Jeffdrew78

|

| posted on 26/11/18 at 05:48 AM |

|

|

Australian BA Falcon as a Donor

Hi Everyone!

I'm in the planning stages of my Locost build. I live in Australia, so we don't have as easy (and cheap) access to a lot of the parts etc

that you UK boys do. As such, i'm finding i'm looking at some interesting approaches for the build.

I already own a 5.4 litre v8 Fairlane, with 4 speed auto, and I'm planning on dismantling it to use the drivetrain in my build. I know

it's overkill for a locost, but I'm an overkill kind of guy, and it's not like a v8 Locost has never been done. I've done a

fair bit of searching and haven't come across anyone using this powerplant so far, so it should be a little bit unique.

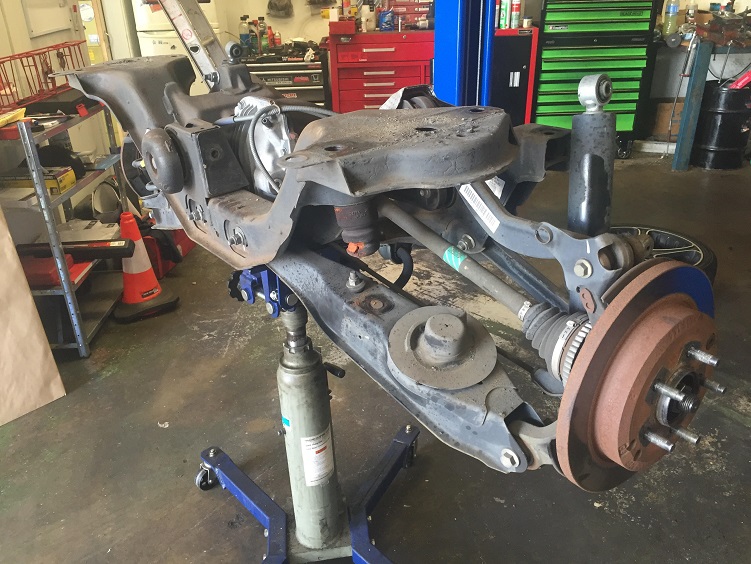

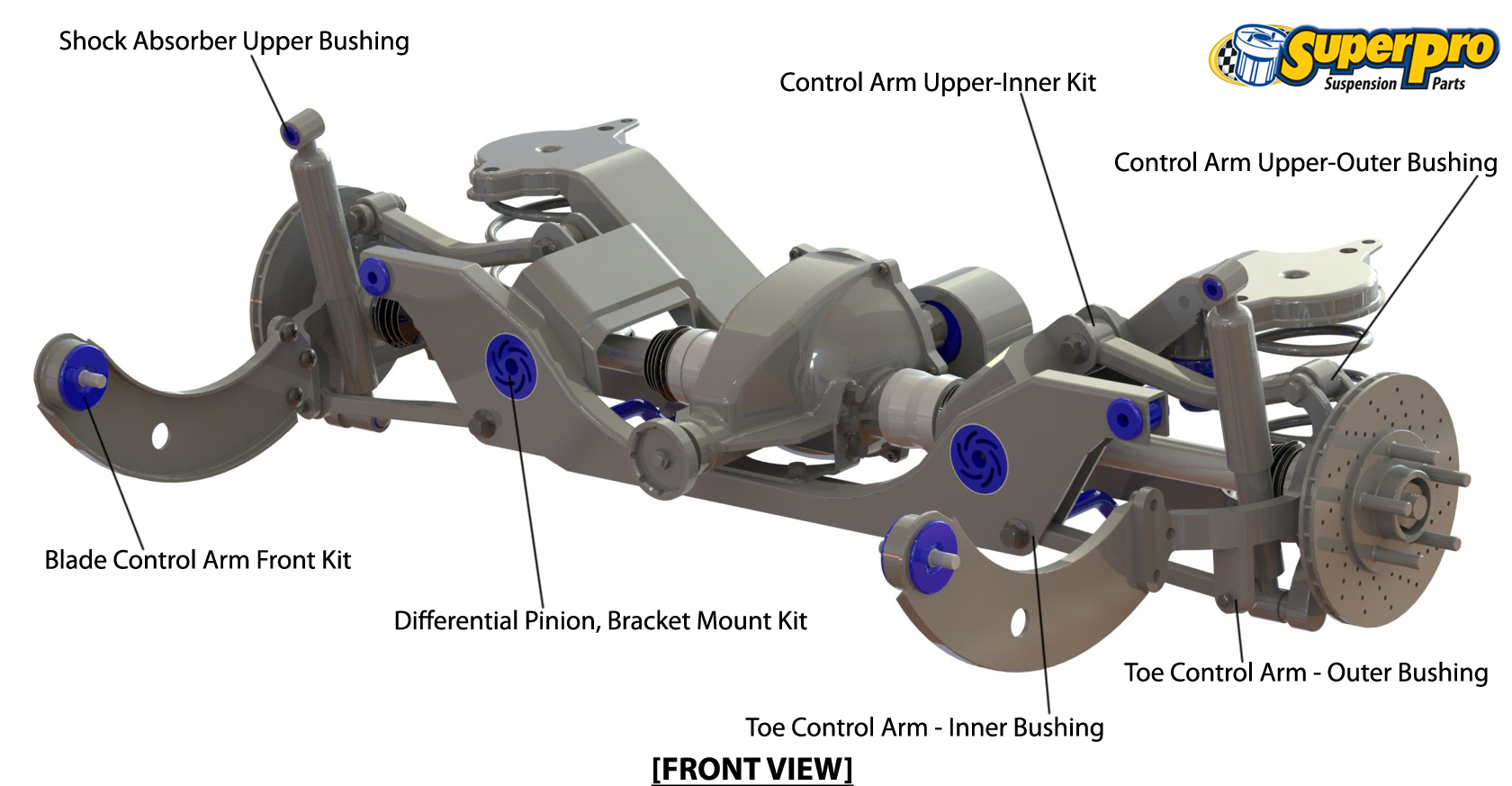

My question is about the rear suspension setup. The Fairlane, like all of the BA falcon/fairlane models has a control blade IRS rear end setup. The

whole cradle and everything suspension and brake related can basically be pulled out by undoing about ten bolts. the question here, is would it be

worth just mounting the whole thing in the rear, or just taking the diff and axles etc, and building a custom setup like the Rorty Locost IRS

setup?

If i can mount the whole subframe in there, it would drop development time and fabrication quite substantially. From what i can see, it would be

possible to simply remove the Control blade arms to simplify things, but I'm not sure that it would work as effectively without them.

Anyone want to give their thoughts on the idea?

