MK_Bob

|

| posted on 26/7/06 at 01:55 PM |

|

|

My midi's short-wishboned independant rear suspension

Good afternoon all.

I've been spending a lot of time trying to figure out a suspension system for my car. It's a Mini with a mid-mounted V6. I'm

planning to make up an IRS system, however with the engine being transverse and the Mini being quite thin, i don't have much room to work with!

I'll outline what i have drawn out at the moment, please point out anything that seems wrong.

For the moment i'm planning to use it as a track/drag car. Although i would like to make it road legal eventually, in which case i will probably

allow a bit more suspension movement.

I will be using double wishbones, according to my drawings the roll centre will be 15mm below ground. When the suspension is fully compressed (25mm)

during roll, the body rolls 3.5 degrees. The camber gain is -2 degrees per 25mm, so by setting the initial camber at around 1.5 degrees the tyre

should be fairly flat to the road during hard cornering. When the suspension is at full droop (again 25mm), the camber gain is -1 degree, but with the

initial setting of 1.5 degrees, the least possible amount of negative camber will be 0.5 degrees at full droop.

The main problem is that as the wishbones have to be very short (top wishbone will only be 100mm long!) the wheel moves inwards by about 16mm at full

bump. Whilst this should be ok during cornering, will driving on uneven roads in a straight line make the handling inconsistent?

This is my first suspension system, so i need all the help and advice i can get!

Thanks.

|

|

|

|

|

TheGecko

|

| posted on 26/7/06 at 02:12 PM |

|

|

When you say the wheel moves in by 16mm at full bump do mean the whole wheel or the contact patch or what? If the contact patch moves inwards by that

much it could make for an "interesting" feeling on uneven surfaces. Control of contact patch movement is as important as camber control.

If the tyre is trying to move sideways relative to the chassis, you're either begging it to break traction or forcing the sidewalls into duty as

suspension components (or both!). Is it possible to use a multi-link arrangment rather than a "pure" wishbone for the top to avoid such a

short wishbone?

For reference, I'm building a mid-engined clubman style car with 4-cylinder FWD drivetrain and I ended up settling on a strut rear because

it's so much simpler to fit around the engine.

Good luck with your design - perhaps you could post some drawings for us to comment on.

Dominic

|

|

|

Fred W B

|

| posted on 26/7/06 at 02:19 PM |

|

|

how long do you reckon the ultima front wishbone is?

ult fs

[Edited on 26/7/06 by Fred W B]

|

|

|

Fred W B

|

| posted on 26/7/06 at 02:24 PM |

|

|

and they use it with tyres THIS wide.

ult sus front

[Edited on 26/7/06 by Fred W B]

|

|

|

Fred W B

|

| posted on 26/7/06 at 02:29 PM |

|

|

This is the rear wishbone

ult rear wish

|

|

|

Fred W B

|

| posted on 26/7/06 at 02:32 PM |

|

|

And the rear tyres are even BIGGER

Probably they have very little travel though.

Cheers

Fred W B

ult sus rear

[Edited on 26/7/06 by Fred W B]

|

|

|

mark chandler

|

| posted on 26/7/06 at 02:58 PM |

|

|

Those bits of sawn off tube look ugly !!!

I guess because of the angle the footprint of the joining tube is larger than the bush, but why not shorten and cap the end ???

Price is the main reason I suppose, its these things that make a home build much nicer... the attention to detail.

Anyone know anything else.

Regards Mark

[Edited on 26/7/06 by mark chandler]

|

|

|

MK_Bob

|

| posted on 26/7/06 at 03:03 PM |

|

|

Aha, very good point Mr Gecko. The hub moves in by about 16mm, but a quick check with my carboard model shows virtually no contact patch movement

between the suspension at rest and at full bump. The camber change of 2 degrees compensates for the inwards movement of the hub! There is however 2mm

of contact patch movement at full droop, but that's pretty much irrelevant! Yay!

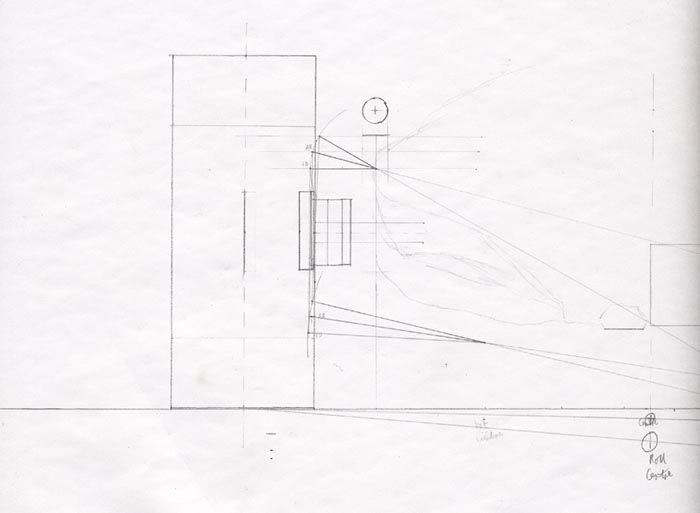

Here's a drawing, it shows the wishbones at full droop, at rest, and full bump. The two roll centres are for full bump (top one) and at rest

