To give you an idea the centre of the flywheel is around the same height as the top of the cylinder heads as I've tried to show in this early image.

Hi,

I've been on this forum for a while now, contributed a little, bought some stuff and sold some stuff, but thought it was about time I put

something on about my project. I consider it a Locost project as I'm trying to do it for far less than is really ideal, and I was going to fit it

into a tiger avon, but sadly had to sell the car recently in order to finish the engine.

Back in 2011 I had moved to a more managerial job, and started to get rusty on my CAD skills so thought I'd start a project. I've messed

around with engines since I was young, learning from my dad on his bikes which were usually given to us or bought as non runners.

I liked the idea of a ZX9 base for a V8 because the parts are very cheap and plentiful, but also because my friend had an engine which a rod had gone

through the case so I could strip and measure. At the beginning I thought I would model the crankcase and covers/adapters etc, get a friend to knock

it up on the CNC mill and we'd be enjoying it within 6 months....

So, 5 years later I have the following:

Lots and lots of CAD models

5 axis machined crankcase (it's a real thing of beauty!)

10 Main bearing caps

A 2 Gallon ex NASCAR dry sump tank

ARE Dry Sump Pump

2 Gears and shafts which transmit drive from cranks to flywheel/front pulley

8 Pistons and Rods

2 Crankshafts (I know, the weight penalty is a bugger, but it made sense at the time, and I want to adjust the timing between banks eventually)

2 cylinder barrels

2 cylinder heads (complete with CAMs etc)

2 sets of carburettors

standard ZX9 ECU and loom, I plan to time the engines so that they fire in exactly the same order until I can afford a nice programmable ECU

Facet Fuel pump and regulator

Davies Craig water pump and controller

Polo radiator ( I know this sounds mad but at the time I'd seen others who were running 300 hp rover V8's with this rad so thought it was

worth a go!

***And these are the parts I'm currently designing/researching or saving up for:***

Sump

Standard ZX9 full bearing and gasket kits

Final gear and mount which changes crank rotation so it will match the opposing bank

Bearing carriers which support the shaft and gears mentioned above

12.9 grade bolts for everything- from what I could see they are just shy of the strength of ARP bolts but a tenth of the cost!

Oil cooler- I may have scrounged one from work but will have to get it professionally cleaned

Oil fittings and lines- Christ these are expensive, as I'm going to be running it in a test frame first of all I may just use JIC fittings from

the local hydraulics place

Pulley to drive dry sump pump, alternator etc

Adaptor which fits flywheel to shaft

Bearings and bits and bobs I've forgotten.

Thanks for reading, I'll be honest I'm not great with negative comments as I take them far too personally, which is the main reason

I've not posted about it before. In reality though, it's my project, which I may well do differently if I had my time again or an unlimited

budget, however I'm determined to finish it, and posting on here might just give me the motivation to keep going!

