idea for steering collumn

blakep82 - 11/3/10 at 11:19 PM

all this talk of addiing steering UJs, a turbos/alternators(thats mine  although i've sorted that now )/oil filters/exhaust header etc being in

the way, i've had an idea. i bet its a complete non starter but here goes

although i've sorted that now )/oil filters/exhaust header etc being in

the way, i've had an idea. i bet its a complete non starter but here goes

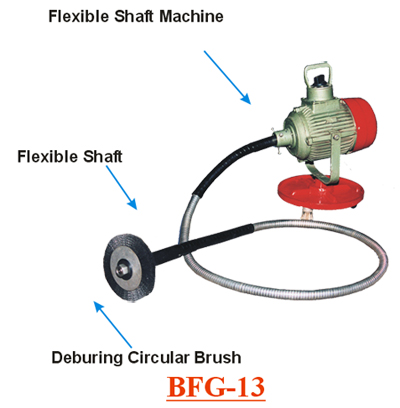

you know those flexible shafts you get to attach to your drill to reach round awkward places like these:

couldn't something like that be used instead of the usual steering column?

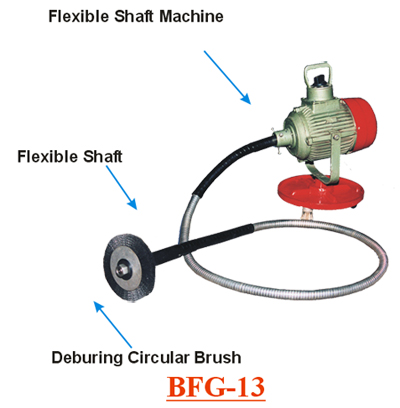

or to put it another way, i found this connected with the terrible picture below:

Flexible Shafts are often used to remotely actuate valves. Typical applications are in ships, where valves buried deep within the hull of the ship can

be actuated from the top deck 60 feet away by use of a Flexible Shaft. Other common applications include chemical and power plants where many valves

spread out over a distance need to be accessed from one location.

not convinced by the power and chemical location thing. surely you'd use servos and electric for that... anyway,

couldn't something similar be used instead of the steering column? it could be routed round all the awkward bits.

yes there'd be a degree or 2 taking up the torque in the cable, but if the outer cable was greased up nicely to take as much friction away as

possible, i think it could work. if it can work 60 feet under the sea, i think it can work the 2 metres or so between steering wheel and steering

rack

[Edited on 11/3/10 by blakep82]

rost - 11/3/10 at 11:40 PM

I'd say there would be too much play on a shaft like that. That said, I only have experience with smaller variants of these.

Wouldn't a simple hydraulic system be easier and more direct?

skinned knuckles - 11/3/10 at 11:47 PM

i have just had a play with one of those that fits on to my handheld drill. with a polishing bonet on the end to give a decent resistance, i managed

to get over 15 degrees of twist down the shaft. not a good omen for your idea.

clairetoo - 12/3/10 at 06:51 AM

There was a Lotus 11 replica at one of the shows a few years ago with a short section of that type of flexi in the column .

I could easily get 10 - 15 degrees of movement EACH WAY in the steering wheel without the wheels moving

Those watching were amused - the guy selling the kit wasnt  (never saw that kit again.......)

(never saw that kit again.......)

02GF74 - 12/3/10 at 07:10 AM

also the way those things are made, spiral wond steel thingy, you'd expect there to be more backlash truning in one direction, and the drill

extension shafts turn the one way so running them in opposite direction may not be too clever.

funnily enough, I was thinking of the possibilities of using one for a propshaft.

britishtrident - 12/3/10 at 08:15 AM

Memories of the flex cable shaft on Hillman Limp gearchange linkages ------ AVOID

Daddylonglegs - 12/3/10 at 08:19 AM

quote:

Originally posted by rost

Wouldn't a simple hydraulic system be easier and more direct?

Don't they call that power steering?

MikeRJ - 12/3/10 at 10:17 AM

quote:

Originally posted by 02GF74

also the way those things are made, spiral wond steel thingy, you'd expect there to be more backlash truning in one direction, and the drill

extension shafts turn the one way so running them in opposite direction may not be too clever.

Alternate layers are twisted in opposite directions to help this if it has to work in both directions.

They are utterly and completely unsuitable for something like a steering column however. Quite apart from the amount of twist these suffer from, has

any ever used a flexy cable on a drill and got the grinding bit jammed

Toprivetguns - 12/3/10 at 10:23 AM

No need to fix an design that works properly. Although keep brainstorming!

although i've sorted that now )/oil filters/exhaust header etc being in

the way, i've had an idea. i bet its a complete non starter but here goes

although i've sorted that now )/oil filters/exhaust header etc being in

the way, i've had an idea. i bet its a complete non starter but here goes