obr_technology

|

| posted on 9/4/16 at 11:26 PM |

|

|

Kawasaki ZX9 V8

Hi,

I've been on this forum for a while now, contributed a little, bought some stuff and sold some stuff, but thought it was about time I put

something on about my project. I consider it a Locost project as I'm trying to do it for far less than is really ideal, and I was going to fit

it into a tiger avon, but sadly had to sell the car recently in order to finish the engine.

Back in 2011 I had moved to a more managerial job, and started to get rusty on my CAD skills so thought I'd start a project. I've messed

around with engines since I was young, learning from my dad on his bikes which were usually given to us or bought as non runners.

I liked the idea of a ZX9 base for a V8 because the parts are very cheap and plentiful, but also because my friend had an engine which a rod had gone

through the case so I could strip and measure. At the beginning I thought I would model the crankcase and covers/adapters etc, get a friend to knock

it up on the CNC mill and we'd be enjoying it within 6 months....

So, 5 years later I have the following:

Lots and lots of CAD models

5 axis machined crankcase (it's a real thing of beauty!)

10 Main bearing caps

A 2 Gallon ex NASCAR dry sump tank

ARE Dry Sump Pump

2 Gears and shafts which transmit drive from cranks to flywheel/front pulley

8 Pistons and Rods

2 Crankshafts (I know, the weight penalty is a bugger, but it made sense at the time, and I want to adjust the timing between banks eventually)

2 cylinder barrels

2 cylinder heads (complete with CAMs etc)

2 sets of carburettors

standard ZX9 ECU and loom, I plan to time the engines so that they fire in exactly the same order until I can afford a nice programmable ECU

Facet Fuel pump and regulator

Davies Craig water pump and controller

Polo radiator ( I know this sounds mad but at the time I'd seen others who were running 300 hp rover V8's with this rad so thought it was

worth a go!

***And these are the parts I'm currently designing/researching or saving up for:***

Sump

Standard ZX9 full bearing and gasket kits

Final gear and mount which changes crank rotation so it will match the opposing bank

Bearing carriers which support the shaft and gears mentioned above

12.9 grade bolts for everything- from what I could see they are just shy of the strength of ARP bolts but a tenth of the cost!

Oil cooler- I may have scrounged one from work but will have to get it professionally cleaned

Oil fittings and lines- Christ these are expensive, as I'm going to be running it in a test frame first of all I may just use JIC fittings from

the local hydraulics place

Pulley to drive dry sump pump, alternator etc

Adaptor which fits flywheel to shaft

Bearings and bits and bobs I've forgotten.

Thanks for reading, I'll be honest I'm not great with negative comments as I take them far too personally, which is the main reason

I've not posted about it before. In reality though, it's my project, which I may well do differently if I had my time again or an

unlimited budget, however I'm determined to finish it, and posting on here might just give me the motivation to keep going!

