Z20LET into a Haynes Roadster

Ben_Copeland - 3/1/14 at 11:04 AM

Its time i posted up my build diary for fitting my Astra turbo engine into my Haynes Roadster, seems to be one of the next upgrades people might start

doing.

Firstly it started out with a NA 2.0 16V Vauxhall Engine C20XE so the conversion is a little easier for me. The Z20LET is a 2.0 16V Turbo engine,

very similar to the C20LET which is the Turbo verson of the C20XE. This all means that the existing bellhousing and engine mounts all fit straight

on, although the passenger side mount needs modifying for the boost pipe to go through.

Picked up a running engine and stripped stripping it all of bits i wont need anymore....

Picked up

Z20LET Engine Before

Cambelt

Its very busy this end and i dont like it !

Description

Thats better.

Next i need to replace the throttle body, the TB on the Z20LET is fly-by-wire and i cant run that on MS2 (or cant be bothered to work out how)

Throttle Body Removed

I've bought a throttle body of a X20XEV which is effectively a NA version of my engine (2.0L 16v from a vectra/astra etc)

Its fits straight on and converts to cable throttle, its slightly larger which cant be a bad thing.

New Throttle Body Fitted

I actually ended up turning this round 180 degrees so it fits better.

Throttle Body

[Edited on 3/1/14 by Ben_Copeland]

beaver34 - 3/1/14 at 11:05 AM

looks fun,

turbo 7 cars are great fun

Ben_Copeland - 3/1/14 at 11:25 AM

Next is to remove the sump which is massive and isnt going to fit, also i removed the balance shafts that are mounted over the crank. These sap power

and also add a massive weight to the bottom of the engine. Unfortunately they are oil feed from the crank bearing caps, so they need tapping and

filling so the oil doesnt come out !

Sump Off

Tapping Oil Feeds

Tapped and grub screwed.

Grub Screws in

Balance Shafts Removed

Caps back in.

The downside of removing the balance shafts is they also act as crank girdle so you either need to find a X20XEV crank girdle that doesnt have balance

shafts (early one maybe) or make your own.

Friend of mine sent me this to play with as it didnt fit with his sump....

Crank Girdle

Unfortunately i ended up having to cut it up as it didnt fit with my sump either, but strips are better than nothing.

Windage

I used the XE windage tray just cutting holes where the girdle stuck through.

I'm fitting a Caterham Alloy Sump from my XE engine, which just fits but ive had to modify the pickup pipe, using the head of the XE one with the

oil pump end from the ZLET engine. Its a bit of a faff to sort and unfortunately i didnt take a picture, but just make sure its got no leaks! I also

had to drill out the sump bolt holes because they are m8 instead of m6 like the XE, but easy enough to do.

Ben_Copeland - 3/1/14 at 11:39 AM

I then started checking over the turbo. It had been fitted with a VXR turbo and wastegate which is a popular power upgrade, pretty much a direct swap

and good for about 300bhp.

I had noticed the oil feed pipe was oily and one of the connections was at an angle..

Oil Line

Dumb Arse!!!

Took it apart and luckily i rescued it with a small file and a bit of patience....

Oil Line

Better.

I took the exhaust manifold off to replace the gasket and found 2 stripped threads in the head and rusted studs/nuts

They'll all need replacing before the turbo manifold can go back on... BALLS.

Exhaust studs

I helicoiled the 2 threads in the head and replaced all the studs. While the exhaust manifold was off i painted the block black to get rid of the Red

as it didnt match which my cars colours.

Painted Black

Also the turbo return pipe was held in with a bolt and self tapping screw and glue. WTF, how difficult would it of been to find another bolt for it.

Again, luckily! i managed to remove the glue and cleaned up the bolt hole. Replaced the gaskets and bolted it all back up.

Oil Return

I also binned the dump valve bits and fitted a nice alloy recirculation valve, back to standard...ish.

Recirculation Valve

maccmike - 3/1/14 at 11:47 AM

nice work keep the photos coming

Ben_Copeland - 3/1/14 at 12:01 PM

Moved back over to the inlet side and decided to check the injectors. As i thought standard, and not suitable for VXR turbo power.

I had some Rover 800 Turbo injectors lurking in the garage which are a direct swap, a lot more cc's. So i sent them off to Mr Injector to get

them cleaned and check etc.

380cc i believe @ 3 bar

Injectors

Refitted the rail. Done

[Edited on 3/1/14 by Ben_Copeland]

Ben_Copeland - 3/1/14 at 12:12 PM

Got a bit of a painting bug from doing the engine block so decided to do the camcover.

Rubbed down

Paint Prep

Primed with a etch primer

Primed

Undercoated white

Primed

Top coated with DynaRod orange and then lacquered to make it oil/petrol/heat resistant.

Painted

Didnt like the standard yellow oil cap, so rubbed that down and painted it black.

Painted Black

Also painted the bolts black too ;-)

Camcover finished

Fitted and finished with a Black VXR spark plug cover.

Ben_Copeland - 3/1/14 at 12:23 PM

Time to strip the old engine out of my car. Ive done this a couple of times so should be easy enough.

Fully assembled car including nosecone etc.

Engine Coming Out

Ok no nosecone in this picture...

To engine out on the bench in 1hr 15mins... not bad for an evening after work.

Engine Out in 1Hour 15mins

New engine hanging ready to go in.

