Warner R4 Build Diary

cloudy - 24/10/06 at 01:37 PM

This project has now significantly changed (see below) from the early design, see the latest pages for the new project...

More information/vids available at: www.wr4.co.uk

[Edited on 27/2/09 by cloudy]

[Edited on 19/5/09 by cloudy]

[Edited on 8/6/09 by cloudy]

[Edited on 8/6/09 by cloudy]

cloudy - 24/10/06 at 02:07 PM

A few mock ups of front end shapes, it always almost looks better without it at all

FUORISERIE, you mentioned you would do the front a bit differently any suggestions?

ideas + drawings welcome!

FUORISERIE - 24/10/06 at 02:50 PM

ok, send me a few 3/4 front and rear view and a side wiew image, for my rough sketches.

I tend to agree with you, it does look better with the steel tubes showing...

I will try .....but the concept looks really good, will see what i can do for you.

[Edited on 24/10/06 by FUORISERIE]

dr-fastlane - 24/10/06 at 04:21 PM

That is a really “cool” buggy which you building. If I can do a suggestion for the front of the car. Perhaps its an idea to bend the top tube from the

nose round out of one tube, if you understand what I mean. It keeps the front of the car simple but smooth.

Greets Roy.

Rescued attachment buggy.JPG

thomas4age - 24/10/06 at 06:54 PM

Looks very nice when it's this low to the ground, what ground clearance are you goin to run?

also not clear to me is what are you going to do with the diffcradle it looks like it's only attached to the rest of the chassis with 4

horizontal tubes? shouldn't that be braced very well?

grtz Thomas

btw nice project and should be quick aswell!

cloudy - 24/10/06 at 07:05 PM

diff mounts are not made yet, don't worry far more framework to surround it yet.

I like that design, i'll try it with photoshop

Ground clearance wise I will run about 120mm. I have 2x tiny 600kg electric rams, it would be quite cool to make a system to raise the front right up

for speed bumps - then I could run more like 100mm

Fuoriserie some plan views for you:

James

cloudy - 24/10/06 at 07:15 PM

I'm really keen on that design dr fast lane - here's it in tubing

Doug68 - 25/10/06 at 12:31 AM

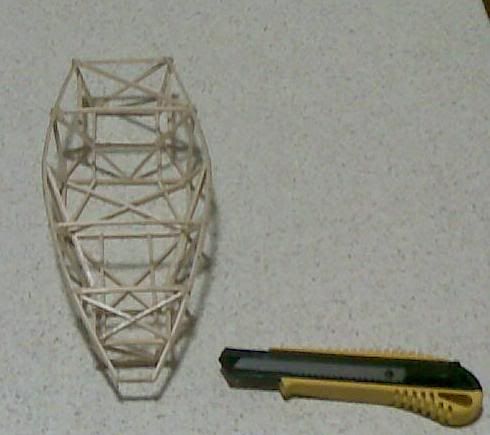

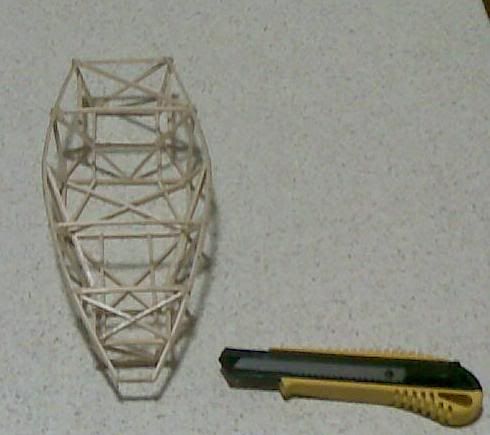

Have you built a stress model in the computer yet or a scale balsa model of the thing?

300kg is a very ambitious goal and I would guess you’re trying to work out where the

tubes need to be to be effective rather than just what looks good.

If you keep at it long enough you should be able to make it work and look good at the same time.

Doug.

cloudy - 25/10/06 at 01:28 AM

It's a good suggestion - i've tried a few bits of force analysis software to model it - but all go way over my head, and I just dont'

havce the time to learn how to use it properly. I've just been using common sense and judging myself how the forces are likely to propagate

James

[Edited on 25/10/06 by cloudy]

Doug68 - 25/10/06 at 06:17 AM

If the software is a mystery to you then build a 1/8th scale model of the frame using 1/8" square balsa and model glue.

Then pick it up and twist the thing.

Make another model of a cube X braced on all 6 sides say 100mm square and compare the 2 models.

Keep modifying your model until you are hard pushed to tell the difference between the 2 models.

Remember if your chassis is not stiff (which is different to strong). All the carfully worked out suspension geometry will go out of the window.

It may seem that this sort of stuff takes a lot of time when you could be welding things together, but I expect like me you want to make the best

vehicle that you can.

Doug.

iank - 25/10/06 at 07:43 AM

Agree completely, a balsa model gives a really good idea of how stiff your chassis is, and is far more intuitive than a computer simulation. Takes an

evening, and you get to bore your mates with it  . If you need/want a number the FEA can be done later to confirm.

. If you need/want a number the FEA can be done later to confirm.

It's amazing how one tube can make a huge difference, it's not something that can be done by eye, at least not until you've done a

few.

See this thread:

http://www.locostbuilders.co.uk/viewthread.php?tid=53918&page=1

Buggy looks really good so far BTW

[Edited on 25/10/06 by iank]

cloudy - 25/10/06 at 08:11 AM

OK I shall give the model a go

FUORISERIE - 25/10/06 at 03:27 PM

This was a personal project of mine, that due to time and work constraints I never came around in building it.... , i

, i

I couldn't build it myself, so why not have someoneelse try instead!.

Having seen your chassis, i thought about adapting my original design to your chassis setup.

this is just a very rough 10 min. sketch, but will be more detailed later in the process.

Let me know what you think, and if you like it?

]

[Edited on 26/10/06 by FUORISERIE]

Rescued attachment img584.jpg

cloudy - 25/10/06 at 04:22 PM

I love it, especially the nosecone area, You'd need to be pretty handy with fibreglassing!

PS: the "final" design for mine...

[Edited on 25/10/06 by cloudy]

ettore bugatti - 25/10/06 at 09:05 PM

Looks cool,

I think with some extra tubes diagonal placed. You would end up with something much stronger.

What is the width of the interior and how much is the track f/r?

FUORISERIE - 26/10/06 at 09:49 AM

quote:

Originally posted by cloudy

I love it, especially the nosecone area, You'd need to be pretty handy with fibreglassing!

PS: the "final" design for mine...

[Edited on 25/10/06 by cloudy]

Actually i think you wouldn't need much work for the nosecone,....... but I like your new bare bones chassis, maybe it looks better without the

body panels....

So no need for it, keep it simple as you have done.

cloudy - 26/10/06 at 10:55 AM

I was thinking of perhaps redoing the chassis when I got bored, and i'd like to loosely base the design on this:

Big problems are going to be making the panels, and getting glass to fit that...

James

iank - 26/10/06 at 11:19 AM

Now that would be a big job.

If you are serious pick the glass first - wander round a big carpark to find something.

The front end looks a bit like the WLR, so getting a nose from them might be a good start for a buck.

[img][/img]

cloudy - 26/10/06 at 11:54 AM

you might be onto something - the elise glass looks similar!

Dick Bear - 29/10/06 at 05:18 AM

There's nothing like seeing 10-minute sketches that look like auto design museum pieces, custom design frames that sit low and stable between the

wheels or a group of visionaries throwing out top-notched suggestions for the benefit of everyone to get the Creative Juices flowing!

Just two pages into Cloud's build and there's already been more helpful suggestions and imaginary response than some sites receive in a

year!

Great start, Cloud! may I suggest aluminum, hand-shaped body panels? Sure would be weight reducing,

Dick Bear

dr-fastlane - 30/10/06 at 07:33 PM

The final design is great looking Cloudy!

I would not put on too much bodywork. The chassis has an raw and racing look, keep it that way. Perhaps it sounds funny but way not copy the looks of

a RC model (toy) buggy. Something like this, but with a glass front window, polycarbonate side windows (like most sevens) and some cycle wings.

Greets Roy

Rescued attachment Baja-Buggy.JPG

ZEN - 30/10/06 at 09:32 PM

For me less is allways more and I like toys for big boys

cloudy - 30/10/06 at 09:50 PM

quote:

Great start, Cloud! may I suggest aluminum, hand-shaped body panels? Sure would be weight reducing,

Dick Bear

Sounds good, I think i'll follow everyone's suggestions and keep panelling to a bear minimum, except where requiured to keep away debris, to

help the shape or to improve aerodynamics..