|

|

|

|

|

obr_technology

|

| posted on 9/4/16 at 11:34 PM |

|

|

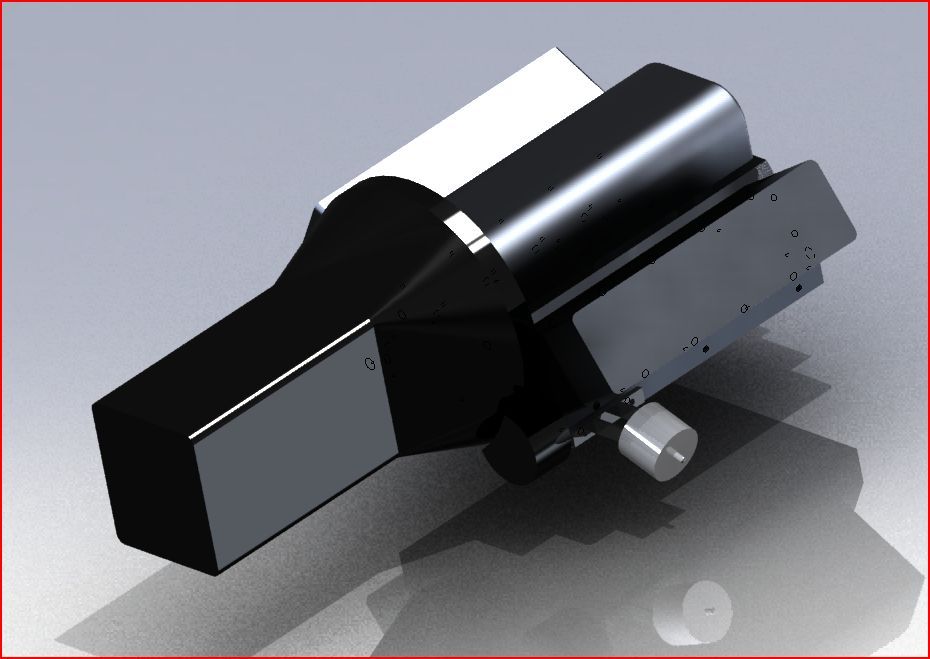

Just remembered, I should have said that another reason for running twin cranks is that the drive of the engine ends up at the top of the engine,

which means that the whole thing has a very low centre of gravity.

To give you an idea the centre of the flywheel is around the same height as the top of the cylinder heads as I've tried to show in this early

image.

|

|

|

ettore bugatti

|

| posted on 9/4/16 at 11:42 PM |

|

|

Interesting!

So it actually an U8 engine? Bugatti did build a couple of U16 in the twenties based on the same principles.

|

|

|

wylliezx9r

|

| posted on 10/4/16 at 12:33 AM |

|

|

I'm pretty sure I sold you a zx10 head and pistons which would increase capacity. Have you still gone down that route ?

I admire your ambition BTW.

I spent a lot of money on booze, birds and fast cars. The rest I just squandered.

George Best

|

|

|

melly-g

|

| posted on 10/4/16 at 06:58 AM |

|

|

Wow this is ambitious! I love it!

You've got to put a picture of the crankcase up.

Keep us all updated, and hurry up I want to see this running.

Good luck with it.

|

|

|

Sam_68

|

| posted on 10/4/16 at 07:19 AM |

|

|

Any idea what you're going to put it in yet?

The high output shaft position relative to the overall engine height would ideal for a mid-engined installation?

|

|

|

obr_technology

|

| posted on 10/4/16 at 07:23 AM |

|

|

quote:

Originally posted by ettore bugatti

Interesting!

So it actually an U8 engine? Bugatti did build a couple of U16 in the twenties based on the same principles.

Yes, it's a U8, but nobody has usually heard of it so I just call it a V8!

From what I've read the Bugatti engine was later developed into a plane engine, and the central shaft was made hollow so that they could fire

bullets through the centre of the propeller.

|

|

|

obr_technology

|

| posted on 10/4/16 at 07:25 AM |

|

|

quote:

Originally posted by wylliezx9r

I'm pretty sure I sold you a zx10 head and pistons which would increase capacity. Have you still gone down that route ?

I admire your ambition BTW.

Yes, they are sat on my shelf awaiting a matching set!

The idea was to increase total capacity to 2 litre, although I was getting a bit ahead of myself at the time and am now trying to keep costs down and

things as simple as possible so I can get my text run completed.

|

|

|

obr_technology

|

| posted on 10/4/16 at 07:30 AM |

|

|

quote:

Originally posted by melly-g

Wow this is ambitious! I love it!

You've got to put a picture of the crankcase up.

Keep us all updated, and hurry up I want to see this running.

Good luck with it.

Thanks, I'll get a picture of the case up as soon as I can find a decent one.

|

|

|

obr_technology

|

| posted on 10/4/16 at 07:35 AM |

|

|

quote:

Originally posted by Sam_68

Any idea what you're going to put it in yet?

The high output shaft position relative to the overall engine height would ideal for a mid-engined installation?