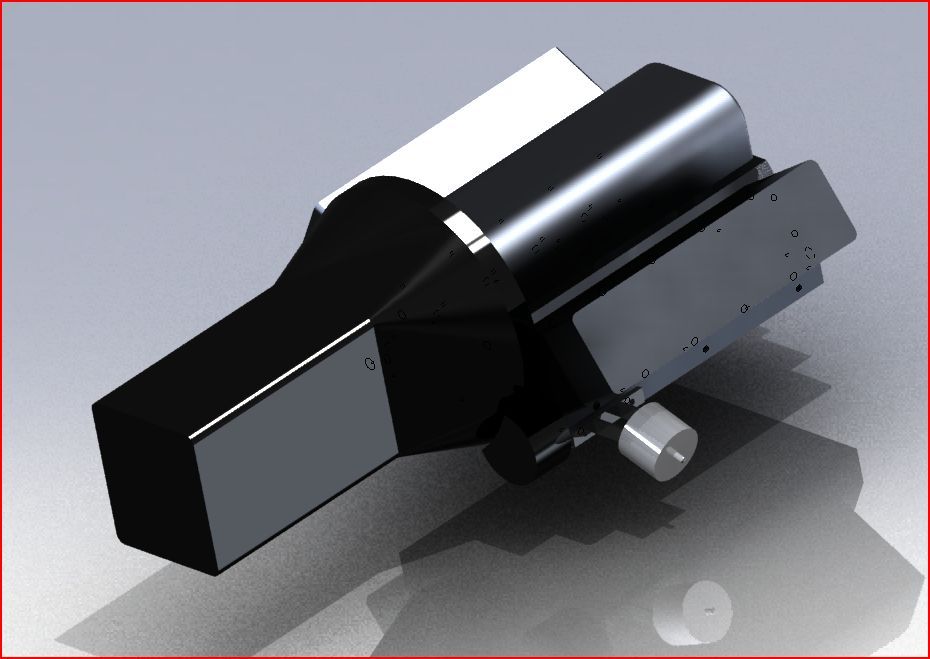

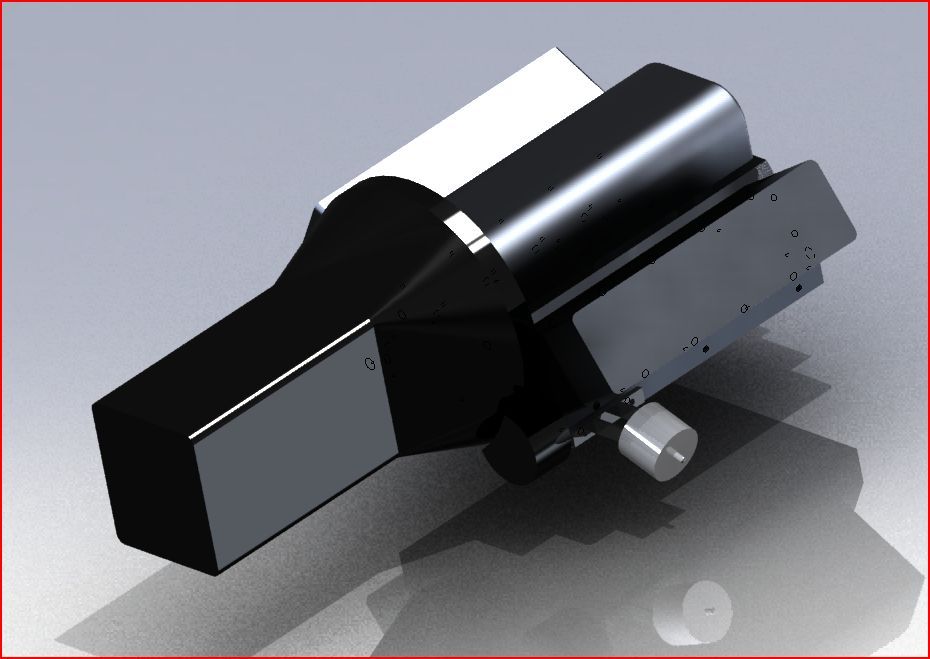

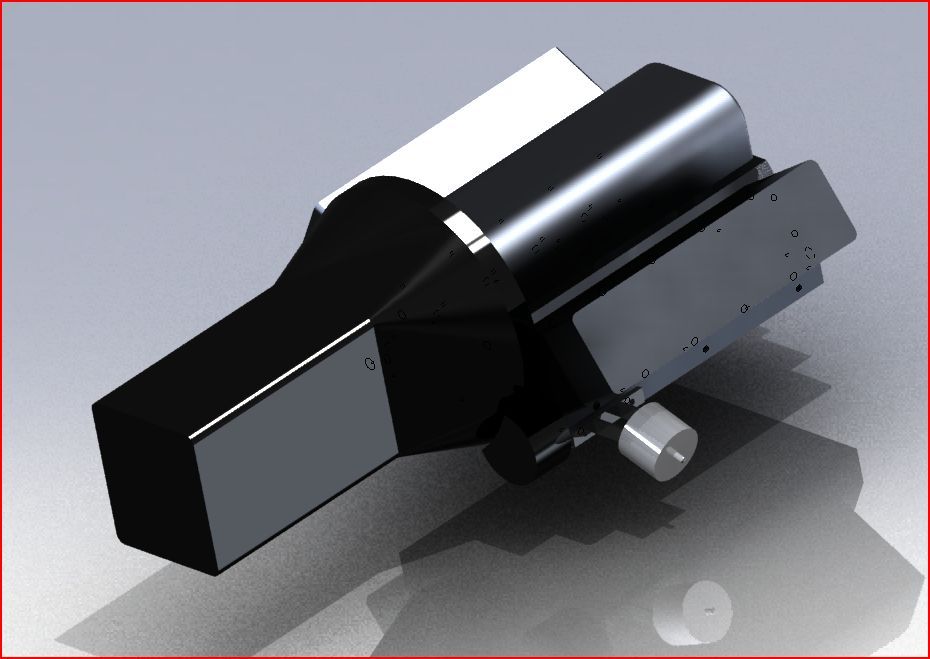

Just remembered, I should have said that another reason for running twin cranks is that the drive of the engine ends up at the top of the engine,

which means that the whole thing has a very low centre of gravity.

To give you an idea the centre of the flywheel is around the same height as the top of the cylinder heads as I've tried to show in this early

image.

Interesting!

So it actually an U8 engine? Bugatti did build a couple of U16 in the twenties based on the same principles.

I'm pretty sure I sold you a zx10 head and pistons which would increase capacity. Have you still gone down that route ?

I admire your ambition BTW.

Wow this is ambitious! I love it!

You've got to put a picture of the crankcase up.

Keep us all updated, and hurry up I want to see this running.

Good luck with it.

Any idea what you're going to put it in yet?

The high output shaft position relative to the overall engine height would ideal for a mid-engined installation?

quote:

Originally posted by ettore bugatti

Interesting!

So it actually an U8 engine? Bugatti did build a couple of U16 in the twenties based on the same principles.

quote:

Originally posted by wylliezx9r

I'm pretty sure I sold you a zx10 head and pistons which would increase capacity. Have you still gone down that route ?

I admire your ambition BTW.

quote:

Originally posted by melly-g

Wow this is ambitious! I love it!

You've got to put a picture of the crankcase up.

Keep us all updated, and hurry up I want to see this running.

Good luck with it.

quote:

Originally posted by Sam_68

Any idea what you're going to put it in yet?

The high output shaft position relative to the overall engine height would ideal for a mid-engined installation?

Future updates

I thought it was worth mentioning my plans should the initial testing go well!

Ideally I will move over to a programmable ECU as soon as I can afford it. I saw somebody on here was selling a DTA S80, which would be ideal but