When the chassis is finished (soon) I'll throw it up to the excellent talent here for some pointers

PS. dr fastlane - exactly the sort of car I was drawing inspiration from, definately a boy's toy!

James

[Edited on 30/10/06 by cloudy]

cloudy - 1/11/06 at 11:16 AM

I've posted the below in the chassis section, but included it here as you midy guys probably are used to more weight over the rear suspension.

OK I've welded the rear shocks on, it gives about 1" ground clearance with the bumps fully compressed and 2" as it starts to hit the

stops

This gives just over 10cm of suspension travel, with the car resting at about 6cm, leaving 4-5cm of upwards travel.

am I going to get away with this based on the photo + measurements above or do I need longer shocks?

James

[Edited on 31/10/06 by cloudy]

[Edited on 1/11/06 by cloudy]

Doug68 - 1/11/06 at 12:02 PM

This is a hard question to answer. But I'd think you'd want 2" at least of clearance at full bump. From reading the book a typical

locost has ~5" of static clearance and ~2" of travel from there to get to full bump.

More of a worry to me would be having the shock laid over that far. Effectively the suspension will get softer as its compressed, which if anything

is the reverse of what you want to happen. I'd get the shock as upright as possible.

Also I'd not want to put the load into the middle of the tube like that at the top end, hopefully you're planning bracing on it?

Similarly at the lower front wishbone point I'd want that braced, I guess I assume that theres going to be a lot more bracing everywhere?

But I'm possibly too worried about that sort of thing, after all I've been tinkering with my design for over a year now and still not got a

single weld done.

Doug.

cloudy - 1/11/06 at 12:26 PM

The angle isn't far off the angle most sevens seem to use at the front, perhaps I could compensate by using rising rate springs?

Obviously the angle is a trade off, the further you lean it the more travel at the wheel you get. where does 10cm sit compared regards

"normal" middy travel?

as regards bracing, yes theres a tube that goes horiztontally from the top shock mount across to the other

[Edited on 1/11/06 by cloudy]

Doug68 - 1/11/06 at 01:11 PM

Just because most 7's do it doesn't make it the best way to do it.

If you look at the front end of a 7 either you have 3 choices:

1. Do what most people do now.

2. Use a push rod type suspension.

3. Build a really ugly frame out the side of the nose to get the shock more upright.

So given the choices I can understand why most people go for choice 1.

10cm (4" is exactly what I'm working around myself and basically what you get from a book built Locost also.

is exactly what I'm working around myself and basically what you get from a book built Locost also.

I expect ~5cm to be used by the static load of the car leaving ~5cm movement left for bump absorption.

Doug.

cloudy - 1/11/06 at 01:34 PM

that's pretty much how it is, i'll go with it for now, I can always redo it later with longer shocks so they can be upright - the beauty of

having no bodywork!

James

Fred W B - 1/11/06 at 02:51 PM

quote:

3. Build a really ugly frame out the side of the nose to get the shock more upright.

Like this - note this is VERY rough mock up work

Cheers

Fred W B

rough upright

[Edited on 1/11/06 by Fred W B]

cloudy - 6/11/06 at 09:30 AM

Anyone know of anywhere to get high range top joints for cortina hubs? I've heard these discussed before. Basically it jams up before the bump

stops will be reached, which of course is pretty dangerous.

James

cloudy - 17/11/06 at 05:14 PM

I'm starting to have reservations on the design so far - it looks malproptioned a little when I wheel it out of garage.

I'm still not 100% happy that the design is the best shape I could choose, what's the general feeling about taking off roof and using a roll

hoop design as below, allows the main body to sit much lower....

cloudy - 17/11/06 at 10:45 PM

haven't seen any responses so i've progressed a litte, what do you think?

cloudy - 18/11/06 at 12:15 AM

plan view

ZEN - 18/11/06 at 12:26 AM

This one loks MUCH better and MUCH more professional looking styling.

Aren't the side bards to close to the drivers and passenger heads on the bottom 2 pics?

I think it would look rely nice with just the side pannels, air intake at the front F1 "nose up" style and opend rear like the Porsche 917

racing car.

What software are you using for the design?

[Edited on 18/11/06 by ZEN]

iank - 18/11/06 at 12:52 AM

Looks very nice, but I thought the original looked good

The side bars do seem very close to the drivers head - not good in an accident. The optional ones on the sylva r10t and full cages on 7's tend

to kick out as far as practical.

Also it won't be as ridged as the full cage version, but it looks close to a balsa model I made a while back which was pretty good.

cloudy - 18/11/06 at 01:31 AM

cheers guys, it's 3dsmax 7 i'm using, given up trying to figure out solidworks! you are right on the proximity to head - will have to mull

that one over...

The old design looked very odd at certain angles (especially the back) , so far this is OK from all

Here's a slightly more refined version, still not happy with the shape of roll bar, and obviously it can't sit on the middle of a tube as

per the current design...

Doug68 - 18/11/06 at 09:10 AM

Firstly I applaud your desire to be original, there's not enough of that these days.

Maybe its the angle of the view but the roll bar looks too low to touch down before the occupants head does.

On the same vein either the seats are too short or those are big wheels?

I'd push the roll tube back to match up with the rear bulkhead then it can be one tube all the way up over and down again. You can then cut

holes for the side tubes to pass through. which means even if the welds fail it can't come apart.

I do like the concept though, I had thought of doing a similar thing at one point using flat ally or carbon panels screwed in between the tubes to

form the body work.

I've been using Solid Edge which due to my CAE background didn't take too long to work out. The 'arty' packages are still a

mystery having tried Studio Tools PLE etc. As at some point I'm going to have to go back and have a look again, did you settle on 3DSMax for a

reason, or was it just what came to hand?

akumabito - 18/11/06 at 02:03 PM

Wow! I think this new design looks damn sexy! I already like the original, but it just gets better and better every time you alter the design!

*joins the requests for an entry-level kit*

Peteff - 18/11/06 at 02:24 PM

If the roll bar is level with the driver's eye which it looks like there you will need a hoist to get in and out of the car. Your vision will be

severely restricted by the bar in front of you as well. The roll bar and seats look out of proportion.

[Edited on 18/11/06 by Peteff]

cloudy - 18/11/06 at 03:27 PM

yeah, still progressing with the design - took the grinder to the chassis this morning took off the old roof

Sat in it to get head height measurement, and therefore the roll bar height required...

James

cloudy - 18/11/06 at 05:21 PM

OK, the bars along shoulders are now further apart - and the roll bar is the correct height.

Not sure on the shape? would a plain hoop be better? or maybe two hoops?

James

dr-fastlane - 19/11/06 at 03:28 PM

Hello Cloudy,

The new design looks much better than the one with the roof on it. And very original I must say. In my opinion build a plain hoop.

One question, how do you get in the car? Climbing over the upper frame tubes doesn’t seems practical.

Greets Roy.

akumabito - 19/11/06 at 05:22 PM

I love the design! Leave the hoop as it is now, it looks great! However, are you sure the scale of the seats/driver is correct in respect to the rest

of the car? Or are you running 24 inch wheels?  It just seems a bit off..

It just seems a bit off..

cloudy - 19/11/06 at 06:38 PM

Yes i'll be just climbing in over the chassis! Shoulda seen me trying to get in the roofed one! I'll go with the old standard plain hoop - I

won't be able to make the bendy one with the bender i've got access to anyway...

I've measured it simulating the recline of the replacement seat, the 3d copy man is probably a little on the small side!

Here's a pic I took, however these seats are going in favour of some more reclined ones, i've used this lower measurement in the 3d copy

[Edited on 19/11/06 by cloudy]

[Edited on 19/11/06 by cloudy]

[Edited on 19/11/06 by cloudy]

sgraber - 19/11/06 at 09:18 PM

The chassis has a very sexy line to it. But I must caution you on the use of the upper frame tube in it's current position. It is too close to

the head. A side impact and the bar will definitely impinge on the head. You simply cannot forsee that everyone driving this vehicle would wear a

helmet and it's possible that even with a helmet, a side impact of medium or large intensity will cause serious neck and or head injury. Please

re-evaluate this!

Graber

akumabito - 19/11/06 at 09:29 PM

Wouldn't that problem be fixed by fitting those rally seats that keep the head in place? (ya know, like a bucket seat but with extra

'flaps' to keep the head/helmet from bouncing all over the place for when the going gets rough...)

Sortof like this:

Only way less ugly and probably a helluvalot cheaper that $1,700.

Or this:

Ohh well, ya get the idea..

cloudy - 19/11/06 at 11:59 PM

I taken your comments on board, i'll look into a solution

James

Doug68 - 20/11/06 at 12:57 AM

I think SVA would throw a fit if you try to use seats with the side restraints, due to the reduced peripheral vision.