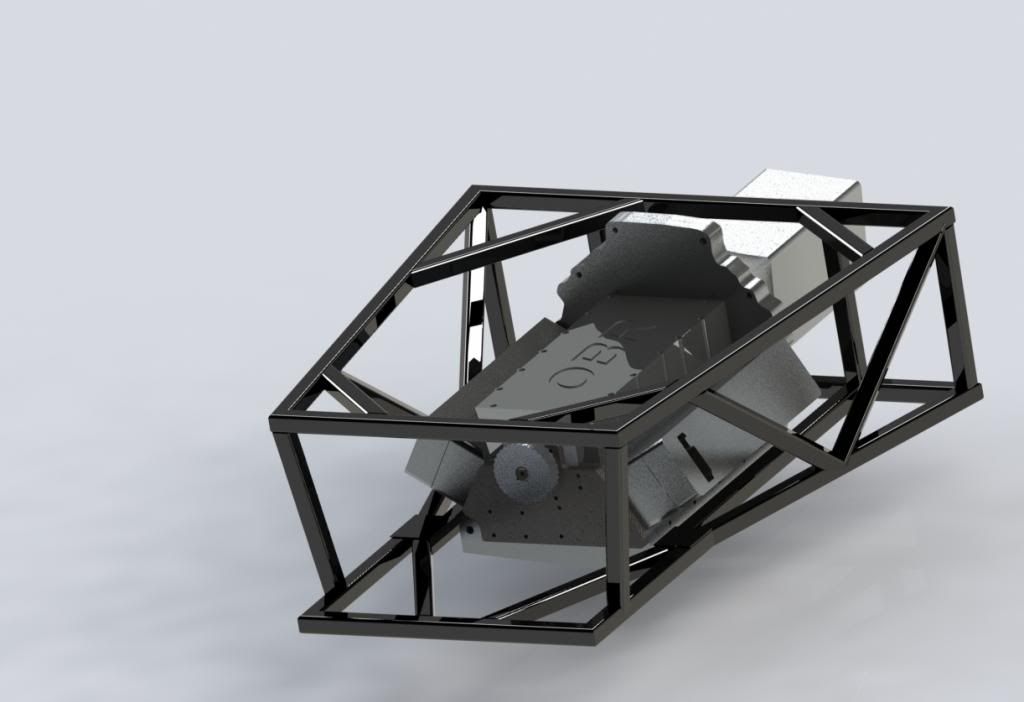

Not sure as yet, having pretty much run out of money at Christmas I'm just focussing on finishing the engine at the moment. I met up with the

Miles from Riot kit cars to see if we could fit it in his new project but it doesn't lend itself well to a front wheel drive transmission as the

driveshafts end up in the same place as they cylinder heads.

Ideally it would be coupled to a transaxle or rear wheel drive box, this is what it would have looked like in my tiger avon:

I like the idea of opening the bonnet and it looking like its sunk right down.

I've had to design the sump to be really shallow as otherwise it would be dragging on the floor!

|

|

|

obr_technology

|

| posted on 10/4/16 at 08:17 AM |

|

|

Future updates

I thought it was worth mentioning my plans should the initial testing go well!

Ideally I will move over to a programmable ECU as soon as I can afford it. I saw somebody on here was selling a DTA S80, which would be ideal but

sadly funds won't allow at the moment.

Once I've got the ECU I can swap out the zx9 carbs for zx10 or Z1000 throttle bodies, injection fuel pump etc.

I'm really infested in learning more about mapping, I've had a little time on an Emerald and even less time on the DTA, but should be

another good skill to pick up once the prototype is sorted.

From there I'll probably go the same route as Dave 424 on this forum check out this link if you've not seen it yet:

http://www.locostbuilders.co.uk/forum/23/viewthread.php?tid=193224

Basically he has an off road buggy which he fitted a zx9 engine into, then turbo'd it with forged high compression Pistons and a base spacer

plate to reduce the compression. I realise this might sound strange but not many people make low compression bike engine Pistons so decent spec high

compression ones are usually used and then a plate similar to a decompression plate but as its under the cylinder barrels you don't get the same

issues that I had with the decompression plate on my supercharged a series engine.