Hanging

Engine in and bolted up to the gearbox. Driver side engine mount in and bolted up. Just need to modify the passenger mount to allow the bottom boost

pipe to pass through it.

IN

Forgot to say: the clutch is ford galaxy 2.8 friction and Vauxhall pressure plate. Using alloy bellhousing and type 9 box

Jumped forwards a bit to fitting the radiator and intercooler.

Intercooler

Next i made up some mountings for the fans, i couldnt get one big fan into the space behind the radiator so went for 2 smaller ones instead.

Double Fans

Radiator is a Honda Civic alloy racing one i bought off ebay and intercooler is a universal alloy one from ebay. Both cost about £75 each

[Edited on 3/1/14 by Ben_Copeland]

swanntech - 3/1/14 at 07:46 PM

Hi ben just fitting an xe engine to my roadster i am useing a metal yukspeed sump is it necessary to fit a windage tray as i dont have one in my xe

powerd grasstrack car

Ben_Copeland - 3/1/14 at 07:59 PM

Needed to change the Inlet Temperature Sensor, but couldn't find one that bolted straight into the manifold, so i had to buy an adapter and tap

that so the sensor could fit inside.

Air Temperature Sender

Went to refit the steering column extension, but it fouls slightly on the inlet manifold so i've had to put an extra joint in and rosejoint to

support it.

Steering Column

Still waiting on some nuts to fit it in place.

Next up is the alternator bracket, its one i made for the XE engine so ive reused it and it bolts up in the same place just needed spacing off the

engine slightly as it fouled on the cambelt cover.

The adjuster is made from 2 rosejoints, one right hand and one left hand thread with matching threaded bosses welded together with a nut between them.

Picture speaks a thousand words...

Alternator Mount

Next i managed to source a belt and new pulley for the alternator that matched the crank pulley.

Belt and Pulley On

Bought some silicone hose and joiners just before xmas and so i started fitting it all. Got a big list of pipework and connectors that i still need

to get, but its nearly there.

PipeWork!

I've also started to tidy up the wiring and using all the OEM connectors i can find.

Tidy Up

[Edited on 3/1/14 by Ben_Copeland]

Ben_Copeland - 3/1/14 at 08:00 PM

quote:

Originally posted by swanntech

Hi ben just fitting an xe engine to my roadster i am useing a metal yukspeed sump is it necessary to fit a windage tray as i dont have one in my xe

powerd grasstrack car

You should do, but a friend of mine has that yukspeed sump and recons its ok without the tray.

swanntech - 3/1/14 at 08:09 PM

Thanks for that might try running it without first .nice looking engine your fitting. is the xe crank and main bearing caps the same as an let.

Ben_Copeland - 3/1/14 at 08:13 PM

Bought a T piece pipe for the coolant system off ebay, but i was less than impressed considering it was quite expensive.

Crap T Pipe

Crap T Pipe

The pipe was all bent and the smaller pipe wasnt drilled out properly.

Connected the laptop up last night and started updating the basic map info to match my engine and i want to test the fans work etc.

Ben_Copeland - 3/1/14 at 08:13 PM

quote:

Originally posted by swanntech

Thanks for that might try running it without first .nice looking engine your fitting. is the xe crank and main bearing caps the same as an let.

C20LET yes, the Z20LET is different but not a lot.

I've got a XE bottom end all built up still if your interested

[Edited on 3/1/14 by Ben_Copeland]

Ben_Copeland - 3/1/14 at 08:16 PM

I'm also selling the Coscast Head atm on ebay and have a ton of spares if your after anything

http://www.ebay.co.uk/itm/331095959224?ssPageName=STRK:MESELX:IT&_trksid=p3984.m1555.l2649

Wheels244 - 3/1/14 at 08:29 PM

quote:

Originally posted by Ben_Copeland

quote:

Originally posted by swanntech

Thanks for that might try running it without first .nice looking engine your fitting. is the xe crank and main bearing caps the same as an let.

C20LET yes, the Z20LET is different but not a lot.

I've got a XE bottom end all built up still if your interested

[Edited on 3/1/14 by Ben_Copeland]

Hi Ben

I thought you was flogging that to me ?

Good work on the install.

loggyboy - 3/1/14 at 10:47 PM

quote:

Originally posted by Ben_Copeland

Bought a T piece pipe for the coolant system off ebay, but i was less than impressed considering it was quite expensive.

Crap T Pipe

Crap T Pipe

The pipe was all bent and the smaller pipe wasnt drilled out properly.

Connected the laptop up last night and started updating the basic map info to match my engine and i want to test the fans work etc.

Is that an ASH one?

Ben_Copeland - 3/1/14 at 11:02 PM

quote:

Originally posted by loggyboy

quote:

Originally posted by Ben_Copeland

Bought a T piece pipe for the coolant system off ebay, but i was less than impressed considering it was quite expensive.

Crap T Pipe

Crap T Pipe

The pipe was all bent and the smaller pipe wasnt drilled out properly.

Connected the laptop up last night and started updating the basic map info to match my engine and i want to test the fans work etc.

Is that an ASH one?

No wish I'd seen the ash ones before I bought that crap.

Ben_Copeland - 3/1/14 at 11:07 PM

quote:

Originally posted by Wheels244

Hi Ben

I thought you was flogging that to me ?

Good work on the install.