(bottom one), the wishbone lines do not meet when at full droop so i couldn't calculate a roll centre. Any idea what this would cause when the

suspension is at full droop?

Those ultima pictures are very reassuring Fred, until now i thought short wishbones were a big no no.

I'm feeling a lot better about this set up now, thanks guys.

|

|

|

NS Dev

|

| posted on 26/7/06 at 05:15 PM |

|

|

heh heh!!!

Personally I love the sawn off tube thing, looks extremely professional in my mind, certainly better than those AWFUL bent tube wishbones used by some

manufacturers!!!!

the Ultima wishbones are too short! yep it will still out-handle most cars but without going into too much detail, there might just happen to be

another version which you won't know about lurking on a car or two!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

froggy

|

| posted on 26/7/06 at 05:54 PM |

|

|

perhaps a mac strut would be more suitable that double wishbones?

|

|

|

MK_Bob

|

| posted on 26/7/06 at 06:10 PM |

|

|

I think i'll have a go with the design i have at the moment. If it doesn't work out as well as i hope, then i can choose between either

trailing arms or struts. It looks more promising than i thought, so as long as nobody points out a fundamental flaw (please tell me if there is one!)

then i think it's worth a try.

|

|

|

NS Dev

|

| posted on 26/7/06 at 07:46 PM |

|

|

why can't you use a longer bone?

If stuff is in the way be creative. You can soon use transverse + trailing link setup and run the transverse links behind the engine.

We use trailing arm rear on the grassers, which again is not ideal but it works, look at the swansea institute darrians, they were pretty competitive

in GT racing using really simple trailing arm rear setups.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

Chippy

|

| posted on 26/7/06 at 10:11 PM |

|

|

I'm fairly sure that having your roll centres below ground is detramental to the handling. Exactly why escapes me at the moment. If you can get

hold of a copy, Andre Jutes "Designing and building Special Cars" has the whole nine yards on the design of suspension, well worth a read.

In your position I would be looking to have a front roll centre of about +1" or 2", and a rear of about +3" or 4". One thing I

do know is that the rear should be more than the front. I designed mine to be 3" front, and 41/2" rear, goes round corners like a roller

skate. I also designed my wishbones to give about 2.5 deg's of body roll at full bounce, which, cornering, has the outside wheel with two

deg's of negative, (leaning in at the top), camber, and the inside at 0 deg's. Hope the above helps. Regards Ray

|

|

|

procomp

|

| posted on 27/7/06 at 07:26 AM |

|

|

HI i can certinaly vouch for the ultima wishbones being to short i built one of the first nobel 23 wich used the ultima wishbones all round . The car

had so much camber change during corners and roll we had to forget the project as the regs stated that we could not modify the original suspension and

Lee nobel would not change it.

cheers matt

|

|

|

MikeRJ

|

| posted on 27/7/06 at 10:33 AM |

|

|

quote:

Originally posted by Chippy

I'm fairly sure that having your roll centres below ground is detramental to the handling.

AFAIK the downside to very low roll centers is that it promotes more body roll, which may need stiffer anti-roll bars etc. to control.

|

|

|

simonk

|

| posted on 27/7/06 at 02:34 PM |

|

|

A question for those with much bigger brains than me.

If you designed a car where the roll centre was above the lateral C of G, would the car lean into corners ? Or if they were in the same place, would

you expect the car to corner completely flat ?

If either of these are case has it ever been successfully used ?

I have no intention BTW of modifying my Viento's suspension, just a philosophical question !! Thanks

|

|

|

MK_Bob

|

| posted on 27/7/06 at 04:58 PM |

|

|

The top wishbone cannot be much longer due to a big engine thingy, which takes up different areas of space in the engine bay. If i came up with a

creative solution for one side, chances are that the same solution would not work on the other side. Also, the circle in the drawing above the top

wishbone mount is a tube that makes up the side of the engine cradle, which i would like to mount the top wishbone from or near to.

