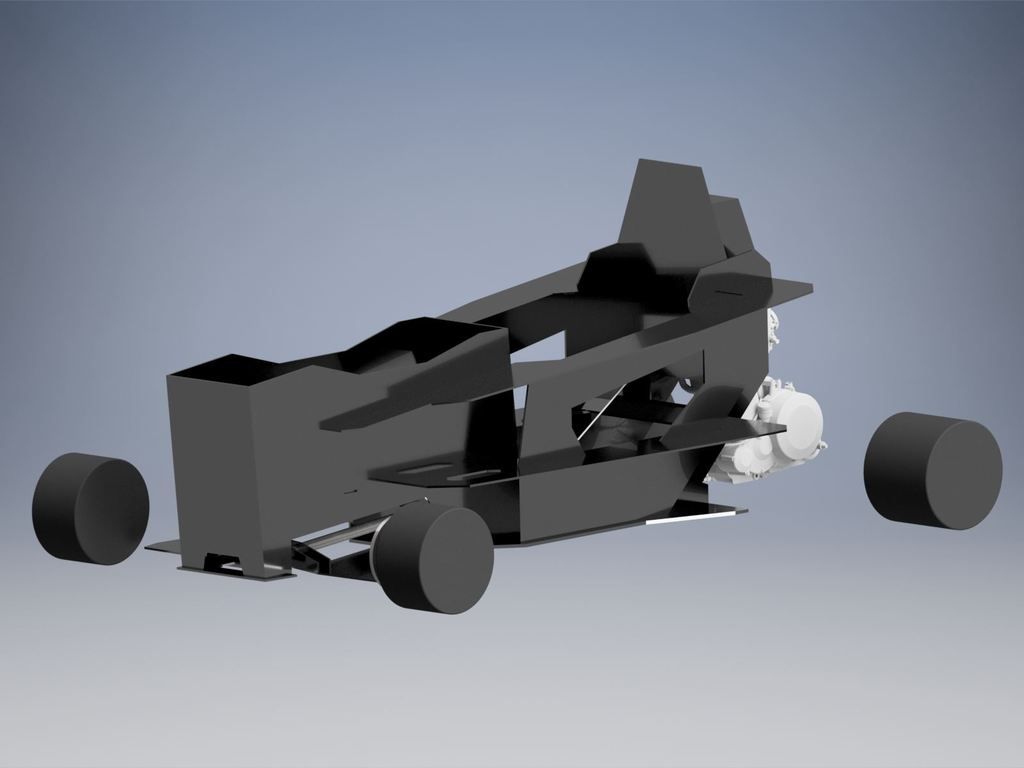

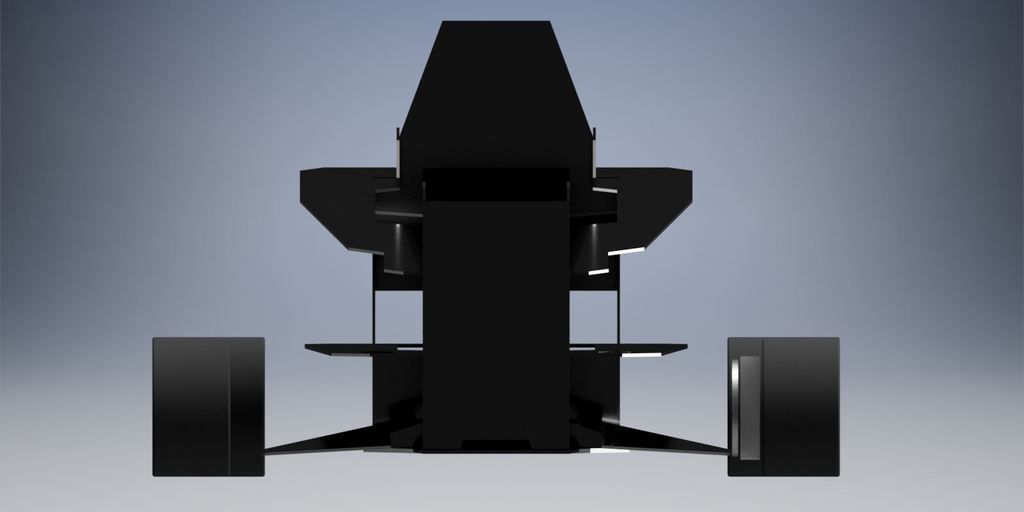

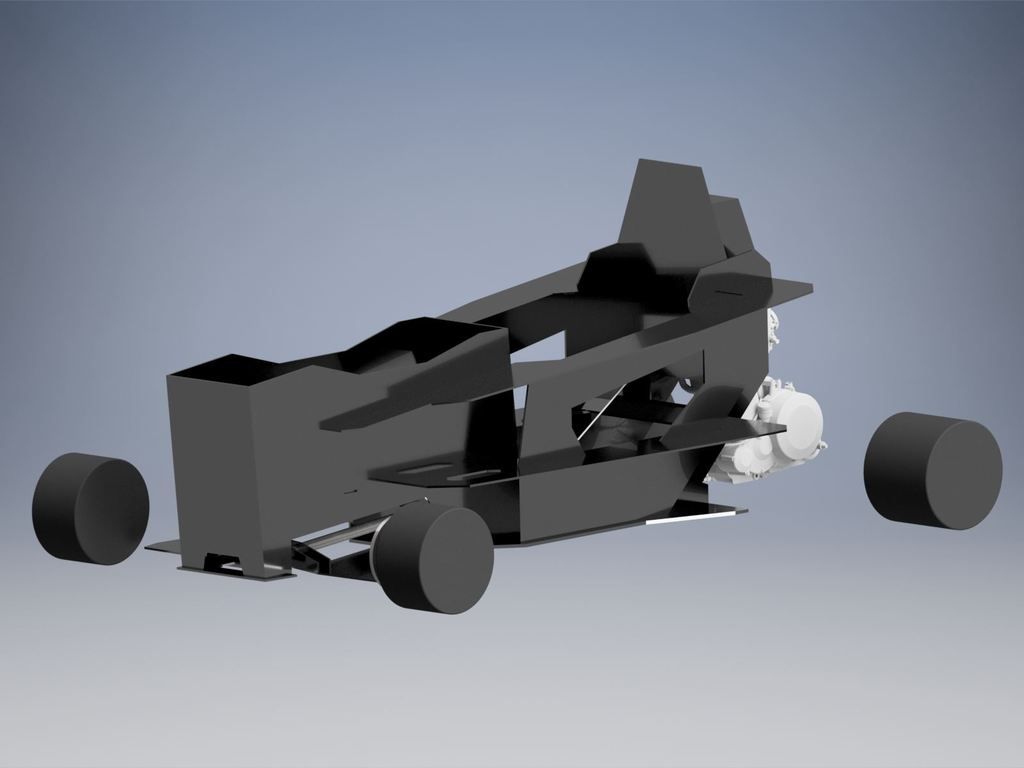

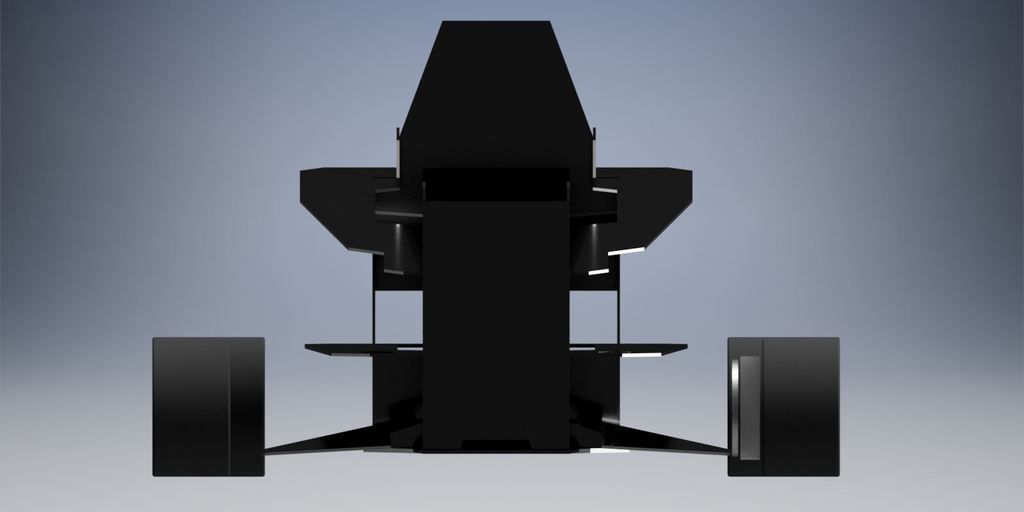

Single seater track day tool

mi2jaca - 15/10/17 at 05:54 PM

Made of wood on a strict budget using a smaller than “usual” motorcycle engine.

