Pedal Design - Opinions?

flak monkey - 22/2/06 at 09:25 PM

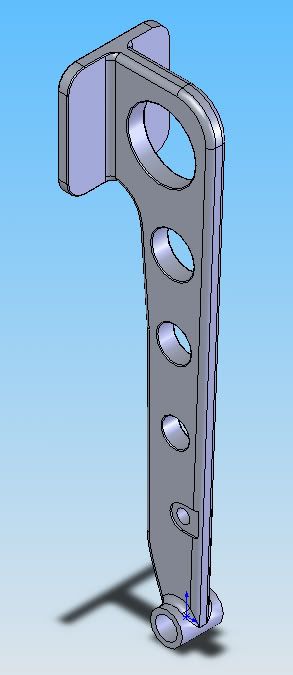

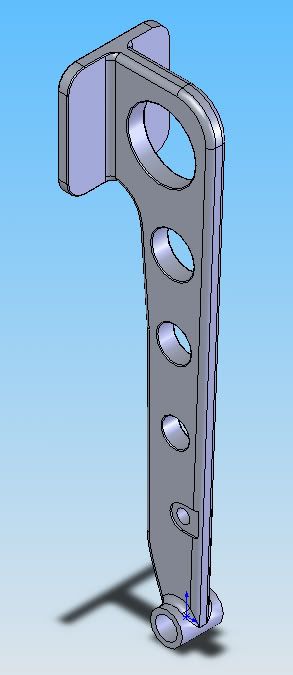

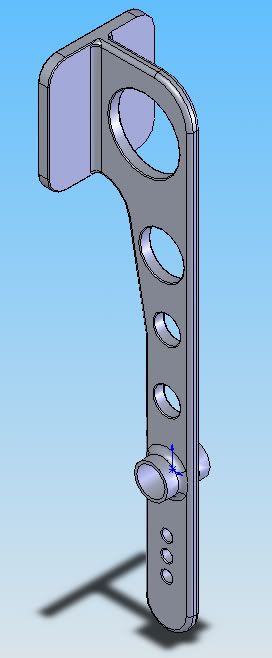

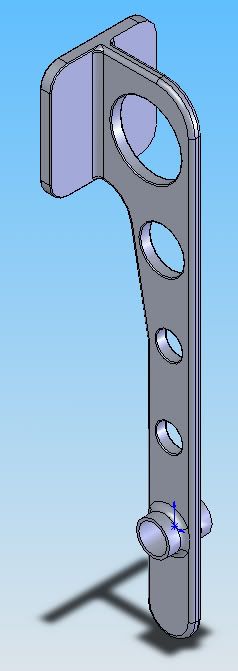

Just had a go at designing a set of pedals for my car. Designs are based on the GTS geometry, but not copied.

They are all aluminium (2018 grade), which is where the fun came in:

Brake is 10mm thick, and weighs 297g. Thickness reduced at clevis point to 8mm, which leaves that point the weakest. Designed to yeild with an 80kg

person (i.e me) standing on it at 2G deceleration. Is that enough?

Brake pedal pic:

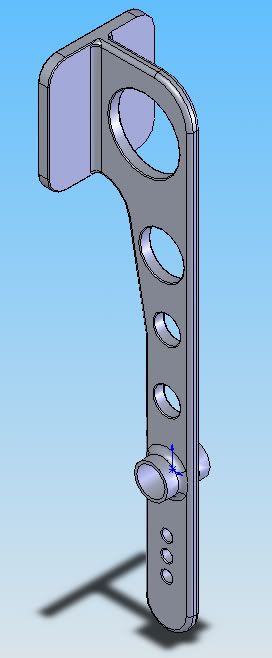

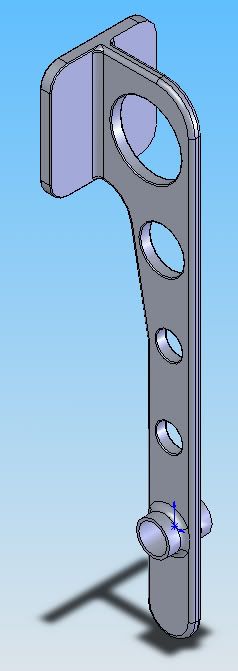

Accelerator and clutch are very similar, both 6mm plate and weigh 180g each. Both will yeild at a load of 1.5G with an 80kg person. Excessive probably

for that application.

Accelerator:

Clutch:

Any opinions or comments appreciated.

