Hi All,

Decided I want to get into machining, and my neighbours father recently passed away leaving him his Myford ML7 and a shedload of tools. It's on a

stand, and seems to look in decent condition. It's been in their family since new but hasn't been used for around 3 years. He wanted £500

for it and that sounded fair so I'll be moving it into my garage later in the week.

Aside from new wicks, oil and a drive belt, is there anything else I should be doing? I intend to rewire it, since it's still got what looks like

the original wiring and I think it's from the 60's.

The last time I used a lathe was on wood in school so this is going to be a steep learning curve. Luckily I've got a friend who's going to

give me a few lessons, but that doesn't help with the setup haha.

It's also got a milling table with it, are these actually any cop?

Any advice is appreciated!

Oh, and it hasn't got a gearbox (Even if it had, I presume I could only cut imperial threads?) so I'm thinking along the lines of fitting a

pulley wheel to the lead screw and fitting a stepper motor on a belt drive so I can drive it from an Arduino and feed it at a rate appropriate for

metric. I might also fit one to the saddle so I can automate the whole lathe. Just a thought...

Get yourself a copy of 'The Amateurs Lathe' by J H Sparey

Yes a milling table is a useful accessory.

You don't need a gearbox to cut threads, you use different combinations of change gears to get the desired feed rates from the lead screw.

It's all covered in the book.

Have fun, it's a great journey.

ml7 must have a gearbox open the door on the left. you probably dont have the gears to change ratios though. theres lots of kit for them on ebay, rdg

tools are very good and quick for stuff. you can buy everything new for them still. read up on installation making sure evrything is level then

setting up for parrallel cuts etc to test.

and most of all start hoarding material to use in the lathe, thats what i find the hardest gettting material without paying big bucks

https://wiki.nottinghack.org.uk/images/e/e8/Myford_Super7_Lathe.pdf

heres a link to the manual for the lathe

quote:

Originally posted by hizzi

ml7 must have a gearbox open the door on the left. you probably dont have the gears to change ratios though. theres lots of kit for them on ebay, rdg tools are very good and quick for stuff. you can buy everything new for them still. read up on installation making sure evrything is level then setting up for parrallel cuts etc to test.

and most of all start hoarding material to use in the lathe, thats what i find the hardest gettting material without paying big bucks

I love my ML7 I also did the CNC thing from a PC laptop.

https://www.youtube.com/watch?v=JvU0Uo-ntZw

The CNC conversion took a long time and to be honest I have not used it that much. Made some spacers for a clock frame shown in the video.

The gearbox is a must have, you can do metric threads with a conversion cog.

My CNC conversion is metric I made a converter gear box for the lead screw to make the numbers work out easier for the stepper motor.

You can also get metric screws for the cross slide and tool post thingy.

Best of luck you will not look back. Your next toy is a CNC milling machine that I do use regularly, did the conversion on that also.

CNC conversion guide............................http://www.jeffree.co.uk/modelengineering.html

Find out how old your lathe really is.......http://www.lathes.co.uk/myford/page17.html

Thanks for the advice guys

quote:

Originally posted by Wadders

Get yourself a copy of 'The Amateurs Lathe' by J H Sparey

Yes a milling table is a useful accessory.

You don't need a gearbox to cut threads, you use different combinations of change gears to get the desired feed rates from the lead screw.

It's all covered in the book.

quote:

Originally posted by Wadders

Think the OP was expecting to see a quick change type gearbox.

quote:

Originally posted by theprisioner

Your next toy is a CNC milling machine

Well, I got it!

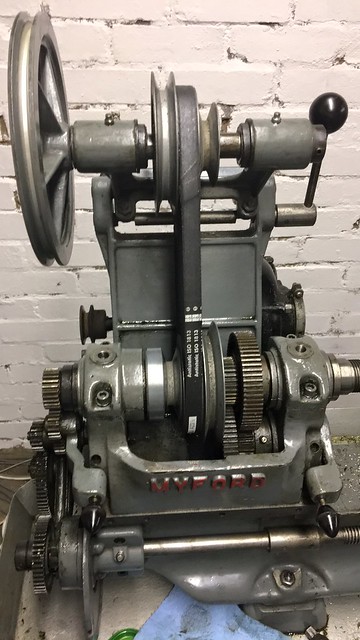

The first thing to do was give it a once over, and it was mostly in pretty good condition as it obviously hasn't seen a lot of use. I noted that

the drip oilers didn't really work and the belts definitely needed changing. Other then that I just striped, cleaned and re-lubricated most of

the moving parts and polished up the handles a bit.

Then I fitted the new belts:

Which was a bit of a pain as you have to remove the main shaft out of the headstock which has two bearings on it. Not difficult just annoying.

Anyway, got the belts in and the covers back on:

Then I stripped and cleaned out the oilers, re-assembled them and low and behold they work a treat!

Then I wired it into a fused isolator switch and an emergency stop button and it's all set:

I've also got to buy some round bar stock to practise on (stainless and aluminium) so if anybody has a cheap source for some other than ebay

I'd appreciate it

I've just been practicing, made a copy of a wheel spacer from my R1:

And started making a door knob for the bathroom haha:

Since I've not used a metal lathe before I think I'm doing OK considering all I've done so far has been learnt via youtube. I've

got a friend coming over this week hopefully to show me some more stuff (like threading) and then hopefully it'll just be a case of practice

makes perfect!

Avoid stainless steel for a while, as it can be tricky to machine; if the tool rubs at all the surface can work-harden and you'll never machine

it nicely. Saying that, there are some easy-machine grades available, especially through the model engineering channels. Good old cold-drawn mild

steel is best for early experiments - it's relatively cheap, easy to machine and can give good results.

ordinary mild steel - easy

brass - easy, but you need to change the cutting angle on the tools

aluminium - easy, but tends to clog the cutting edge

stainless steel - requires properly made cutting tools and good technique.

[Edited on 18/7/16 by David Jenkins]

Have a look near you for a machine shop the smaller the better then knock on the door and explain

what you have bought and how you do not want large amounts of stock and can you buy from the scrap

box and with a bit of luck they will be pleased to give you some material to work with.

I remember when our school got a new Myford but that was back in the late 50's, No computers then only log tables and slide rules.

Hope you enjoy your new experience as there is nothing better than making the things only you can see in your dreams.

Keep at it its most rewarding

Regards ALLAN

Next time you change the belt, see if you can hang another spare on in there too. It looks like there's room to zip-tie one to the left side.

It'll save having to pull the headstock to bits for a quick belt change.

Getting tool cutting point central is important. A quick way is to trap your trusty steel rule between the tool tip and the work piece. When the rule

is vertical, the tip is central.

And don't forget.....lathes are to make things flat too. I've skimmed cylinder heads and exhaust flanges on my lathe.

Just a thought on the emergency stop. It would be better on the front where you don't have to lean over the lathe to reach it. Ideally, keep one

where you've got it and put another on the front - even better a bar right across the base of the stand, so you can kick or stamp on it in an

emergency, without having to use your hands at all. Having said that, my father's that I nip round to use, hasn't got an emergency stop at

all

Yep, move that e-stop button (or as above, add another one). You REALLY don't want to have to lean over the lathe to hit it, especially as the reason that you need it stopped NOW is usually because the large jagged chunk of steel that you are machining at several hundred rpm has just come loose in the chuck.....