sadly funds won't allow at the moment.

Once I've got the ECU I can swap out the zx9 carbs for zx10 or Z1000 throttle bodies, injection fuel pump etc.

I'm really infested in learning more about mapping, I've had a little time on an Emerald and even less time on the DTA, but should be

another good skill to pick up once the prototype is sorted.

From there I'll probably go the same route as Dave 424 on this forum check out this link if you've not seen it yet:

http://www.locostbuilders.co.uk/forum/23/viewthread.php?tid=193224

Basically he has an off road buggy which he fitted a zx9 engine into, then turbo'd it with forged high compression Pistons and a base spacer

plate to reduce the compression. I realise this might sound strange but not many people make low compression bike engine Pistons so decent spec high

compression ones are usually used and then a plate similar to a decompression plate but as its under the cylinder barrels you don't get the same

issues that I had with the decompression plate on my supercharged a series engine.

If I used the same turbos/setup as Dave I'd be looking at around 500hp from roughly a 1.9 litre displacement.

Here is the mocked up crankcase with barrels and heads loosely fitted:

As you will see the V angle is very wide in order to fit everything in. Eventually I'll fit throttle bodies, which will then be mounted

vertically but for the moment I'll knock up some adapters which fit the carbs at the correct angle to the heads.

I have just come over all unneccessary!

Great project, would look nice in a spire gtr (mini lmp2 type car) with an audi a4 / bosxster transaxle, boxster may be beter as it has the gear

change going the right way (forward), not sure if these boxes will rev to 10k though. In fwd format the s2000 may be a good choice as it is designed

to 9k as standard.

i assume the two cranks turn in the same direction, have a cog on the end that meshes with a cog on the end of of the central drive shaft or are the

cogs at either end of the drive shaft?

Keep us posted.

[Edited on 10/4/16 by Ugg10]

Thanks, I like the idea of a spire or similar!