Cheers,

David

PS: Anyone know where I can get some 2018 or equivalent plate from? Obviously I dont want much!

JoelP - 22/2/06 at 09:30 PM

me personally, id design a little more strength into the brake - 2g isnt that much really, even though your full weight doesnt really hang on it, but

failure would be bad news.

ps, is it a hydralic clutch?

flak monkey - 22/2/06 at 09:40 PM

Cable clutch. There are just no holes in the bottom of the clutch pedal as I dont know where to put them at the moment.

Problem is I cant design any more stength into the brake as I am limited by the material The weakest point is where the clevis pin goes through the

pedal. The bit that sits inside the saddle is actually the weakest part. Short of going up to a long clevis (which is huge) I dont think I can do much

about it....unless anyone has any bright ideas!

David

ed_crouch - 22/2/06 at 09:57 PM

Would that be a UniGraphics model??

Presumably your strength figures are based on an ANSYS buckling analysis...

The design might change a little if you were to use 2 master cylinders in parallel with a balance bar in the middle??

When I was at Uni we tended to design aeroplane parts in 6061 and 7075 tempered to T4 or T6. I never actually machined any though: its probably a

right bugger to work!

Looks good, though. FEA and CAD are really coming within the grasp of the amateur car builder, and it'll result in more professional looking

kitcar builds.

Ed.

JonBowden - 22/2/06 at 10:01 PM

Can't see any point in trying to make that pedal light as failure would be quite bad

JonBowden - 22/2/06 at 10:03 PM

quote:

FEA and CAD are really coming within the grasp of the amateur car builder

Are any free / cheap FEA packages good enough and understandable with a bit of effort

(sorry, don't mean to steal the thread)

eddymcclements - 22/2/06 at 10:08 PM

The brakepedal might resist the 2G forces the first time you stand on it hard...and the second and third. What about the 237th time? The 946th? In my

opinion the lack of resistance to fatigue of aluminium and its alloys rules it out as a suitable material unless it's a pretty hefty forging or

casting. Save weight somewhere else.

Just my tuppence worth,

Eddy

flak monkey - 22/2/06 at 10:08 PM

Its a solidworks model actually. FEA with Cosmos. Not a bad package, simple to use. Got it through Uni

As for making it light, the drilled holes make no difference to where the pedal fails. All bending stresses are carried by the outer edges of

beams.

David

ed_crouch - 22/2/06 at 10:09 PM

Do a google search on free FEA

or get a "student license". Im *sure* David knows what I mean there...

Ahem.

Ed.

P.S. they are almost all limited in some way though... ANSYS multiphysics is still the big boy, and costs the earth.

As far a CAd goes, SolidWorks is probably the best cheap one. UG, ProE, CATIA (YUK!!!) are all biiiiig money, still.

ed_crouch - 22/2/06 at 10:11 PM

As a small point, David, the area where you have got the pedal thinned down to fit the clevis doesnt appear to allow any pivoting of the clevis

relative to the pedal. Expanding the thinned area to fix this may affect its buckling load.

Ed.

flak monkey - 22/2/06 at 10:21 PM

Heres the FEA showing those areas with a safety factor of less than 1.5 with that 2G design load. As you can see its all in that area within the

clevis. I could go up to a 10mm clevis and make a pushrod on the lathe at home to suit. That a reasonable solution?

You are right Ed, theres not quite enough room for the clevis to pivot. There is enough in there to allow a couple of degrees, but it does need

expanding.

David

Rescued attachment failure point.jpg

Bob C - 22/2/06 at 10:38 PM

I did a similar thing with the brake: apparently the ford spec is 1500newtons on the pedal & even using 8mm steel it was tough to get a safety

factor.

On your design the overstressed bit is where from the look of it the material is in compression due to the leverage exerted by the pedal -

shouldn't the design taper down towards the pedal ? (you effectively have a beam balanced on the clevis). You could make the ally a couple of

inches by 8mm up at the pivot/clevis end???

Bob

greglogan - 22/2/06 at 10:39 PM

Saw a brake pedal failing in Corolla rally car in Ireland some time back. It wasn't pretty. Don't know much about thew engineering side of

it but surely a bit more wouldn't hurt?

flak monkey - 22/2/06 at 10:46 PM

OK that makes me happier because thats designed for 1600N force on the pedal.

Yes the failure is on the compression side of the pedal. And it was modelled with a beam restrained at the pivot and with a force 5x that at the pad

at the clevis (pedal ratio is 5:1) as that was the simplest way of modelling it I could see.