If I used the same turbos/setup as Dave I'd be looking at around 500hp from roughly a 1.9 litre displacement.

|

|

|

obr_technology

|

| posted on 10/4/16 at 08:22 AM |

|

|

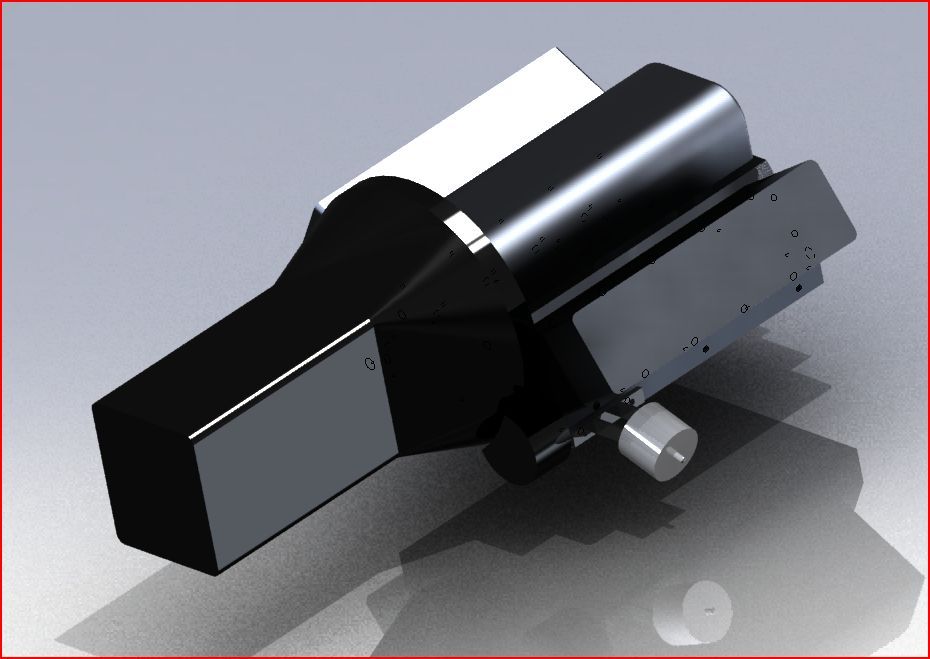

Here is the mocked up crankcase with barrels and heads loosely fitted:

As you will see the V angle is very wide in order to fit everything in. Eventually I'll fit throttle bodies, which will then be mounted

vertically but for the moment I'll knock up some adapters which fit the carbs at the correct angle to the heads.

|

|

|

Ugg10

|

| posted on 10/4/16 at 11:53 AM |

|

|

I have just come over all unneccessary!

Great project, would look nice in a spire gtr (mini lmp2 type car) with an audi a4 / bosxster transaxle, boxster may be beter as it has the gear

change going the right way (forward), not sure if these boxes will rev to 10k though. In fwd format the s2000 may be a good choice as it is designed

to 9k as standard.

i assume the two cranks turn in the same direction, have a cog on the end that meshes with a cog on the end of of the central drive shaft or are the

cogs at either end of the drive shaft?

Keep us posted.

[Edited on 10/4/16 by Ugg10]

---------------------------------------------------------------

1968 Ford Anglia 105e, 1.7 Zetec SE, Mk2 Escort Workd Cup front end, 5 link rear

Build Blog - http://Anglia1968.weebly.com

|

|

|

obr_technology

|

| posted on 10/4/16 at 12:50 PM |

|

|

Thanks, I like the idea of a spire or similar!

For the transmission I have geared down the output speed by using larger gears that the crank has fitted so 12000rpm at the crank will be 8000rpm at

the flywheel. This should allow use of a more 'normal' box, even if it does need uprating. Obviously the torque output isn't going

to be huge so should be okay for initial testing.

