Tried to fit my extended wheel studs today so I can fit spacers.

I bought the extended studs from mtec on eBay and tried to pull them through using a spacer and wheel nut. It was pretty tight and after lots of

tightening the extended stud snapped.

I'm sure my car uses sierra hubs. Are these a 13.1mm spline diameter? I measured the old stud and it looked closer to 13mm.

Wish I had got bolt on spacers now.

I cant help you with the technical dimensions of your studs but can say that I have pressed a few studs in ali hubs. They went in with ease. I doubt that was because they well ali.

Assuming hubs are off the car, just twat em in with a hammer, easy peasy

No chance you will get them in with a hammer.

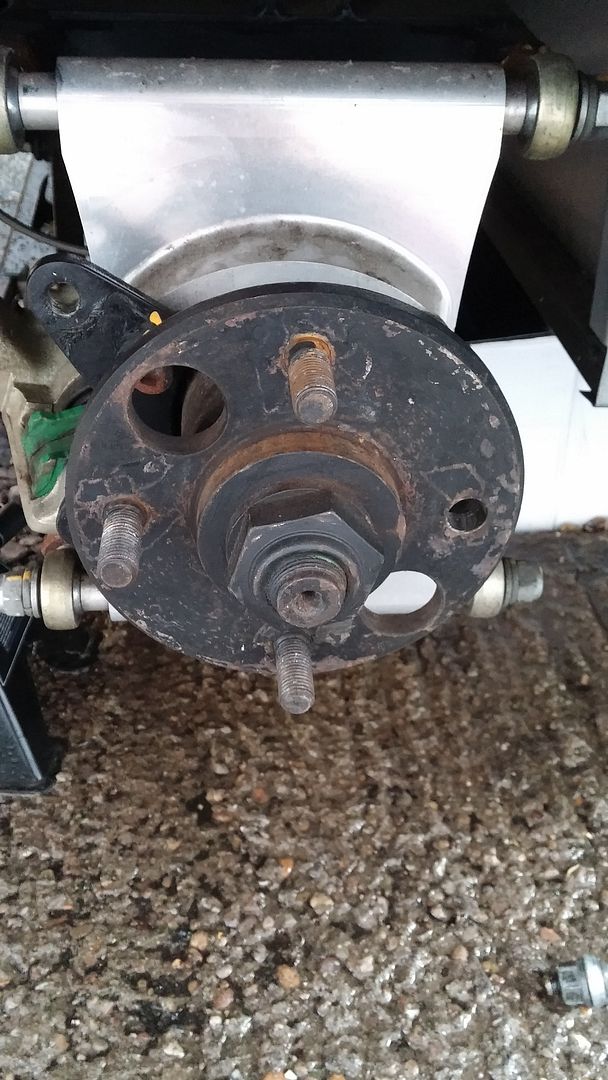

This is what the snapped stud looked like after I had removed it.

The stock one looks fine but the extended has been mangled as if its too big.

Just a sanity check, these are Ford Sierra hubs right?

They definitely use M12 1.5 bolts.

Got a reply from mtec. Supposedly you can't pull studs through and they have to be pressed fit.

Don't know if it will do much good in this case, but you could try one part in the oven, the other part in the freezer.

I've never known studs to be pulled through into a hub like that.

as above remove flange and then just hit them in with a hammer, will go in easy!

you can see by the damage to the stud where you went wrong, its started to pull the stud in but then the stud has turned when you were tightening the

nut and flattened the ridges, not a sniff of it going in then!

[Edited on 27/6/15 by CosKev3]

You can pull them in on new hubs, but on used ones it can be a PITA. A big hammer stops the turning that, as said, has folded the splines over and jammed the stud solid.

just replaced studs on my Cortina hubs, I heated hubs with gas torch then drew the studs through with spacer and wheel nut , went in with ease

ray

I expect that if you can get the new splines to key well with the splines left in the hub and stop it from turning then they should pull in fine. If you don't want to remove the hub then a G-clamp and some tube could be used to press them in