For the transmission I have geared down the output speed by using larger gears that the crank has fitted so 12000rpm at the crank will be 8000rpm at

the flywheel. This should allow use of a more 'normal' box, even if it does need uprating. Obviously the torque output isn't going to

be huge so should be okay for initial testing.

The cranks turn in opposing directions as otherwise you end up with one exhaust in the middle of the bank. I'm using an idler gear to reverse the

rotation but space restrictions and 27000 rpm mean I'm struggling to find a suitable bearing!

Here is the dry sump tank I got from the U.S.

It's from a NASCAR, has built in heaters to get the oil up to temperature before cranking and clamp in the middle to take it apart and clean.

It's capacity is 2 gallon, so capable of holding enough oil for two cranks, four cams etc...

[URL=http://s279.photobucket.com/user/hornetob/media/Engine/_57.jpg.html] [/

URL]

[/

URL]

[Edited on 10/4/16 by obr_technology]

The terry Davis Yamaha R1 v8 is a work of art. As seen in Tim elmer hillclimb Dallara

I think I saw that one at Autosport some years ago,

There is a guy who hillclimbs at Wiscome (Trevor Willis??) who runs a powertec/RPE v8 which looks lovely.

Trevor's a former British hillclimb champion with the RPE v8 in it.

quote:

Originally posted by obr_technology

I think I saw that one at Autosport some years ago,

There is a guy who hillclimbs at Wiscome (Trevor Willis??) who runs a powertec/RPE v8 which looks lovely.

Nice! Have you seen the SHP spaceframe mk1 escort fitted with one? It's a thing of beauty.

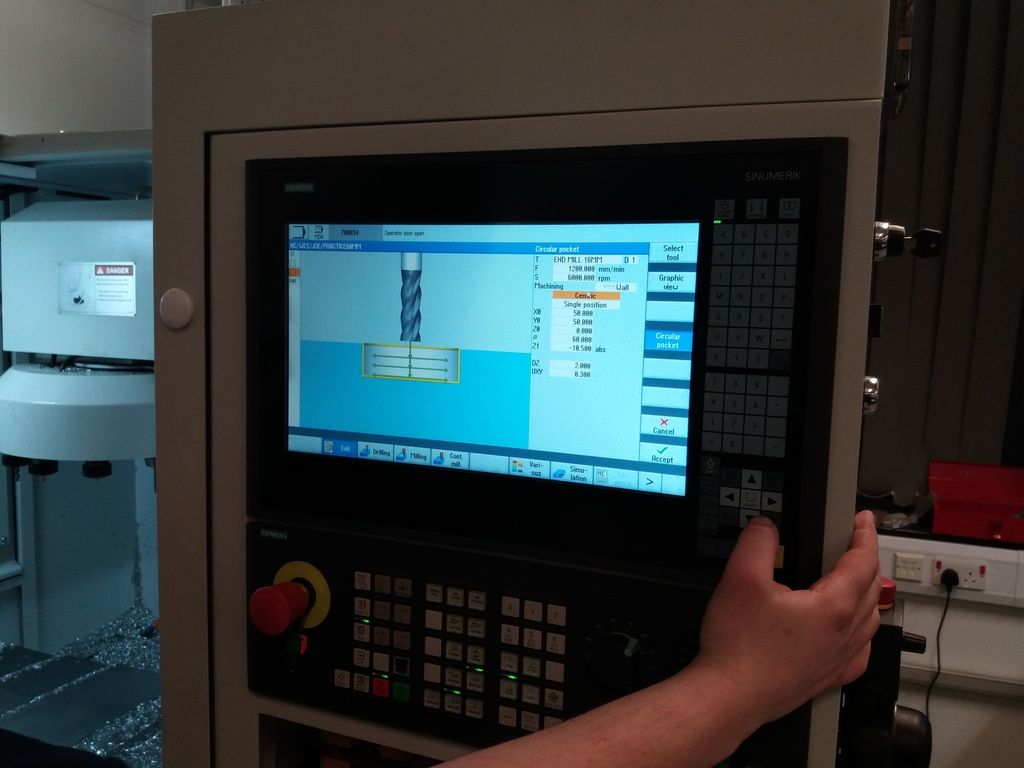

Ive just finished the Sump design, and have a colleague who is going to machine this for me as it is quite basic. Size wise it doesn't fit on the

bed of our regular mills, but we have a new CNC machine which has a large enough travel. I'm keen to spend a bit of time with him doing this as

I've not done any CNC programming or milling since I was studying so good to keep my hand in!

