[Edited on 4/10/15 by snapper]

Hi Guys

I've decided to treat my 1600cc xflow to a rebuild however now I'm getting close to reassembling it, I'm beginning to wonder whether I

should be upgrading some of the internals?

The engine started life as a 1600GT 711M and has been modified thus:

+0.030" cylinder rebore, new pistons/rings, deck faced, head skimmed and converted to unleaded, new valves and valve guides.

crank ground +.010" new mains and big end shells.

Kent BCF2 camshaft kit (that came with new valve springs and followers.

moderately lightened flyweel.

600cc bike carbs (fzr) on custom inlet manifold

original GT exhaust manifold modified to mate to 2" pipe and 5" silencer.

Megajolt mappable ignition with steel crank pulley and trigger wheel.

With these changes, am I getting into the territory of needing up-rated rod bolts, main bolts, timing gears/chains, valve gear, oil pumps etc?

Cheers

Gary

Your engine has a similar spec to mine - and I didn't go for any of the uprated components you've listed. So far the engine's done

around 11K miles without incident, but I'm not one to rag the engine to an inch of its life - just the occasional blast up to max revs, which

I've set to around 6200 rpm.

If I was going to do anything, I'd consider steel posts for the rocker gear. Oh - and like you, I did change the crank pulley for the alternator

belt to a machined steel one, rather than the original pressed steel thing, which had a tendency to burst at very high revs.

[Edited on 4/10/15 by David Jenkins]

Unless your turbocharging then its engine speed rather than spec. The formula ford 1600 boys used to recon on not revving xflo's above 6500. With

the spec you have I doubt there's much power up at that speed anyway so you'd be stressing the engine for no real gain.

Personally when I build anything that will rev higher than stock I always fit arp rod bolt and flywheel bolts. I know its an expence and probably not

needed, I just view it as insurance.

[Edited on 4/10/15 by chillis]

[Edited on 4/10/15 by chillis]

Its all about expence. I have been running FF 1600 @6800 for a long time and an engine we had with a BCF3 cam was reving to 7500 without any problems. However, the rods are the weak spot and if they let go will take half the engine out. Certainly agree with using steel pillars, but dont be fussy about the oil pump upgrades. If the engine is getting 55psi when hot, it will be ok. We ran the Juniors with no more than that and I never had more that 60 with the FF1600. We always dry sump however. I have a dry sump system on our Zetec and that runs at no more than 60psi...

[Edited on 4/10/15 by snapper]

Perhaps a decent crank case breather system /oil catch tank? Steel pulley makes sense as well as steel rocker pillars

rod bolts --- no

main bolts -- no

timing gears/chains -- no, but as with an engine overhaul you should change it anyway...you can upgrade it to double chain, incl. adjustable

sprocket

valve gear -- no

oil pumps -- no and yes:

after such an engine overhaul you want to fit a new pump anyway...a high pressure&high volume pump doesnt cost much more than a standard

pump...

