Weird fan problem (airflow, not electrical)

nobrakes - 11/7/16 at 10:22 AM

I've got a 14" and 2 x 7" curved blade fans (from McGill Motorsport) on my radiator, they're set up as pushers and the surrounds

are on a strong rigid frame that holds them virtually touching the core - there's probably only a couple of thou clearance if that to minimise

air loss between the surround/core gap. The flanges on the surrounds were bigger than I thought so I've trimmed to fit round the top and bottom

tanks and I've filled the gaps with black polyurethane sealer.

When the fans are on you can feel air blowing out the back of the radiator and place a hand in front of the fan near the middle and you can feel it

sucking if you see what I mean.

Now here is the weird thing - move your hand to the front outside edge of the fan surround and air is being blown out! Its as if the blades suck air

in and resistance through the core means there is enough pressure to force air back out through the gap between the fan blade tips and the

surround.

Has anyone else had this happen? If so, what did you do?

I'm thinking, either lining the inside of the surround with something to reduce the blade-to-surround clearance (but by how much?) or block off

the outside edge of the fan grills to redirect the escaping air back into the fan (would that work?) or something else?

Slimy38 - 11/7/16 at 10:36 AM

Won't the airflow when you're driving be different anyway? You're replicating the engine cooling itself down when you're stuck in

traffic and the temperatures are going up. When you're driving normally there should be (reasonably) equal atmospheric pressure on all parts of

the radiator.

Bluemoon - 11/7/16 at 10:37 AM

quote:

Originally posted by nobrakes

I've got a 14" and 2 x 7" curved blade fans (from McGill Motorsport) on my radiator, they're set up as pushers and the surrounds

are on a strong rigid frame that holds them virtually touching the core - there's probably only a couple of thou clearance if that to minimise

air loss between the surround/core gap. The flanges on the surrounds were bigger than I thought so I've trimmed to fit round the top and bottom

tanks and I've filled the gaps with black polyurethane sealer.

When the fans are on you can feel air blowing out the back of the radiator and place a hand in front of the fan near the middle and you can feel it

sucking if you see what I mean.

Now here is the weird thing - move your hand to the front outside edge of the fan surround and air is being blown out! Its as if the blades suck air

in and resistance through the core means there is enough pressure to force air back out through the gap between the fan blade tips and the

surround.

Has anyone else had this happen? If so, what did you do?

I'm thinking, either lining the inside of the surround with something to reduce the blade-to-surround clearance (but by how much?) or block off

the outside edge of the fan grills to redirect the escaping air back into the fan (would that work?) or something else?

Your hand is not a great indicator of flow, use smoldering cigarette or joss stick similar and check again. Your had is large enough to effect flow

etc..

nobrakes - 11/7/16 at 11:00 AM

quote:

Originally posted by Slimy38

Won't the airflow when you're driving be different anyway? You're replicating the engine cooling itself down when you're stuck in

traffic and the temperatures are going up. When you're driving normally there should be (reasonably) equal atmospheric pressure on all parts of

the radiator.

Agreed, it isn't a problem when driving and maybe I'm worrying about nothing because when I held it at 2000rpm for 20 minutes the fans were

running full blast and the temperature gauge was showing a steady 90°C.

What I'm wondering about is being on holiday stuck in heavy traffic up a steep hill in the south of France in the summer when I'll be

needing every last drop of air to keep a 4.6 V8 cool.

nobrakes - 11/7/16 at 11:23 AM

quote:

Originally posted by Bluemoon

Your hand is not a great indicator of flow, use smoldering cigarette or joss stick similar and check again. Your had is large enough to effect flow

etc..

A good point but air is definately being blown back out of the front outside edge, I also tried it with a leaf gradually pushed over the edge and it

was blown/bent forwards. On full speed you can actually feel it several inches away from the fans too, more so on the two 7" fans because they

are rated higher. The 14" says 90 watts/670cfm and the 7"s say 80 watts/1270cfm each which surprised me. The flows probably bear no relation

to my installation but I suppose they're useful as a comparison.

I think I'll knock up a crude manometer with some water in a plastic pipe and try taping over the outside front edge to see if it makes any

difference?

