Cobra289

|

| posted on 21/7/20 at 06:05 PM |

|

|

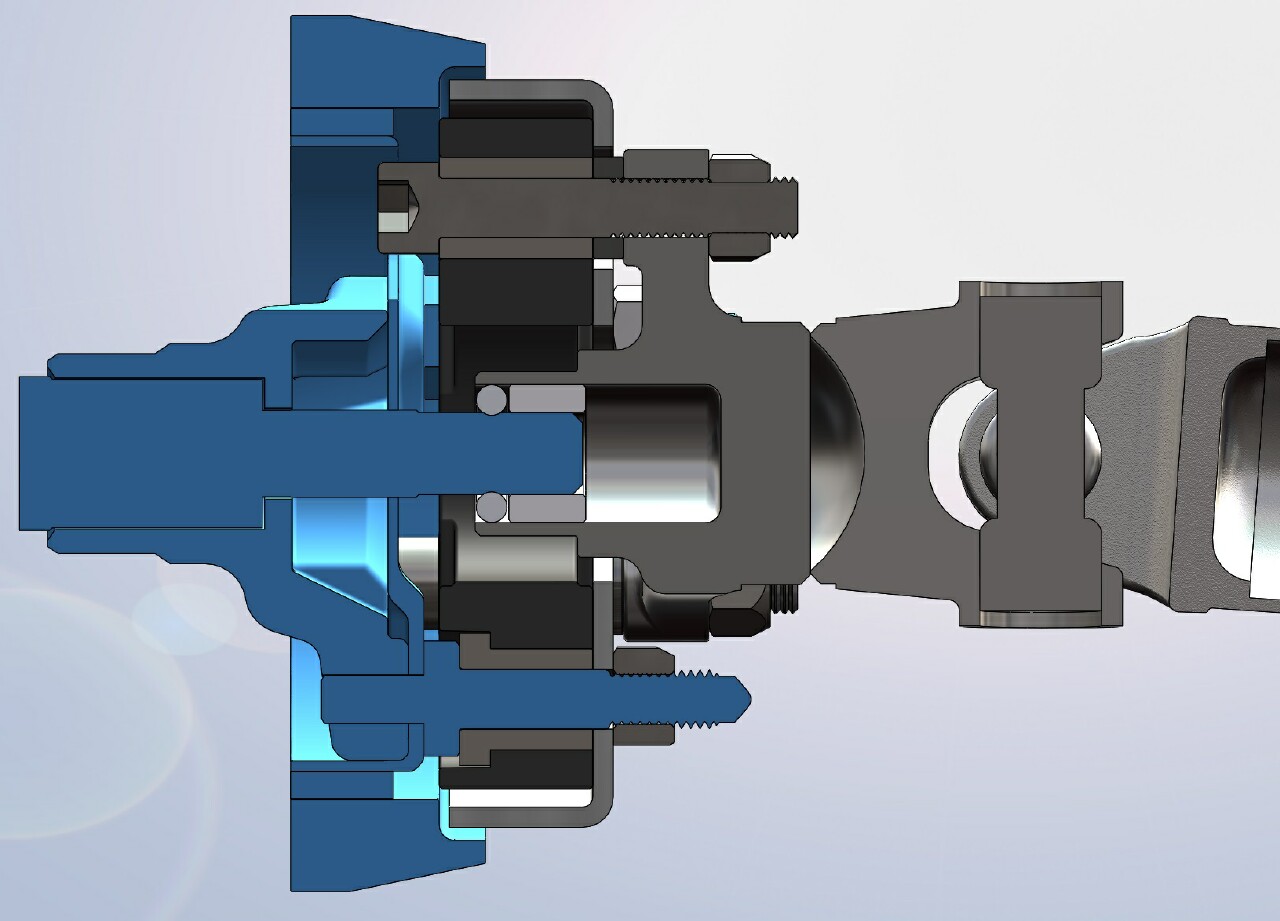

Propshaft 3 prong Bearing or guide

Hello,

I wonder where I can buy the bearing or guide that has the Sierra 3x prong flange.

This is the flange that connects to the rubber donut.