Pics to show what i'm talking about

[Edited on 26/11/18 by Jeffdrew78]

|

|

|

|

|

snapper

|

| posted on 26/11/18 at 07:01 AM |

|

|

It might go under a Luigi wide kit but in all honesty you will not get the benefit from a Seven Type Kit if you bolt the running gear of your Falcon

under it.

This is Locost builders though (contradicting myself) and you can do anything you like as it’s your car, you’ll still get great support.

My Lotus 7 replica has the complete rear end from a Sierra underneath it and I’ve been looking at fabricating a lighter cradle to get rid of the

weight of the massive cradle and A arms

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

Mr Whippy

|

| posted on 26/11/18 at 12:34 PM |

|

|

have to agree with the above ^

Fitting that huge lump of metal to a lightweight 7 would do nothing but spoil it. Not convinced about you power plant idea either, 7's are about

small thrashy engines in a light and agile little car for twisty winding roads. What you seem to be going for something more like a hot rod dragster

and will probably handle just as badly while all the time trying to kill you.

Good luck.

|

|

|

johnnybizzle1986

|

| posted on 26/11/18 at 12:55 PM |

|

|

Have you considered the Cobra replica route? it would give you more engine bay room for the V8 and box, hide unsightly falcon suspension and offer

more weather protection, and a 60's le-Man would look awesome

|

|

|

loggyboy

|

| posted on 26/11/18 at 01:27 PM |

|

|

quote:

Originally posted by snapper

It might go under a Luigi wide kit but

I also preferred the Mario version.

