Fireblade downshift issue after track day.

DANMAN - 6/7/12 at 12:21 PM

Hi guys.

I had the Locoblade at a track day today and about half way throught the day it didn't want to let me down shift, clutch or not no go. It then

just got stuck in a false nuetral type deal. If you blipped the throttle as you tried to upshift it would eventually go into the next gear (after some

horrible sounds) and then you could down shift but then it wouldn't let me downshift at all.

Any info on such a problem would be greatly appreciated. I'm sure it won't be easy or cheap though judging by the sounds.

tony.g - 6/7/12 at 02:21 PM

I presume its a carbed blade and 4th gear you were suffering with.

Just had the same problem!!!

joni - 6/7/12 at 02:54 PM

quote:

Originally posted by tony.g

I presume its a carbed blade and 4th gear you were suffering with.

Just had the same problem!!!

gearbox is scrap mate time for a rebuild ... you can buy a second hand box of ebay but be careful the gearbox might be as bad as the one you are

taking out ......try to buy of a breaker who will stand over it and will take returns if it not good .A gearbox rebuild should cost around £150 labour

...............hope this helps

mark chandler - 6/7/12 at 04:35 PM

Whoa wait a minute, loose linkage not moving far enough can do this, check basics first.

GreigM - 6/7/12 at 05:42 PM

quote:

Originally posted by mark chandler

Whoa wait a minute, loose linkage not moving far enough can do this, check basics first.

Yup, check that the linkage is tight, and that the throw for up and down is the same length (i.e. its not restricted from giving a full pull/push).

Also re-try when the engine is cold - could be the oil isn't up to the job when hot, or is overheating.

Hector.Brocklebank - 6/7/12 at 06:24 PM

quote:

Originally posted by mark chandler

Whoa wait a minute, loose linkage not moving far enough can do this, check basics first.

+1 on that, dont listen to any armchair experts.

Do it properly and professionally, follow a methodical process eliminating the simplest things before ripping the things guts out.

DANMAN - 9/7/12 at 11:08 AM

I took the car for another spin the other day, checked the linkages and tried the shifts cold and hot. It shifts into every gear fine on the upshift,

coming down it is fine from 6th to 5th but 5th to 4th sounds like a bunch of marbles in a tin can. 3rd to 2nd and 2nd to 1st is also fine.

Doesn't jump out of gear or anything so I imagine it is some nastily worn dogs on 4th? The clutch only has about 500kms on it and is a heavy duty

uprated item. What else should I be replacing whilst I'm at it? Should I be looking at the drum and shift forks as well? I have also been told

that splitting the case to get the gearbox out can also compomise the crank shaft bearings, is this true?

[Edited on 9/7/12 by DANMAN]

ReMan - 9/7/12 at 12:02 PM

That it does not jump out of gear ponts more at bent selector forks /barrel than the gears themselves to me

But as said, as long as you are happy the linkages are all working, then you need to get it out and inspect it all.

There should be no issue with crank bearings if done carefully/cleanly and lubed up properly and primed when back together

DANMAN - 9/7/12 at 01:17 PM

The other option is to replace the whole engine. The engine I currently have has had a dynojet kit fitted so I am thinking I could pull the carbies

off my current engine and fit them to the new one. I also thought about going for a fuel injected later model engine but I don't know if a later

model engine will bolt back into the old cradle?

gixermark - 10/7/12 at 08:19 AM

i think the cradle woudl be least of your worries on an engine change to later model....

you'd also need loom, ECU, swirl pot/fuel injection pump/tank mods, most likely exhaust manifold modifications... cooling system, possibly prop

adjustments..

you'd be better stripping your current motor and fix the gear(s) required... you could take a punt on a complete motor - but unless its from a

known source, you coudl end up with same/worse... these motors are getting a bit tired at this stage...

DANMAN - 10/7/12 at 09:37 AM

quote:

Originally posted by gixermark

i think the cradle woudl be least of your worries on an engine change to later model....

you'd also need loom, ECU, swirl pot/fuel injection pump/tank mods, most likely exhaust manifold modifications... cooling system, possibly prop

adjustments..

you'd be better stripping your current motor and fix the gear(s) required... you could take a punt on a complete motor - but unless its from a

known source, you coudl end up with same/worse... these motors are getting a bit tired at this stage...

I wasn't too worried about all of the above except I did forget about the swirl pot and tank mods.