If I use a 10mm clevis then the overstressed part isnt a problem any more. It just means I will have to make up a custom pushrod at home. Not a major

issue.

[Edited on 22/2/06 by flak monkey]

Bob C - 22/2/06 at 10:48 PM

here's a dodgy picture of what I was trying to say above.....

See what COSMOS thinks of it . . . . .

cheers

Bob

Rescued attachment pedals.GIF

flak monkey - 22/2/06 at 10:52 PM

Yep, that gives a safety factor of 1.6 for the design as opposed to only 1.05 that i had originally. Much better. Just needs a bit of tweaking i

think.

These are floor mounted pedals by the way...but the pivots are offset from eachother like the GTS pedals.

Liam - 22/2/06 at 11:15 PM

With all due respect it's still a scary design if you ask me! 6mm ally plate just aint up to the job imo. In engineering, for a critical

component (this is certainly critical) you work to a safety factor of at least 4 and commonly 10. If you factor in the fatigue you get with ally you

might even work to a safety factor of 40. A strong guy panic braking with all his leg strength, with his back restrained by the seat could probably

yield your pedal in a single operation!

Furthermore your design isn't stiff in torsion which will further stress it if the pedal is pressed nearer to it's edge.

Check out designs of tilton or AP racing pedal boxes for example. Or lotus elise pedals. They all will have a way higher safety factor than 1.6!

Please dont use this design in a car, even in steel!

Elise Pedals

CAD view of thinner throttle pedal

Elise brake pedal extrusion is about 20mm thick.

Liam

flak monkey - 22/2/06 at 11:23 PM

OK, point taken (brakes 10mm). Just figured that the material i specced on isnt suitable either. So bugger it.

*Note to anyone else thinking about this - Ali pedals arent a good idea.*

Will make them in stainless steel instead, or maybe i will just buy a set!

David

ed_crouch - 22/2/06 at 11:27 PM

When us aero types are desgning a bit of aeroplane, we go with a factor of safety of 1.5 for yield stress, and 2 for UTS.

But, we also eliminate single point failures, so there is always a "backup", or alternative route.

A brake pedal structural failure is a single point of failure of the braking system(catastrophic failure too), unless you consider the handbrake an

alternative!!!!!! I woudn't!!!

Ed.

P.S. I think that a brake pedal might be better made out of steel (EN1A is nice and easy), and run a higher FoS. But, this is still a good exercise,

and can safely be used for the clutch and gas pedal.

ed_crouch - 22/2/06 at 11:31 PM

Also remember that sometimes steels (7800kg/m^3 and UTS of about 300MPa) CAN give lighter solutions that Aluminium (about 2700kg/m^3, 60MPa?????

IIRC!).

Certainly where fatigue cycling is an issue the S/N curve (load stress Vs no. of cycles until failure) for steel is much better.

Hence why the ally locost chassis is a "unique" idea. No bugger'll trust one.

I thoroughly agree with using CAD to optimise designs though.

Ed.

C10CoryM - 22/2/06 at 11:43 PM

Do your calculations take into account that pretty much anyone can squat twice their body weight?  In the driving position you are nearly in a

seated leg press excersize. You can leg press MUCH more than you can squat. Not to mention that you may be stomping the pedal, not smoothly applying

weight. Also you will not be applying perfectly straight force into the pedal. There will be twisting forces as well. I have seen production car

pedals (rougly 1"X 0.25" carbon steel) get bent/twisted in panic braking. Even saw a guy with a VW take part of his dash apart and blow up

his M/C from stomping the brakes

In the driving position you are nearly in a

seated leg press excersize. You can leg press MUCH more than you can squat. Not to mention that you may be stomping the pedal, not smoothly applying

weight. Also you will not be applying perfectly straight force into the pedal. There will be twisting forces as well. I have seen production car

pedals (rougly 1"X 0.25" carbon steel) get bent/twisted in panic braking. Even saw a guy with a VW take part of his dash apart and blow up

his M/C from stomping the brakes  . I had to replace a bunch of parts to get him going again. He was maybe 65kg. I am the same weight as you and

I don't think 6mm of aluminum stands a chance

. I had to replace a bunch of parts to get him going again. He was maybe 65kg. I am the same weight as you and

I don't think 6mm of aluminum stands a chance  .

.

Cheers.

