scootz

|

| posted on 5/11/17 at 06:37 PM |

|

|

Steering Column - Delete Key / Steering Lock Portion

Evenin' all.

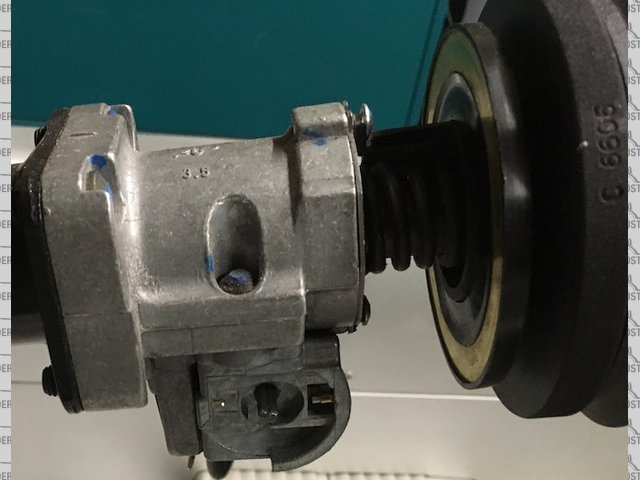

My steering column will be exposed in my project, so I want it to look neat and minimal. Pics below of how it looks with column, locking device and

boss.

I want to remove the boss and cut the column wall (not the shaft inside) immediately prior to the flange with the locking device), and then pull the

alloy locking component off. Then either leave the steering-shaft exposed, or bridge the gap to the boss by welding on a same diameter column

sleeve.

Now, me and my favourite tool (grinder) have cut into many things, but I've never been inside one of these locking components, so I've no

idea what I'm likely to find.

I can't just unbolt the component as they are finished-off with studs (so naughty folk can't bypass the locking mechanism by just

unbolting them). I know from experience that these fasteners are normally made from super-strong steel, so I'm not wasting drill bits.

Basically, what I'm trying to establish is if the final steering-shaft bearing is likely to be inside the column sleeve, rather than being

inside the locking component.

I wouldn't be worried about losing the spring loaded part as the angles of my full steering system are such that if the steering wheel hits my

face in a collision, then I'll already have lost everything from the bellybutton down! Also not worried about losing the steering-lock as I

have a removable steering-wheel. Oh, and the indicator cancelling flange can come off too - I won't be using traditional stalks.

So, before I do what I normally do (butcher a perfectly functioning component, then go out and buy another), I thought I'd ask if anyone has

been inside one of these parts and can provide some insight into the work I'd need to do if deleting the locking component and either leaving

the steering-rod exposed, or extending the column sleeve.

In my head, I'm hoping that the final steering-shaft bearing is located pre-locking component, and that I could leave it either with the

steering-shaft exposed for the last 3 to 4 inches, or continue the column sleeve without having to insert / retain a final bearing

Cheers

It's Evolution Baby!

|

|

|

|

|

scootz

|

| posted on 5/11/17 at 06:39 PM |

|

|

PS - the locking component is a Lotus part, so likely from some Ford or GM parts bin.

It's Evolution Baby!

|

|

|

mark chandler

|

| posted on 5/11/17 at 06:45 PM |

|

|

When I removed all that extra rubbish off my Sierra column I had to machine up a bush to support the revolving shaft, apart from that plain sailing

and looks much better without.

|

|

|

gremlin1234

|

| posted on 5/11/17 at 06:53 PM |

|

|

quote:

Originally posted by scootz

I can't just unbolt the component as they are finished-off with studs (so naughty folk can't bypass the locking mechanism by just

unbolting them). I know from experience that these fasteners are normally made from super-strong steel, so I'm not wasting drill bits.

the studs are normally bolts with a shear-off section, and often not too tight. (they are really only the to deter a casual thief.)

First, I would try to undo them, probably tap them round with a cold chisel, centre punch, or similar

|

|

|

scootz

|

| posted on 5/11/17 at 07:18 PM |

|

|

Cheers guys. It will look so much neater without.

Mark - did you just put the bush in the column at the flange mating point with the locking component, or did you extend the shafts sleeve?

It's Evolution Baby!

|

|

|

rusty nuts

|

| posted on 5/11/17 at 07:45 PM |

|

|

As already suggested use a dot punch at an angle to loosen the shear bolts , once moved they normally come out easily.

|

|

|

big_wasa

|

| posted on 5/11/17 at 08:09 PM |

|

|

With them shear bolts I cut a slot in them with the dremel nice and deep and use a flat screw driver with a spanner for leverage.

|

|

|

daviep

|

| posted on 5/11/17 at 08:59 PM |

|

|

Often you can unscrew the security bolts using a small chisel to tap the head around, if that doesn't work then weld a nut on top of the shear

bolt and unscrew as normal.

Cheers

Davie

“A truly great library contains something in it to offend everyone.”

|

|

|

scootz

|

| posted on 5/11/17 at 09:13 PM |

|

|

Cheers y'all

It's Evolution Baby!

|

|

|

russbost

|

| posted on 6/11/17 at 11:12 AM |

|

|

Just a thought if the "project" is pre - IVA you'd be better to leave the steering lock on until you've tested as it

automatically complies with the security features by having the steering lock

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

mark chandler

|

| posted on 6/11/17 at 10:36 PM |

|

|

quote:

Originally posted by scootz

Cheers guys. It will look so much neater without.

Mark - did you just put the bush in the column at the flange mating point with the locking component, or did you extend the shafts sleeve?

I just machined a bit of nylon round into a top hat bush and bashed it in (tight fit) with a bit of glue, no need to extend the sleeve as it felt

plenty strong enough as all the flex is in the collapsable section.

|

|

|

scootz

|

| posted on 9/11/17 at 11:46 AM |

|

|

Thanks for all your input guys.

Have found a Powerflex top hat bush set that has the right OD. Will just need to bore out the hole to suit.

It's £20, but as it's intended as a suspension bush, I get 2 top hats... so can have a spare.

[Edited on 9/11/17 by scootz]

It's Evolution Baby!

|

|

|