Thought it was too much for you ;-)

yellowcab - 4/1/14 at 11:18 AM

Looking good Ben, good pics and diary showing your difficulties and how you overcome them, a good source of information for those other LCB readers to

learn from.

Keep up the good work pal, should be a hoot to drive!

Looking forward to having a go already

Ben_Copeland - 4/1/14 at 05:42 PM

Olz if you ever come and visit, we'll do a swap for the day ;-)

andywilson - 4/1/14 at 07:35 PM

good progress Ben, looking really good!

should be getting back on with mine in a month or so expect questions!

Ben_Copeland - 4/1/14 at 10:14 PM

Cheers Andy

Modified the Rally Design pedal box to take a Vauxhall accelerator cable, had to add a small box to space up the cable sleeve and bend the back of the

pedal up so the cable pulls further.

Pedal Box Modify

Decided while i was waiting for funds for more parts i'd flared the side panels to get some of the heat out!

Side Panel Flare

Side Panel Flare

Side Panel Flare

Not much left i can do currently

Ben_Copeland - 9/1/14 at 09:54 AM

Ordered £300 worth of bits and pieces yesterday so when they come I'll post a picture of the bounty

Ben_Copeland - 20/1/14 at 12:35 PM

Sorry about no activity recently, my parts came in dibs and drabs so I didn't bother taking a picture. Still missing some bits which is

annoying.

Anyway, I had a go at making an exhaust for the car. Tacked it all together and hopefully I can get it tig up later this week.

Exhaust

I also had to rejig the coolant lines off the back of the water pump because I found another pipe off the head, which is annoying as it means I cant

fill it up with water till I get another t-piece.

Found Pipe

That's it for now, i'll hopefully have all the bits by the weekend (except the extra t piece) and I can finish most of the pipework

[Edited on 20/1/14 by Ben_Copeland]

Ben_Copeland - 27/1/14 at 01:54 PM

Got my mate to tig up the exhaust last week, so fitted it this weekend. Fitted perfect first time, right slap bang centre of the cut out in the side

panel too. Really pleased how its turned out!

Exhaust

Exhaust

I'm also struggling to find a place for my airfilter, where am I going to get fresh air from ?

Air Filter

[Edited on 27/1/14 by Ben_Copeland]

laptoprob - 27/1/14 at 02:27 PM

quote:

I'm also struggling to find a place for my airfilter, where am I going to get fresh air from ?

Air Filter

[Edited on 27/1/14 by Ben_Copeland]

Scoop in the bonnet mate or maybe in the side panel?

Ben_Copeland - 27/1/14 at 02:30 PM

I have a scoop, which I thought maybe I could attach a funnel and flexy pipe too, but its the agro of disconnecting if I want to remove the bonnet.

daveb666 - 27/1/14 at 02:32 PM

Won't it go where my old one was?

Description

but put it in a box/shield or something?

Ben_Copeland - 27/1/14 at 02:38 PM

Dave, that's a hideous place for an air filter lol sucking lovely hot air off the radiator

In all seriousness I cant fit anything in the front, theres no space

daveb666 - 27/1/14 at 02:44 PM

I agree Ben; that's why I added the scoop and put the filter in a sealed box so that only the air from the scoop got to the filter

Description

Ben_Copeland - 27/1/14 at 03:19 PM

Good Lad

laptoprob - 27/1/14 at 07:01 PM

quote:

Originally posted by Ben_Copeland

I have a scoop, which I thought maybe I could attach a funnel and flexy pipe too, but its the agro of disconnecting if I want to remove the bonnet.

My mate finishhed the MAC1 with the LET engine(think i mentioned it) in and basically he made a 'box/pocket' near the scuttle which is where

the air sccop was and put the cone filter inside it so when are was pushed into the 'pocket' the only place it could go is down the

filter.

If i can get you a photo Ben ill send it over.

Ben_Copeland - 27/1/14 at 07:43 PM

Cheers rob

yellowcab - 27/1/14 at 11:25 PM

Looking good Ben, think it looks awesome when there is only a single pipe exiting the engine by, crys out dirty turbo

BangedupTiger - 27/1/14 at 11:43 PM

excellent work mate, considered an LEH for mine, but decided to go down the Z16LER route instead.

Ben_Copeland - 28/1/14 at 08:04 AM

quote:

Originally posted by BangedupTiger

excellent work mate, considered an LEH for mine, but decided to go down the Z16LER route instead.

I did think about it, but I wanted easy grunt

laptoprob - 28/1/14 at 04:17 PM

quote:

Originally posted by Ben_Copeland

Cheers rob

Email sent to your hotmail account with pictures

Ben_Copeland - 28/1/14 at 05:10 PM

Yep, got them. I see what you mean. I could box a vent in and put the air feed into it.

daveb666 - 28/1/14 at 05:15 PM

seen something similiar on a turbo zetec (although not boxed in):

but has an airfeed from the side:

yellowcab - 28/1/14 at 05:35 PM

Lovely oil cooler position lol

Ben_Copeland - 28/1/14 at 05:37 PM

quote:

Originally posted by yellowcab

Lovely oil cooler position lol

Wow I missed that !

Crazy dutch

Ben_Copeland - 28/1/14 at 06:47 PM

Well, Huge update time !!

I filled the oil up, cranked it over for a bit till the light went out (with the coilpack and fuel pump unplugged).

Next came the startup. The first actual start was witnessed by yellowcab via facetime... soz

But this is the 2nd start up, not bad considering its still running the same map as the xe, I just upped the req_fuel.

