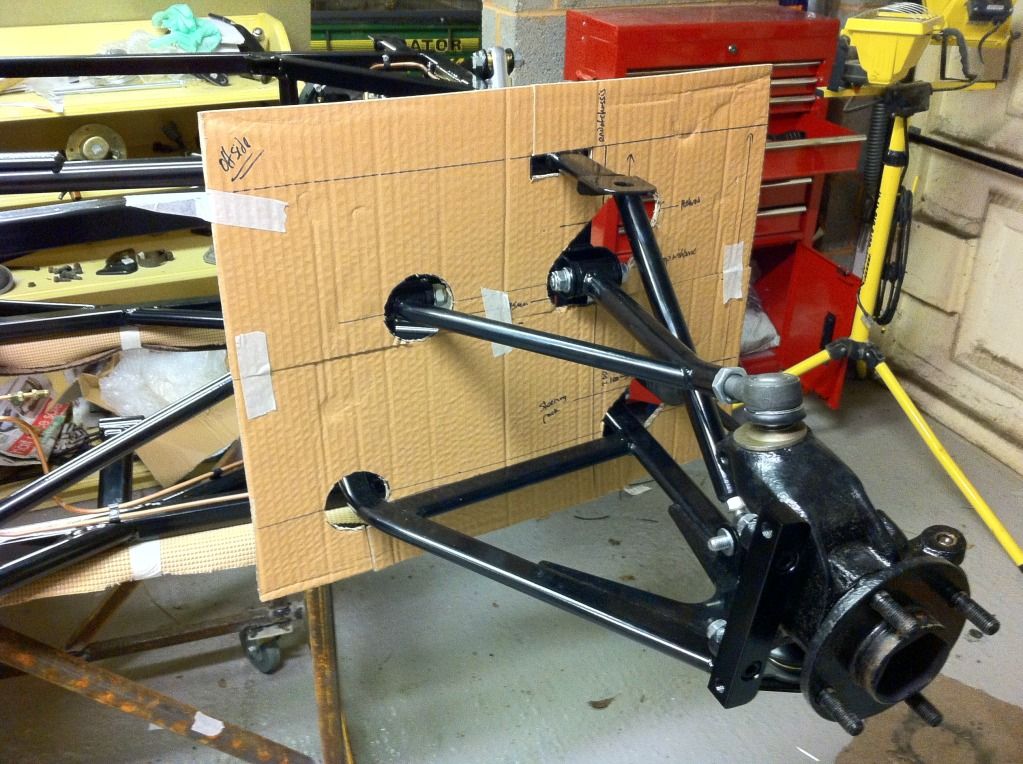

I had a go at a template for individual holes so tempted to go that route. lower wishbone + steering rack holes would need lifting slightly as i have

measured this with no weight on the suspension. Any ideas how much it will move up when on the ground?

Cheers

mark chandler - 6/11/12 at 09:36 PM

Mine were cut to match the movement

Finished front

I prefer the look, also my radiator is set behind the wheels so I need to trap as much air as possible.

If you look behind the holes I made the panel in two bits and joddled one edge which makes it much easier to align

After a few days the holes did become bent where I made to small, bit of U trim to tidy up, the lower bone is hard to fit in so had to elongate a bit

horizontally so I could insert.

Regards Mark

Barkalarr - 6/11/12 at 10:15 PM

I went for the cut outs but didn't allow for enough upwards suspension travel the first time I cut the holes. Make sure you have a dremmel

before you start and you will need plenty of the u shape edging for IVA around each hole you cut out.

This was my side panel on the near side.

fimi7 - 6/11/12 at 11:56 PM

I cut individual holes with a hole saw. The one word of advice is go up a single size on the hole saw to make sure it fits. Take very careful

measurements or you will be off. Your template looks pretty good, but make sure you have the rest of your bodywork aligned. example the nose.

Tape and then cut, always tape and then cut

Here is mine