Mistral Motorsport

|

|

|

nick205

|

| posted on 26/11/18 at 01:43 PM |

|

|

I'd favour using the donr differential, driveshafts, brakes and possibly uprights.

Fabricate the rest with a double wishbone IRS rear suspension setup. Much lighter and the way many 7 type cars are built in the UK using Ford Sierra

donor cars. The Ford Sierra has a rear subframe that could be bolted to the rear of the chassis in a similar way to what you describe. Ultimately it

would add a significant amount of weight to an otherwise light car so is generally avoided.

Looking at your photo just the subframe alone must weigh quite a bit!

[Edited on 26/11/18 by nick205]

|

|

|

Angel Acevedo

|

| posted on 26/11/18 at 03:41 PM |

|

|

Jeffdrew78..

Welcome to the forum.

There´s plenty of knowledge to be tapped using the search function. So use it before posting some silly question, most likely it has been answered a

couple of times, if it doesn´t come up, most likely it is not that silly then.

For what I see in your pictures, that rear end is used on American Cougars and Thunderbirds. It has been used extensively in kit cars and there are a

few locosts that use that drivetrain.

Mine was originally going to use a Cougar, but later changed my mind and went Live Axle.

You probably want to subscribe to the USA forum as there is more info on this setup.

Regards

Angel Acevedo

Beware of what you wish.. for it may come true....

|

|

|

steve m

|

| posted on 26/11/18 at 07:44 PM |

|

|

That rear suspension setup will weigh the same as my 7, and no wonder it needs a 5.4 ltr V8 engine just to lug that piece of battleship around

As said above, you need to build light, and with small ish engines, 2.0 is probably the optimum in a 7

steve

Thats was probably spelt wrong, or had some grammer, that the "grammer police have to have a moan at

|

|

|

Jeffdrew78

|

| posted on 26/11/18 at 11:11 PM |

|

|

To those with constructive criticism, I thank you.

There's always going to be arguments and naysayers when you mention a V8 in a locost, and i knew that before i posted.

Where I live, it's an hour of highway driving to get pretty much anyway, so the idea of a slow loping V8 appeals to me. Not to mention the

sound, and the torque when you want it. That said, it's a rather heavy engine, and I do realise that it will have an impact on handling. I like

to play in the twistys, but it's likely never going near a track. 99% of its use will be 3 hour drives down the highway to visit my father. And

the more important part of the equation - I already own it.. and in keeping with the name - I'd like my build to be low-cost.

I've considered the cobra replica route, and every cobra chassis I have seen is awful. Most of them are still for all intents and purposes a

ladder chassis.

I've often heard V8 locosts referred to as "Baby Cobra"'s, and I think it's fitting. A Cobra style car with a real

chassis...

As to the rear suspension setup - Yeah, it will definitely be heavier than a custom built double wishbone IRS. There's no question of that. I

find myself wondering if all that weight would offset the engine weight when it comes to the balance of the car. I know that as light as possible

should be the goal, but for handling, I (Maybe mistakenly) believe that weight balance is an important factor as well. I can't help but wonder

if that rear end might make it less of a lead tipped arrow. I'm actually only shooting for keeping the car under 1000kg's - which should

be easily doable. And considering that the donor car is 1800kg's, it should quite lively without being "OMG I'm going to die"

every time I touch the accelerator. When I think about how insane my 200hp Honda integra was at just over 1200kg, a stock 300hp v8 in a 1000kg car

should be a weapon, and should leave me never wanting to make it more powerful.

My though process on using that rear was twofold - 1. I would imagine that the ford engineers know more than I can learn from reading my copy of Des

Hammill's Sports car and kit car suspensions and brakes high performance manual. 2.Rapid development and build.