steel rocker posts -- no

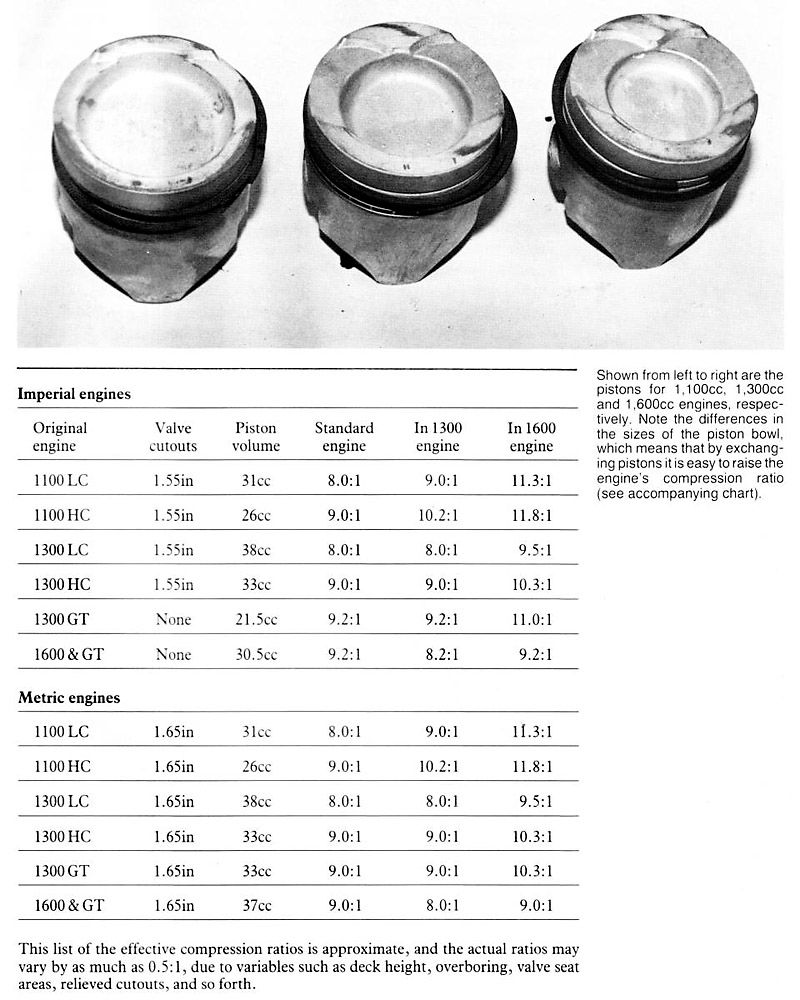

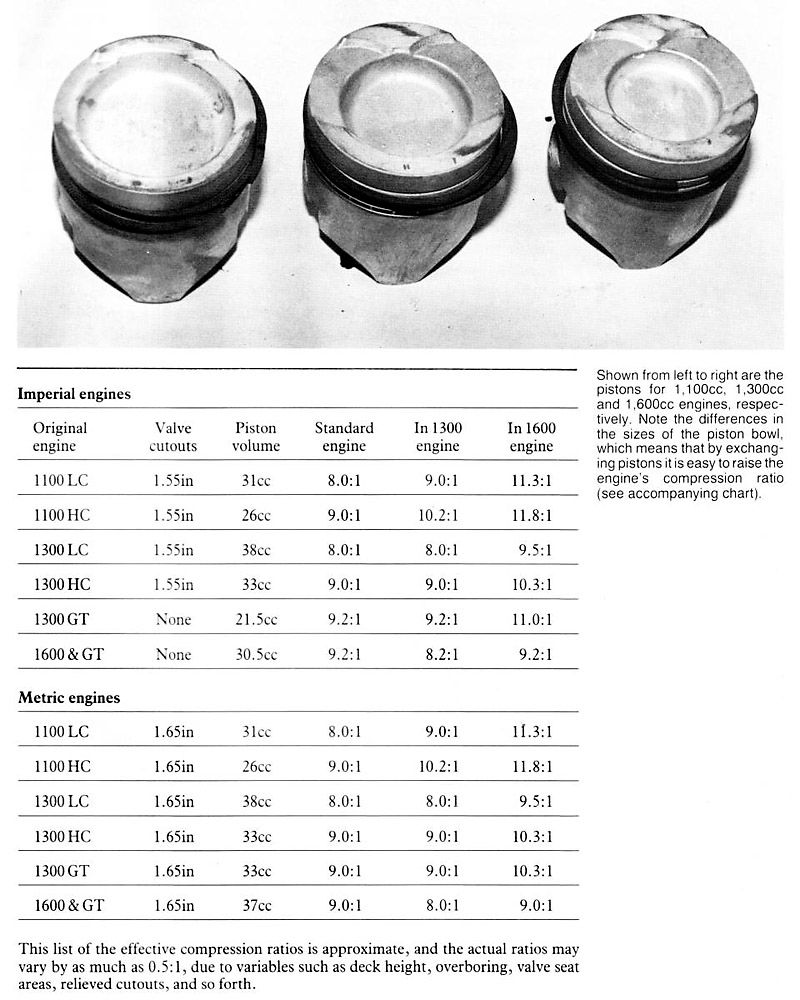

more important would have been to increase compression ratio, using 13000 pistons!!!

[Edited on 4/10/15 by alfas]

My reason for suggesting steel rocker posts was because they can break if overloaded by a hot cam and a BCF 3 has a lot more lift than standard. Never found a need for duplex chain even when running A6 or A8 cams but a vernier pulley is handy for swinging the cam.....

he is fitting a BCF2 not a 3

the 2 is a fast road cam which improves torque, rahter than high rev ower.

so no necessity improving rocker-gear, imo.

Crossflow 1600 conrods are actually very strong; it's the rod bolts that break. I would fit a set of heavy duty bolts - they don't need to be ARP - Kamax are more than good enough.

quote:

Originally posted by alfas

he is fitting a BCF2 not a 3

the 2 is a fast road cam which improves torque, rahter than high rev ower.

so no necessity improving rocker-gear, imo.

quote:

Originally posted by Memphis Twin

Crossflow 1600 conrods are actually very strong; it's the rod bolts that break. I would fit a set of heavy duty bolts - they don't need to be ARP - Kamax are more than good enough.

Hi Guys

Thanks for all your input, it's certainly given me food for thought.

Just for clarity, the upgrades I listed are currently fitted to the engine and have been for the last 1500 miles since the car was first built.

I'm only rebuilding the engine again because I made the mistake of not re-boring the cylinders when I first rebuilt it (which it really

needed).

It is not my intention to rev the engine higher than the OEM limit.

I have no idea what power output my engine is capable of in it's current spec. and without knowing this, it's hard to research what internal

strengthening might be necessary (looking at tuners guides).

I guess the only extra power producing upgrades my engine has are the BCF2 camshaft (which I don't intend to change) and the bike carbs, maybe

the exhaust. The ignition/fuelling was originally tuned by myself (on the road) using a wideband O2 sensor and my ears (listening for knocking).

Anyone brave enough to hazard a guess at the probable bhp?