I am taking a little different approach to the locost concept although I am not sure if this qualifies as a locost. Thought I would share this

anyways. Comments and critique is welcome but try to be nice, I understand that I am out of the normal locost “box” but please don’t be nasty to

me.

The idea being to create a very simple to make/build design with relatively cheap components. Monocoque chassi using plywood as primary material with

glued joints keeping everything together. Independent double wishbone front suspension and stiff rear axle with swingarm. Engine from a large single

cylinder four stroke (+600 cc KTM or similar) or maybe a 650 twin (ER6 or similar), not sure yet.

Rear axle, wheels and tires from a Superkart should cope with the performance I am aiming for but at the same time keep costs down? Am I right?

Still only in the basic design stages so please bear with me and be gentle

//C

JAG - 15/10/17 at 06:26 PM

Sounds like a great idea - if you only want a track day car

Have you thought about how you'll attach the metal wishbones to the wooden monocoque chassis?

Are you using bushes or Rose type joints?

How will you bolt to the wooden monocoque?

Plenty of high performance craft are made/were made from Plywood.

Always loved the De Havilland Mosquito - and that's all Plywood airframe

perksy - 15/10/17 at 06:28 PM

Are many single seater track days available in the UK ?

CosKev3 - 15/10/17 at 06:37 PM

As above,not many single seater track days.

Lots of test days for competition cars,but I wouldn't mind betting something made of wood wouldn't be allowed on?

ettore bugatti - 15/10/17 at 07:03 PM

I like the concept.

I assume you already have seen the Hyper Pro Racer?

Nickp - 15/10/17 at 07:07 PM

quote:

Originally posted by CosKev3

As above,not many single seater track days.

Lots of test days for competition cars,but I wouldn't mind betting something made of wood wouldn't be allowed on?

You may get on with some wheel arches / cycle wings, but tbh would you want to be sharing a track with potential loons in 2ton tin tops?? Ermm, not me

Dingz - 15/10/17 at 10:50 PM

" I wouldn't mind betting something made of wood wouldn't be allowed on "

That would rule out early Marcos cars, and Costin Amigos, for a start.

The Costin raced at LeMans.

[Edited on 15/10/17 by Dingz]

mi2jaca - 16/10/17 at 06:30 AM

The part about actually getting this thing on the track could be a show stopper. Will maybe talk about it with some organizers and I have a friend

running a Radical who maybe has some connections I can use. Was hoping that the novelty of the design would open a few doors. I am also a little

uncertain about what lap times to expect, I don’t want to big differences if i mix it up with other cars. The more I think about it the worse it

sound.

Of course I am inspired by the Hyper Pro Racer but that’s on the other side of the world and costs a small fortune. Being a family man means that I am

on a low budget but I try not to look at the total cost to much but instead to make an annual budget that decides my spending’s and my rate of

progress year by year. As an engineer I am of course using an Excel-sheet to keep track.

Since I lack any form of real fabrication skills or facility’s I plan on using as much of external manufacturing resources as possible and keeping my

focus on a simple to assemble design. I am a mechanical engineer by trade so I have some feel for what works and what doesn’t. So far I have ordered

and received some samples for laser cut plywood parts to evaluate and test. Attachment to the wooden monocoque is still being debated.

Has anyone used www.weerg.com to make metal parts? They do look interesting since I have no problem designing parts in 3D CAD.

//C

[Edited on 16/10/17 by mi2jaca]

Sam_68 - 16/10/17 at 07:51 AM

quote:

Originally posted by mi2jaca

Was hoping that the novelty of the design would open a few doors

Regrettably, I think you might find that the opposite is true: both track day organisers and track operators are increasingly cautious in these

litigious times, and will be happier with something that is either road legal, or is MSA scrutineered within a recognised race class.

I assume that you're already fully conversant with Frank Costin's work, but if the plywood construction is a major objective for you and

you'd be willing to consider something a little more conventional as the path of least resistance for track use, then this project might interest

you by way of inspiration:

The Logan Superior

Camber Dave - 16/10/17 at 09:22 AM

I spent far too much time trying to build a ‘two seater’ racing sports car using Carbon fibre honeycomb flat panels.

