Rescued attachment swirl pot lcb.jpg

Has anyone fitted the injection pump in a swirl pot?

Does it / Would it work?

dont see why not, it would displace quite a lot of fuel though, in a small swirl pot.

i nearly bought a swirl pot from a rallly car which had the pump built into it.

I am about to try it.

Suffered fuel surge issues at Cadwell so I need to fit a swirl pot.

The ZX14 needs to run on the intank original motorcycle pump so the only solution i see is to run the fuel pump in the swirl pot.

I'm just in the middle of sourcing a one off swirl pot.

Ill let you know how it goes.

Antnicuk, What problems did you have at Cadwell?

May I ask how much for the swirl pot? I am faced with the same problem. I am tempted to try putting some sort of sump into my fuel tank to have the inlet in. Alternatively, can you build some sort of swirl pot arrangement by dropping a large tube over the inlet, and have the fuel rail return topping up the ib-built resevior. The only issue I see wit that is that the fuel might warm up if there was no flow at all through the tube (if you see what I mean?)....

quote:

Originally posted by GBaggott

Antnicuk, What problems did you have at Cadwell?

Brow,

I see what you mean about the tall pipe above the fuel outlet and inlet so there is always some fuel in it as its filled from the return.

It might work, but your then restricting some of the fuel in the tank from entering the pipe, hence having a half full tank but it not being able to

get out.

Simple solution.

You can run a sump/swirl pot on the bottom of the tank, not in the tank.

On the bottom of the tank the sump is gravity fed, so in essence you run a gravity fed swirl pot and don't require a lift pump.

The hole in to the sump will be about 25mm diameter and the sump about a 100 x 100 x 50mm the small hole feed into this small sump stops the fuel

surging away.

This is a standard design which isn't working for the zx14 and pump layout.

Ive only just sent out a few requests for bespoke swirl pots so have no prices as yet

Sorry to hear about the engine issues ant

If you're looking for an all-in-one solution you could try the VW digifant system. You can usually get a complete unit for £30-40 off ebay.

Hello,

i build a swirl pot around my standard ZX12 fuel pump.

So , a red top facett pump fills my swirl pot, thenn zx12 pump give pressure to the fuel rail.

return to the swirl pot and excess from the swirl pot goes to the tank.

Works well

Gerardo

quote:

Originally posted by GBaggott

Brow,

It might work, but your then restricting some of the fuel in the tank from entering the pipe, hence having a half full tank but it not being able to get out.

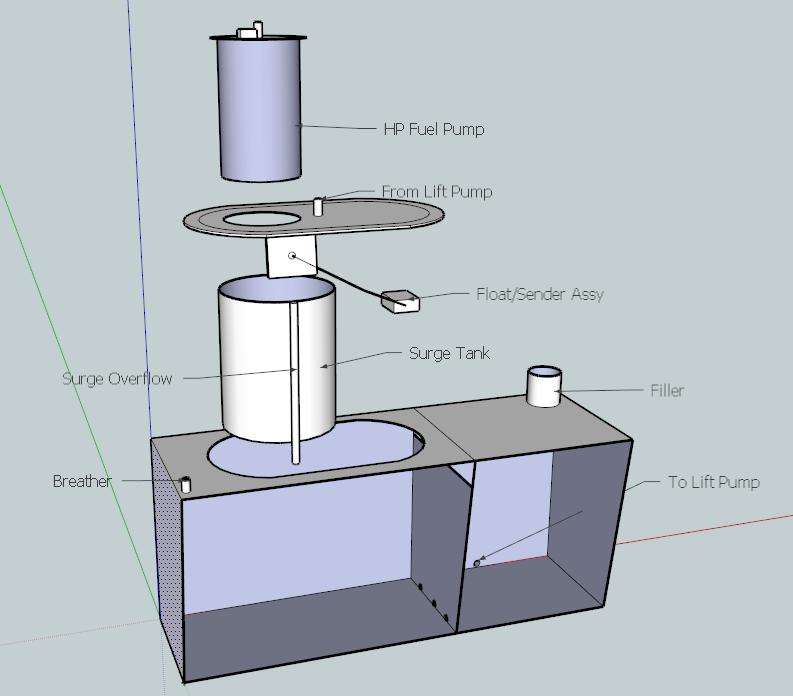

heres mine, not tested it yet but cant see any reason why it wont work. Just a blackbird injection pump in a small pot fed by the main tank with an

overflow back to the main tank and the fuel rail returns to the swirl pot

[Edited on 9/7/09 by andrew-theasby]

Rescued attachment swirl pot lcb.jpg

Here is our front mounted swirl pot containing the standard Blade injection pump. It is fed from the main tank by another pump and has a return back

to the tank.