From the general consensus I'm now thinking of leaving most things as they are with the exception of:

1. Using the heavy duty (not ARP) rod bolts that Burton's sell.

http://www.burtonpower.com/heavy-duty-con-rod-bolt-ford-x-flow-lotus-twin-cam-bda-fl245.html

2. Fitting the Burton high pressure oil pump mod.

http://www.burtonpower.com/oil-pump-uprating-kit-65lbs-ford-x-flow-lotus-tc-bda-fp202.html

3. Oil temp sensor/gauge.

As I'm worried the classic 20W50 oils will not be able to handle higher temperatures as well as modern day synthetics. If the oil runs hot then

I'll look to fit an oil cooler.

On a different but related matter.....I did chop the original sump but unfortunately experienced some surge on an airfield day so I know my redesign

is not perfect. Does anyone have any photos of a chopped xflow sump that incorporates effective baffling and or trap doors?

Many thanks for all your input.

Gary

[Edited on 6/10/15 by GaryM]

i would buy a new oilump instead doing this upgrade.

buy a high pressure & high-flow pump

ARP big end bolts is always a good idea & changing bearing shells at same time.

The main reason for fitting the cast Lotus Twincam crank pulley was not really because the welded Cortina type broke up but because of the smaller

diameter of the cast one which reduced rotational speed of the old style dynamos as the commutator used to self destruct if over revved and also to

reduce the water pump RPM to reduce power and coolant flow rate loss due to cavitation.

The main weak points of X-flos at high RPM are due to the forces caused by the weight of the pistons.

Although very early Kent 1500 engines had weak rods it was brought to Fords attention by rod failures in the very early 1500 Lotus Twincam , Ford

dealt with the problem pdq by upgrading the rods used in all pre-xflo production, 1600 xflo rods are even stronger than the "125e" lotus

rods..

ISTR uprated rods were only required for full house race engines as used in 1970s/early 1980s Mallock Clubmans A class racers

The oil pump mod is really just a packer for below the reief valve hence of no real benefit, I don't know if high capacity oil pumps are still

available for the xflo as they will deliver more oil but do you need one -- I think not.

Had more than a few X-Flows in various cars with the ultimate being an 1860 bored and stroked steel race engine in the Seven. That had all the nice

bits available but most have been more mundane.

A standard build back in the 80's and into the 90's would bore the block and use 1300 pistons. The best to use at the time were +0.060

Powermax which were much stronger (but no lighter) than the standard ones and cost only a little more, no idea if they are still made. Rods were

always lightened/polished/balanced and cranks balanced. We used suitably sized 12.9 caphead bolts for the rods in place of the mega expensive Cosworth

alternatives and never had a single failure even using stupid revs. Duplex timing chain, steel valvegear uprights and standard rockers were also used.

We tried the steel spacers in the valvegear but had problems with them binding, reverted to the Ford supplied springs and no more issues.

Valve sizes and springs were chosen to suit the cam used. Initially we used Holbay cams but changed to Kent, eventually reverted to Holbay for the

last I built. Had no problems with any. Isky springs and Paul Ivey valves were the norm.

I used lightened standard flywheels for years but eventually decided my feet and legs were too valuable and bought a used lightweight twin cam steel

flywheel, used it for over 10 years.

For a wet sump engine we would use a genuine Ford oil pump but don't expect they are sold now.

A typical 1660 (+0.060 with Powermax), a Kent 244 cam on twin 40's would rev reliably to 7800 rpm and put out about 145 bhp.

The steel 1860 revved to 8600 rpm and put out about 175 bhp using a Kent 254 cam. The change to the Holbay cam lost about 10 BHP but the mid range was

much better and as a result the car was actually faster on a lap.

Building a reliable x-flow for 6500 rpm and up to 125 bhp is relatively easy but not cheap if you use good gaskets, bearings etc.

As a keen xflow owner and fan - I have to say that spending all that money to upgrade an old xflow is probably not worth it any more. A good Zetec or

Duratec (perhaps with a few modest tuning bits) will give similar power and will be a lot less stressed while doing it.

I've said it before - while I like my 1660cc xflow, if it ever dies on me it will be replaced with something more modern, for purely practical

reasons.

As for oil, I always use valvoline VR1 20/50. Touch wood, no issues as of yet. Temp and pressure stable and it is driven hard!

quote:

Originally posted by David Jenkins

As a keen xflow owner and fan - I have to say that spending all that money to upgrade an old xflow is probably not worth it any more. A good Zetec or Duratec (perhaps with a few modest tuning bits) will give similar power and will be a lot less stressed while doing it.

I've said it before - while I like my 1660cc xflow, if it ever dies on me it will be replaced with something more modern, for purely practical reasons.

quote:

Originally posted by Adamrish

As for oil, I always use valvoline VR1 20/50. Touch wood, no issues as of yet. Temp and pressure stable and it is driven hard!

quote:

Originally posted by Paul Turner

The most important thing with X-Flow oil is to ensure it contains XDDP and if it doesn't you can buy it as an additive. Most modern oils don't contain it since it kills your cat but its essential to the cam and followers in older designed engines.

quote:

Originally posted by David Jenkins

Not heard of that - do you have a brand name for the additive?