[Edited on 11/7/16 by nobrakes]

Bluemoon - 11/7/16 at 11:25 AM

quote:

Originally posted by nobrakes

quote:

Originally posted by Slimy38

Won't the airflow when you're driving be different anyway? You're replicating the engine cooling itself down when you're stuck in

traffic and the temperatures are going up. When you're driving normally there should be (reasonably) equal atmospheric pressure on all parts of

the radiator.

Agreed, it isn't a problem when driving and maybe I'm worrying about nothing because when I held it at 2000rpm for 20 minutes the fans were

running full blast and the temperature gauge was showing a steady 90°C.

What I'm wondering about is being on holiday stuck in heavy traffic up a steep hill in the south of France in the summer when I'll be

needing every last drop of air to keep a 4.6 V8 cool.

If the thermostat is working correctly the gauge should be solid close to the thermostat temperature. The thing to check is that the top and bottom

hoses have a good temperature difference, indicating the fan and radiator is cooling, you should also see the thermostat doing it's thing and

this will be reflected in the radiator heater hose temperatures (i.e. you will see fluctuations in the top and bottom hose temperatures as the

thermostat opens and closes). If the thermostat is always fully open (i.e hoses temperature stable) then the radiator cooling is insufficient.

If the fan thermostat temperature is set correctly this should cycle on and off as required and also indicates that the system is working, if the fan

is on all the time something is amiss...