The cranks turn in opposing directions as otherwise you end up with one exhaust in the middle of the bank. I'm using an idler gear to reverse

the rotation but space restrictions and 27000 rpm mean I'm struggling to find a suitable bearing!

|

|

|

obr_technology

|

| posted on 10/4/16 at 09:46 PM |

|

|

Here is the dry sump tank I got from the U.S.

It's from a NASCAR, has built in heaters to get the oil up to temperature before cranking and clamp in the middle to take it apart and clean.

It's capacity is 2 gallon, so capable of holding enough oil for two cranks, four cams etc...

[URL=http://s279.photobucket.com/user/hornetob/media/Engine/_57.jpg.html] [/

URL] [/

URL]

[Edited on 10/4/16 by obr_technology]

|

|

|

daniel mason

|

| posted on 10/4/16 at 09:56 PM |

|

|

The terry Davis Yamaha R1 v8 is a work of art. As seen in Tim elmer hillclimb Dallara

|

|

|

obr_technology

|

| posted on 10/4/16 at 10:00 PM |

|

|

I think I saw that one at Autosport some years ago,

There is a guy who hillclimbs at Wiscome (Trevor Willis??) who runs a powertec/RPE v8 which looks lovely.

|

|

|

daniel mason

|

| posted on 10/4/16 at 11:04 PM |

|

|

Trevor's a former British hillclimb champion with the RPE v8 in it.

|

|

|

Ugg10

|

| posted on 10/4/16 at 11:14 PM |

|

|

quote:

Originally posted by obr_technology

I think I saw that one at Autosport some years ago,

There is a guy who hillclimbs at Wiscome (Trevor Willis??) who runs a powertec/RPE v8 which looks lovely.

There is a guy putting one of those in an Anglia 105e at the monent over on the 105speedhyperboards forum.

---------------------------------------------------------------

1968 Ford Anglia 105e, 1.7 Zetec SE, Mk2 Escort Workd Cup front end, 5 link rear

Build Blog - http://Anglia1968.weebly.com

|

|

|

obr_technology

|

| posted on 11/4/16 at 06:47 AM |

|

|

Nice! Have you seen the SHP spaceframe mk1 escort fitted with one? It's a thing of beauty.

|

|

|

obr_technology

|

| posted on 11/4/16 at 01:54 PM |

|

|

Ive just finished the Sump design, and have a colleague who is going to machine this for me as it is quite basic. Size wise it doesn't fit on

the bed of our regular mills, but we have a new CNC machine which has a large enough travel. I'm keen to spend a bit of time with him doing this

as I've not done any CNC programming or milling since I was studying so good to keep my hand in!

Material should be ordered mid-this week, hope to start machining early next week.

|

|

|

obr_technology

|

| posted on 14/4/16 at 09:12 PM |

|

|

quote:

Originally posted by obr_technology

Ive just finished the Sump design, and have a colleague who is going to machine this for me as it is quite basic. Size wise it doesn't fit on

the bed of our regular mills, but we have a new CNC machine which has a large enough travel. I'm keen to spend a bit of time with him doing this

as I've not done any CNC programming or milling since I was studying so good to keep my hand in!

Material should be ordered mid-this week, hope to start machining early next week.

Further to this post it appears that the new CNC machine has just been set up with the rotary table for 5 axis machining and I think the guys are a

bit worried about dismantling before they have the full training.

We will most likely be back in 3 axis mode by late June so I'm going to crack on and get all the remaining technical drawings finished and

material ordered so that we can do all the machining as soon as the mill is ready.

|

|

|

Ugg10

|

| posted on 19/4/16 at 11:19 AM |

|

|

Couple more techie questions as I am really interested in understanding this idea (a couple of zx6r engines would make a nice 1200cc 200hp+ engine ?

Seems to only work with bike engines, if you double the output of a car engine you may as well buy a car v8 i.e. 2 x Zetec SE 1.6 (good efficient car

engine) is approx. 240hp, 3.2l jag V8 is not dissimilar and probably lighter???):

1) do you have any assembly drawings/cad pictures of the output shafts/gear/idler, I am interested to see how they fit together and how central the

main shaft is?