SO here it is :

http://youtu.be/1Qoy9cHD1wQ

Think a belt is too tight, but apart from that. No nasty sounds heard

yellowcab - 28/1/14 at 06:52 PM

Awesome mate

stevepj - 28/1/14 at 08:12 PM

Nice work Ben, not long now til it's all done and spreading a smile all over your face.

Reminds me a lot of this, I don't know why!

Ben_Copeland - 28/1/14 at 08:48 PM

quote:

Originally posted by stevepj

Nice work Ben, not long now til it's all done and spreading a smile all over your face.

Reminds me a lot of this, I don't know why!

Thanks for all the help Steve. Life saver!!

Ben_Copeland - 31/1/14 at 08:27 AM

Few more bits done over the past couple of nights.

Boost Gauge, I was going to replace the oil pressure gauge to save drilling another hole but I might swap that for a oil temp gauge instead so I put

the boost gauge where I could see it

Boost Gauge 1

Boost Gauge 2

Boost Gauge 3

Next was some prop catchers, I originally planned to fit 2 sets of catchers inside the tunnel. One set at each end, but my prop is quite short and I

had nowhere to mount them other than in the middle.

I got these from FastDan, they don't seem wide enough for the Haynes Tunnel I'm guessing the locost tunnel is a little narrower so I had to

make some crude brackets up, while trying to work in a tunnel with the prop still attached.

Prop Catchers

Prop Catchers

I then decided to tackle the air filter location problem... Somehow I just got it to sit infront of the engine, the 73mm flexy cold feed JUST squeezes

down between the radiator/intercooler and nosecone. That should hopefully be ok, just need to work out a way of mounting the air filter.

Filter

Air Feed

Air Feed

[Edited on 31/1/14 by Ben_Copeland]

stevepj - 31/1/14 at 01:19 PM

if you hadn't chopped that big horrible engine mount off the front you could have got a fixing on there somewhere

Ben_Copeland - 31/1/14 at 01:35 PM

Don't worry steve, i'll find somewhere to mount it. Theres no way that mount is coming back !

Ben_Copeland - 1/2/14 at 05:18 PM

Airfilter mounted

Enclosed Airfilter mounted using the bracket that came with it, slightly modified. I used the cambelt cover bolt to hold it all in place.

Tight

I'll have to turn the hose clamp around to stop it getting in the way.

Description

Mounting bracket

Ben_Copeland - 3/2/14 at 04:50 PM

Description

Small update, couldn't find a t - piece the right size (32mmx18mm) to join that surprise pipe up to the bottom/water pump hose so I had one made

I already had the individual pipes so I cut and shaped the smaller one and drilled the larger pipe, then my friend tig'd them together for me.

Hoping tonight I can get all the water system finished

[Edited on 3/2/14 by Ben_Copeland]

Ben_Copeland - 3/2/14 at 10:53 PM

All plumbed in and filled up with water and antifreeze. No leaks so far ran the engine for a bit but it was too late and too noisy.

ran the engine for a bit but it was too late and too noisy.

stevepj - 4/2/14 at 11:01 PM

All coming together nicely now Ben, you should be ready in plenty of time for the good weather.

Have managed to map in the IACV on mine today so now it starts and fast idles from cold and the fast idle decays to normal idle as the temp increases.

Ben_Copeland - 5/2/14 at 10:12 AM

I've left mine disconnected, I could wire it into the ecu but I'm not sure its worth it tbh.

Perhaps once its at mapping the tuner can make that decision for me

yellowcab - 5/2/14 at 10:41 AM

GoPro action required

Ben_Copeland - 5/2/14 at 11:25 AM

Think i'll have it recording the tuning

Ben_Copeland - 10/2/14 at 05:45 PM

http://youtu.be/n3vVJiQOv-g

I had to turn the oil filter mounting so the pipe connections didn't rub on the alternator belt, I also found the wastegate was rattling, so

tightened up the actuator arm.

Hey presto much quieter running engine.

Thanks Daveb666 for the suggestion of rotating the oil filter mounting, id forgotten they were bolted on.

yellowcab - 10/2/14 at 06:33 PM

Gook work Ben - roll on Saturday huh!?

Ben_Copeland - 10/2/14 at 07:22 PM

Bloody well looks like it. I've got the ok from Allison and I've got most of the money for it.

Just need to try get the car up to running temperature tomorrow night and hope it's got no problems.

Ben_Copeland - 7/3/14 at 08:15 AM

Bit of an update, I missed my original tuning booking due to a leaking clutch cylinder and a noisy clutch.

The leak been fixed but the noise is still there, I replaced the clutch bearing but its not that. So don't know what's wrong. I've

given up trying to fix it, so it'll either get worse or whatever's touching when the pedal is pushed down will wear away enough to stop

Tuning is now booked for Friday 14th March, so i'll update then.

But it does drive fine and the water and oil system all works. I've also fitted an oil temperature sender but i'll update at the weekend

once its all working ok.

New Road View

beaver34 - 7/3/14 at 08:23 AM

looks great

Ben_Copeland - 7/3/14 at 08:30 AM

Forgot I missed a step, Faired side panels... I also meshed them to hide the chassis behind.