In the picture what the heck is the remote controlled do-dad with the camera strapped to then?

akumabito - 20/11/06 at 03:11 PM

Hmm... maybe you could simply cover those bars with rollbar padding? It looks kinda cool without any body panels. Just add padding to the chassis

around the driver area.

cloudy - 20/11/06 at 05:26 PM

the doodad is a (now) PC tele operated exploration robot I built, tested 1km range - theoretical 5km range

some video from the field trials

http://www.digital-car.co.uk/video/trials.wmv

I built it in the times the car was giving me grief and I needed something else to work on....

cloudy - 19/12/06 at 08:12 PM

Some progress, sorry for the awful pic - it was dark.....

Now thinking about fuel tank placement, its the half round object in the back center of this render. Is this a really bad idea for location? Shame as

it works well in this orientation....

Peteff - 19/12/06 at 08:17 PM

Is it going to have an engine, where is it going to fit and how are you going to get it in there? There's not going to be a lot of options with

the bar from the roll bar over the gap behind the seats and the diff cage and suspension there as well.

cloudy - 19/12/06 at 08:24 PM

read back through the thread before asking stupid questions!

Yes it will have an engine, a new concept I know

It's a motorbike engine, and it's already included in that render if you look carefully!

James

gttman - 19/12/06 at 08:53 PM

I have to say I share the concern about getting in and out with the side bars so high.

Like the design though and I think you are definatelly on the right lines.

cloudy - 19/12/06 at 09:07 PM

this won't be a luxurious ride! you will need to get in by stepping in on the bar

I expect the discomfort to continue during the journey with the engine exhausts behind your head, and the possiblility of wheels falling off....

James

Peteff - 20/12/06 at 12:26 AM

I posted earlier in the thread and you answered that you had removed some bars if you go back over the thread. I view things from a practical

perspective and think other people do the same. If something looks right it probably is and the bar over where your engine drops in doesn't look

right to me, possibly a bar either side with a gap in the middle. Show me the engine in place with a viable drive solution and I'll admit

I'm stupid. I have built cars and driven them and helped build cars from scratch and from kits and have a good idea of what works.

cloudy - 20/12/06 at 01:21 AM

The top bar is removable, yes the engine fits through the gap, and yes the entire drivetrain fits. I may be new to this and learning, I am not

however, stupid.

James

Doug68 - 20/12/06 at 01:35 AM

Like - lets chill dudes!

I think that there's plenty of pre-Christmas tension in the air at the moment.

Sven - 20/12/06 at 05:49 AM

James,

I love it. Like the look, the idea and your execution. Nice!

I agree with others that the topmost horizontal tubes near the passengers heads need moving for safety and that the rear bulkhead outer tubes and

rollbar should be one. Does seem to be a lot of unusable space behind the drivers seat.

The gas tank is right out there. Could you fit one in the front, forward of the passengers feet? That way it'll help balance the car and keep

it inside the frame away from annoying SUVs and whatnot.

-Steve

cloudy - 20/12/06 at 09:17 AM

Sorry, bad day!

I've built the entire car around the engine, it fits in the space, as i've already hoisted it in to check, I wanted the minimum wheelbase I

could get away with

Agreed on the tubing near the head - Im' still mulling that one over!

James

cloudy - 20/12/06 at 09:28 AM

you can see here how it fits in the space:

gttman - 20/12/06 at 10:04 AM

quote:

Originally posted by cloudy

this won't be a luxurious ride! you will need to get in by stepping in on the bar

I expect the discomfort to continue during the journey with the engine exhausts behind your head, and the possiblility of wheels falling off....

James

LOL, very good

Actually my concern is not getting in, its getting out.

But it will be no harder than the Batmobile and Robin used to manage.

cloudy - 20/12/06 at 10:12 AM

lol i'll be sure to provide a video for your entertainment

James

gttman - 20/12/06 at 12:25 PM

Will that mean you will also be wearing tights?

Peteff - 20/12/06 at 06:19 PM

See, that's all it needed, now it makes sense. Is it mounted same as the bike with a chain driven diff? I can't see it in your render

although I have looked.

cloudy - 20/12/06 at 10:13 PM

yeah, sorry for going off on one - yeah its a chain driven cossie diff

James

andyd - 20/12/06 at 10:51 PM

quote:

Originally posted by cloudy

yeah its a chain driven cossie diff

Can I ask where you sourced the diff from? I'm still deciding whether to use a chain driven one or use a very small prop shaft.

cloudy - 21/12/06 at 09:11 AM

I bought the entire rear axle from ebay. Then took the diff out of the casting, knocked the bearings off - made up some spacers and fitted sealed

block units. Then had B&C express make up the correct sprocket to match up with the crown mounts

James

andyd - 21/12/06 at 10:48 PM

quote:

Originally posted by cloudy

I bought the entire rear axle from ebay. Then took the diff out of the casting, knocked the bearings off - made up some spacers and fitted sealed

block units. Then had B&C express make up the correct sprocket to match up with the crown mounts

Ah right you did it the easy way then!

Doug68 - 22/12/06 at 12:25 AM

The fuel tank looks relatively small 20L or less?

If thats the case why not put it on top of the engine behind the roll bar, essentially where it'd be on the bike?

I had a 1993 GSXR-1100WP it didn't have a fuel pump so going for gravity feed may be cause less aggro in the carburation dept.

Given a small tank i don't think the change in height of the CofG would be much to worry about.

cloudy - 22/12/06 at 09:32 AM

yeah i'm tempted to do it that way, trouble is the shape, its very tall and thin - I was hoping to have the nice curved back polished and

engraved with the logo for that extra something, so wanted it to be on show. I know 7's have it right at the back, but they have the fibreglass

offering *some* protection. What do people reckon?

James

gttman - 22/12/06 at 09:48 AM

On your car I'd put it between the front wheels if there is room, this is what I have done and it keeps the variable weight low and protected by

the chasis.

Most ideal place for it though is right in the centre of the car, but not very practical.

cloudy - 22/12/06 at 09:54 AM

I'm hugely lacking in space at the front end, I *might* manage it but it would be VERY close to a front impact, just a bit of a worry

James

iank - 22/12/06 at 11:04 AM

I've seen triangular (prism shaped) tanks that fit behind the seats. Good weight distribution, but you lose the helpful little space that can be

used for weathergear and an emergency toolkit.

Minicooper - 22/12/06 at 05:47 PM

quote:

Originally posted by iank

I've seen triangular (prism shaped) tanks that fit behind the seats. Good weight distribution, but you lose the helpful little space that can be

used for weathergear and an emergency toolkit.

The Atom has the tank behind the seats see piccie, but it doesn't look like you have the room with the bike engined being further forward than a

car engine would be

What wheelbase are you going to have? I know it would be a total pain but a few more inches always helps......probably the safest bet

Cheers

David

[Edited on 22/12/06 by Minicooper]

sgraber - 22/12/06 at 06:05 PM

I'm really intrigued by your chassis shape and I think it has a lot of potential. It just looks 'fast' sitting still and that's

great. I would like to know about the sightlines for the driver and have you done any modeling or research into that and let me tell you what I am

thinking. The trouble right now is the side bar and the head, Your current seating is very upright. So why not recline the seating position

drastically and get the noggin below the bar? Then remove the crosstube in front of the passenger area, replaced by a triangulation brace forward.

That would open the sight line to the front, and lowering the head would give you a sight line out between your top tubes?

Just an idea....

Graber

thomas4age - 22/12/06 at 06:23 PM

I don't now how wide the area between the seats is, but MR2 MK1's have very slim tanks in the transmissiontunnel, maybe one of those would

fit your needs,

they're steel items so easily modified

here's a piccie

That would sureley be the best spot to put the tank cog wise and safetywise

Nice going there btw!

grtz Thomas

[Edited on 22/12/06 by thomas4age]

gttman - 22/12/06 at 06:44 PM

quote:

Originally posted by cloudy

I'm hugely lacking in space at the front end, I *might* manage it but it would be VERY close to a front impact, just a bit of a worry

James

Why is it a worry... it'll be better protected than a tank at the rear and further from the driver and no hot engine to ignite it!

And its not always the front of the car that takes the impact in a crash, you just as likelly to go backwards into a hedge or get hit from behind etc.

Doug68 - 23/12/06 at 08:56 AM

The thought with my previous post was to tip it so the flat was on the bottom.

I'm sure I've seen more than one trike with a beer keg as a petrol tank and those things are near indestructible (the keg that is)!

In my design the tanks on the floor behind the seats BTW, but I want to have 40L+ on tap.

Dick Bear has really neat pictures of doing it this way where he used 2 separate tanks.