02GF74 - 11/7/16 at 12:24 PM

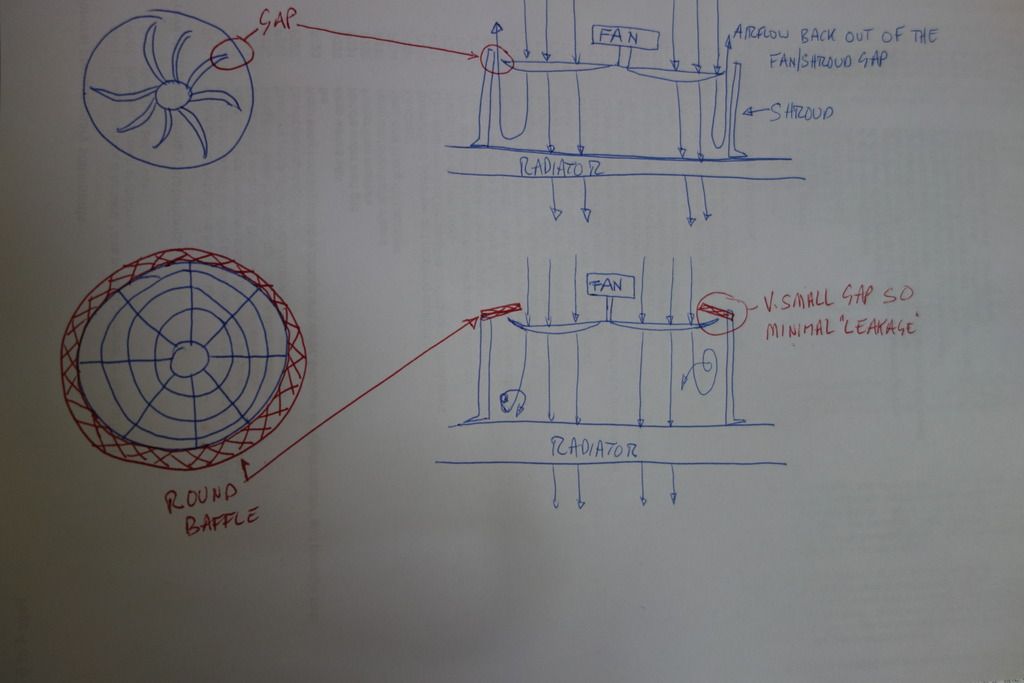

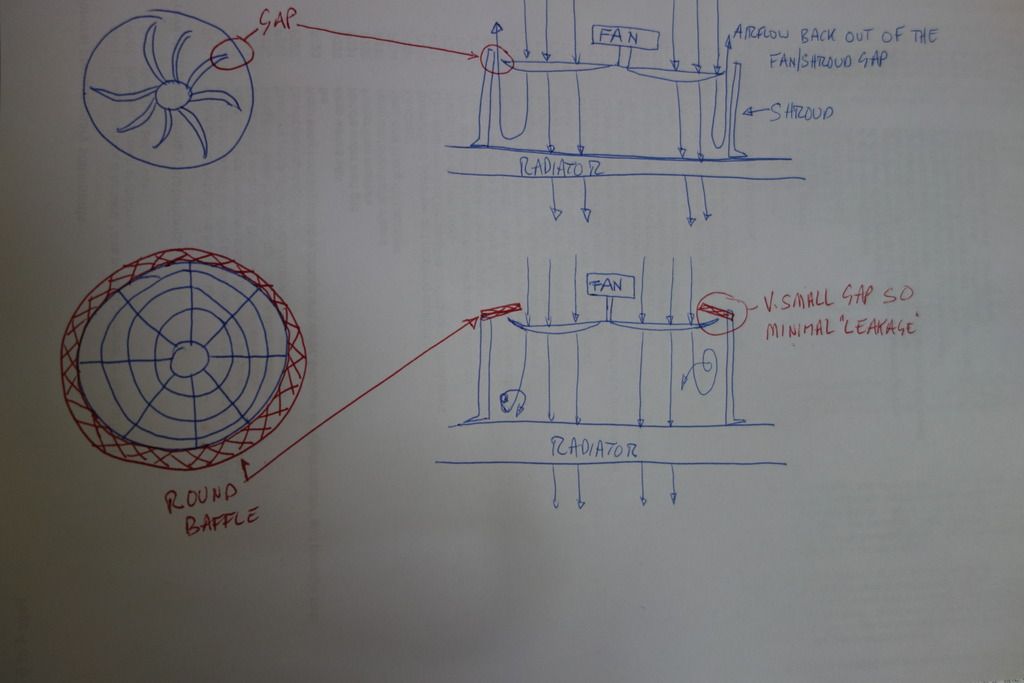

Not sure I follow all that, I prefer pictures to lots of words, so is the diagram below a summary of what you feel is happening?

The blue arrows is what you are concerned about and it would be strange if the radiator was in fee air. I assume it is fitted in a car that has

enclosed sides and top (i.e. bonnet) and engine behind it - the air has to exit somewhere and it appears to want to go back through the radiator.

Providing the temperatures is maintained at idle when fans are running there is nothing to worry about; ensure the hot air can get out

easily.

Due to the hysteresis in the fan switch, the fans usually will run for a while, then stop and then run again; if they don't stop at all, then

that is a sign the cooling is not up to scratch.

Unless you have the resources of a large manufacturer who has access to a test department and all data for engine, radiator etc. it is almost pure

guess work as to what radiator will suit each engine; generally people shout polo and that is fine in most cases and that is only based on the

experience of others. You won't know if the cooling is sufficient for extreme situations unless the car is subjected to them.

nobrakes - 11/7/16 at 12:26 PM

I don't know how good the ancient Smiths temperature gauge is but I used an 82° thermostat. The fan switch is low speed on at 88°/off at 83°,

high speed on at 92°/off at 87°.

Also, there's no engine driven fan so I suppose the electric ones are bound to come on sooner or later when stationary.

I was bedding in the cam running it at 2000rpm on the driveway (luckily the neighbours didn't mind the noise) so I think that's why all the

fans were running fast, normally there'd be no reason to run the engine like this.

Turner Engineering put 4 temperature sensitive stickers on the core plugs in the engine block, during this run the 88° bit changed to black but the

next bit labelled 99° was still white so the engine was over 92° but under 99 if the fan switch and indicator strips are accurate.

I've since left it on the driveway running on tickover (which was around 850rpm, I've since lowered it a bit) and eventually the fans did

cut in and out at low speed, they were on for longer than they were off but its a brand new engine so maybe I should expect it to run a bit hotter

than usual until its properly run in?

