Minicooper

|

| posted on 22/2/07 at 12:27 PM |

|

|

New Bearings Sierra Hubs

I've had the Sierra disc braked hubs blasted and I'm now replacing the bearings, the flange, etc come apart easy enough, I'm now

left with part of the roller bearing inside the hubs, how on earth do you get them out, they are very tight

Cheers

David

|

|

|

|

|

macnab

|

| posted on 22/2/07 at 12:29 PM |

|

|

a press I think

|

|

|

smart51

|

| posted on 22/2/07 at 12:47 PM |

|

|

I used a punch and a hammer to drive mine out. Tap alternatly on opposite sides to keep the bearing outer straight.

Push the new ones in with a press.

|

|

|

mookaloid

|

| posted on 22/2/07 at 12:49 PM |

|

|

As Mr Smart51 says Drift and hammer to get the old ones out, but I was able to tap the new ones in using the old bearing as a drift. Just make sure

it's fully home before reassembly.

Cheers

Mark

"That thing you're thinking - it wont be that."

|

|

|

Duncan_P

|

| posted on 22/2/07 at 12:50 PM |

|

|

I wouldnt recomend this as a particularly good way of doing it but.....

I knocked mine out very carefully with a copper drift. On inspection i dont appear to have damaged the hub carrier itself but only time will tell.

|

|

|

mcerd1

|

| posted on 22/2/07 at 12:59 PM |

|

|

Yep, knock them out from the centre with a drift/ punch - it shouldn't be to tight

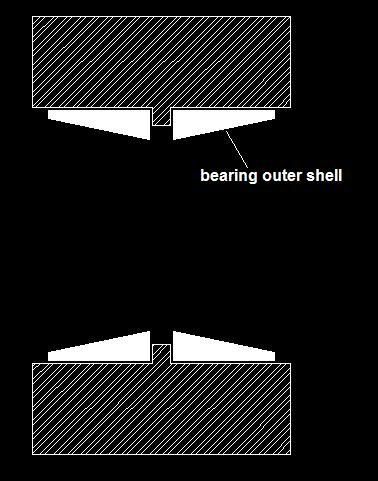

here's a pic of the hub carrier with them removed:

and a quick sketch of the x-section

|

|

|

Minicooper

|

| posted on 22/2/07 at 01:05 PM |

|

|

Thanks everyone,

I've done other wheelbearings in the past, they have started to move fairly easily, but these seem very tight. I have soaked the carriers in

WD40 overnight, it may or may not help but I'll give it another go

Cheers

David

[Edited on 22/2/07 by Minicooper]

|

|

|

ReMan

|

| posted on 22/2/07 at 02:00 PM |

|

|

quote:

Originally posted by CaLviNx

Hi

........ its not recommended to be done by the ham fisted

Not heard that phrase since my mother used to call me it!!

ham-fisted

adj : not skillful in physical movement especially with the hands;

"a bumbling mechanic"; "a bungling performance";

"ham-handed governmental interference"; "could scarcely

empty a scuttle of ashes, so handless was the poor

creature"- Mary H. Vorse [syn: bumbling, bungling,

butterfingered, ham-handed, handless,

heavy-handed, left-handed]

|

|

|

Agriv8

|

| posted on 22/2/07 at 03:31 PM |

|

|

if you have acses to a welder a run of weld arround the bearing outer shell surface. ( needs to crank up the amps )

When the welds cool it contracts pulling the shell with it the bearing. turn over quick tap and they drop out.

need to be reasnoble shot beause you dount want to weld it to the carrier.

used this method several times and it works. from a freind who plays with big diggers

regards

Agriv8

Taller than your average Guy !

Management is like a tree of monkeys. - Those at the top look down and see a tree full of smiling faces. BUT Those at the bottom look up and see a

tree full of a*seholes .............

|

|

|

andyps

|

| posted on 23/2/07 at 07:54 PM |

|

|

WD40 is unlikely to be much help. Application of heat to the housing via a blowtorch should do the job. Main thing if you want to re-use the bearing

is to ensure the drift that you use to knock the bearing out is of a softer material than the bearing itself. Same applies to fitting the new ones (or

re-fitting old parts) although as Mark suggests, the old bearing outer can be a really useful drift as it will give a nice maximum surface size drift

so reducing the possibility of any stress risers which can occur using point contact.

Andy

An expert is someone who knows more and more about less and less

|

|

|