Merry Christmas!

erwe - 23/12/06 at 08:16 PM

quote:

Originally posted by cloudy

I was thinking of perhaps redoing the chassis when I got bored, and i'd like to loosely base the design on this:

James

Do you more information or pics of this desing?

cloudy - 23/12/06 at 11:12 PM

To answer your comments,

sgraber - many thanks, re: the seats - that's the current plan, but as you rightly point out reclining the seats may bring out serious visibilty

problems, at the moment it's fine - I will have to do a bit of experimentation when it's warm enough to get back out to the garage

erwe: That car is an australian concept I can't remember the name - it's similar to the caparo T1, will post if i can think of it

EDIT: It's the "Hulme F1"

as regards the tank, it fits well where it is, and would be great for a logo, (see latest renders) - any comments on whether this is safe

'enough'

J

[Edited on 23/12/06 by cloudy]

kb58 - 24/12/06 at 12:32 AM

I haven't read the entire thread, so maybe I missed it, but my only concern is how close the driver's head is to the side bars. As long as

the helmet isn't optional.

Other than that, I think it's fantastic.

gttman - 24/12/06 at 11:02 AM

Well the tank does have some chasis protection at the rear, my only real concern is that it is above the engine so if it does get damaged.......

But lets be realistic here, bikes have them above the engine, and many other kits have them completely unprotected and by the engine.... so if thats

what you want, go for it.

Now its been pointed out, Kb has a very good point about how close your head is to that top rail.

cloudy - 24/12/06 at 01:27 PM

yeah its been pointed out numerous times, I have a few ideas - the only practical one so far is to step the curved tubes lower for the cabin but it

totally ruins the lines - Still scratching my head on this one.

tank would be behind the engine (over the diff)

J

James

gttman - 24/12/06 at 04:47 PM

How about lowering the top one 2inches or so and also the one below it by similar amount.

Have you also considered curving the lower bar to a similar shape to the upper one? I think that would compliment the lines well.

BTW It's looking awsome at the moment, great project.

cloudy - 24/12/06 at 05:54 PM

the lower half has all been built as per my other version, I don't want to have to rip up any more than I have already.....

James

JoelP - 24/12/06 at 06:24 PM

Id be happy with the tank there. Maybe use a fuel cell inside the metal tank? Dont know lots about them but some sort of tear proof tank sounds a good

idea

dr-fastlane - 25/12/06 at 11:54 AM

Hello James,

Because I had nothing better to do on this Sunday morning. I did some brainstorming, how to get the upper curved tubes free from the driver’s head.

And not to disturb the lines of your buggy. Probably taking the upper tube higher, would be the only solution to not hit your head. And it makes it

easier to get in and out of the car. Perhaps you can do something with this idée.

Happy Christmas, greets Roy.

Rescued attachment roofless_sketch.JPG

cloudy - 25/12/06 at 12:03 PM

interesting approach, I'll have a play about with it - thanks

akumabito - 25/12/06 at 08:24 PM

I don't like the high bars..

Just make it a center-steered single-seater!

JoelP - 25/12/06 at 09:00 PM

i like the high bars myself. I would also make it a centred single seater, but have a pair of 'seats' on either side (more like padding and

harnesses) so that you can still have passengers. I know a bec isnt ideal for a 3 seater but when theres no one in it, its only a few kilos extra, and

i think the centre driving position would make up for it - especially the better corner balance.

cloudy - 25/12/06 at 11:36 PM

quote:

Originally posted by akumabito

Just make it a center-steered single-seater!

sooooooo tempting!

Sven - 26/12/06 at 07:33 AM

I wonder if you could cross those top two tubes or make a halo and join the front and rear to the halo?

-Steve

designer - 26/12/06 at 02:42 PM

This style has been done before

http://twintechcars.com/

Alan B - 26/12/06 at 03:40 PM

quote:

Originally posted by JoelP

......... I would also make it a centred single seater, but have a pair of 'seats' on either side (more like padding and harnesses) so that

you can still have passengers..........

Ohhh...sounds familiar...

JoelP - 26/12/06 at 03:51 PM

must be a good idea then! I have plans from '04 and a lawyer at the ready!  lol

lol

cloudy - 26/12/06 at 04:57 PM

quote:

Originally posted by designer

This style has been done before

http://twintechcars.com/

that's awfully malproportioned, not keen!

Ratman - 26/12/06 at 11:54 PM

I like this chassis. I like the high bars. When you compare frame designs, ask yourself, which one whould I prefer to be strapped into when the car

rolls through the fence and down a bank. High bars win. Note that F1 cars have special inserts each side of the cockpit to limit the sideways movement

of the helmet. Obviously the bars will need to be padded. I like the idea of making the finish shape of the car in the frame. But this can have weight

liabilities if the resulting frame shape gets compromised when it comes to getting ridged support to the suspension etc mounting points. Permission to

rave sir? My preferred concept is (a) make the suspension and engine mounts and seat mounts and roll-over protection frame. (b) locate all these in

space. (c) joint them all with straight tubes (d) make it all triangles with extra tubes (e) make closed solid shapes (pyramids etc) with more tubes

to give torsional stiffness (f) then start making compromises and contrivences so there is actual space the the engine and driver etc... but try not

to compromise the step (e) structural achievements. Shouldn't need to use anything stronger than 20mm ms tube with 1.6 wall. Might not look so

svelt, but gets best stiffness for weight. Cheers, Brian

kreb - 27/12/06 at 03:46 AM

If I may chime in, the overall design is quite pleasing to the eye, but as has been previously noted, the high side bars are lethal. Also very

important is that they'll be a distraction and create a claustrophobic effect. If you've a light car, it should feel light, not like a

coffin. Don't be a slave to fashion.

kb58 - 27/12/06 at 06:12 AM

The side tubes appear to be at eye-level. If so, the driver has no peripheral vision, and to see what coming from the sides means raising or lowering

the head to see above or below them.

cloudy - 13/1/07 at 08:13 PM

OK, two possible solutions - after some feedback from you guys...

iank - 13/1/07 at 08:33 PM

I'd vote for the second option. Looks less fussy to my eye, and can't obscure vision to the mirror (might just be the angle it's

rendered) or the front wheel (nice to see exactly where you are putting it.

Mansfield - 13/1/07 at 09:03 PM

Second option me definately. I laid out the basics of a midi design in CAD and came up against all the same problems as you. I had to get rid of the

files as it was driving me mad. I really admire the work you have done so far.

I can't photoshop it but I quite like removing the top rail as your second picture, replacing it with the bracing as you have from the scuttle

back down to the mid (or new top rail) AND similar bracing from the rear down to the mid (or new top rail) at around a 45deg angle. To me it looks

better with the extra triangle.

I quit the idea of making my own middy because it took me a year to decide between a +4 and a +442 Locost and I realised I would never build a thing

at my rate of descision making.

I am following your progress (and JC's) with immense interest, I wish I had the bottle to go for it as you have. I think your car is fantastic.

cloudy - 13/1/07 at 09:09 PM

thanks both of you

I prefer different soluctions depending on the angle viewed, I'll play around with a few more ideas.

Mansfied, i'll give your idea a spin later, just have to avoid introducing the problem again, as anything there is instantly close to the head

James

Dick Bear - 14/1/07 at 03:49 PM

James,

I haven't kept up with your thread in a while but did my usual backwards reading of it today. It is great to see the progress and the

suggestions at each stage in your design process. Brings the best out in everyone! The result so far is a great looking and a promising solution to

an original build... keep it goin'!

I wish you had picked up the moon rover just once so we could see its' camparable size. Pushing the barrel up the hill was the only time that a

perspective of size could be judged.

I'm sending the clip to my son in California who is an active DP (Director od Photography), thought perhaps he would be interested in its use in

filming from angles and environments not suitable for current rails, slides or other contraptions.

Now if you can only make the little monster clean up the junk in your yard.... you'd really have something!

Kidding, of course!

Dick Bear

cloudy - 14/1/07 at 04:13 PM

I'm baffled by your last 3 paragraphs?

James

Dick Bear - 14/1/07 at 06:49 PM

I'ms sorry James that was a bit of a curve ball but wasn't meant to be.

I was refering to the link you posted on page 5 of this thread and the video of the RC car. That's what i get for reading things backwords. The

first intallments are thought of as the most recent and sometimes I forget that what is news to me is old news to those who do things more

conventionally.

http://www.digital-car.co.uk/video/trials.wmv

I hope this makes sense to you now.