All in all, I'm reasonably confident that the cooling will be ok although I haven't been out on the road yet (first time on the road will be

a trip to the MOT station this week), its just that I'd like to try and get as much air from the fans as possible through the radiator for those

stuck in traffic in a heatwave moments.

nobrakes - 11/7/16 at 01:00 PM

quote:

Originally posted by 02GF74

Not sure I follow all that, I prefer pictures to lots of words, so is the diagram below a summary of what you feel is happening?

No, the fans are blowing through the radiator as per your red arrows, no air is following your blue arrows back through the rad.

Imagine it like this - lets say the fan blades are 7" across and the surround is 11" across (the gap isn't this big but it'll do

for this explanation).

Now slide a thin sheet of plywood between the fan and the radiator (my rad isn't blocked off like this but again, it'll do to help

explain)

Turn the fan on and what'll happen is the fan will suck air in, turn it through 180° and blow it out around the 2" gap between the fan blade

tips and the surround.

Does that help visualise it?

What I've actually got is a lot less than 2" gap and air gaps between the radiator tubes/gills so most of the air is going through the rad

but the fans are pressurising the surround to the point where its easier to blow back through the gap between the blades and surround than through the

rad.

No problems with bodywork hindering airflow because there isn't any, its in a trike and the rad sits in front of the engine (Reliant rather than

tadpole wheelplan).

I don't actually know what the radiator is from, this is one of the problems of working on something built by and probably altered by one or more

of the previous owners.

02GF74 - 11/7/16 at 02:53 PM

See, that is why i like pictures.

So what i understand now is there is a gap of 2 inches between fan blades and shroud?

That is bad, the gap should be minimal as air will take path of least resistance, which is not through radiator..... as you seem to have

discovered.

You need to fit correctly sized shroud or larger fan so there is no gap.

Let me find a picture of what i mean. See on this page

http://calsonic.com/en/products/engine-cooling/fan-shroud

Two fans sitting in a hole in the shroud that are just a bit bigger than the fan blades.

[Edited on 11/7/16 by 02GF74]

MikeRJ - 11/7/16 at 03:30 PM

quote:

Originally posted by 02GF74

See, that is why i like pictures.

So what i understand now is there is a gap of 2 inches between fan blades and shroud?

That is bad, the gap should be minimal as air will take path of least resistance, which is not through radiator..... as you seem to have

discovered.

Absolutely this. An axial fan without a close fitting shroud waste a lot of airflow by moving the air outwards along the blades like a centrifugal

blower.

nobrakes - 11/7/16 at 03:33 PM

quote:

Originally posted by 02GF74

See, that is why i like pictures.

So what i understand now is there is a gap of 2 inches between fan blades and shroud?

That is bad, the gap should be minimal as air will take path of least resistance, which is not through radiator..... as you seem to have

discovered.

You need to fit correctly sized shroud or larger fan so there is no gap.

Let me find a picture of what i mean. See on this page

http://calsonic.com/en/products/engine-cooling/fan-shroud

Two fans sitting in a hole in the shroud that are just a bit bigger than the fan blades.

[Edited on 11/7/16 by 02GF74]

No no no, I was trying to make it clearer but appear to have failed.

Like I said, I don't have a 2" gap, just a small one where air is coming out between the fan and the surround/shroud.

I want to reduce this 'leak' of air from the fans just in case I ever need every last bit of cooling (like if I'm stuck in heavy

traffic going uphill in summer in the south of France and the temperature is up in the 30's)

nobrakes - 11/7/16 at 03:43 PM

quote:

Originally posted by MikeRJ

Absolutely this. An axial fan without a close fitting shroud waste a lot of airflow by moving the air outwards along the blades like a centrifugal

blower.

Yes, that's it! The shroud round the fan isn't close enough to the fan so this is whats happening.

Hence I'm thinking, either:

- line the inside of the shroud with something to reduce the blade-to-shroud clearance (but by how much, how close does it have to be?)

- block off the outer edge of the fan grills with a round baffle like a giant polo mint to redirect the escaping air back into the fan (would that

work?)

- something else?

coyoteboy - 11/7/16 at 03:43 PM

Fan recirc

02GF74 - 11/7/16 at 04:26 PM

just had a look at one fan, distance between end of blade and shroud about 1.5 - 2 mm.

I see your picture now.

