Volvorsport

|

| posted on 27/12/09 at 01:22 PM |

|

|

Roll Cages ?

Right , theres no seperate section for roll cages - i think it might be good as a sticky topic since so many questions are asked about MSA specs ,

road use etc etc .

Anyway , my first question would be .

why not start with the roll cage , then make the chassis to it ?

Does that make it difficult to get certified .

Does the manufacturer of the cage have to install it ?

In a tin top , i can buy a weld incage myself , and it would pass scrutineering - so whats the deal with us locosters ?

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

|

|

iank

|

| posted on 27/12/09 at 01:43 PM |

|

|

The blue book is now, officially, on line here

http://www.msauk.org/site/cms/contentviewarticle.asp?article=646

The regulations regarding roll cage design are in the pdf called "C(c) Competitors - Safety"

clicky here

There are lots of diagrams showing cage designs the MSA consider to be appropriate towards the back.

AFAIK so long as the design is certified by the designer (e.g. Procomp) and has it's certificate then it's ok no matter who installs it

(providing the scrutineers are happy with the mounting, diagrams also in C(c)).

So I think starting with the cage and designing a chassis around it is perfectly feasible and won't make things harder - but should in theory

make it easier as you are starting with a known strong shape.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

JoelP

|

| posted on 27/12/09 at 02:17 PM |

|

|

i always thought the chassis and cage should be designed together, madness to do them seperately when you think about it.

|

|

|

AdrianH

|

| posted on 27/12/09 at 03:01 PM |

|

|

Just an update to the links above

http://www.msauk.org/site/cms/contentviewarticle.asp?article=876

Is a link to the 2010 blue book section. Pity it is not one download but lots of smaller ones.

Adrian

Why do I have to make the tools to finish the job? More time then money.

|

|

|

minitici

|

| posted on 27/12/09 at 03:58 PM |

|

|

So long as your cage complies with the appropriate drawing in the MSA blue book and the material dimensions and specifications are as per the book,

then you do not need 'certification' of the cage.

However if you designed a cage from different spec/size materials or did not follow the drawings then you would need a certificate from the

manufacturer to prove that the cage is suitable.

Note also that there are different requirements depending on which category your car comes under. 'Sports Libre' requires larger diameter

tubing than 'modified' categories.

|

|

|

Volvorsport

|

| posted on 27/12/09 at 04:08 PM |

|

|

keep the info coming .

so how does a Z cars mini fit in to all this ?

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

mark chandler

|

| posted on 27/12/09 at 05:36 PM |

|

|

I have made a few cages before which have passed MSA, as above no need to be certified, just make to the rules.

If I made my car again I would build the lower frame, add suitable strengthing plates as defined and build out the roll cage, then hang the upper

frame around this.

MSA scrutineers feel for joined metal so design for continous lengths then get someone with a proper mandrel bender to bend the tubes, its very hard

to keep everthing in the same plane, so purchase as a preformed to your specification flat pack.

They will also examine the welds and bracing, proper fishmouths required, do not try and fill gaps with weld.

Make sure its high enough for you...

|

|

|

hicost blade

|

| posted on 27/12/09 at 05:39 PM |

|

|

Bolt in cages like the caged type need to be fitted properly on proper welded in mounts to keep the scrutineers happy. The fitting kit supplied with

my Westfield Caged cage would have been laughed out of scrutineering. Its best to get someone with experience/manufacturer to fit the cage.

Pro Comp fitted mine, in hindsight I would have got them to make a cage on the car (good old hindsight!!!)

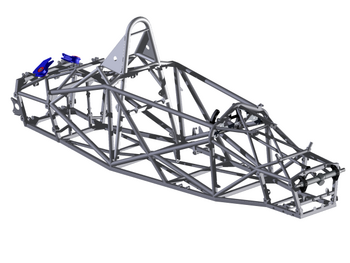

Quite a lot of 'proper' racing space frame chassis are designed/built around roll over/intrusion protection.