No fuel in it yet, hence no pipe clips.

Geoff.

If the pump fails, how do you get it out?

quote:

Originally posted by scudderfish

If the pump fails, how do you get it out?

Mines not as posh as that, just drew round the pump flange and marked the mounting holes on, then made the tank around it tall enough to suit. Used the original gasket.

Hi Andrew.

Popular opinion says that we both may need to put a restrictor in the feed line to the swirl pot so that the feed pump has a small resistance to work

against, otherwise it may run too fast and either overheat or simply wear out quickly.

We haven't put a restrictor in yet. What are your thoughts?

Geoff.

Hi, thanks for that, i questioned that quite some time ago when i was originally thinking about it, and no one really had any definite answers, ive thought through loads of ideas so far including restricting the outlet so air escapes quickly but once its full it slows down (but this way it means the swirl pot is pressurised to whatever your pumps rated at) dont know if that will cause probs but i personally think the high pressure side will be increased in pressure too as a result, so im settled on using a piece of 8mm brass bar in the fuel line near low press pump and drilling it 1mm if the pump is hardly working then going a bit bigger until its pumping steadily. If thats too big (bear in mind it will be at 4 psi ish) then might need to be even smaller. Only draw back i can think with this is on the first ever engine start it will take ages to fill the pot, but you could do yours through the lid. Im going to use clear fuel line returning from swirl pot so i can monitor when its full, but you only have to fill it at the rate the engine is using it which is very low, so im fairly confident this way should work well.

I've got loads of drills in the 1 - 2mm range if you need any.

U2U me.

Geoff.

Thanks for the offer, keep us informed on how you get on with yours too

Geoff,

That is a nice tank. Who are GE Motorsport? Is it you? I googled and only found a Swedish company.

If it is you, have you thought of making a batch of these? I'd be interested, as it allows me to retain all my fueling stuff for the carbs (if

one day I decide I want to go racing). ANy idea of the cost of a tank like this?

Regarding the air return, you could use a one way valve such as those used on to top of fuel tanks. These allow the air in/out but have a ball valve

to prevent the escape of fuel.

Matt

p.s. nice chassis, I haven't seen many round tube Phoenix

Hi Matt. GE Motorsport is a fanciful idea constructed from our initials. It's not a business. Eldon does do various fabrications, fuel tanks,

breather tanks etc on a casual basis. I'll ask him about making these tanks and get a price. That's if he's got time.

All his work is A1. You won't find a better welder.

He would need to know what pump etc.

I'll U2U U.

The chassis is a 2004 , I think, and is round tube up to the rear bulkhead. We've added some extra triangulation in various areas.

It now has the body fitted and will hopefully soon be ready to roll!

Geoff.

I'm thinking about using a float arrangement in trhe top of the swirl pot, lika a carburettor, the low pressure pump would work as normal then??..

Some lovely welding !

Question is ...if you have the facilities to do that why not simple make a fuel tank with a swirl pot in the bottom and mount your HP pump in that.

Saves on a lot of pluming and does away with a LP pump. This replicates what is done in all Injection cars (and bikes).

quote:

Originally posted by jeffw

Some lovely welding !

Question is ...if you have the facilities to do that why not simple make a fuel tank with a swirl pot in the bottom and mount your HP pump in that. Saves on a lot of pluming and does away with a LP pump. This replicates what is done in all Injection cars (and bikes).

I am currently looking at putting in a restrictor based on the discussions on here. however, my restrictor will be in the swirl pot overflow return to the tank....

Sorry to bring this up again, I am also going to go down this path of intank pump in swirl pot, the idea of having it lower than the main tank is good

but then you'll have an awfully exposed swirl pot hanging from the bottom of the car (with position of most 7's fuel tanks)

I am putting my swirl pot inside the main tank, swirl pot capacity is about 2L and main tank about 34L Here is a wee drawing I came up with, but

might also run the lift pump as intank too. Also the positions of inlets and outlets have changed as I have read the inlet to swirl pot should be low

on the pot.

If you take a look at the throttle bodies page in my website there's some notes and photos concerning the restrictor (and other stuff). 1mm in

the return line from the swirlpot to the tank is fine.

There's no need to make it a long hole. Take an 8mm bar, drill something like a 4mm hole almost the length of the bar, then just break through

with the 1mm, so it's more of an orifice than a long hole.

There was also a comment earlier about time to bleed the system, I didn't find that. It leaked very quickly after turning the fuel pump

on...seriously, it's not a problem and the swirl pot doesn't drain down once it's full, so instant starting every time.