scutter

|

| posted on 29/6/08 at 04:23 PM |

|

|

Zetec to RS2000 bellhousing?

Having got the car running well, i've now run into a problem with the clutch . .

I've a 2L blacktop zetec, V6 type nine with a cut down input shaft, Alloy RS2000 bellhousing and 1800 zetec flywheel.

I've used the friction and cover plate from the 1800 engine and got myself the CT133 release bearing, but can't seem to get enough movement

on the clutch cable to disengage the clutch to engage gear. You can move the car with the engine running by applying slight pressure to the gear

lever, but i don't fancy smashing the box to pieces to prove it

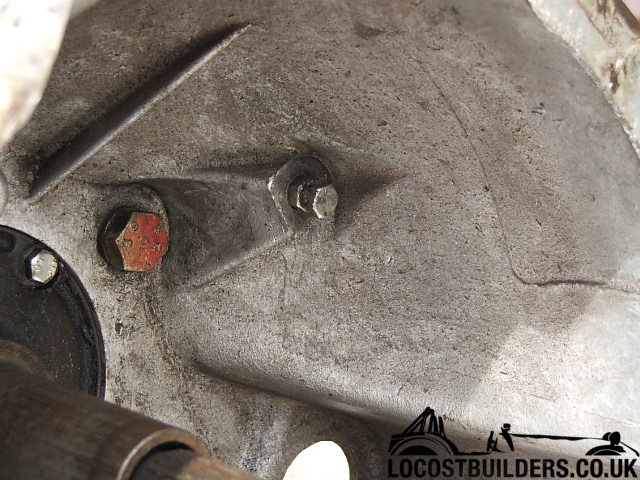

So the main question did i use the correct lever arm? it's the centre one in the pics below and is the previous owner of the bellhousing pulled

out the Fulcrum pin and replaced it with a M6 bolt, what is the correct pertrusion for the bolt?

Many Thanks Dan, help me get this damn thing on the road before winter

The less I worked, the more i liked it.

|

|

|

|

|

theconrodkid

|

| posted on 29/6/08 at 04:57 PM |

|

|

similar idea as to mine,i had to move the pivot point out a fair way to get it to work.....maybe 1/2 inch?

who cares who wins

pass the pork pies

|

|

|

scutter

|

| posted on 29/6/08 at 07:28 PM |

|

|

Fair enough, i'll give it a try, does the centre clutch arm look about right?

I've just measure the gearbox, the advice that i just needed to cut down the input shaft, was well wrong, the guide tube and splined section

need either cutting down by 10mm or turning down on a lathe

Still didn't want to drive this year anyway.

ATB Dan.

The less I worked, the more i liked it.

|

|

|

theconrodkid

|

| posted on 29/6/08 at 09:09 PM |

|

|

no idea whitch arm is right,easier to take the bell housing off and adjust pivot to fit like that

who cares who wins

pass the pork pies

|

|

|

:{THC}:YosamiteSam

|

| posted on 29/6/08 at 10:03 PM |

|

|

looks similar to the prob i had - when you tightened down the pressure plate how far towards the friction plate did the spring fingers move on the

pressure plate? it may simply not have the range of movement to be able to seperate the plate.. i had to get the pinto cover to fit the flywheel by

getting it drilled - the pinto clutch has been around now for so long there is a lot of options with that pattern

|

|

|

MikeRJ

|

| posted on 30/6/08 at 11:28 AM |

|

|

quote:

Originally posted by scutter

I've just measure the gearbox, the advice that i just needed to cut down the input shaft, was well wrong, the guide tube and splined section

need either cutting down by 10mm or turning down on a lathe

I suspect that was implied when "cut down was mentioned", as clearly you still need an accurately machined end to run in the spigot

bearing (you do have one fitted don't you?).

The top arm is for the standard type 9 cast iron bellhousing, and won't fit within the RS2000 light alloy bellhousing without clearance issues.

The middle one looks correct from memory.

|

|

|