If the gap is as above, then I would leave it - we can probably assume the fan manufacturers know what they are doing?

If you start to cover the gap, then will that not restrict the flow of air into the fan as the open area is reduced?

Which of the two situations is worse I cannot say.

The radiator matrix should be covered by the cowl, as per the photo I posted and the fan(s) sit(s) in the holes, the air pushed by the fans will pass

through the entire matrix not just a part of it for maximum effieciency, again as done by car manufacturers..

[Edited on 11/7/16 by 02GF74]

nobrakes - 11/7/16 at 04:26 PM

Does this help? (Isuppose I should have shown all of the air arrows going through the radiator in the side view with the baffle)

SPYDER - 11/7/16 at 09:39 PM

So the fans are "set up as pushers".

This obviously needs the direction of rotation to be correct.

It also requires the fan to be the correct way round, otherwise the fan efficiency suffers.

Are your fans the right way round?

Dusty - 11/7/16 at 10:26 PM

A rotary fan will always impart a centrifugal(centripetal?) force to some of the air-mass so some goes straight through the rad and some goes

sideways. Regardless of how tightly the shroud fits some will be blown as you describe. Best answer is to fit the fan behind the rad as a sucker and

the problem goes away. It is more efficient in this configuration. Shrouding can be more imaginative also if its behind the rad without reducing

airflow through the rad although due to the increased efficiency it doesn't need to be.

02GF74 - 12/7/16 at 07:55 AM

quote:

Originally posted by Dusty

Best answer is to fit the fan behind the rad as a sucker and the problem goes away. It is more efficient in this configuration. .

Hmm - how do you mean more efficient - better cooling for given power than front mounted? Can you provide figures?

Fan positioning was discussed not too long ago - I argued that a push fan will flow more than a pull fan (rear mounted), my argument being a pull

fan can only suck at most 1 atm whereas a push fan can go over that, and more air through a radiator will shift more heat so more cooling.

Regarding efficiency, the pull fan may be more efficient than push at low flows - for reasons you state (I don't know it that is a fact but it

sounds plausible), but eventually the pull becomes less efficient as it runs out of air to suck (its limited to 1 atm) whereas the push will keep

flowing air as long as it is available and I would guess is limited mainly by the power of the motor and design.... and I don't have figure for

that but is it obvious from the physics.

Other than many production cars have fan mounted at the front, that wouldn't be the case if it was significantly less efficient than rear

mounted, anyway I'm not saying anything more on this as we are heading off on a tangent and I don't want a repeat of previous

'argument'.

nobrakes - 12/7/16 at 05:26 PM

quote:

Originally posted by coyoteboy

Fan recirc

Nope, there isn't any significant amount of air escaping between the rad & shroud as per the grey curly arrows.

nobrakes - 12/7/16 at 05:30 PM

quote:

Originally posted by SPYDER

So the fans are "set up as pushers".

This obviously needs the direction of rotation to be correct.

It also requires the fan to be the correct way round, otherwise the fan efficiency suffers.

Are your fans the right way round?

They're pushers because of the lack of space between the engine & rad.

One of the reasons I bought these particular fans is because you can run the motor in either direction and also the fan blade can be flipped over so

its running in the right direction.

nobrakes - 12/7/16 at 06:10 PM

I had a measure up today and the gap between the blades and shroud on the 7" fans is around 4mm or so which looks like is just too big. Also the

fan is just blades sticking out of a hub, it doesn't have any sort of ring around the outside so all in all I think it's pretty poor

design.

I think the way forward is to reduce the inner diameter of the shroud to only slightly larger than the fan blade diameter.

Maybe a couple of lengths of uPVC tapered edge architrave, bent into a circle and with the tapered edges facing the front and back of the shroud would

do the job.

coyoteboy - 13/7/16 at 08:56 AM

Are you sure it's that bad? The amount escaping the sides will be orders of magnitude less than the amount going through?

nobrakes - 13/7/16 at 10:16 AM

quote:

Originally posted by coyoteboy

Are you sure it's that bad? The amount escaping the sides will be orders of magnitude less than the amount going through?

This is the thing, I'm not entirely sure. Remember the fans are quite powerful (1270 cfm each according to the maker's specs) and to me, it

feels like a strong draft but it is hard to quantify.