Dick Bear

cloudy - 14/1/07 at 07:44 PM

ah right with you now. It was way too big and heavy for the usages I require - so it's currently being scaled down. Going back to tracked drive

to allow it to use stairs...

tadltd - 15/1/07 at 11:54 AM

Put the tank behind the seats, there's plenty of space (so it could be bigger), it's safer, AND it improves weight distribution.

quote:

Originally posted by cloudy

as regards the tank, it fits well where it is, and would be great for a logo, (see latest renders) - any comments on whether this is safe

'enough'

[Edited on 23/12/06 by cloudy]

[Edited on 15/1/07 by tadltd]

akumabito - 15/1/07 at 02:10 PM

Designwise I prefer the first option, although as other have pointed out, the second option is much more practical.

rav - 16/1/07 at 12:19 PM

Love it!

Really fresh concept, that front end looks spot on IMO and I think using panels here and there as needed rather than hiding everything in a jelly

mould is a very good idea.

I'm a beliver in form follows function so I tried extending the tubes in the second render so they run right back to the roll hoop, which should

make the chassis stiffer and probably a bit stronger.

Also added another diagonal bracing the roll hoop. Is it a bit too functional??

Fuel tank in the space behind the seats seems logical to me too - keeps it low and central, and in the part of the car which is best protected in a

crash - at lleast you'd hope so if you're going to be strapped in there!

Someone mentioned fitting exhausts in. If space is a problem, they could be run forwards between the seats in a very narrow 'tunnel', which

needn't be structural - just folded ali sheet for example. Then exit at the front somewhere, may help with fitting in silencers as well. Its

worked pretty well that way on my middy project - see pics.

Not sure how that would work if you had tank behind the seats as well though.

Anyway, just some ideas to add to the pot, keep up the good work!

Rescued attachment middy car.jpg

cloudy - 16/1/07 at 12:39 PM

I quite like the straight tubes actually, they echo the tube below nicely, I also like the extra bracing on the roll hoop.

have actually welded the roll hoop to the chassis at the weekend, but found despite many measurements sitting in the car - I just dont feel it's

high enough to be safe without having a very laid back driving position. Trouble is as soon as I put even just the 8cm rise I calculate will make it

safe, it destroys the proportions entirely

I will produce some more updated renders with the revised roll hoop tonight, you guys are always great for fresh idea's

James

cloudy - 16/1/07 at 12:59 PM

OK easier to just photoshop the change on, here's it with the revised height. Those rear braces certainly help to avoid it looking like an after

thought towering above the chassis.

But it still look a lot less sleek than I'd hoped for. Obviously this is a fixed measurement - any ideas where i might be able to rescale to

reduce the apparent height?

James

[Edited on 16/1/07 by cloudy]

[Edited on 16/1/07 by cloudy]

akumabito - 16/1/07 at 01:21 PM

Hmmm, the high-hoop is definitely less sexy looking, but safety is more important than looks, I guess.

I still like this look best though, it gives a really nice look to the car:

Perhaps you cold try something like that again? With the higher rollbar you just might have enough headroom..

I guess that would make it more similar to this:

Idunno... it may make things easier if you'd ever decide to fit weather gear

cloudy - 16/1/07 at 02:10 PM

truth is none of these designs appeal to me like the original one with the complete curves did - it's just starting to look boxy like the first

one did again. Might revert to this design and try and again find a solution to the head + visibility problem...

James

sgraber - 16/1/07 at 04:11 PM

quote:

Originally posted by cloudy

truth is none of these designs appeal to me like the original one with the complete curves did - it's just starting to look boxy like the first

one did again. Might revert to this design and try and again find a solution to the head + visibility problem...

James

[Edited on 1/16/07 by sgraber]

cloudy - 16/1/07 at 05:07 PM

I hear's you  still cannot see any traffic to the left or right though

still cannot see any traffic to the left or right though

sgraber - 16/1/07 at 09:45 PM

quote:

Originally posted by cloudy

I hear's you  still cannot see any traffic to the left or right though

still cannot see any traffic to the left or right though

You're right. Visibility in many directions is a huuge issue with your best looking design, even if you can solve the head against the steel tube

problem the visibility problem will not go away...

Doug68 - 17/1/07 at 07:21 AM

I feel your pain.

Go back to the beginning keep what you liked ditch the rest and keep going until you get something that works.

And remember whatever you make will be better looking than the thing below

Rescued attachment pontiac_aztek_2001_01_b.jpg

gttman - 17/1/07 at 08:37 AM

quote:

Originally posted by cloudy

have actually welded the roll hoop to the chassis at the weekend, but found despite many measurements sitting in the car - I just dont feel it's

high enough to be safe without having a very laid back driving position. Trouble is as soon as I put even just the 8cm rise I calculate will make it

safe, it destroys the proportions entirely

I will produce some more updated renders with the revised roll hoop tonight, you guys are always great for fresh idea's

James

I went through the same thing on the GTT and ended up raising it around 80mm higher than I planned as safety overuled looks.

cloudy - 17/1/07 at 11:53 AM

looks like that's the magic measurement then!

James

gottabedone - 20/1/07 at 04:04 PM

James,

your original design is cool but the progressive edits are moving further from what you wanted and closer to many designs that have already been used

- Atom etc. etc.

Keeping the reclined seating, are you able to scale up the design slightly and raise the offending top rail and incorporate it as a roof line? Maybe

use gullwing doors or Nova styled front hinged roof. You could then keep the original proportions.

regards

Steve

cloudy - 17/2/07 at 02:40 PM

Working long hours at the moment, so not much progress - but I finally got the correct fuel parts, so I gave the engine a good thrashing. Gives me

some inspiration to keep going!

cloudy - 21/2/07 at 02:05 PM

With some inspiration I saw on MK engineerings site for a roll bar, I think i've cracked the issue with making a roll bar that's tall enough

for safety that also doesn't make it look overly tall

I see you've been working your magic again in the MEV thread Fuoriserie - feel free to experiment on mine too!

Thoughts?

Oh and also - I know you all like videos here's that engine run up from last weekend. Don't worry the engine was up to temp and I was just

checking the rev limiter...

http://www.digital-car.co.uk/wr4/r4_engine.wmv

gttman - 21/2/07 at 04:00 PM

it certainly ticks the boxs for me

sgraber - 21/2/07 at 04:40 PM

I must say, I REALLY like that shape. I think you nailed it.

iank - 21/2/07 at 04:43 PM

Agree time to tack tubes I'd say.

FUORISERIE - 21/2/07 at 09:59 PM

quote:

Originally posted by cloudy

I see you've been working your magic again in the MEV thread Fuoriserie - feel free to experiment on mine too!

Thoughts?

http://www.digital-car.co.uk/wr4/r4_engine.wmv

Thanks....will see what i can do. , but yuo've done a great job so far!

, but yuo've done a great job so far!

[Edited on 21/2/07 by FUORISERIE]

Doug68 - 22/2/07 at 12:43 AM

Looks superb

If it were me and for give the rubbish photochop I'd make the mods below:

Also the front tube going over the dash is shown as 3 bits welded together if this were one bent tube with the fore-aft tube butting into it it'd

look much better I think.

Top man for sticking at it!

Rescued attachment altrollbar1.jpg

Fred W B - 22/2/07 at 06:05 AM

I also wanted to suggest Doug's mods.

Cheers

Fred W B

rpmagazine - 22/2/07 at 08:51 AM

Doug has a point, the previous setup would risk folding in half in a serious rollover.

cloudy - 22/2/07 at 10:56 AM

I like you're thinking doug although it would be destroying a lot of chassis that has already been built - would look something like this....

[Edited on 22/2/07 by cloudy]

[Edited on 22/2/07 by cloudy]

[Edited on 22/2/07 by cloudy]

Doug68 - 22/2/07 at 12:39 PM

Yep, that's it.

cloudy - 4/3/07 at 06:28 PM

I'm moving forward with this new design - thanks everyone for the great input

Sorry about the messy garage!

cloudy - 5/3/07 at 04:58 PM

OK the fun old job of mounting the steering rack this coming weekend. I've bought myself a laser level to visualize my bump steer, but where

should I be mounting rack fore/aft? should the rack arms be straight at centered steer?

James

Doug68 - 7/3/07 at 12:58 AM

Go get yourself a copy of the Race & Rally Car Source book it'll explain what you need to do better than any answer you'll (probably)

get here.

[Edited on 7/3/07 by Doug68]

cloudy - 13/3/07 at 01:38 PM

It's too quiet in the middy section of late, we are all slacking!

Last weekend I put my new digital angle gauge to good use, by setting up the front suspension for 6 degrees of castor. Also tested out the laser level

method of bump steer checking, which seems to work a treat. Next weekend I hope to get the rack positioned and mounted. Cleared up the build area a

little....