Material should be ordered mid-this week, hope to start machining early next week.

quote:

Originally posted by obr_technology

Ive just finished the Sump design, and have a colleague who is going to machine this for me as it is quite basic. Size wise it doesn't fit on the bed of our regular mills, but we have a new CNC machine which has a large enough travel. I'm keen to spend a bit of time with him doing this as I've not done any CNC programming or milling since I was studying so good to keep my hand in!

Material should be ordered mid-this week, hope to start machining early next week.

Couple more techie questions as I am really interested in understanding this idea (a couple of zx6r engines would make a nice 1200cc 200hp+ engine ?

Seems to only work with bike engines, if you double the output of a car engine you may as well buy a car v8 i.e. 2 x Zetec SE 1.6 (good efficient car

engine) is approx. 240hp, 3.2l jag V8 is not dissimilar and probably lighter???):

1) do you have any assembly drawings/cad pictures of the output shafts/gear/idler, I am interested to see how they fit together and how central the

main shaft is?

2) what are you doing about the different oils in the system. usually the engine and gearboxes run different spec oils so do you have the drive gears

running in a separate sump with gear oil in it ?

3) are the drive gears straight cut or helical, was thinking that you could use gearbox gears mounted on a new shaft, plenty of ratios available for

the Type 9 that you could used ?

4) the questions everyone is really wanting the answer to - are you going to be selling kits in the future ?

Cheers, great project, do keep us all posted on progress.

Hi,

Really appreciate your interest, will try and answer those in turn.

1) I'll get some pics up of the assembly, there might be some feedback people can give regarding what I have designed. Essentially the gear on

the crank which originally fed the gearbox is now connected to a large gear which transmits to the central shaft above the cranks. I've built a

couple of things into this, firstly the whole assembly can be mounted a lot lower in comparison to the gearbox input shaft, which is lowered the c of

g for a 70 or 80 kg part. Secondly the gears are larger which means the output speed of the engine is reduced from a maximum of 12000rpm to 8000rpm

meaning a more conventional gearbox can be used. I'm not sure if I've mentioned this before but the idler is causing a real headache as it

will be spinning at 27000 rpm max and that is difficult to find a bearing which isn't going to cost me a fortune! I've also built in an

anti-vibration coupling which can run in oil, but provides a little flex in case one side is running at a slightly different speed to the other, as

well as hopefully reducing any of the issues caused by the combined primary/secondary forces (this area of engine design isn't my strong point,

but I believe I know enough to overcome the issues).

2) I have always planned to use a similar oil to that which Kawasaki specified as from memory the oil is shared between gears and engine in the bike.

I do have a dry sump pump which I believe will reduce the life of the oil due to the way it circulates, but I'll keep an eye on that as and

when.

3) The drive gears are metric straight cut. I've already got these, and as they are metric they are pretty much off the shelf other than the

fact I wanted the highest spec material. These have come pretty much as blanks, so I will be lightening these, although I had a hare-brained scheme

to build in some kind of adjustment once the engine is running as I'd like to consider what affect changing the link between the cranks has, ie

if the second bank fires 10 degrees after the first does the power or torque change (I'm thinking of the big bang engines). Alternatively

I'd like to look at whether it is possible to run on one bank and then fire up the second bank at another time on demand.

I'm not 100% sure I understand what you mean about the type 9 gears? My flywheel is bolting onto a drive flange similar to that which is on the

end of a zetec crank, which allows traditional car engine flywheel and clutch to engage with the type 9. Sorry if I have missed your point.

4) I'd love to sell some of these, in all honesty I'd like to get to a point where I could start selling some of these in the future. The

main issue I have at the moment is that the crankcase itself has been so expensive that by the time I've finished the costs will be huge.

However if I can get to the point where I'm able to order larger quantities of all the machines parts then it would be much more cost effective

for any potential customers.