2) what are you doing about the different oils in the system. usually the engine and gearboxes run different spec oils so do you have the drive gears

running in a separate sump with gear oil in it ?

3) are the drive gears straight cut or helical, was thinking that you could use gearbox gears mounted on a new shaft, plenty of ratios available for

the Type 9 that you could used ?

4) the questions everyone is really wanting the answer to - are you going to be selling kits in the future ?

Cheers, great project, do keep us all posted on progress.

---------------------------------------------------------------

1968 Ford Anglia 105e, 1.7 Zetec SE, Mk2 Escort Workd Cup front end, 5 link rear

Build Blog - http://Anglia1968.weebly.com

|

|

|

obr_technology

|

| posted on 19/4/16 at 12:24 PM |

|

|

Hi,

Really appreciate your interest, will try and answer those in turn.

1) I'll get some pics up of the assembly, there might be some feedback people can give regarding what I have designed. Essentially the gear on

the crank which originally fed the gearbox is now connected to a large gear which transmits to the central shaft above the cranks. I've built a

couple of things into this, firstly the whole assembly can be mounted a lot lower in comparison to the gearbox input shaft, which is lowered the c of

g for a 70 or 80 kg part. Secondly the gears are larger which means the output speed of the engine is reduced from a maximum of 12000rpm to 8000rpm

meaning a more conventional gearbox can be used. I'm not sure if I've mentioned this before but the idler is causing a real headache as

it will be spinning at 27000 rpm max and that is difficult to find a bearing which isn't going to cost me a fortune! I've also built in

an anti-vibration coupling which can run in oil, but provides a little flex in case one side is running at a slightly different speed to the other, as

well as hopefully reducing any of the issues caused by the combined primary/secondary forces (this area of engine design isn't my strong point,

but I believe I know enough to overcome the issues).

2) I have always planned to use a similar oil to that which Kawasaki specified as from memory the oil is shared between gears and engine in the bike.

I do have a dry sump pump which I believe will reduce the life of the oil due to the way it circulates, but I'll keep an eye on that as and

when.

3) The drive gears are metric straight cut. I've already got these, and as they are metric they are pretty much off the shelf other than the

fact I wanted the highest spec material. These have come pretty much as blanks, so I will be lightening these, although I had a hare-brained scheme

to build in some kind of adjustment once the engine is running as I'd like to consider what affect changing the link between the cranks has, ie

if the second bank fires 10 degrees after the first does the power or torque change (I'm thinking of the big bang engines). Alternatively

I'd like to look at whether it is possible to run on one bank and then fire up the second bank at another time on demand.

I'm not 100% sure I understand what you mean about the type 9 gears? My flywheel is bolting onto a drive flange similar to that which is on the

end of a zetec crank, which allows traditional car engine flywheel and clutch to engage with the type 9. Sorry if I have missed your point.

4) I'd love to sell some of these, in all honesty I'd like to get to a point where I could start selling some of these in the future. The

main issue I have at the moment is that the crankcase itself has been so expensive that by the time I've finished the costs will be huge.

However if I can get to the point where I'm able to order larger quantities of all the machines parts then it would be much more cost effective

for any potential customers.

Hope this answers your questions, thanks again for your interest it certainly keeps me going!

|

|

|

obr_technology

|

| posted on 19/4/16 at 12:47 PM |

|

|

I've just been having a look at the 1.8t RX8 thread next door and the chap has just confirmed that the starter motor for an RX8 6 speed box is

on the bellhousing side.

As you can probably imagine if you take a look at the image below of the mocked up engine a conventional type 9 bellhousing puts the starter motor

pretty much exactly where my cylinder head is, so the RX8 unit should be far better.

I'm hoping that should I be able to find a suitable transaxle which operates in the same way as well, but have already looked at the Porsche

boxster and the starter is on the engine side. I'm sure that once I have the money for a hewland then bellhousings will be plentiful in all

manner of shapes and sizes!

|

|

|