A bigger job is to extend the car to give another 10-15cm in the cabin, another mis-calculation on my part

All part of the learning experience I suppose - although I seem to be having more of the experience than most

Another render as I'm bored in work today!

cloudy - 16/3/07 at 06:46 PM

any comments on suitability/improvements to this rack mount i've designed? It's based around the locost mount, but uses 3mm plate boxed into

an L profile for strength

Alan B - 16/3/07 at 07:51 PM

I'd brace directly between the mounts parallel to the tubes as close as possible to the rack and then use just one diagonal.

cloudy - 18/3/07 at 08:07 PM

Something strange happened when I tried to position out the bump steer, the rack had to sit a lot lower than the line between the pivots rule would

suggest.

I believe the reason for this is because of the unequal length wishbones, which obviously add camber in bump, which in turn move the steering arm in

and toe out occurs. Presumably this applies to locosts that also have unequal length wishbones, I cannot see any others with such a low mounting

point however?

Any ideas? Should I just go with it here as it's resulting in least bump steer - or do I have another problem at play here?

Ratman - 19/3/07 at 03:41 AM

I resently worked through a similar rack and bump-stear problem with a friend's car. I suspect, that low position that you have indicated will

give a small amount of bump stear with small suspension movement, and then will get very bad if the suspension moves further.

Long and short wishbones is not a problem. But the suspended tierod needs to be in proportion. As an initial set up, if the outer end is at say 30% of

the vertical distance between the suspension joints, then it should also be 30% of the vertical distance between the suspension joints at the inboard

end. The length of the suspended tierod should then be proportional to it's location. i.e. average of upper and lower wishbone if it is located

at mid point, ands correspondingly longer or shorter if it is not.

When I was doing this we made up a very crude dummy tierod for one side and made endless 5mm adjustments with clamps and blocks of wood etc. Using a

two meter long bar attached to the hub, to measure bump stear, you can expect to get the end of a 2m bar staying within 20mm of a vertical line as

you move the hub up and down 200mm.

because there are several dimensions that you can change, and you can't be sure what the effect is going to be, keeping good records of your

trials is important. We used a spreadsheet to plot the results, and that helped zero in on the optimal tierod length and inboard location.

You are very likely to find that your rack is too long or too short. Nothing you can do about this except change the length some how. be sure that you

have the ackerman angles that you want at this stage, as any change in the stearing arm on the hub for this reason will directly affect the length of

the rack, if you want to keep zero bump stear.

let me know if you want more (clearer) description of the way we did this.

Cheers, Brian

gttman - 19/3/07 at 09:18 AM

looks like the rack is too wide to me.....

cloudy - 19/3/07 at 09:36 AM

That's the odd thing though, it is adhering to the proportion rule in that it's sitting proportionally about the same height as the steering

arm. I'm only measuring around 2 cm of deviation of the laser on the wall about 4 meters away, which by my calculations is about half a degree of

bump steer, which must be pretty good?

James

Ratman - 20/3/07 at 06:59 AM

That sounds very good. For that deviation, is that moving the hub through it's full range of suspension movement?

cloudy - 20/3/07 at 02:33 PM

damn, now the bump steer is better (rack still needs shortening) The TRE's bind at full bump

It would be ok if the pivot went through the uprights, upright - but its at a funny angle, common problem?

James

cloudy - 2/4/07 at 01:54 PM

I don't know if you stumbled across my other threads, but was basically having all sorts of travel issues.

I've managed to get around this by raising all mounts and moving upper mounts inboard allowing for a longer top wishbone (via adjuster) and

therefore less angle on the top joint for a given deflection...

(The top mounts will be webbed in, just temporarily mounted in the pic)

Only complete on one side, but happy to be over this hurdle. Well aside from needing to find different TRE's or bend the rack ends

I promise better updates soon!

[Edited on 2/4/07 by cloudy]

[Edited on 2/4/07 by cloudy]

FUORISERIE - 15/4/07 at 01:05 PM

quote:

Originally posted by cloudy

I don't know if you stumbled across my other threads, but was basically having all sorts of travel issues.

I've managed to get around this by raising all mounts and moving upper mounts inboard allowing for a longer top wishbone (via adjuster) and

therefore less angle on the top joint for a given deflection...

(The top mounts will be webbed in, just temporarily mounted in the pic)

Only complete on one side, but happy to be over this hurdle. Well aside from needing to find different TRE's or bend the rack ends

I promise better updates soon!

[Edited on 2/4/07 by cloudy]

[Edited on 2/4/07 by cloudy]

Looking very good so far, any updated pictures of your project? I like how it's progressing........

Cheers

Italo

cloudy - 27/5/07 at 08:11 PM

Sorry no updated pictures yet - i've been slacking!!

I have a new render though

DIY Si - 27/5/07 at 08:31 PM

Just stop doing renders then you lazy bum!

Looking good though so far.

cloudy - 27/5/07 at 11:11 PM

I'll go out and get cracking tomorrow if the garage isn't underwater of course....

[Edited on 27/5/07 by cloudy]

FUORISERIE - 4/6/07 at 09:12 AM

quote:

Originally posted by cloudy

Sorry no updated pictures yet - i've been slacking!!

I have a new render though

Nice rendering, is that a RHINO 3D Render? or 3DMAX?

Looking forward to more, and keep it up

Ciao

Italo

cloudy - 8/6/07 at 04:46 PM

That's 3dsmax using the mental ray renderer

James

FUORISERIE - 10/6/07 at 09:42 AM

quote:

Originally posted by cloudy

That's 3dsmax using the mental ray renderer

James

James,

I should get you to work on a few of my sketches..... , your talent with 3dmax is great...

, your talent with 3dmax is great...

Italo

cloudy - 20/6/07 at 09:44 PM

Bit more done on the chassis:

Here's a pic with the roll bar taped on at correct height - looks huge in comparison to the rest, any good ideas for a clever shape or reducing

the height i'll need?

Tralfaz - 20/6/07 at 11:05 PM

Painting the bar darker than the frame should reduce it's impact.

T

Doug68 - 20/6/07 at 11:39 PM

What's it look like when someones sitting in it?

I expect it will look just right then.

To me aesthetically it looks just fine the way it is.

If you don't like it though maybe disguise by mounting the rear wing off it or something like that?

cloudy - 4/7/07 at 08:27 PM

Thanks to 'rickys2000' for lending me his engine hoist - which will allow me to drop the engine in saturday!

James

FUORISERIE - 4/7/07 at 08:30 PM

That looks really good.........I like your latest chassis design.....

Italo

cloudy - 7/7/07 at 02:59 PM

The engine is mounted, I couldn't resist starting it up (with the help of some gaffa tape!) - here's a vid

http://www.digital-car.co.uk/wr4/r4firststart.wmv

and some pics:

[Edited on 7/7/07 by cloudy]

sgraber - 8/7/07 at 12:07 AM

It looks simply SMASHING!!!!

Can you tell me the wheelbase and width (out to out) front and rear?

kb58 - 8/7/07 at 12:25 AM

quote:

Originally posted by cloudy

The engine is mounted, I couldn't resist starting it up (with the help of some gaffa tape!) - here's a vid

http://www.digital-car.co.uk/wr4/r4firststart.wmv

[Edited on 7/7/07 by cloudy]

"Windows Media Player cannot play the file because a network error occurred. The server might not be available. Verify that you are connected to

the network and that your proxy settings are correct."

Doug68 - 8/7/07 at 03:58 AM

It works OK for me, a bit slow to buffer but it gets there.

you could also right click and "save as".

Its coming along nicely!

I particularly like the part where you duck in to get the ear defenders!

And the exhaust routing may need a bit of a rethink

cloudy - 8/7/07 at 11:13 AM

Steve,

Wheelbase: 229cm

Track front and rear(out to out) 162cm

James

cloudy - 25/7/07 at 08:36 PM

Thanks to some rack extensions from MAC#1 i've installed the steering system.

It feels fairly smooth - but does this look like too much of an angle for the UJ? (It's around 45 degrees)

[Edited on 25/7/07 by cloudy]

sgraber - 26/7/07 at 01:04 AM

I think that angle will be ok as long as you don't feel a 'hitch' at any specific point as it rotates?

However... I am not too happy with your rack mounts. At least not if you are leaving it that way... They should be much beefier.

quote:

Originally posted by cloudy

Thanks to some rack extensions from MAC#1 i've installed the steering system.

It feels fairly smooth - but does this look like too much of an angle for the UJ? (It's around 45 degrees)

[Edited on 25/7/07 by cloudy]

Ratman - 26/7/07 at 05:23 AM

maybe you could replace the fibre disk joint with a UJ and split the angle between the 2 UJs. this way you can get exact CV between the steering wheel

and the rack. I have been surprised to find how many cars use common splines in their steering systems. If you use Toyota stuff you can find shafts

and UJs of all lengths that can be cobbled together.

cloudy - 26/7/07 at 12:18 PM

Good idea - I think rally design sell a compatible UJ

There is no notching of the UJ, just thinking about logievity

The rack mounts are not finished, I have both an X brace to prevent sideways movement and a another two to prevent any fore-aft movement

nkosta - 26/7/07 at 01:07 PM

Hi !