It can't hurt to increase the airflow in the right direction, especially if I can do it just by glueing some plastic inside the shroud.

(unfortunately, because I was worried about vibration loosening the push-fit fan brackets, I put Tigerseal in all the joints and brackets so got to

see if I can get it apart first...)

r1_pete - 13/7/16 at 12:43 PM

One simple thing to check is that the fins on the radiator are not distorted, if they are they will interrupt the airflow through the rad.

If you hold the rad up you should be able to see through it, and any patches of twisted / distorted fins will be obvious.

nobrakes - 15/7/16 at 11:44 PM

quote:

Originally posted by nobrakes

All in all, I'm reasonably confident that the cooling will be ok although I haven't been out on the road yet (first time on the road will be

a trip to the MOT station this week), its just that I'd like to try and get as much air from the fans as possible through the radiator for those

stuck in traffic in a heatwave moments.

Well, it looks like the radiator isn't up to the job after all because when I tried driving at a steady 60-ish the fans came on and were running

on full blast continuously so going to see about getting a bigger rad this weekend.

02GF74 - 16/7/16 at 06:15 PM

quote:

Originally posted by nobrakes

Well, it looks like the radiator isn't up to the job after all because when I tried driving at a steady 60-ish the fans came on and were running

on full blast continuously so going to see about getting a bigger rad this weekend.