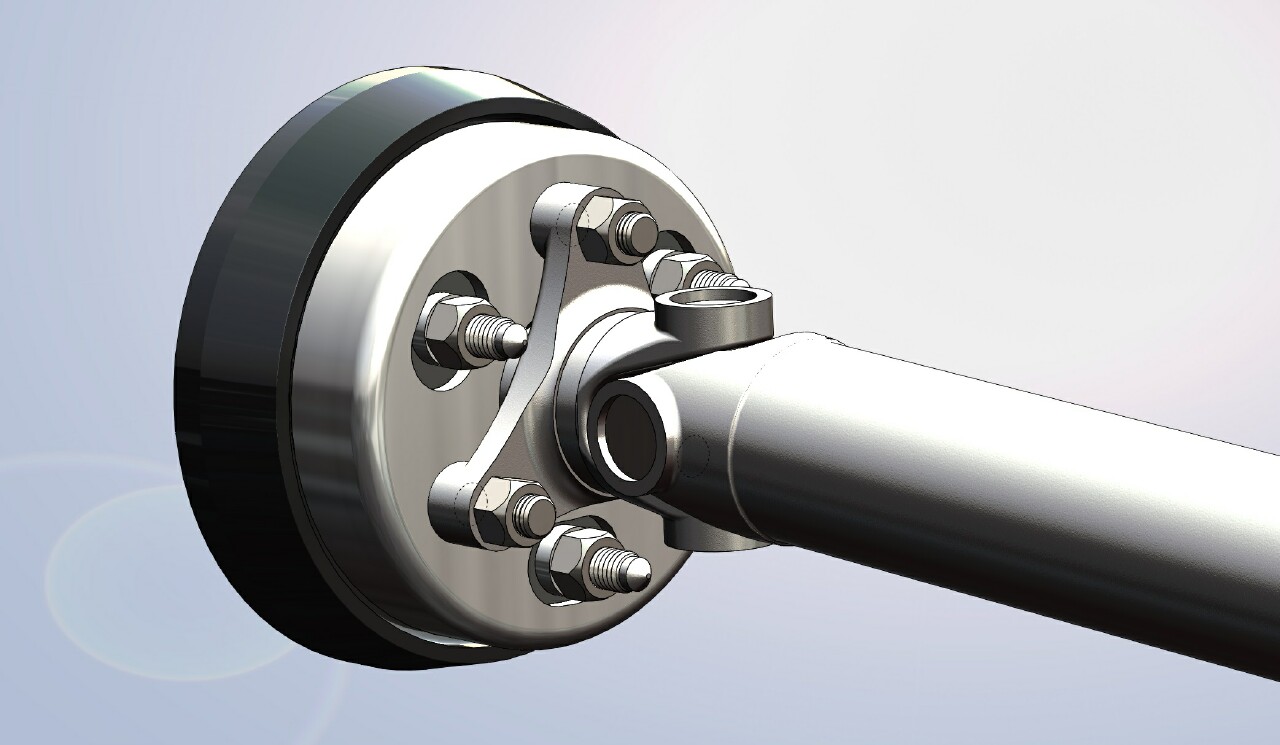

See picture that show the old bearing or guide.

Best regards,

Cobra289

|

|

|

|

|

big_wasa

|

| posted on 21/7/20 at 06:52 PM |

|

|

You should be able to measure the old one and find somthing.

Is that a Westfield Mt75 prop ? I have one in the garage.

|

|

|

Cobra289

|

| posted on 21/7/20 at 07:18 PM |

|

|

quote:

Originally posted by big_wasa

You should be able to measure the old one and find somthing.

Is that a Westfield Mt75 prop ? I have one in the garage.

It is an original propshaft from the Sierra XR4

It looks like it is a plastic type, probably I can build one from Nylon PA6 would be perfect.

It guides the 17 mm diameter output shaft of the MT75.

The hole can be 25 mm

It looks like it is a dried old seal, but there is nothing to seal (no liquids) just a support guide.

I want to build a propshaft using existing components.

Also I will introduce the protection shield in case of the donut disintegrate.

Regards,

Cobra289

|

|

|

big_wasa

|

| posted on 21/7/20 at 07:31 PM |

|

|

Turn up a bronze bush.

There are two big firms that do props over here. One turns up an adapter to go from the tripod to a standard uj. The other modifies a uj to bolt to

the tripod.

|

|

|

Cobra289

|

| posted on 21/7/20 at 07:43 PM |

|

|

If you remove the original black disk you loose the "harmonic balancer"

The rubber donut is just to absorb large vibrations and torque upsets.

But the harmonic balancer prevent the wave bending of the gearbox output shaft.

I have clean out and do some measurements and it looks like suspension bushing,

an outer plastic ring of 27 mm with an internal metal cylinder with a inside diameter of 16 mm.

And the gearbox drawings say 17 mm wow!

A beryllium-bronze insert will be a good idea.

Now I need to pull out the old one, perhaps the hydraulic method.