Description

Ben_Copeland - 7/3/14 at 10:38 AM

quote:

Originally posted by beaver34

looks great

Thanks pal

Ben_Copeland - 9/3/14 at 07:58 PM

Saturday morning I finished wiring in an oil temperature sender. Drilled and tapped the oil cooler line banjo bolt and inserted a smiths water

temperature sensor. This was then wired to a switch along with the original water temperature cable.

Basically this all means that I can flip a switch and see what the oil temperature is, then flip it back for water temperature on the same gauge.

Otherwise I've got to buy another smiths gauge which are over £50, plus £15 for the sender. That's fine but I'm running out of space

on my dash!!

I'll stick a couple of pictures up tomorrow when I get to work as my laptops charger has had it at home.

Ben_Copeland - 15/3/14 at 11:21 PM

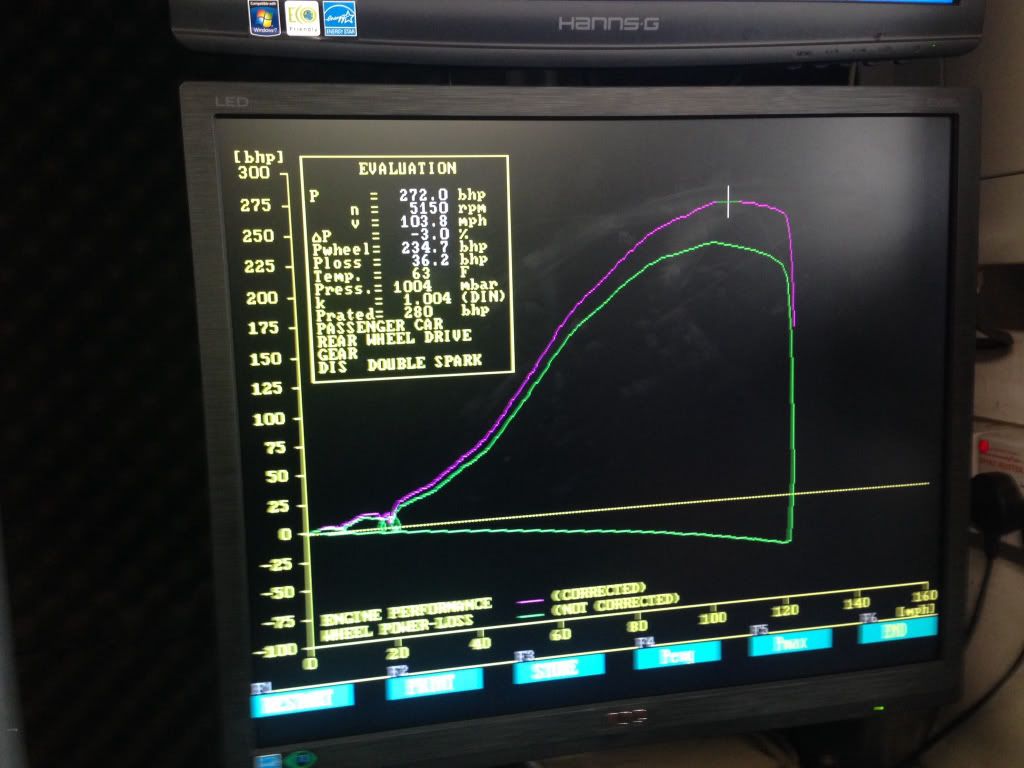

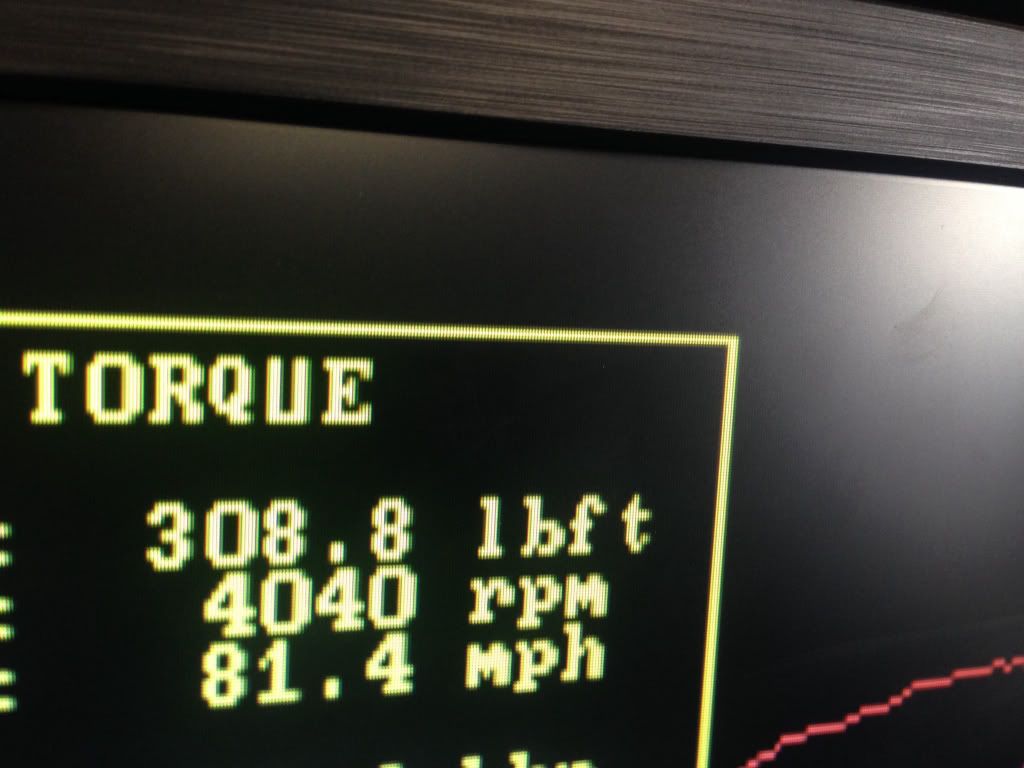

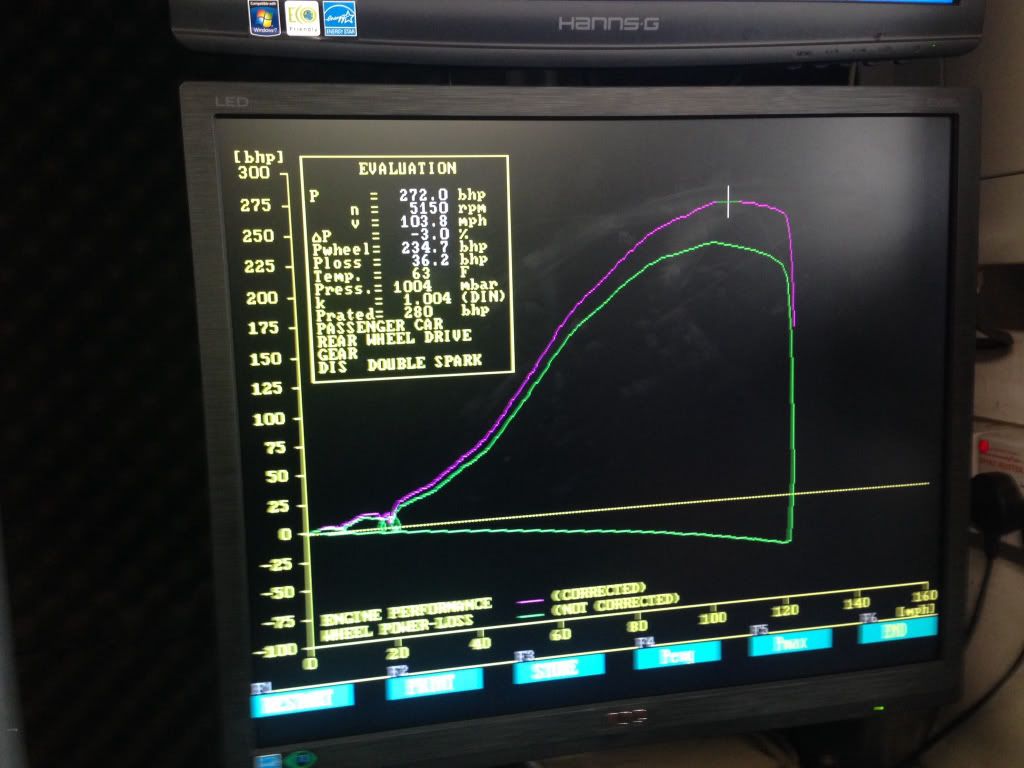

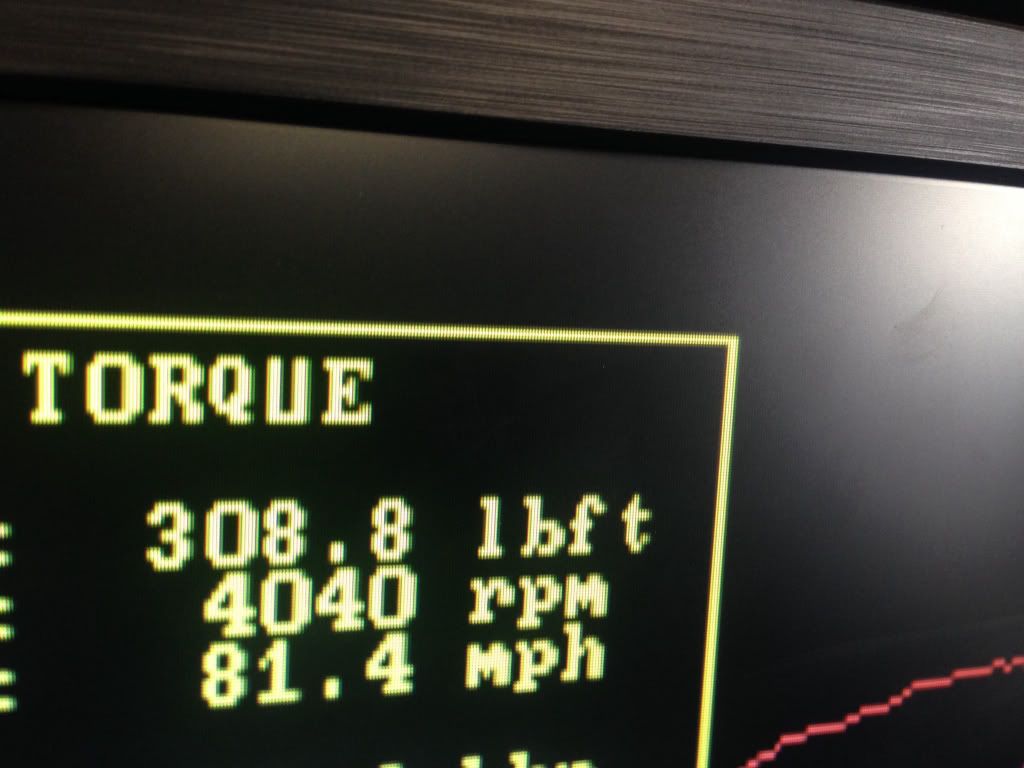

So, the big day was on Friday! Tuning day at Bailey Performance!