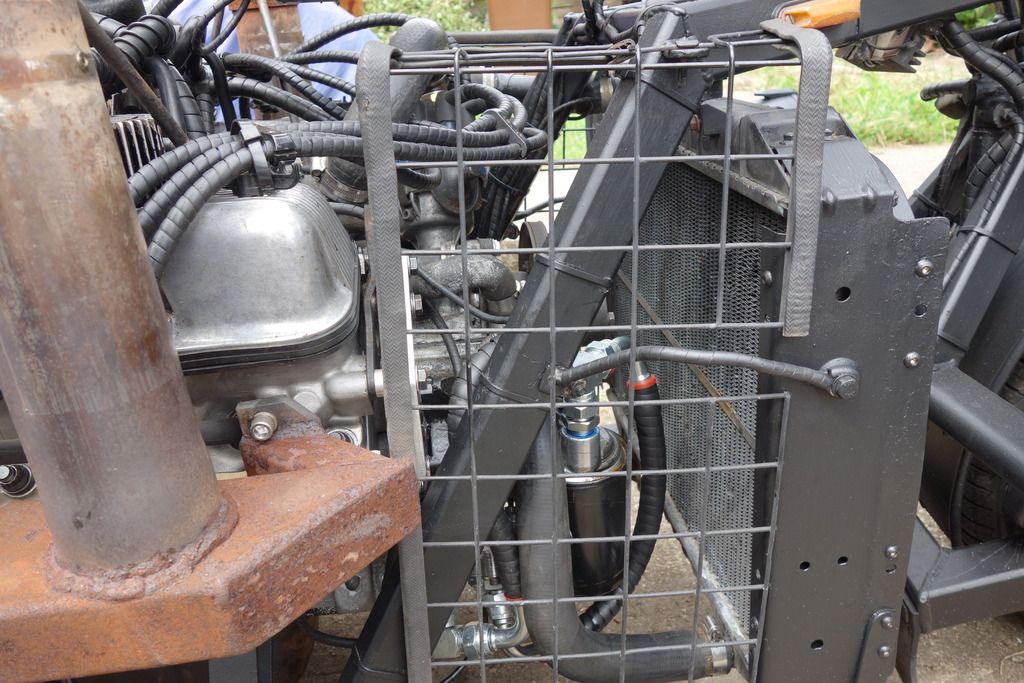

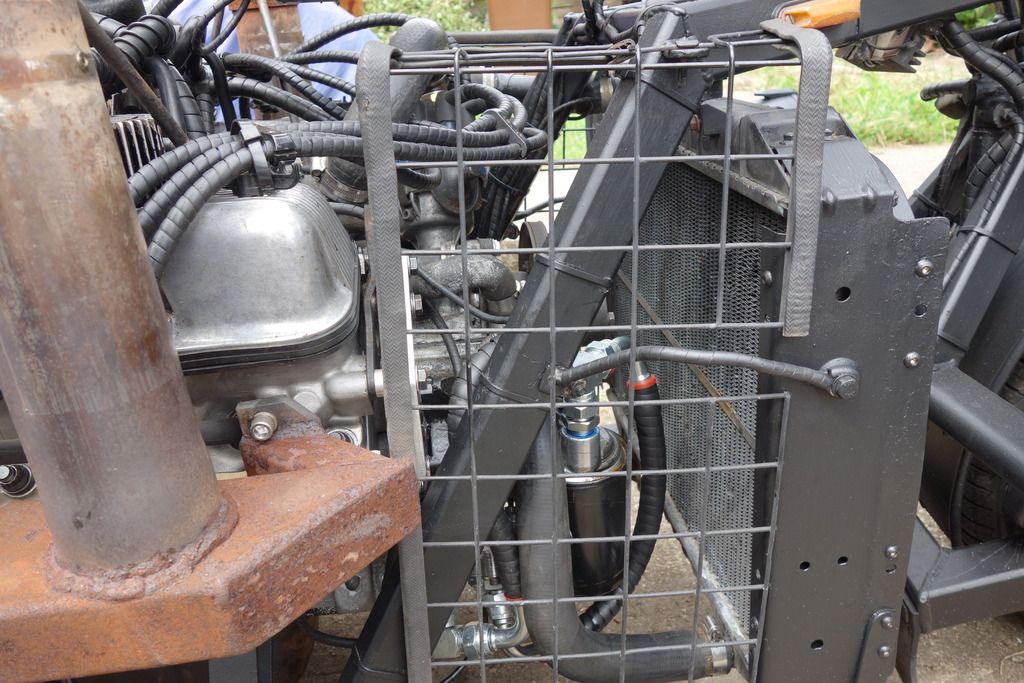

post a photo of your current section so we can all laugh, sorry, I meant advise.

Bear in mind a car has body work with an opening at the front to channel air to the rad - I expect you don't have that on your v8 trike.

what is the radiator from and approx. size of the matrix?

rachaeljf - 16/7/16 at 10:34 PM

You can't avoid some small leakage back past the blade tips. It happens because there is a gap and there is a pressure difference between front

and back. The shroud massively reduces the loss round the ends of the blades but will never completely eliminate it. It sounds like you have quite a

high pressure ratio front to back as a result of your setup. If you ran the fan in free air you should find that leakage round the blade ends would be

negligible.

As someone has said, make sure the blades are orientated correctly for the desired airflow. If they have a curved aerofoil shape, the concave side

should face the intended air flow direction.

nobrakes - 17/7/16 at 11:40 AM

Pic as requested. Looking at it, I've just noticed something. The top hose, running up from the middle of the inlet manifold the across to the

nearside and forwards into the rad, is higher than the top of the rad. That can't be helping.

- the core is about 520mm wide & 370mm tall

- the old engine was from a 1972 Rover p6, I've misplaced the measurements but they had a rad a little bigger than this

- I believe it cooled the old 3.5 v8 but the rad in a P38 with a 4.6 like mine is 570 x 500, thats nearly 30% bigger

- the side plates used to be 'U' shaped, I straightened out the front bend so I could use it to mount the electric fans, the top offside one

is just showing (maybe I could extend them outwards to make scoops, like on the Honda GL1100 model without a fairing?)

- there's an overflow bottle, not an expansion tank

- it looks like there is a lot of room behind the rad but its an optical illusion, there isn't space for a puller style fan

mark chandler - 17/7/16 at 04:00 PM

I cannot see the bubble pipe, is it running SU's

On the lump the carbs bolt to there is a 1/4 barb pointing forward that carries water, this needs to go to the top of the rad, if it's blocked

(quite common, have a good poke in it) as it takes the air bubbles that come off the water boiling in the head.

Missing the car will quickly blow out water and overheat,

Rad looks quite big, p38 is designed to tow heavy loads up steep hills, your time on WOT will be very limited so I cannot see this being an issue if

in good condition.