Top upright joint on a rocking arm suspension.

chrisg - 22/8/07 at 12:56 PM

Hey Up

I've been designing a top rocking arm front suspension and I had been intending to use the old Transit draglink end.

I've been having doubts because of the extra load imposed transfering the spring/damper loads through the joint.

Do you chaps think that a switch to a bolt on type joint which can be backed up with a plate is necessary?

All comments welcomed

Cheers

Chris

[Edited on 22/8/07 by chrisg]

MikeR - 22/8/07 at 01:12 PM

I have a vague memory of this conversation from a long time ago. Consensus then was it wasn't up to the job. Personally i haven't a clue

procomp - 22/8/07 at 01:16 PM

Hi reaserch on the raw striker setup would be a good start.

But the trouble is that no one as yet has managed to get this setup to work properly and last any real lenght of time without issues arrising. Inc

raw.

cheers matt

bob - 22/8/07 at 01:19 PM

Wasnt this a big topic on one of the cobra forums a while back, i seem to remember the bmw based cobra having the drag links or similar and getting a

right slating.

Although this car was linked to limelight/filby so it was never going to get good praise but thats another story.

clockwork - 22/8/07 at 01:30 PM

Sylva phoenix has rocker arm front suspension...

clockwork - 22/8/07 at 01:34 PM

As does the R1ot for that matter.

andyps - 22/8/07 at 01:42 PM

The stryker uses a Metro ball joint and seems pretty well set up to me - have a look at the times recorded by Strykers when competing against other

cars with similar engines in hillclimbs and sprints and they have to be good.

I'm using the Transit link unless someone convinces me otherwise!

britishtrident - 22/8/07 at 01:47 PM

A proper ball joint is required ideally one designed for push in loads --- Maxi, Mini spring to mind.

With this setup you might want to consider a different method of camber adjustment.

matt_gsxr - 22/8/07 at 02:11 PM

I know this has been mentioned...

but this may be more explicite!

Striker/Phoenix

METRO (late) -Top wishbone knuckle joints (for rocker arms).

Matt

mookaloid - 22/8/07 at 02:22 PM

I would have thought that the threaded portion of the transit draglink end would be an ideal site for fatigue cracking as it is subjected to repeated

and large amounts of bending force.

So not only not ideal but an accident waiting to happen IMHO

Cheers

mark

indykid - 22/8/07 at 03:38 PM

what about something like the joints dax use on the top wishbone? can't remember whether it's on the tojeiro or the rush

the bolts are perpendicular to the balljoint taper, so you can adjust camber with shims.

there may be nothing suitable in such a format, but just thought i'd throw it in.

tom

chrisg - 22/8/07 at 03:54 PM

Thanks for the replies chaps.

It was the sideways stress on the threaded part that worried me.

I have a contact at Dax, I'll give him a ring.

Re camber alteration would slotted holes with some sort of locking device do this?