Wow what a guy, Dale knows his stuff. I'm going to do a separate thread with a bit of a report with plenty more details.

But, the gory figures ars so:

272bhp and 308ftlb torque, it's was savage on the rollers and it kept spinning the rear wheels as peak torque come on. We ended up removing the

splitter so it could be strapped down tighter.

I've not driven it anywhere yet, but Dale promises me it'll do 30mpg on cruise!

Happy bunny and no Major issues thankfully.

http://youtu.be/S0lndNHN5eY

[Edited on 16/3/14 by Ben_Copeland]

andywilson - 16/3/14 at 08:11 AM

Great result Ben!

me! - 16/3/14 at 08:41 AM

That'll shift!

beaver34 - 16/3/14 at 09:27 AM

get ready!

300lbft at 4k you will be going anywhere but straight

CosKev3 - 16/3/14 at 09:45 AM

Great conversion

That power will be very interesting! What diff do you run?

Would have popped down for a nosey when it was being tuned if I had known, as I'm only just up the road from Bailey Performance.

Ben_Copeland - 16/3/14 at 11:13 AM

Hi chap. It's got a LSD sierra diff from a 2.0 xr4x4 I seem to remember.

Ben_Copeland - 17/3/14 at 08:57 AM

I did a write up of the day on a separate thread.

Please see it here:

http://www.locostbuilders.co.uk/forum/9/viewthread.php?tid=189685&page=#pid1595632

Ben_Copeland - 21/3/14 at 09:02 AM

Well, I've sent my ECU back to Dale so he can add the necessary bits to run my rev counter (diodes off the coil was causing interference)

I've found the oil leak on the bottom of the turbo and hopefully sealed it.

I bought a set of cooler plugs, but they turned out to be too big (14mm socket) to fit in the spark plug holes. Dale's going to send me some of

the right ones when he returns my ecu.

I've bought a ford coil pack to replace the GM one. The GM one seems to be causing a minor misfire during hard acceleration.

I'll update with pictures once its arrived and all fitted

Ben_Copeland - 2/4/14 at 11:51 AM

Well taxed the car and off out I went!! Holy poo the car shifts. Turbo kicks in low down the rev range. I had to really watch the speedo as I was

speeding very quickly.

80degrees water temperature all the time and oil got up to 110degrees.

It doesn't scream off like the engine I had before, where your watching the revs go up ready to change gear. It's all about torque now, it

just shoots off up the road like a scalded cat with no effort.

Big grins from me. Had the go pro running but it's was a bit dark,

Couple of Really Boring Videos :

http://youtu.be/KgD1qUD5g7I

http://youtu.be/C_kAP_ZjV24

[Edited on 2/4/14 by Ben_Copeland]

beaver34 - 2/4/14 at 06:08 PM

Awesome!

Watch your oil temps though as that's quite high for pottering around

Ben_Copeland - 3/4/14 at 09:24 AM

I'm not 100% sure that's correct. The temperature sensor I put into the banjo bolt for the oil cooler take of is not really the best

place.

I'm going to relocate it to the sump and see what difference that makes.

I'm also going to drill a 6mm hole in the coolant thermostat to allow for lack of heater bypass. Which might explain why the fans coming on but

gauge is only reading 80c

Ben_Copeland - 22/4/14 at 02:21 PM

Right, bit of an update.

Oil temperature is now fine. The thermostat wasn't opening properly and I had the oil temp sensor in the wrong place. Its now located in the

sump plug and appears normal.

I also installed a massive oil cooler, but its obvious its not necessary so will probably swap it back to a smaller one.

Water cooling, I had a bit of an issue where the fan was coming on during normal driving. Appears that I wasn't getting enough air in the

front.

I'll made some crude cowling to try and force more air through the rads. I've also removed the meshing from the nosecone... The mesh I had

was very restrictive. Just need to find something to replace it with.

I've also replace the thermostat with a 82c one and put the heat bypass pipe back in.

I'm yet to give it a blast on a hot day, so I'm hoping for some nice evenings or spot of sun this weekend where I can give it a bit of a

hoon and see what's what.

I'm also going to Stoneleigh so come and say hi if you see me / the car.

[Edited on 22/4/14 by Ben_Copeland]

daveb666 - 22/4/14 at 03:07 PM

quote:

Originally posted by Ben_Copeland

I'm also going to Stoneleigh so come and say hi if you see me waiting on the hard-shoulder for the AA.

[Edited on 22/4/14 by Ben_Copeland]

Ben_Copeland - 22/4/14 at 03:10 PM

Thanks for your support Dave ;-)

Think it'll manage the 20 miles from Olivers lol

daveb666 - 22/4/14 at 03:17 PM

Aww didn't realise you were cheating and doing the journey in two bits.

Ben_Copeland - 22/4/14 at 03:18 PM

Yeah, bleep that... I need to change my diff if I want to start doing long runs !

beaver34 - 22/4/14 at 04:26 PM

quote:

Originally posted by Ben_Copeland

Yeah, bleep that... I need to change my diff if I want to start doing long runs !

why whats it reving to at normal speeds?