I realise that Springs and shocks will need to be changed to suit the weight of the car, and I'm looking around for an expert on the subject

that can spec the springs, and revalve the shocks to suit. But that aside, it's theoretically no different from bolting in a sierra subframe -

just heavier. And as it should be, being designed to hold 470nm of torque from the 5.4. From a cost and development time perspective, I see it as

possibly being a good solution - Even if it only gets done on the first chassis I build. At least 1 in 5 build diaries I read, detail how they built

the whole car and then realised they didn't like something, or it didn't work as expected, so they pulled the whole thing apart and

changed it - and I expect I'll be no different. I'm currently reading through the Rorty IRS plans, and I may yet go that direction as I

can see I could use the falcon diff and shafts, and uprights after some severe modification. I have a few months before I can dismantle the donor, so

I have time to do more research before the build starts.

I probably should have mentioned in the beginning, that i'm looking to base my build on the McSorley 442 plans. I plan to move up to a larger

tube size, and of course will be doing the "Aussie" mods to the chassis design. I'm also planning on building a full fibreglass

body, which will allow me to hide exhausts out the side, gives me more options for radiator and placement, and save me from worrying about headers

sticking out and other such issues that tend to come up when building a V8 locost. (And will also give me more options in hiding that big-a## rear end

if i use it)

That said, i'm not cutting a single pipe until i strip the donor car, and can take accurate measurements of the drive train and any other donor

parts i might use. I know i can't use the front uprights, but some research shows me that I can use 2006 Toyota hilux (2wd) front uprights -

which will also allow me to easily maintain common stud pattern between front and rear. It also has the advantage of being plentiful and cheap - about

$500 for both sides, complete upright, rotor, and calipers.

I think I'm done rambling now.. and again - I'd love any feedback or idea's you guys might have - especially on the weight balance

issue... And the idea of remove the control blades and the impact it would have on suspension geometry.

|

|

|

steve m

|

| posted on 26/11/18 at 11:38 PM |

|

|

Before you start cutting, have you considered whats acceptable for your Country ? as I was under the impression (maybe wrongly) that the Aus system

didn't allow one offs / kit cars,

As im sure my Son told me that years ago when he lived out there, (now back here !!  ) )

steve

Thats was probably spelt wrong, or had some grammer, that the "grammer police have to have a moan at

|

|

|

Jeffdrew78

|

| posted on 26/11/18 at 11:56 PM |

|

|

Hi Steve,

The Australian NCOP (National Code of Practice) for motor vehicles allows for ICV's - Individually constructed vehicles. They are subject to

engineering certificates, and must pass torsional rigidity testing, and emissions testing, and some other factors.

A lot of it boils down to what your engineer will allow. I've spoken with a friend of the family who runs a business doing engineering

certificates and he has made it clear that i shouldn't have too many issues as long as the design is sensible and the build quality is

sufficient to make it fit for daily use.

|

|

|

ettore bugatti

|

| posted on 27/11/18 at 11:01 PM |

|

|

Using the rear suspension assembly is a very cost and engineering effective solution.

Mounting is relative easy, you only need to worry about the attachment of the subframe to the chassis, the components are fully engineered and up to

the task.

And when something breaks, you just bolt a replacement part in.

Drawbacks are the weight and the need to get a custom spring unless the lower arm is strong enough to have the shock replaced with a coilover.

It would make sense if you would use the front suspension/ subframe from the BA Falcon too, so you can keep the brake system the same.

To link the the two ends, I would start with a ladder frame/ perimeter frame. Because that is the easiest way to link them (and to fabricate). The

stiffness of the frame can be then be increased with a 3D structure (multi-tube) on top of it.

|

|

|

Jeffdrew78

|

| posted on 28/11/18 at 11:31 PM |

|

|

ettore bugatti - Yeah, after some research, I've decided that's probably the only way to do a decent job of it.. It will make the basic

chassis simpler to build - but ends up being a much more cobra style chassis. Since I already own the donor (It's my daily), I think I'll

hold off on the idea for now. And that engine is so big and heavy!! I think it would be great in a mid mount, but for something like a locost, it will

just end up being a bad handling nuisance.

|

|

|