The roll centre would hopefully not have too much of an effect due to the small amount of suspension movement, and as Mike says, an anti-roll bar

would help with that. I think i was lucky to be able to even calculate two out of three roll centres, let alone control their position! I will be

happy if the contact patch stays square and doesn't scrub sideways, i'll have to save controlling roll centres for the front

suspension.

Well i went to start on the original design, but quickly realised that the 70mm of ground clearance below the bottom wishbone mounts would not only be

very impractical, but look absoloutely ridiculous from behind. I've tried a few other wishbone lengths and positions, but none are as good as

the original design. I still want double wishbones, there are significant advantages over trailing arms (particularly for my type of car) so i

don't want to give up on them just yet. It's very frustrating to get stuck with this kind of problem, my target for having a rolling

chassis is september.

|

|

|

MikeRJ

|

| posted on 27/7/06 at 05:48 PM |

|

|

quote:

Originally posted by simonk

A question for those with much bigger brains than me.

If you designed a car where the roll centre was above the lateral C of G, would the car lean into corners ? Or if they were in the same place, would

you expect the car to corner completely flat ?

I wondered about this a while back, as it seems such an obvious thing to do.

The problem is that to raise the roll center up past to the average cars COG requires to the wishbones to point upwards at a silly angle, and the

resulting geometry causes bad "jacking" problems, just like the old Triumph rear swing arm suspension.

|

|

|

MikeRJ

|

| posted on 27/7/06 at 05:51 PM |

|

|

Just a thought, could you use a Jag rear axle arrangement where the driveshafts forms one of the suspension links?

|

|

|

MK_Bob

|

| posted on 27/7/06 at 07:14 PM |

|

|

I actually read about that method just this afternoon. I would think it requires driveshafts that don't plunge in and out, are held in the

gearbox by more than a circlip, and very strong bottom wishbones to stop the uprights from twisting. A little too involved for me. Interesting

thought though.

|

|

|

MK_Bob

|

| posted on 27/7/06 at 09:41 PM |

|

|

Here's a photo to put the drawing in perspective, and show how limited the space is! Both tubes are 20mm or so from the gearbox. The bottom rail

is part of a new geometry system that will give me greater (but not great) ground clearance. I will be re-doing the bottom rail as i have deformed it

too much by bending it with an unsuitable former.

|

|

|

Chippy

|

| posted on 27/7/06 at 10:46 PM |

|

|

Answer for SIMONK, if you bring the roll centre up to the COG, you will have no body roll at all, BUT, and its a big but, you would end up with the

same problems as having a swing axle, (ala VW beetle), and that would be total c**p.   Regards Ray Regards Ray

|

|

|

cymtriks

|

| posted on 29/7/06 at 10:47 AM |

|

|

quote:

Originally posted by MK_Bob

I will be using double wishbones, according to my drawings the roll centre will be 15mm below ground. When the suspension is fully compressed (25mm)

during roll, the body rolls 3.5 degrees. The camber gain is -2 degrees per 25mm, so by setting the initial camber at around 1.5 degrees the tyre

should be fairly flat to the road during hard cornering. When the suspension is at full droop (again 25mm), the camber gain is -1 degree, but with the

initial setting of 1.5 degrees, the least possible amount of negative camber will be 0.5 degrees at full droop.

The main problem is that as the wishbones have to be very short (top wishbone will only be 100mm long!) the wheel moves inwards by about 16mm at full

bump. Whilst this should be ok during cornering, will driving on uneven roads in a straight line make the handling inconsistent?

Thanks.

Your maths is wrong somewhere. One degree of roll equates to roughly one inch of total travel, half an inch each side. So 3.5 degrees, which is a lot

for a road car, would give about 1.5 to 2 inches travel each side. It isn't an equal ammount each side as the RC moves.

Your RC is very low. While some race cars have used below ground level RCs most designs have drifted back to just above ground level. The Elise and

the Caterham CSR have a front RC at 30mm. If that isn't a very good hint I don't know what is!

Your top wishbone is TINY. I've seen some of that length on race cars but it's still TINY. A minimum of 8 inches is much more usual.

|

|

|

Benonymous

|

| posted on 17/1/08 at 05:57 AM |

|

|

Short bones..

There has to be a downside for using such short wishbones. I think it mainly comes down to the travel and droop characteristics. With such short

wishbones, the useful vertical wheel travel is limited in both droop and bump. If you consider suspension designed for long travel, invariably it has

long wishbones so that the vertical travel affects the geometry less. So I'd say its possible to make effective short travel suspension with

short wishbones (the Ultima as an example) but if you want more "road car" like travel, you'll have to go for longer wishbones.

|

|

|