Ben_Copeland - 22/4/14 at 04:52 PM

Runs about 3.5k at 70mph

If I can get that down to 3k at 70 I'd be happy.

Runs out of revs at 120mph

beaver34 - 22/4/14 at 06:57 PM

Really? Must be odd ratios for that to happen 3,500 is normal revs really for 5th at 70

Is it live axle or IRS?

Ben_Copeland - 22/4/14 at 07:13 PM

Type 9 v6 box and a sierra 3.9 (I think) LSD diff.

I'm thinking that if I get hold of a 3.38 diff and swap the crown wheels etc. or find a lobro 3.38 diff and bolt LSD in. Then I'll get

better top end but as I have a lot of power the acceleration won't be so affected.

Ben_Copeland - 6/11/14 at 08:06 AM

Cover 1

Cover 2

Cover 3

Cover 4

Last weekend I had my tonneau cover made and fitted. Should keep the rain out when parked up

Made by a local place - Browns Custom Trimming

[Edited on 6/11/14 by Ben_Copeland]

daveb83 - 10/11/14 at 12:40 PM

Liking the cover.

I could have done with one just like that on friday for a very wet track day, was unable to get a garage and didnt want to put my car cover over as

would have melted on the exhaust. something like that would have been ideal though.

If you dont mind me asking, how much was it just so i know a ball park figure to try and find a local trimmer near me to make one for myself?

Ben_Copeland - 10/11/14 at 01:00 PM

It should cost between £200 - 300 from a trimmers. Depending on how complicated it is.

Soft bits for sevens wanted £450+ to do the same thing and they are quite unhelpful via email.

[Edited on 10/11/14 by Ben_Copeland]

Ben_Copeland - 16/2/15 at 06:22 PM

Made my own Rosejointed wishbones a while ago, ahead of finding someone to set up the suspension.

Description

Took the car to get the suspension setup today. Its been too long with ropey handling.

Description

Description

Description

Description

Description

Steve @ Dover Cambelt Centre certainly knows his stuff. Explaining to me what he was doing and why, I helped out with alterations as much as I could

to help speed things along.

Camber, tracking and corner weights were adjusted and this is what we ended up with in the end.

Rear Camber -1 degree.

Rear Tracking 2mm toe in.

Front Camber -1.5 degree

Front Tracking 0.5mm toe in.

Corner Weights:

LF 169kg cross weights RR to LF 49%

RF 177kg cross weights LR to RF 51%

LR 190kg

RR 217kg

The drive home was a lot of fun, pushing it into roundabouts even with a slightly damp greasy road the grip was 100% better.

Steve @ Dover Cambelt Centre

2-3 Ethelbert Road, Tower Hamlets, CT17 0DR, Dover, Kent

01304 448878

07973 304038

[Edited on 16/2/15 by Ben_Copeland]

CosKev3 - 16/2/15 at 11:27 PM

Wishbones look good

Have you made them from scratch or just added the rose jointed ends?

What set up have you got on the top of hubs where wishbone rose joint attaches?

[Edited on 16/2/15 by CosKev3]

Ben_Copeland - 17/2/15 at 07:33 AM

Half made them. I used some old mk wishbones. Cut the tubes off and welded in threaded bar that I made myself.

The rose joint goes where the original bush tube was into the top of the upright. Then used spacers either side so the upright doesn't move

about. Same as the rest of the joints in the wishbone chassis brackets

Benzo - 28/8/18 at 09:38 AM

Been Reading through this thread thinking of doing something similar to my Westie XE.

How have you found the Turbo power now after a few years? Has it been reliable?

What clutch & flywheel setup do you use on the Z20? with Type9 box?

Ben_Copeland - 28/8/18 at 10:36 AM

Hi Benzo

Itís been very reliable, I changed the turbo core as the previous owner of the engine had messed about with it and it failed prematurely, otherwise

itís been fine.

Clutch wise, I used a Astra turbo clutch cover, galaxy v6 friction plate and bearing that came with slave.

Tbh, Iíve changed the type 9 to a Vauxhall omega box. R25-28 itís a lot stronger if your looking to increase the power at all.

Benzo - 28/8/18 at 10:41 AM

quote:

Originally posted by Ben_Copeland

Hi Benzo

Itís been very reliable, I changed the turbo core as the previous owner of the engine had messed about with it and it failed prematurely, otherwise

itís been fine.

Clutch wise, I used a Astra turbo clutch cover, galaxy v6 friction plate and bearing that came with slave.

Tbh, Iíve changed the type 9 to a Vauxhall omega box. R25-28 itís a lot stronger if your looking to increase the power at all.

Awesome, its bound to be Mega on the road, what diff ratio do you run?

What did you source the Z20 from initially? are you just running the standard FWD Flywheel?

I thought they where only VX220 but now I see they are in Astra coupes, GSI's etc etc

Ben_Copeland - 28/8/18 at 10:51 AM

Diff ratio was originally 3.9 but I swapped it out for 3.6, make sure you have a LSD as itíll just spin a wheel.

I used an 8v cavalier flywheel as itís lighter but you could use the original flywheel, bit of a lump tho.

Engine was out of a converted Astra fake GSI, he gave me everything including the dash loom lol

If you want to run the original Ecuador you need the ignition module and key module. Otherwise bin it all and use a 3rd party tuner ecu