Like this DSR chassis, most of these types of car are made completely from CDS or t45 or in the case of this one 4130 aircraft grade seamless tube.

This chassis is the protection

|

|

|

kb58

|

| posted on 27/12/09 at 06:30 PM |

|

|

I build the cage first, then welded the rest of the chassis to it. As said above, it's nuts to build the entire car and then bolt on a cage.

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

alistairolsen

|

| posted on 27/12/09 at 09:09 PM |

|

|

Ok, Ive built a chassis, and fitted threaded bosses for cage mounting feet in the suspension towers. Can anyone advise what I need to do to build an

acceptable cage?

My Build Thread

|

|

|

Ben_Copeland

|

| posted on 27/12/09 at 10:58 PM |

|

|

quote:

Originally posted by alistairolsen

Ok, Ive built a chassis, and fitted threaded bosses for cage mounting feet in the suspension towers. Can anyone advise what I need to do to build an

acceptable cage?

i dont like the idea of Threaded bosses for a roll cage.

Weld it in and it'll be much better.

Ben

Locost Map on Google Maps

Z20LET Astra Turbo, into a Haynes

Roadster

Enter Your Details Here

http://www.facebook.com/EquinoxProducts for all your bodywork needs!

|

|

|

Richard Quinn

|

| posted on 28/12/09 at 08:07 AM |

|

|

quote:

Originally posted by Ben_Copeland

quote:

Originally posted by alistairolsen

Ok, Ive built a chassis, and fitted threaded bosses for cage mounting feet in the suspension towers. Can anyone advise what I need to do to build an

acceptable cage?

i dont like the idea of Threaded bosses for a roll cage.

Weld it in and it'll be much better.

Why? Bolt-in cages can be fine and I've seen some weld-in cages held in with pigeon-shit

welding. There is a lot more to it that just the mechanics of the attachment.

|

|

|

kennyrayandersen

|

| posted on 28/12/09 at 10:38 AM |

|

|

Also, keep in mind that when you use a structural fastener that load carrying capability as well as fasteners quality is also is well known (lots of

test data and the [high-strength]. So, if you know the load, you can calculate the fastener required (and actually give it whatever margin of safety

floats your boat).

|

|

|

alistairolsen

|

| posted on 28/12/09 at 12:20 PM |

|

|

4 off M12x1.5 sockethead cap screws (12.9) on each side of the main hoop so far.

I didnt want to weld it on as id like to be able to remove it in the future if necessary!

My Build Thread

|

|

|

procomp

|

| posted on 29/12/09 at 09:56 AM |

|

|

Hi

A few thins to clear up regarding MSA FIA.

If a cage is constructed from 45mm dia tubing that complies with the blue book then anyone can manufacture /fit it. As long as it complies with the

MSA/FIA blue book criteria.

However if below the 45mm DIA then for use under MSA /FIA it has to be certificated. which will now cost 2k plus as full crash testing has to take

place on the cage and chassis as a combined construction. And then it can only be fitted installed by the manufacturer or the agents who are licenced

and registered on the MSA/FIA paper work that goes with that design.

And yes that dose mean that the majority of rollcages being sold in magazines DT Etc Etc are being sold illegally for MSA/FIA use. and the majority of

cages sold for kitcars and Westfields in particular are also being sold illegally and the so called certificate and labels are meaningless.

And yes the scrutineers are cracking down on it as has been seen with the majority of MK rollcages being refused at race meetings.

Cheers Matt

|

|

|

Volvorsport

|

| posted on 29/12/09 at 11:02 AM |

|

|

thanks matt ,

given this scenario , of making a roll cage before the chassis is made , as long as its to the blue book specifications , it would appear to be ok

.

in the case of it being part of the chassis , ie the uprights where the dash mounts to , and it didnt have any mounting plates at the bottom of the

tube , is that part of the chassis or the roll cage ?

i dont want to spend £700 on a cage that doesnt pass scrutineering , so im thinking that i should make a new chassis with the cage incorporated into

the design , ie built first .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

hissingsid

|

| posted on 3/1/10 at 08:27 PM |

|

|

When making the cage to the blue book, do you need to follow the guidelines and drawings exactly?