It is time to promote this design in to Mk I ( beta version ) of official locostbuilders`s mid engine car?

Many good and competent gay are included in discussion and I suppose that exist general agreement about look and strength and easy to build quality

of this particular design

Or I am wrong and this is only special BEC construction not strong enough to carry MOST of contemporary FWD car modules (many Japan models , WV ,

PSA group of France etc. .. etc)?

I am sorry not to hear Rorty opinion here (read historical tread : http://locostbuilders.co.uk/viewthread.php?tid=34017 )

At least I am middle aged man ( mid.... if you assume that life expectancy are about 100years!) and not have a time to wait next 50 y. for new FWD

locost.

Spend last 2-3 y. on the NET looking for something that I can build ( in the first time buggy , lather super 7 and at the end middy with Suzuki

Swift 1.3 GTI module ...single seater may be for general safe?)

My "neighbor" kikiturbo have nice space frame single seater and I waiting for final conclusion

after careful FEA work (whatever mean that).

May be I can finally bay plans from somebody similar to Book Design and finish little screamer before going to die("Never attempt to build

locost after 40thy probably you not drive them"

cheers to all

[Edited on 26/7/07 by nkosta]

Alan B - 26/7/07 at 05:15 PM

quote:

Originally posted by nkosta

....It is time to promote this design in to Mk I ( beta version ) of official locostbuilders`s mid engine car?......

As much as like Cloudy's car I'm obviuosly going to answer no......I think all of us doing our own thing would probably say "no, pick

mine instead"......IMO it's down to someone building one, writing a book, offering parts etc.....until then we'll go our own

way....which isn't necessarily a bad thing.....

cloudy - 26/7/07 at 08:16 PM

I wouldn't even volunteer my own car for it! I'm brand new to all this and i'm making it up as I go - far better designed by someone

with experience...

James

nkosta - 27/7/07 at 08:05 PM

With all my heart I support diversity ( ..of species ....Charles Darwin my favored tuner ) And concern and modesty of some"non

experiencing " but generous people .... but IMHO its time that Lord ( Law and Order) take things in hands ' '

'

I t is time to make some basic recommendation about tube material ,cockpit , front end , front suspension etc. .. etc at least in level of so many

Book design ? . Ariel Atom established one particular point of view and slowly become standard. Especially with this large-long- curved good looking

tubes up ( a MUST for mid engine?) . It is time to identified a couple most affordable front end donor? .. across the world of course. Many good gay

almost finished their FEA-patran - nastran work

At the end this while help diversity its self

Good plan and numerous variants of this plan are key for longevity

Who are a Jim McSorley in mid-engine-transverse mounted kingdom?

(sorry splecheckered English)

Thank you for patience

kosta

[Edited on 27/7/07 by nkosta]

cloudy - 9/9/07 at 10:28 PM

It's still coming along,

Brakes are in and almost completed gear change assembly...

Have been throwing some idea's round for a 1+1 revision to the chassis to be completed after mk1 is complete - a few renders...

The basic layout:

Atomesque?

cloudy - 9/9/07 at 11:01 PM

The design for the "transmission tunnel" for the current car

cloudy - 21/9/07 at 04:45 PM

was hoping for some input there on the 1+1 design

Just weighed the car today, 345kg minus floor, exhaust and diff - on the heavy side!

I will definately have to rebuild the chassis at some point with lighter tube and be more intelligent with my space frame attitude

Weight distribution is 58:42 rear:front - sound OK for a middy?

James

thomas4age - 21/9/07 at 05:19 PM

wait a minute, your whole car weighs in at 345kg with engine and everything you need, exept exhaust, diff and 2 floor pannels? and you're on the

heavy side?

I can only dream........

grtz Thomas

[Edited on 21/9/07 by thomas4age]

cloudy - 21/9/07 at 05:25 PM

I was aiming for 350kg all in!

I must weigh my alloys at some point, I suspect the final wheels will weigh considerably less (16"

James

thomas4age - 21/9/07 at 05:34 PM

maybe team dynamics are something to look at those seem to very light and not really expensive

still I can only dream, that things going to fly, a Global GTlight weighs in at 380kg with an R1 fitted, yours is very light indeed

grtz thomas

[Edited on 21/9/07 by thomas4age]

cloudy - 21/9/07 at 06:01 PM

My 17 "wheels are 21.6kg a pop with rubber - how's this compare to a light 16"?

Just weighed all of the additional components to add - just a shade over 30kg's making a total of 375kg dry

Tralfaz - 22/9/07 at 12:18 AM

Light 16's with rubber should be down around 15-16 kg.

The 15's I am looking at are 11.5-12.8 Kg dependant on tire width.

T

Doug68 - 22/9/07 at 09:29 AM

Scour Tirerack.com for tyre and wheel data, there's a lot on there.

As for the 1+1 I've never seen this arrangment look anything other than fugly to me.

The roll bar won't protect the driver and the passenger never has any legroom.

We need to see more pics of the the current project coming along!

Confused - 22/9/07 at 09:02 PM

I echo the "more pics" comment!

Someone on my "local" forum posted this information up, might help if you try

to find some lighter wheels!

Garry

cloudy - 23/9/07 at 05:19 PM

I've made a temporary dash just to house the clocks for now: (Notice the gear lever - thanks Steve!)

Here's the spoiler i've just picked up in place - it needs one of the wings taken out and the whole thing made thinner. Hopefully this

avoids the chav looks it's currently adding to the car!

cloudy - 1/10/07 at 09:52 PM

OK, decided to remake the chassis properly now - the dimensions are a little large in passenger area. All the sus mounts will be kept in the same

locations though...

I know i'm seriously in atom territory here, but i'm not too bothered. Thoughts (back needs a little work)?

Fred W B - 3/10/07 at 05:25 PM

Looks awesome, seems you are also suffering what I am finding, which is that you work out how to do it better once you have actually made it up.

WRT the rear, if you want to even pretend the rear wing will work at all it needs to be higher.

Cheers

Fred W B

violentblue - 3/10/07 at 07:11 PM

the height of the rear wing, may not be functional, but looks much better than way up in the air.

FUORISERIE - 26/10/07 at 11:56 AM

quote:

Originally posted by cloudy

The engine is mounted, I couldn't resist starting it up (with the help of some gaffa tape!) - here's a vid

http://www.digital-car.co.uk/wr4/r4firststart.wmv

and some pics:

[Edited on 7/7/07 by cloudy]

I Like your chassis, are you going to sell plans for it ?, it does have potential

[Edited on 26/10/07 by FUORISERIE]

FUORISERIE - 26/10/07 at 11:58 AM

quote:

Originally posted by cloudy

OK, decided to remake the chassis properly now - the dimensions are a little large in passenger area. All the sus mounts will be kept in the same

locations though...

I know i'm seriously in atom territory here, but i'm not too bothered. Thoughts (back needs a little work)?

design looks good in my opinion, maybe an engine cover

cloudy - 29/10/07 at 07:27 PM

Maybe in the distant future when i've finished it and smoothed out any problems

quote:

Originally posted by FUORISERIE

]

I Like your chassis, are you going to sell plans for it ?, it does have potential

[Edited on 26/10/07 by FUORISERIE]

FUORISERIE - 31/10/07 at 04:16 PM

2008..??

quote:

Originally posted by cloudy

Maybe in the distant future when i've finished it and smoothed out any problems

quote:

Originally posted by FUORISERIE

]

I Like your chassis, are you going to sell plans for it ?, it does have potential

[Edited on 26/10/07 by FUORISERIE]

cloudy - 31/10/07 at 05:31 PM

2050?

nkosta - 21/11/07 at 06:43 PM

just watching

any progres or decision ?

cloudy - 25/11/07 at 02:55 PM

Little bit,

My homemade tube roller (my tube bender won't produce smooth large radius bends)

Yesterday's progress on the chassis:

Doug68 - 27/11/07 at 01:16 PM

The tube bender looks great!

I love this thread when you go back to page one and look at how this project has progressed its just great to see the evolution of it.

cloudy - 28/11/07 at 10:33 PM

Little more progress

FUORISERIE - 29/11/07 at 12:59 PM

Nice work on the new chassis..

