http://www.carbonfiberfilm.com/blog/

[Edited on 4/1/12 by jossey]

I've made my dash and want to spray it matt black. Has anyone done this and know some good paint to use? I'm worried its going to scratch very easily.

That would be my fear too,what about di-noc?

Di-noc, not heard of that...

Have it anodised or do it yourself?

quote:

Originally posted by chrisbeale

Di-noc, not heard of that...

Linky

This stuff,you'll know it when you see it.

Cheers. Talking with some guys at work, what I might do is spray it, if it gets scratched then cover it.

what about powder coating???

what about vinyl ????

http://www.carbonfiberfilm.com/blog/

[Edited on 4/1/12 by jossey]

My dash is MDF, sealed, then gloss black paint which looked crap, so sanded with fine paper then sprayed with a few coats of Dry Film Lube, this gave

a great durable satin/matt finish.

On Ally you could use acid etch primer, then Dry Film Lube on top.

I got it from Apex Speciality Solutions in Aberdeen.

[img][/img]

Or you could use these two products, as I did on my ali back panel, but it does give a slightly shiney finish.

[img] [/img]

[/img]

[Edited on 4/1/12 by Slater]

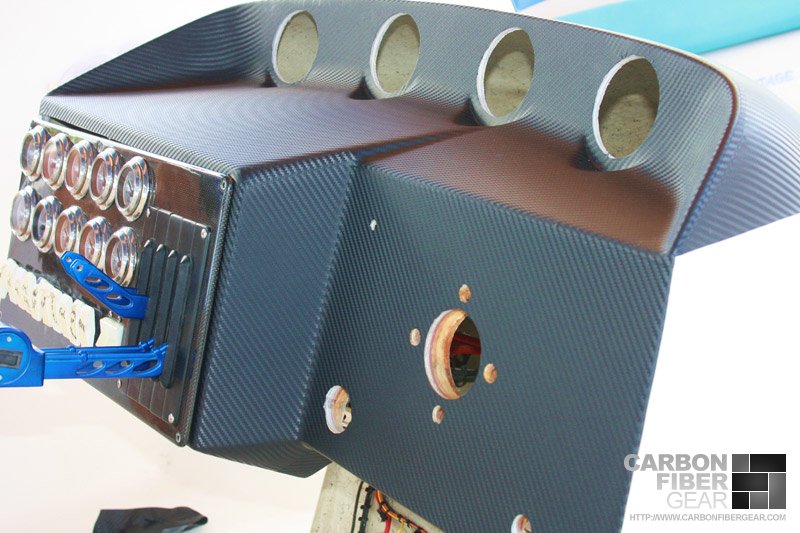

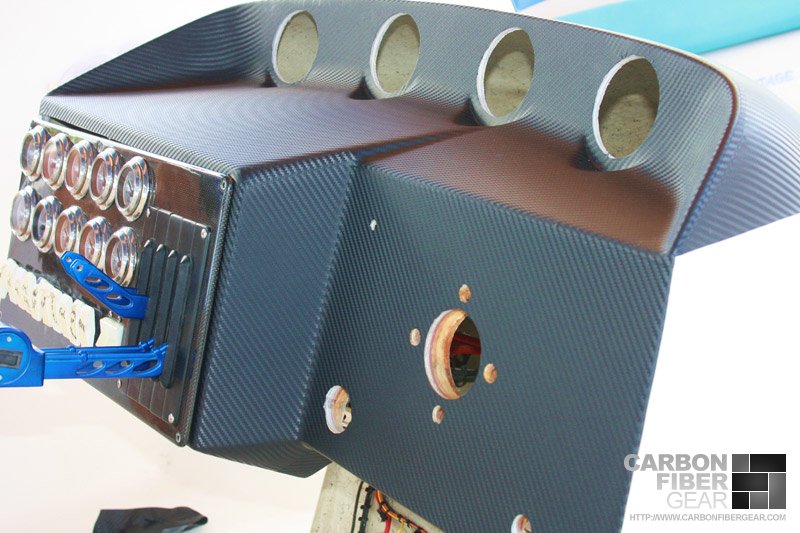

That much fake carbon is just tacky (IMO)

Try this sort of spray, a couple of coats and it should be quite durable.

http://www.plasti-kote.co.uk/Product/pcode---4181

(halfords, wilkinson etc)

If you want a matt/satin finish then you cant protect it with a laquer really, which would be the best way to protect a paint finish.

What about flocking? Gives an interesting and finished look I think.

I have never been able to achieve a durable finish with a rattle can. Don't get me wrong some paint finishes are beautiful even from rattle cans

but not durable. I have tried all sorts of methods. I recently sprayed a kenwood chef with aluminium etch, then acrylic primer, then acrylic and

then three coats of 2pack laquer all from rattle cans. The finish is lovely but not that durable. On taking it home in a cardboard box one edge

must have been rubbing as it dulled the finish. I'm not sure how long it will last. I recently got some stuff professionally sprayed and the

sprayer claimed that the drying temperature is absolutely critical for chip and scratch resistance. He 'cooked' the products in his spray

booth. What temperature he meant by this I don't know but I think somewhere between 60 - 80c. The professional spray said 'without heating

them you won't get a real hardwearing finish'.

I haven't started my dash yet but I am going to use finishes that are pre-made. I.E either vinyls (like your carbon fibre wrap), stretched

fabrics or pre-finished lightweight sheeting like diabond. Diabond is a sign making material that is a composite sandwich of ali, nylon, ali. It

comes in many many finishes.

http://www.signforce.co.uk/Signforce/Dibond.html