Cheers

Chris

chrisg - 22/8/07 at 04:09 PM

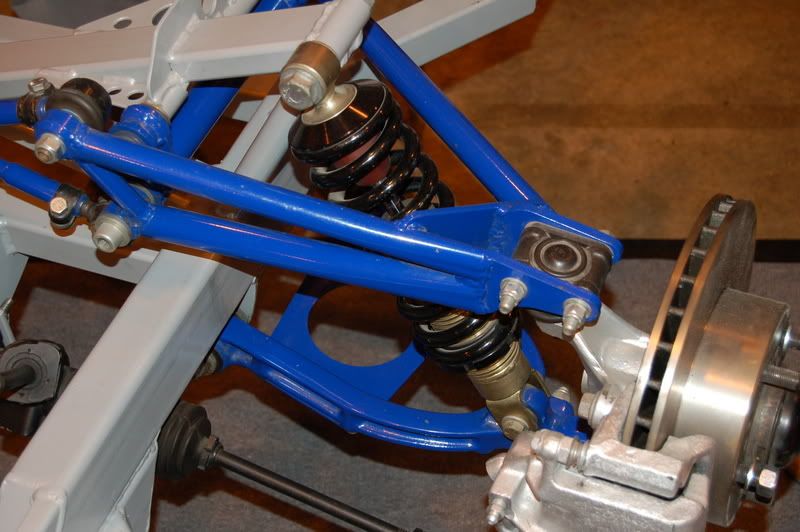

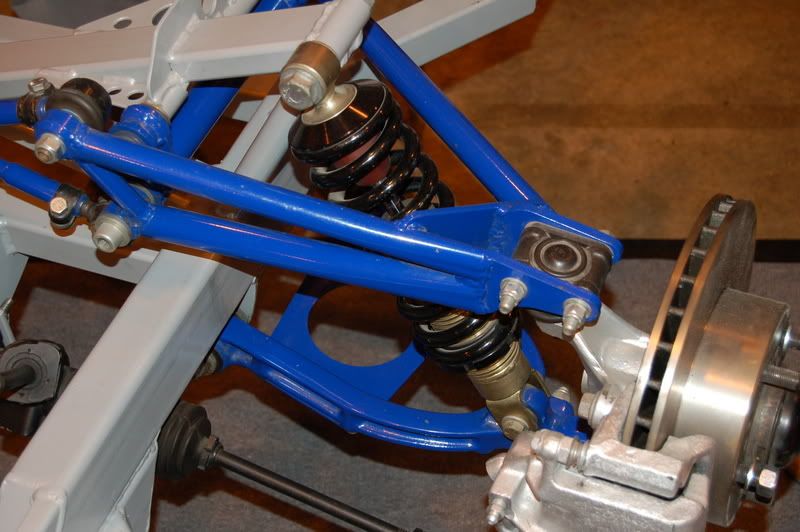

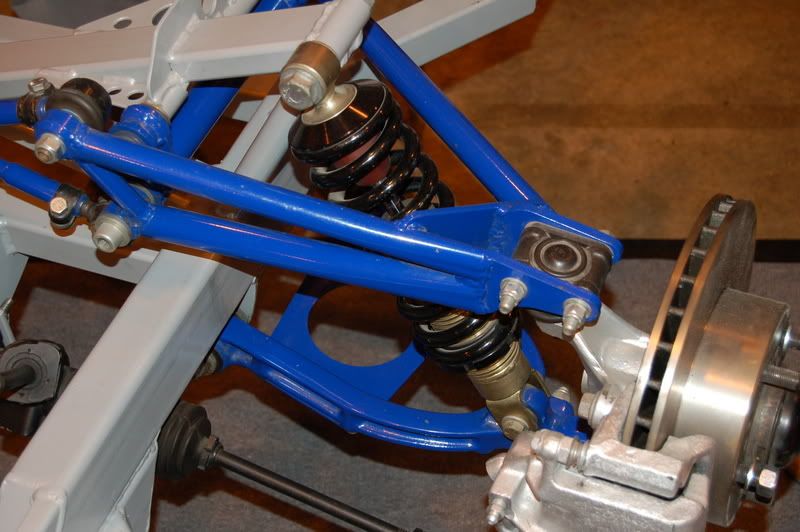

I've just rooted out this picture from stoneleigh.

This set-up looks pretty good, anyone any idea where that joint is from?

Cheers

Chris

Liam - 22/8/07 at 04:42 PM

That's a dax top joint - not sure what it's from but they'll be able to tell you. I'm using maxi joints on my setup.

Liam

chrisg - 22/8/07 at 04:55 PM

Yeah I know, it's from the Tojerio, camber compensation set up.

Just don't know where the BJ is from!

Cheers

Chris

40inches - 22/8/07 at 05:07 PM

quote:

Originally posted by chrisg

Yeah I know, it's from the Tojerio, camber compensation set up.

Just don't know where the BJ is from!

Cheers

Chris

Jaguar XJ6 around 1993

OK! make that 1995-97 http://www.autopartswarehouse.com/replacement_sm/jaguar~ball_joint~replacement.html

[Edited on 22-8-07 by 40inches]

jack trolley - 22/8/07 at 05:08 PM

The Tojero (Cobra) uses Jag IRS & IFS.

Obviously the top wishbone is fabricated for the camber compensation set up, but

the rest are probably Jag parts.

iank - 22/8/07 at 05:13 PM

If it's a Jag part it should be pretty rebust

chrisg - 22/8/07 at 05:29 PM

god bless you - I'll get one tomorrow!

Cheers

Chris

40inches - 22/8/07 at 05:38 PM

Used Just Jags before,very good service http://www.justjagsuk.com/shopdisplayproducts.asp?Search=Yes

MikeRJ - 22/8/07 at 05:46 PM

Apart from the strength of the threaded part of the drag link, the other reason not to use it is that the ball joint is spring loaded in order to

eliminate any play as it wears. By putting loads verticaly into the balljoint, the spring will be compressed and you will end up with a floppy ball

joint.

mark chandler - 22/8/07 at 10:38 PM

David Manners for me when asking for Jag bits

linky thing

They list a lower ball joint on the front suspension as CAC9937, its £20.56 with VAT. Although its years since I had a jag it does look familiar.