I'm thinking of making my own but wish to copy the curved roof bars in the Caterham cages. I know the book says you can have a X brace roff

bars, but would curved roof bars be included in that?

Is it a case of read between the lines abit?

If anyone can shed some light on this for me that'll be great!

Graham

|

|

|

procomp

|

| posted on 4/1/10 at 09:21 AM |

|

|

Hi

You need to follow the drawing and text very closely. Roof bars that are not straight ( only certificated cages are allowed to deviate from the

drawing in the book ) are part of the reason why so many non certificated cages even in 45mm are being thrown out of MSA events. And the fact that the

front legs have two or double bends when the very first section of the text clearly states that this is not allowable. And feet / mountings not being

attached as per the MSA FIA criteria. Tubes mounted to chassis rails that are in fresh air with no support.

Cheers Matt

|

|

|

alistairolsen

|

| posted on 4/1/10 at 10:04 AM |

|

|

So this design for instance:

If constructed at home from the required tubing would be unsuitable due to the bends at the base of the A pillars, double bends in the rear loop and

curved roof bars to clear helmet tops?

on this one:

the two loops are ok, but again the roof bars present a problem?

But then looking at yours:

The roof rals are curved again?

Id imagine with straight roof rails and the full tubing thickness above your helmet the cage would get very high, the front loop and the rear would

need to be close on the same height and to avoid the issues with bends in the cage feet one would have to bring the front legs down inside the cockpit

which utterly destroys the legroom?

My Build Thread

|

|

|

iank

|

| posted on 4/1/10 at 10:10 AM |

|

|

The last one has a certificate

quote:

http://www.procomp.co.uk/rollcage.html

MIRA have tested and passed the cage, chassis and mountings to FIA requirements.

[and]

The MSA have issued a roll over protection certificate.

You can build what shape you like if you are prepared to pay and have it tested and a certificate issued. If you want to do it without paying you

have to follow the rules to the letter.

(just like the rules for SVA/IVA vs what Ford et.al. do).

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

procomp

|

| posted on 4/1/10 at 12:21 PM |

|

|

Hi

The mountings on the first pic do not comply with MSA.

The other cage with the roof bars clearly do not comply.

The cage shown on our car is fully certificated to the very latest standards which include the mountings and the chassis as a whole structure. It is

the only Seven type in the UK to have been through the latest tests.

Cheers Matt

|

|

|

hissingsid

|

| posted on 4/1/10 at 09:50 PM |

|

|

Ok, so I CAN do the curved bars as the Caterham design BUT ONLY if i want to pay for certification. Otherwise I have got to follow the rules to the

letter and do a completely straight barred cage.

I wasn't going to have any bends in the front legs as I knew that would be a problem.

Is it ok to add a horizontal bar in the rear hoop at shoulder height for harness bosses?

Too many questions not enough time! It's best to ask these to people that know tho!

|

|

|

alistairolsen

|

| posted on 4/1/10 at 10:37 PM |

|

|

Would the external style of mounting on the blue westfield A pillars be acceptable?

My Build Thread

|

|

|

procomp

|

| posted on 5/1/10 at 07:32 AM |

|

|

Hi

Without seeing exactly what chassis structure has been or not added inside can't really say. But if the mounting is as per the caged ones where

it is mounted to an unsupported area of chassis with no vertical support and is hanging extensions that have been bolted through the chassis then it

dose not comply and will have weakened the chassis to such an extent that the car can not be corner weighted as every time you drive it and place it

back on the scales it will read different due to chassis flex.

Cheers Matt

|

|

|

jeffw

|

| posted on 5/1/10 at 08:55 AM |

|

|

OK....so is it possible to retro-fit a cage to something like a Phoenix (which I have) or a Fury and what would the ball park cost be ???

|

|

|