Liam - 22/2/06 at 11:46 PM

Yeah the aerospace industry is unique in that sense. But with tracable materials, strict lifing of components and double and tripple redundancy, you

can get away with lower safety factors (in order to make the things light enough to get in the air).

Just another point, flak - to get a more accurate picture of the stress throughout the whole pedal, I'd have though you'd want to restrain

both the pivot and part of the pedal surface, then load the clevis. This will get the pedal bending as it would in reality.

Liam

Liam - 22/2/06 at 11:55 PM

P.S. Ed - f.y.i my ally flywheel is 7075-T6. My mate who machined it from my solidworks model reported it was very nice to work with! Excellent

properties too. He has also made some 6061 parts for my mate's mountain bike, which went well too.

Liam

C10CoryM - 23/2/06 at 02:35 AM

Ok, Ive been home all day with a cold so Im bored. With a scale between me and a wall in a seated position I can easily push approx 280lbs (127KG)

with my right leg before my wall made a CRACK noise and I stopped  . I know I have pressed much harder than that while driving. I am not that

strong but I do mountain bike so I probably come up about average for a 180lb guy (82kg)

. I know I have pressed much harder than that while driving. I am not that

strong but I do mountain bike so I probably come up about average for a 180lb guy (82kg)

Hope this helps.

flak monkey - 23/2/06 at 08:19 AM

quote:

Originally posted by Liam

Just another point, flak - to get a more accurate picture of the stress throughout the whole pedal, I'd have though you'd want to restrain

both the pivot and part of the pedal surface, then load the clevis. This will get the pedal bending as it would in reality.

OK tried that, and yes you get different results. The the pedal fails at the weld between the pivot tube and the pedal arm.

I was modelling the pedal with a force on the pad equal to the force being applied by your foot, then restraining the pivot as it cannot move in the

car, and applying a force of 5x the pad pressure to the pivot (since the pedal ratio is 5:1). Whats wrong with this?

britishtrident - 23/2/06 at 08:42 AM

The basic premise of the calculations is flawed pedal pressure isn't always applied at 90 degrees to the pedal axis --- I would work with 10kn

applied at an angle of 30 degrees -- do that and I suspect your pedal will buckle like tissue paper. Then of course there are fatigue and stress

concentrations at welds to consider.

With brake pedals always use steel if made from solid material at least 8mm thick -- brake pedals do snap look what happed to Clay Regazzoni in an

F1 Ensign at Long Beach in 1981 ---"In the 1980 Long Beach race a brake pedal snapped and Clay's car went careering down a slip road to slam

into a parked Brabham which had retired earlier in the race. Clay sustained back injuries which invalided him out of the sport. Thereafter, partially

confined to a wheelchair - he can stand, but not walk - he sustains an active presence at most European Grand Prix commentating for Swiss

television."

Quote taken from http://www.gpracing.net192.com/drivers/careers/482.cfm

[Edited on 23/2/06 by britishtrident]

Hammerhead - 23/2/06 at 09:24 AM

Supplied MK pedals aren't 8mm steel.........do they need beefing up? Flak, how about having two uprights connecting the foot plate and the

pivot?you could weld tube between your machined holes to increase torsional stiffness.......just a thought.

NS Dev - 23/2/06 at 09:34 AM

Was going to post a reply and then I read BritishTrident's reply, which said exactly what I was going to say.

Also, in the first fea drawing, the pedal would not fail in compression at that point, as soon as the material started to distort, it would pinch the

clevis pin which would stop further collapse, then the pedal would fail in tension the other side.

Bob C - 23/2/06 at 10:55 AM

I found COSMOS less than perfect for this FEA task - it wouldn't model the pivots properly - so I couldn't get what I considered to be a

realistic overall simulation - ended up doing it in bits (and welding lots more steel on....)

It's good to see a consensus of concern about brake pedals and safety, I bet there's a lot of systems on the road that would fail the panic

test. And I'd include the offerings of most of the kit suppliers in that bracket!

re: angle of application of force - this angle is readily and accurately measurable as it is applied exactly from the right buttock. It's

probably more like 10 degrees.

cheers

Bob

Jumpy Guy - 23/2/06 at 12:19 PM

First off- I know nothing about materials, stress or any of that malarky!!

But- i design test rigs for a lot of F1 and sports car manufacturers

Recently, we did a test rig for a major F1 player who also make road cars...