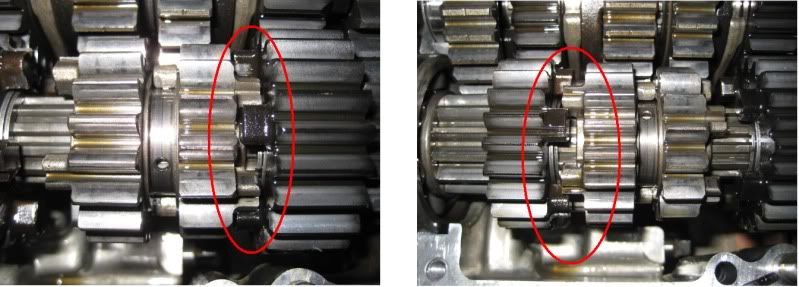

I got the gearbox out tonight and the dogs certainly don't look great:

I am a noob at bike engines in general so replacing the gearbox is certainly new to me so although I'm no expert it looks pretty knackered to

me.

I have found another box for AU$400 which they say is in good condition. Unfortunately they are 500kms away so I will have to rely on some pics from

them. Besides getting new gaskets for reassembly is there anything else I should do while I have it apart and is there anything I can do to avoid a

repeat occurance?

Lightning - 10/7/12 at 09:42 AM

Stripping the gearbox is easier than you think, However whan I had a blade and now with the kwaka motor you will find that the parts you need can add

up. With my blade I just replaced the engine and kept the other for spares. I managed to find a good engine with no carbs etc for £250 which was less

that the gearbox bits I needed.

Lightning - 10/7/12 at 09:43 AM

Ooopsmy post was too late

Lightning - 10/7/12 at 09:49 AM

As was stated before. If its not jumping out of gear I wouldnt have thought the problem was the dogs. Is there any chips off the barrel? how does the

fork look for engaging 4th gear?. Is there any wear on the pegs on the end of the barrel?

DANMAN - 10/7/12 at 12:08 PM

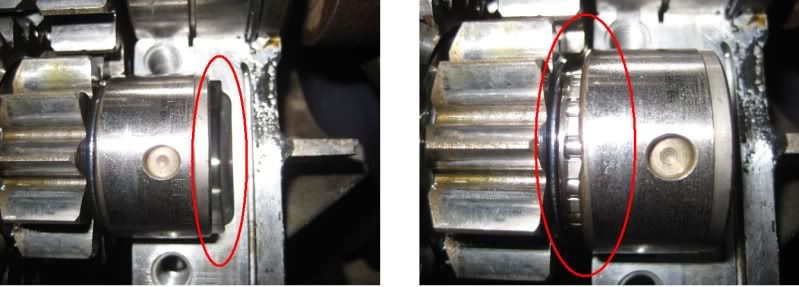

It didn't seem to have any problems jumping out of gear, had a few false nuetrals here and there but when changing down from fifth to fourth it

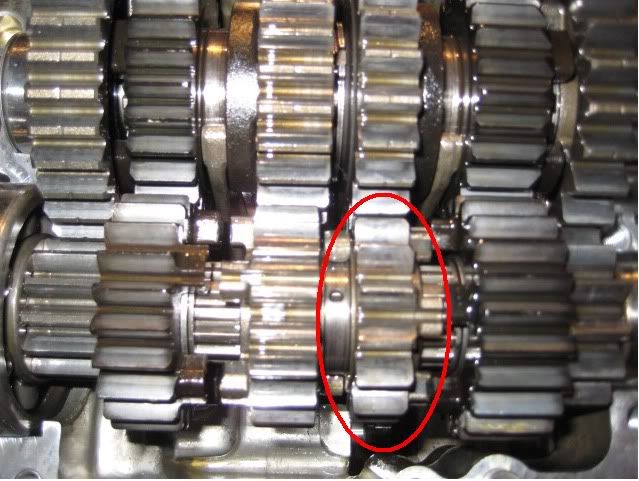

wouldn't go in and made a grating clattering sound. Forks look ok as does the drum but I had a bit more of a look at the gears themselves and

found this:

Forks and drum seem ok though:

DANMAN - 11/7/12 at 11:28 AM

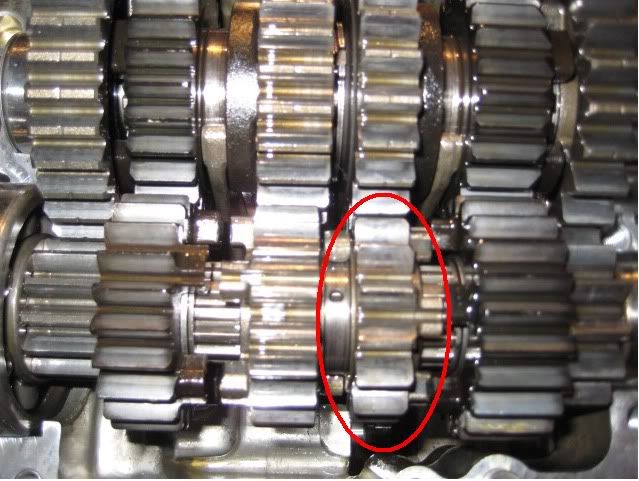

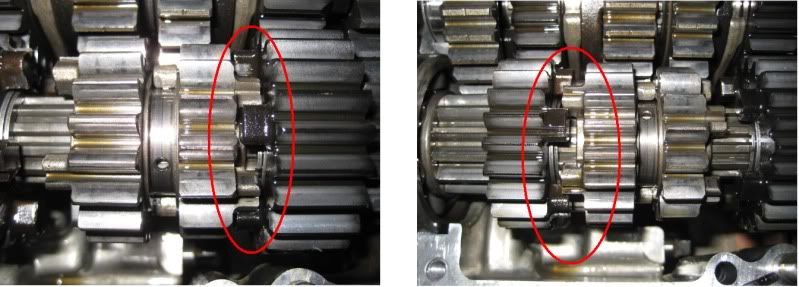

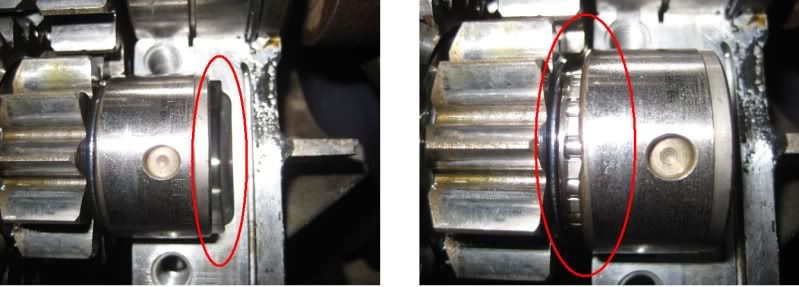

I also found that some gears interlock better than others.

The picture on the left shows them fully engaged circled in red but on the right you can see they don't seem to fully seat. Bent clutch fork?

I also noticed that one of the end bearings has a gap at the end of it where it seats in the crank case which allows it to move back and fourth:

If I move it in towards the gear set it seems to foul on the opposite gear when I turn the gears. WTF is the go there?

mad-butcher - 11/7/12 at 07:31 PM

I'm almost certain the hole in the outer bearing is for a locating peg , but it's been many a year since I've had to strip a motor

tony

ReMan - 11/7/12 at 08:43 PM

quote:

Originally posted by mad-butcher

I'm almost certain the hole in the outer bearing is for a locating peg , but it's been many a year since I've had to strip a motor

tony

So it is, is the peg still in the lower case you took off?

Also the engagement of those does does not look right.

Is that with the forks in place?

Have you had a good look at the forks out?

DANMAN - 13/7/12 at 10:14 AM

Thanks guys.

Yep, I'm a dunce, there is a locating peg for the bearing in the top crank case cover. I havn't had the forks out yet (hopefully over the

weekend) but they don't look bent. It could be wear on the peak on the drum where the fork may not be being pushed up as far as it should be to

seat the gear properly. I ordered another gearbox from a wreckers for $430 delivered and it looks a fair bit better than my current one. For starters

it doesn't have chunks missing out of one of the gears!

Speaking of which, does anyone know what gear this is?:

It's the one with the chunks missing out of it. If it is fourth than that would explain a lot.

tony.g - 13/7/12 at 10:37 AM

You should be able to work it out from this.

http://www.lingshondaparts.com/honda_motorcycle_parts_selection_pfk.php?block_01=13MW0N41&block_02=E__1500&block_03=1158

[Edited on 13/7/12 by tony.g]

DANMAN - 13/7/12 at 11:37 AM

Thanks mate.

"GEAR, MAINSHAFT THIRD & FOURTH" That explains the chatteing sound from the missing chunks on that gear!

joni - 28/7/12 at 07:15 PM

quote:

Originally posted by Hector.Brocklebank

quote:

Originally posted by mark chandler

Whoa wait a minute, loose linkage not moving far enough can do this, check basics first.

+1 on that, dont listen to any armchair experts.

Do it properly and professionally, follow a methodical process eliminating the simplest things before ripping the things guts out.

WHO IS THE ARM CHAIR EXPERTS NOW ???????????????????????????????????