Cobra289

[Edited on 21/7/20 by Cobra289]

|

|

|

big_wasa

|

| posted on 21/7/20 at 07:47 PM |

|

|

Yes I am aware itís a damper but there isnít a lot of room in the tunnel of most kits.

|

|

|

big_wasa

|

| posted on 21/7/20 at 07:49 PM |

|

|

|

|

|

Cobra289

|

| posted on 21/7/20 at 08:05 PM |

|

|

quote:

Originally posted by big_wasa

Yes I am aware itís a damper but there isnít a lot of room in the tunnel of most kits.

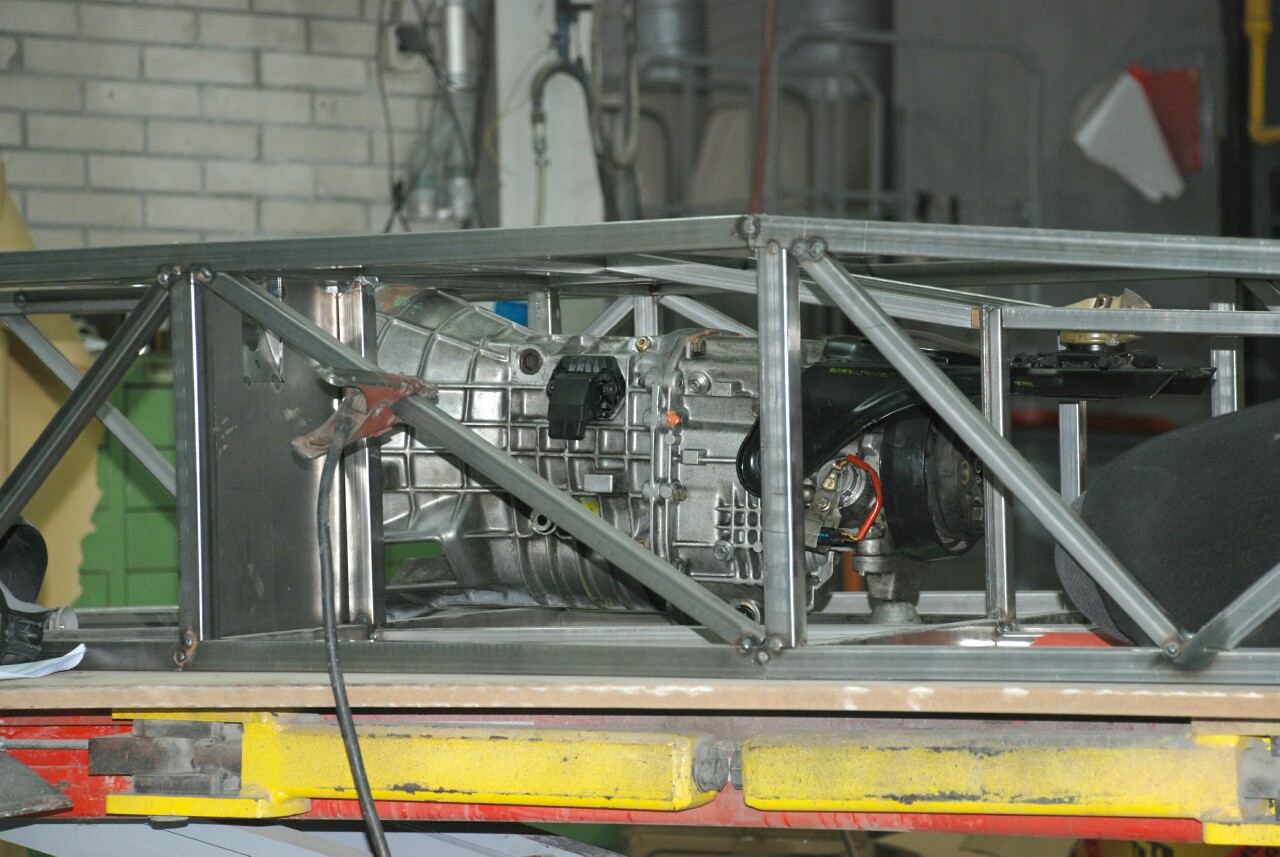

Oh! I understand, I don't have the space problem I made a wider chassis.

|

|

|

Cobra289

|

| posted on 21/7/20 at 08:17 PM |

|

|

Here is a better picture.

Dust seal?

27x16x7 mm

And than a bronze bushing of 27x16 mm L= 15mm

|

|

|

Cobra289

|

| posted on 22/7/20 at 09:15 AM |

|

|

Do you have experience with this kind of U-Joint???

