Sloan85

|

| posted on 14/4/13 at 07:52 PM |

|

|

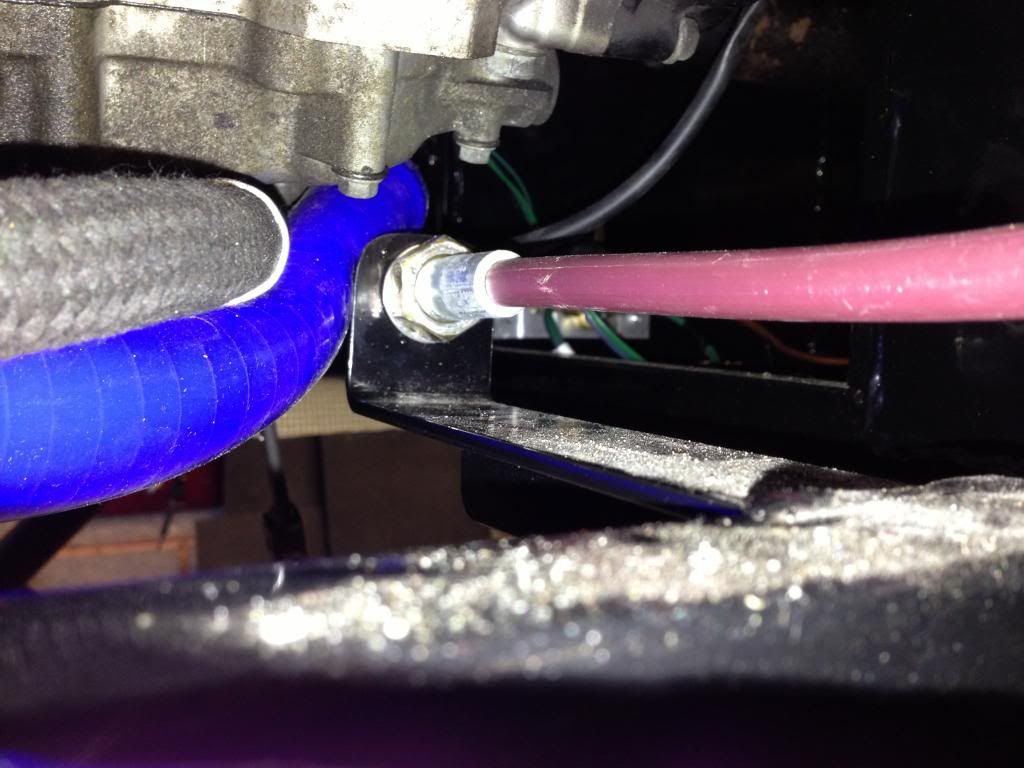

Tight squeeze for a silicone hose.... Will it be a problem?

I laid out the silicone hoses to see where they will be going today and there is one area that concerns me.

The connection to the water pump is very close to the gear shift bracket and the oil cooler pipe. The hose fits but as can be seen in the pictures it

is tight. Will this cause problems? Will the hose wear out? If it is I could possible replace this small section with alloy tube or cut a length of

alloy tube open and protect the outside of the silicone with it?

In hindsight I probably shouldn't have cut the GSXR oil cooler pipe so short before getting new unions crimped on but its done now.

Any suggestions?

Cheers!

|

|

|

|

|

Davegtst

|

| posted on 14/4/13 at 07:58 PM |

|

|

I wouldn't want it there, it will chafe. Best move it.

|

|

|

steve m

|

| posted on 14/4/13 at 08:19 PM |

|

|

Agreed, it will end up chaffing, and leaking, at just the time you did not want

Could you have a solid (metal) pipe to extend it out of the offending area ?

steve

|

|

|

Sloan85

|

| posted on 14/4/13 at 08:30 PM |

|

|

I could try and get through the tight bit with alloy tube but even that may be tight. Ill give that a go tomorrow.

If the alloy tube is touching the gearshift bracket, would that be an issue too?

http://mkindygsxr.blogspot.co.uk

|

|

|

sdh2903

|

| posted on 14/4/13 at 08:37 PM |

|

|

Yes it would, you don't want anything touching anything, eventually even the alloy would chafe through.

|

|

|

perksy

|

| posted on 14/4/13 at 09:09 PM |

|

|

Its wear through like that sadly

You need a decent gap all the way around hoses & alloy pipes to allow for vibration & movement etc

|

|

|

Sloan85

|

| posted on 14/4/13 at 10:10 PM |

|

|

Im really struggling with space if both alloy and silicone cant be touching anything. Photos below show the space available.

The only thing I can think of at the minute is to bend the gear linkage bracket down 20-30mm I could do this by cutting a wedge out the stiffener web

next to the chassis rail, bending the bracket down and re-welding it. Obviously this would make a mess of the powdercoating though.

Any other suggestions?

Cheers!

http://mkindygsxr.blogspot.co.uk

|

|

|

inkafone

|

| posted on 14/4/13 at 11:32 PM |

|

|

Can you fit a reducer (say 50mm to 40mm) at the pump end to a metal pipe with a lug welded on to take a solid rubber bobbin (exhaust type) and then

back to original size for remainder of hose. The gear change bracket looks like it can be trimmed back a bit to allow more room. All

movement/vibration - rad to metal pipe - will be taken on the hose.

|

|

|

40inches

|

| posted on 15/4/13 at 07:15 AM |

|

|

Can you get a silicon elbow in there? I take it the hose is 25mm bore?

|

|

|

Tiger Super Six

|

| posted on 15/4/13 at 09:05 AM |

|

|

Can you get an off cut and cut it down it's length and then put it round that piece of pipe and cable tie it in place. That way it will wear on

the offcut and as long as you keep an eye on it you can just replace that as and when, then it will never get through to the actual pipe?

Not ideal, but could see you through.

Mark

Tiger Avon

|

|

|

MikeRJ

|

| posted on 15/4/13 at 10:25 AM |

|

|

quote:

Originally posted by Sloan85

Im really struggling with space if both alloy and silicone cant be touching anything.

It's not the "touching" that's the problem, it's any relative movement/vibration between parts that will cause damage to

the pipe. You should be able to make up some brackets/clips to hold a silicone or alloy pipe away from danger.

|

|

|

Sloan85

|

| posted on 16/4/13 at 10:08 AM |

|

|

Going to have to cut the end of the bracket and make up a new one to move the gear shift cable further towards the bulkhead by about 60mm

Photo below shows where silicone elbow will be positioned in relation to the new position of the gear shift cable. It will also line up the cable

better than it is at present.

How should I protect the steel when I cut the end off? What paint is best to use?

Cheers

http://mkindygsxr.blogspot.co.uk

|

|

|