The brake test schedule was -

250 Kg *1000 operations

100 kg * 249,000 operations

flak monkey - 23/2/06 at 12:45 PM

quote:

Originally posted by NS Dev

Was going to post a reply and then I read BritishTrident's reply, which said exactly what I was going to say.

Also, in the first fea drawing, the pedal would not fail in compression at that point, as soon as the material started to distort, it would pinch the

clevis pin which would stop further collapse, then the pedal would fail in tension the other side.

Thats what I thought would happen. I am going to play on the full Cosmos works soon and model it with a pin through etc and see what the results say

then. Should be a lot better I think.

Thanks for the loading info Jumpy Guy. Will work on something similar to those for my final designs.

Oh and thanks to everyone for all the input, always most appreciated

David

silex - 23/2/06 at 12:58 PM

Out of interest, once upon a long century ago I was working as a test engineer, and testing the brakes system in the vehicle was part of my job.

I could apply a steady force of 500lbs (approx 2200N) to a pedal with my right leg and in a sumulated panic braking sutuation (ABS or not) I could

apply an instantanious 950lbs (approx. 4240N)force to a pedal.

Admitadly I weigh in a tad more than your 80kg, but you would be so suprised how much force you are capable of generating on certain situations.

Liam - 23/2/06 at 01:19 PM

quote:

Originally posted by flak monkey

OK tried that, and yes you get different results. The the pedal fails at the weld between the pivot tube and the pedal arm.

I was modelling the pedal with a force on the pad equal to the force being applied by your foot, then restraining the pivot as it cannot move in the

car, and applying a force of 5x the pad pressure to the pivot (since the pedal ratio is 5:1). Whats wrong with this?

Hi there,

Ok i misinterpreted your description of your first model - i thought you just had a restrained pivot and a big load at the clevis and nothing else.

Still, as has been said, the solidworks bundled cosmos isn't realy capable of accurately modelling this situation. If the full version lets you

use pivots as restraints properly you're in business.

liam

britishtrident - 23/2/06 at 01:22 PM

FEA and FDA are tools that should only be applied after a liberal chunk of sceptical engineer common sense back of an envelope engineering.

I have straighten a few brake pedals that had bee bent sideways -- mainly on Minis and Imps but also Transits (istr the Transit used a pedal cut

from 8mm thick plate).

[Edited on 23/2/06 by britishtrident]

Liam - 23/2/06 at 01:38 PM

Here's an early shot of my nicely overbuilt steel brake pedal, made by my buddy Mark...

Liam

Rescued attachment pedal.jpg

NS Dev - 23/2/06 at 11:30 PM

now that ain't gonna bend is it!!!

Who does your lasering?

Liam - 23/2/06 at 11:34 PM

quote:

Originally posted by NS Dev

now that ain't gonna bend is it!!!

Who does your lasering?

LOL!! He he heee

Hacksaw, files and a bench grinder all the way!

LIam

NS Dev - 23/2/06 at 11:37 PM

......now that's patience!! It is funny what designs you can come up with that only use a holesaw and straight lines though! Lots of stuff on my

cars in the past made that way!

Very neat there though around the master cyl mounts, thought it was lasered!

britishtrident - 24/2/06 at 08:48 AM

quote:

Originally posted by Liam

Here's an early shot of my nicely overbuilt steel brake pedal, made by my buddy Mark...

Liam

Now that would give me confidence :-)

In the driving position you are nearly in a

seated leg press excersize. You can leg press MUCH more than you can squat. Not to mention that you may be stomping the pedal, not smoothly applying

weight. Also you will not be applying perfectly straight force into the pedal. There will be twisting forces as well. I have seen production car

pedals (rougly 1"X 0.25" carbon steel) get bent/twisted in panic braking. Even saw a guy with a VW take part of his dash apart and blow up

his M/C from stomping the brakes

In the driving position you are nearly in a

seated leg press excersize. You can leg press MUCH more than you can squat. Not to mention that you may be stomping the pedal, not smoothly applying

weight. Also you will not be applying perfectly straight force into the pedal. There will be twisting forces as well. I have seen production car

pedals (rougly 1"X 0.25" carbon steel) get bent/twisted in panic braking. Even saw a guy with a VW take part of his dash apart and blow up

his M/C from stomping the brakes  . I had to replace a bunch of parts to get him going again. He was maybe 65kg. I am the same weight as you and

I don't think 6mm of aluminum stands a chance

. I had to replace a bunch of parts to get him going again. He was maybe 65kg. I am the same weight as you and

I don't think 6mm of aluminum stands a chance