Regards Mark

Regards Mark

chrisg - 22/8/07 at 10:51 PM

I think it's the upper one CAC9938?

cheers

Chris

Peteff - 23/8/07 at 09:56 AM

Are they spring loaded Mike? Bottom ball joints on metro etc are but these are top joints and are track rod ( drag link) ends which don't usually

have springs. Has anyone destroyed one so we can check inside?

britishtrident - 23/8/07 at 06:06 PM

quote:

Originally posted by chrisg

I've just rooted out this picture from stoneleigh.

This set-up looks pretty good, anyone any idea where that joint is from?

Cheers

Chris

1960s-90s Jag XJ6 -- part -- not designed for spring loads

Triumphs and SAAB 99 also use something similar.

The SAAB one is designed for push in balljoint loads as is the Triumph Dolomite one.

britishtrident - 23/8/07 at 07:03 PM

Saab 90,99, 900 1974-1990

http://www.partsforsaabs.com/product_info.php?cPath=2_78&products_id=1664

Rescued attachment PFS901664_large.jpg

chrisg - 24/8/07 at 03:35 PM

Thanks trident!

When you say that the jag part is "not designed for spring loads", is it not used in this way on the DAX?

I presume that he SAAb part IS designed for spring loads?

Cheers

Chris

40inches - 24/8/07 at 04:09 PM

quote:

Originally posted by chrisg

When you say that the jag part is "not designed for spring loads", is it not used in this way on the DAX?

I was thinking the same,the Jag part is a TOP ball joint,why isn't it suitable? I was planing on using these on the 40

MikeRJ - 24/8/07 at 11:14 PM

quote:

Originally posted by Peteff

Are they spring loaded Mike? Bottom ball joints on metro etc are but these are top joints and are track rod ( drag link) ends which don't usually

have springs. Has anyone destroyed one so we can check inside?

Definately, at least the track rod ends I have seen have had springs to preload them, thats why they are so stiff to move. I can't imagaine them

lasting 60,000 miles plus if they simply relied on the fit of the ball in the socket. Just like rose joints, the tinest bit of wear and they would

get very sloppy.

Don't need to destroy it to check, just clamp it up in a vice.

[Edited on 24/8/07 by MikeRJ]

gazza285 - 24/8/07 at 11:35 PM

quote:

Originally posted by chrisg

When you say that the jag part is "not designed for spring loads", is it not used in this way on the DAX?

It is not designed to takes any weight in the plane you want it to. On the Dax it does not carry any of the cars weight, it only stoppes the wheel

from falling over, the load is carried by the bottom joint.

In a normal Locost the bottom ball joint takes the weight and is used in tension. A Transit drag link can also be used in tension. To use a rocker arm

suspension you need a joint that will work in compression. The point that BT is trying to make is that tension ball joints have a spring that pushes

the ball onto the joint preventing play, when you then put this joint in compression the spring is then taking the weight, not the ball, and the ball

will move out of the cup, leading to play, and joint failure.

britishtrident - 25/8/07 at 08:26 AM

quote:

Originally posted by chrisg

Thanks trident!

When you say that the jag part is "not designed for spring loads", is it not used in this way on the DAX?

I presume that he SAAb part IS designed for spring loads?

Cheers

Chris

It is a Jag XJ6 & MK10 top ball joint.

On Jags the spring (or in the case of the E Type the torsion bar) works on the lower wishbone much in the style of the Mk3-5 Cortina, the Jag lower

ball joint is massive.

On the SAAB and the Triumph Dolomite/1500 the coil-spring-damper unit acts on the top wishbone pushing the ball joint down into the cup.

(To explain a bit Standard-Triumph did a lot of the design of the original SAAB 99 for SAAB --- pitty they didn't keep it for themselves)

[Edited on 25/8/07 by britishtrident]

chrisg - 26/8/07 at 07:07 PM

Thanks chaps, looks like the SAAB joint is the one to go for if I can settle the other issues with the top rocking arm set-up.

cheers

Chris

britishtrident - 26/8/07 at 07:38 PM

Taper on the SAAB balljoint is unkown, of course it would also be possible to use SAAB up rights with gutted CVs --- istr PCD is same as Ford up to

the GM take over.

chrisg - 26/8/07 at 07:49 PM

Shoudn't be a probem mate - It's being fitted to a fabricated upright, so the hole can be reamed to fit the joint.

Cheers

Chris