The main problems are.

• Wasted space at the intersections of the panels/buklheads

• Load paths of suspension and major components

• Routing and securing of pipes and cables through the monocoque

The result was a mess of an oversize main tub, a space frame for engine/rear suspension and an overweight alloy box for the front suspension, pedals,

brakes and inboard coilovers.

If I was to do it again, I would forget the chassis initially.

Draw/3d model the driver, power unit cooling system, box and drive train, fuel tank etc as close as possible to each other.

Work out the weight distribution of this package. Then model the layout of your suspension and dampers.

You will then find that flat panels are unlikely to ‘join up the dots’.

However plywood (or Carbon/honeycomb) bulkheads could be used. The essential chassis/monocoque will be multi-planed to keep overall dimensions small

and the load paths can be be fed into junctions of panels/buklheads.

Like the Lotus Elite, Marcos and Costin decades ago, GRP can be used. But like the Lotus Elan construction is eased by having a ‘chassis’, in reality

a load spreading component. The torsional rigidity was substantially increased by the body shell.

Sam_68 - 16/10/17 at 09:57 AM

quote:

Originally posted by Camber Dave

I spent far too much time trying to build a ‘two seater’ racing sports car using Carbon fibre honeycomb flat panels.

The main problems are.

• Wasted space at the intersections of the panels/buklheads

• Load paths of suspension and major components

• Routing and securing of pipes and cables through the monocoque

The result was a mess of an oversize main tub, a space frame for engine/rear suspension and an overweight alloy box for the front suspension, pedals,

brakes and inboard coilovers.

If I was to do it again, I would forget the chassis initially.

Draw/3d model the driver, power unit cooling system, box and drive train, fuel tank etc as close as possible to each other.

Work out the weight distribution of this package. Then model the layout of your suspension and dampers.

You will then find that flat panels are unlikely to ‘join up the dots’.

I saw the photos of your tub when you put it up for sale, so I understand what you're saying.

I've been through the same process, and initially ran up against the same problems as you - your bullet points are all horribly familiar, and a

few others besides!

With a lot of thought (quite a bit of it lateral!) I've come up with solutions that I'm happy with to all the critical issues, however

(indeed it ultimately resolved itself into a ridiculously simple and efficient design): it can be done, I reckon - but it's taken

me several years of thinking and playing around with models and test sections to get there!

The OP's design is obviously preliminary, but it incorporates some very valid features - in particular the horizontal elements at cockpit top and

mid-height level, which will substantially stiffen the cockpit opening. If I remember correctly, your design was very similar to the Strathcarron tub

for the cockpit area - basically just an open top box with no returns or perimeter stiffening around the upper edge of the side panels - so would have

been lacking stiffness in that area.

[Edited on 16/10/17 by Sam_68]

Camber Dave - 16/10/17 at 10:13 AM

Quote

If I remember correctly, your design was very similar to the Strathcarron tub for the cockpit area - basically just an open top box with no returns or

perimeter stiffening around the upper edge of the side panels - so would have been lacking stiffness in that area.

Agreed

My customer had the design FEA'd and was happy. However I was intending to add outward horizontal flanges 'to support the bodyshell'.

As you say the project was offered for over a year but unsalable. I now have £15k of carbon honeycomb to dispose of, offers anyone?

Sam_68 - 16/10/17 at 03:24 PM

quote:

Originally posted by Camber Dave

My customer had the design FEA'd and was happy.

Purely out of curiosity, do you recall what sort of figures it was generating for torsional stiffness?

Camber Dave - 16/10/17 at 04:20 PM

Sorry Sam not disclosed to me, though I often wondered.

U2U sent

steve m - 16/10/17 at 04:27 PM

I had thought of doing something similar about 15 years ago, as build with wood !

But my way of doing this was to make a ladder section in 100mm steel square, (still have some in the garage)

The metal chassis would of been for all the suspension to hang/suspend from, and to locate the engine on

But the rest of the car would of been in marine ply, my aim was for a 60's lemans lola, style

somewhere, I have the folder with all my musings, and if I had a double garage, it would off been started

steve

ettore bugatti - 16/10/17 at 06:33 PM

I just remembered, Motus build some gokarts with a plywood chassis/ monocoque.

I think they were even used in sprint and or hillclimbs