Italo

cloudy - 29/11/07 at 03:22 PM

I'm making good use of some time off work!

cloudy - 29/11/07 at 08:56 PM

and some more

nkosta - 2/12/07 at 07:47 AM

perfect , just perfect shape! ( girl like )

Can you PLEASSSEEEE put on pictures some dimension (weight , tube diameter , wall of tube , steel quality , current Amp for welding , MIG or TIG

, material for welding)

I know its time consuming but while be of greatest help for rest of us

And final question : do you ,PERCHANCE , have some plans for this , just for reading before slip

, just for reading before slip

Mave - 2/12/07 at 09:31 AM

I love it. (but your "old" one was also very tasty)

But just a slight remark; your wishbones look a bit flimsy compared to the rest of the car. I've seen people using 40x20x3 elliptical tubing, and

I think that would look just great with the rest of your car. Again; I'm only referring to the looks of your wishbones, I'm not saying that

they're not strong enough.

nkosta - 2/12/07 at 02:26 PM

or, maybe,main tubes are slightly huge

never mind

Mr Whippy - 2/12/07 at 05:48 PM

wishbones look normal

cloudy - 2/12/07 at 11:03 PM

They are standard book locost wishbones - on a car I expect to weigh a good 100kg less than a seven. Should be plenty strong enough - allthough had I

not bought them early on, i'd probably had a go at it myself...

nkosta: I'm using 1 1/2" and 50mm tubing, both in 16g (bright steel)

I'm welding using a clarke 160en MIG - using 0.8 wire with just co2 shield

no plans as yet, i'm still rejigging things slightly as I go...

James

Mave - 3/12/07 at 06:39 PM

As I said before, I'm not referring to the strength, but purely the cosmetic part of the 'bones. I think it would look great when the

wishbones are more in line with the chassis, dimensionwise.

But each to his own of course!

nkosta - 6/12/07 at 06:11 PM

Thanks James

kreb - 6/12/07 at 10:00 PM

Am I the only one who thinks that you should throw some planking on the sides and a propeller on the back?!

Seriously, nice, clean work. Thumbs up!

cloudy - 7/12/07 at 10:55 PM

A little more progress on the front, just making up the rack mounts. I'm still ooming and aahing about my rack position in the fore/art direction

- any comments? I think i'm happy about where it is..

James

Echidna - 8/12/07 at 02:51 PM

Steering rack position is not for the faint of heart. You should "design" its position as it will determine the amound of bumpsteer you will

get.

kb58 - 8/12/07 at 03:13 PM

Moving the rack fore/aft sets Ackerman, a hotly debated issue as far as how much or little you need.

cloudy - 9/12/07 at 12:40 AM

Indeed, I have a test method for achieving zero bump steer, but on the ackerman side nobody has a clear answer - some people have more than that some

less!

James

nitram38 - 9/12/07 at 09:32 AM

Seeing as you have lots of space at the front, why not make an adjustable bracket in the plain where you have dialed out the bumpsteer?

That way you can experiment with the rack position if you are unhappy with the way it behaves.

hughpinder - 10/12/07 at 10:52 AM

In the picture of the front end of your car, it looks like the steering arms are angled further 'in' at the front, to a front mounted rack.

Surely they need to be 'out' at the front for ackerman steering???

Hope I'm not being stoopid here.....

Hugh

cloudy - 10/12/07 at 01:26 PM

It's standard cortina uprights so I assume its right - but I can see where you are coming from, anyone else have any comments on this?

sgraber - 10/12/07 at 01:41 PM

quote:

Originally posted by kb58

Moving the rack fore/aft sets Ackerman, a hotly debated issue as far as how much or little you need.

Agreed. My basic comment without hotly debating the issue of ackerman is that you should attempt to engage each steering arm in a direct plane with

the tie rods to avoid any unforeseen geometric changes due to the differences in the arc of motion caused by the steering rack not being in plane with

the outer tie rod ends. That's just my .02cents which are virtually worthless anyways!

My rack is foreward of my tie rod outers by a good 3 cm and it induces negative ackerman. (Being changed for the next one) This makes it difficult to

push the car at full lock. Never mind that people say a bit of negative ackerman makes a car more stable at high speeds. I wouldn't be able to

tell the difference.

nitram38 - 10/12/07 at 02:00 PM

That is why my rack is set at the same height as my bones (pivot same as bones for no bump) and straight onto my uprights:

Description

You can see where the tie rod goes at the top rear of the upright:

Description

[Edited on 10/12/2007 by nitram38]

cloudy - 13/12/07 at 08:14 PM

Can anyone comment on the best aluminium alloy for use as floor material?

6082 T6 or 5251 H22?

Aluminium alloy 6082 is a medium strength alloy with excellent corrosion resistance. It has the highest strength of the 6000 series alloys. Alloy 6082

is known as a structural alloy. In plate form, 6082 is the alloy most commonly used for machining. As a relatively new alloy, the higher strength of

6082 has seen it replace 6061 in many applications. The addition of a large amount of manganese controls the grain structure which in turn results in

a stronger alloy.

Aluminium alloy 5251 is a medium strength alloy possessing good ductility and therefore good formability. Alloy 5251 is known for work hardening

rapidly and is readily weldable. It also possesses high corrosion resistance particularly in marine environments.

Alan B - 14/12/07 at 04:15 AM

5251 is the one to use IMO...good formability

cloudy - 14/12/07 at 06:12 PM

reckon the rapid work hardening could cause a flintstone effect with all the flexing though ?

James

nkosta - 15/12/07 at 09:14 AM

just for ilustration:

russian Midy Lada Revolution 650 kg , 1600ccm 165-215 ks

http://autoreview.ru/new_site/year2004/n22/ladarev/1.htm

[sorry slightly of topic but i am suprised with this lada]

More on this place

http://www.locostbuilders.co.uk/viewthread.php?tid=79347

[Edited on 15/12/07 by nkosta]

[Edited on 16/12/07 by nkosta]

[Edited on 16/12/07 by nkosta]

cloudy - 28/12/07 at 02:55 PM

Had to take it out of the garage to spin round today - so I put some wheels on (completely wrong size - going for 195/45/15 I think) while it was

outside to get some idea of how it was progressing...

cloudy - 28/12/07 at 08:24 PM

Also a check layout check on the engine/diff combination...

I intend to have some driveshafts made up so the engine is able to sit centrally. Anyone have any comment on whether such a short chain is likely to

have alignment issues?

James

clanger - 1/1/08 at 06:34 PM

CURSE YOU !!!!!!

Just read your thread. Pure inspiration. Hats off to your design and ingenuity. Brilliant

I been umming and aarhhing about a RWD bike engine Mini project I'm planning and waking up in cold sweats about the design. Can't bring

myself to shell out £5K+ for a Zcars one, nice though they are

Your car makes my plans look like an infants school project, and me with 25 years engineering experience

What's your background, If you don't mind me asking ??????

Great stuff, best of luck. I'll be following closely from here on in.

cloudy - 3/1/08 at 12:20 AM

My very limited (I'm 22) background is IT - which is not proving very useful so far except with the CAD drawings!

I recommend you just go for it, if you look back in this thread you'll see it's taken a good few tries to get to this point so don't be

afraid to experiment

James

COREdevelopments - 4/1/08 at 07:30 PM

,22! by just reading all this thread tonight i would of never thought you the "creator" would be 22. not knockin you in anyway. im 24 and

would love to have come up with this design (btw can i copy it in the future as it looks the dogs balls)  any more progress?

any more progress?

cloudy - 6/1/08 at 02:52 PM

Engine's going in today - will have some more pics in the next day or two...

Just two of the latest renders showing the OZ alloys and the diff mounts...

COREdevelopments - 6/1/08 at 05:57 PM

just how do you do these detailed pics. they are amazing and must take a while??

how come got no pic archive?

Rob

cloudy - 6/1/08 at 06:10 PM

All made in 3D studio max - I still can't get my head around solidworks!

Benonymous - 7/1/08 at 01:08 AM

I'm trained in 3D Studio Max and I found Solidworks quite easy to use. The big difference with SW is that you have to be much more deliberate in

how you do things. Another snag is that Max is designed to let you make absolutely anything whereas SW is an engineering program. When I was

designing my chassis I found that it wouldn't put a weldment profile on a spline. It only wanted to play with arcs so I made my tube an arc and

worked with a regular shape rather than a custom one. Another downside is the rendering in SW. I don't have the 'Photoworks' package

so I'm limited to screen captures as far as I can tell. After using Max and Mental Ray, it's a real let-down! I'm still learning SW

and I no longer use Max but if you can learn Max you can easily learn SW. Hard to put down the familiar tools though

Alan B - 7/1/08 at 02:10 AM

I guess the difference is that 3DS max will let make anything on the screen...whereas the parts in SW you can make in real life (for the most

part)...