Normally the u-joint yokes have the cir-clip to locate the u-joint, but this prop-shaft from a Ford Sierra (Germany) has some indents to fix the

location of the u-joint.

The question is:

- If I remove the indents will appear the grove for a cir-clip??

I wonder if you guys have had this situation.

All the u-joint's of the propshaft have the same fixing method.

Thanks in advance.

|

|

|

big_wasa

|

| posted on 22/7/20 at 05:04 PM |

|

|

Iíve never taken one to bits.

|

|

|

big_wasa

|

| posted on 22/7/20 at 05:06 PM |

|

|

I did make my own remote linkage.

|

|

|

r1_pete

|

| posted on 22/7/20 at 05:47 PM |

|

|

Here's how I did it, machined my own...

Bailey Morris used to supply this, but now they do a welded version.

|

|

|

big_wasa

|

| posted on 22/7/20 at 06:48 PM |

|

|

Iíve got a B&M in this one. A D&F in the last one. I doubt I will need another Mt75 Ďs are getting extremely hard to find.

I donít like the idea of a welded yoke at 7000rpm plus.

|

|

|

Cobra289

|

| posted on 22/7/20 at 07:33 PM |

|

|

Thanks for the pictures.

I like to see other solutions.

Welding the yoke is a standard procedure in the propshaft industry.

All the manufactures know how to do it.

They also use the "Friction Welding" method but that is for production.

Off course I will not weld my self those item I will bring to a dedicated shop that will be balance to 6000 rpm.

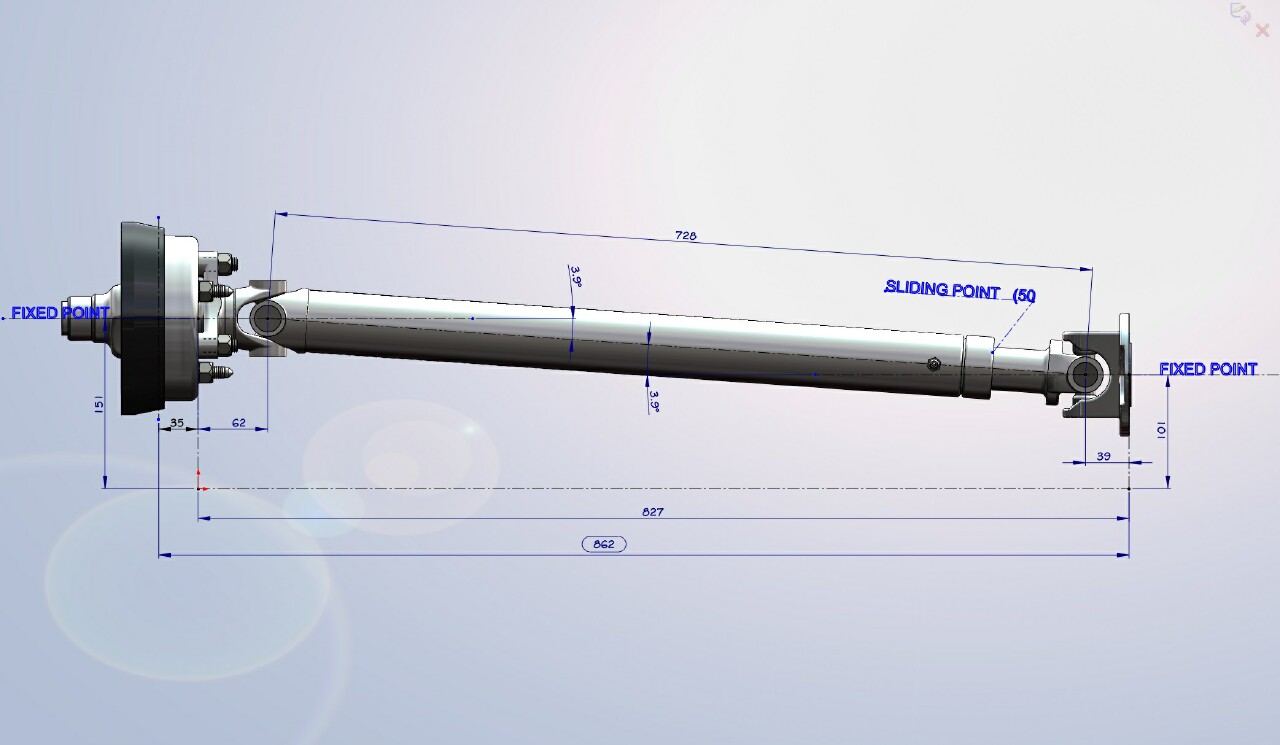

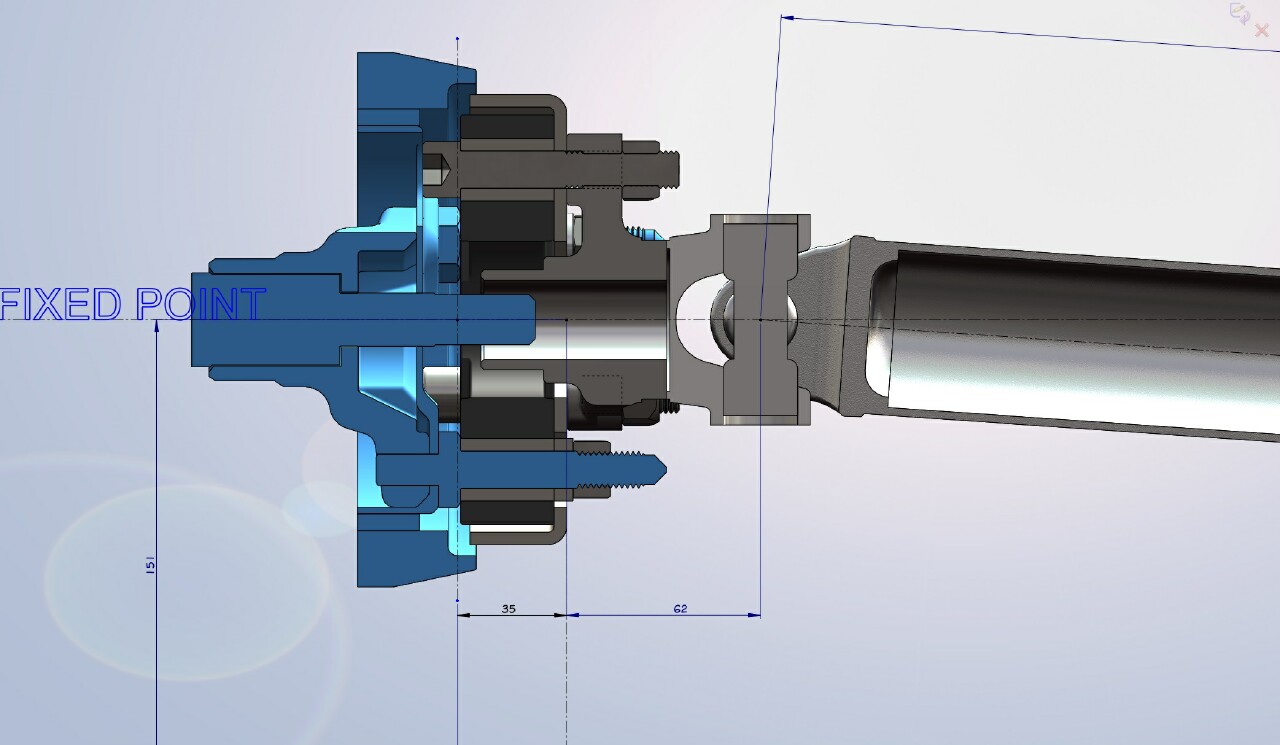

Here is my final design.

The 4 mm cover plate will now fabricated in Spain from AISI 4340 annealed to Rockwell 30-40

I like to use the triangle flange (tripod) because it fix the shaft via the internal bearing.

The output shaft of the gearbox is encapsulated inside the tripod flange. It is a nice safety provision from Ford.

My solution of the bearing is just keep the bearing an I will install a "O"-ring to seal the space between the shaft and the bearing.

Because both parts are bolted so there is no rotation the only thing that we need to prevent is the ingress of dirt in the area.

So a O-Ring is a perfect solution.

See the drawing.

The yoke's are not easy to solve I think that I should use the other shaft that I have and adjust the length.

Nice shifter Big_Wasa

kind regards,

Cobra289

|

|

|

r1_pete

|

| posted on 22/7/20 at 10:08 PM |

|

|

Ref your peened in UJ's, you will need a specialist to machine circlip grooves and supply the corresponding UJ's.

|

|

|

Cobra289

|

| posted on 22/7/20 at 10:23 PM |

|

|

Thanks!

Probably it would be better to buy new yoke's with the circlip grove all ready integrated.

I have an other porpshaft with the right yokes. See photo.

The right side is correct for the Sierra diff, so I will need to remove the left flanged yoke and replace for a tube yoke welded to the Sierra tripod

flange.

I thought that I could use the original Sierra propshaft but it is clear that this will not work.

Regards,

Cobra289

|

|

|