Hope this answers your questions, thanks again for your interest it certainly keeps me going!

I've just been having a look at the 1.8t RX8 thread next door and the chap has just confirmed that the starter motor for an RX8 6 speed box is on

the bellhousing side.

As you can probably imagine if you take a look at the image below of the mocked up engine a conventional type 9 bellhousing puts the starter motor

pretty much exactly where my cylinder head is, so the RX8 unit should be far better.

I'm hoping that should I be able to find a suitable transaxle which operates in the same way as well, but have already looked at the Porsche

boxster and the starter is on the engine side. I'm sure that once I have the money for a hewland then bellhousings will be plentiful in all

manner of shapes and sizes!

Many thanks for your time, much appreciated.

On the type 9, it was just a thought that as a gearbox this already has either helical, semi helical or straight cur gears that you could use on the

end of your cranks/driveshaft to transmit the power (with lots of ratio alternatives), helical would reduce noise but may not be as strong.

Daft question, did you consider running one of the engines backwards, I know this has been done with the Honda B series vtec engine in the past which

turns anti clockwise IIRC so is difficult to use with longitudinal boxes (there is a mad one in a rally escort, video's on youtube)? Given you

are running a dry sump and electric water pump this may have been as simple as a cam swap ands then you could use a simpler gear system ?

Just some thoughts that are too late but I enjoy the lateral thinking process and seeing if my daft ideas are daft or not.

[Edited on 19/4/16 by Ugg10]

UN1 transaxle and Subaru adaptor ?

http://www.thesamba.com/vw/forum/viewtopic.php?t=582345

If you know someone who can weld ali then I am sure you can make up an adaptor to fit a starter on the rear of the audi/boxster transaxle.

Edit

Easier solution - Subaru Impreza greabox with the centre diff removed and a 2wd converter kit put in place (rear drive locking nut and rear blanking

plate), search SDR Storm WR3, this kit car uses this system and there is a company in AUS that do the same (about £250 for the kit IIRC).

http://www.bremarauto.com/products/subaru-2wd-conversion-kit/

http://www.carbasics.co.uk/blog/wp-content/uploads/2013/07/1996-Subaru-Impreza-WRX-Manual-Gearbox-TY752VB3AA-6.jpg

You can play about with drive speeds and tyre sizes with this calculator

http://www.subarugears.com/Ratios/Ratios.html

[Edited on 19/4/16 by Ugg10]

quote:

Originally posted by Ugg10

Many thanks for your time, much appreciated.

On the type 9, it was just a thought that as a gearbox this already has either helical, semi helical or straight cur gears that you could use on the end of your cranks/driveshaft to transmit the power (with lots of ratio alternatives), helical would reduce noise but may not be as strong.

Daft question, did you consider running one of the engines backwards, I know this has been done with the Honda B series vtec engine in the past which turns anti clockwise IIRC so is difficult to use with longitudinal boxes (there is a mad one in a rally escort, video's on youtube)? Given you are running a dry sump and electric water pump this may have been as simple as a cam swap ands then you could use a simpler gear system ?

Just some thoughts that are too late but I enjoy the lateral thinking process and seeing if my daft ideas are daft or not.

[Edited on 19/4/16 by Ugg10]

quote:

Originally posted by Ugg10

UN1 transaxle and Subaru adaptor ?

http://www.thesamba.com/vw/forum/viewtopic.php?t=582345

If you know someone who can weld ali then I am sure you can make up an adaptor to fit a starter on the rear of the audi/boxster transaxle.

Edit

Easier solution - Subaru Impreza greabox with the centre diff removed and a 2wd converter kit put in place (rear drive locking nut and rear blanking plate), search SDR Storm WR3, this kit car uses this system and there is a company in AUS that do the same (about £250 for the kit IIRC).

http://www.bremarauto.com/products/subaru-2wd-conversion-kit/

http://www.carbasics.co.uk/blog/wp-content/uploads/2013/07/1996-Subaru-Impreza-WRX-Manual-Gearbox-TY752VB3AA-6.jpg

You can play about with drive speeds and tyre sizes with this calculator

http://www.subarugears.com/Ratios/Ratios.html

[Edited on 19/4/16 by Ugg10]

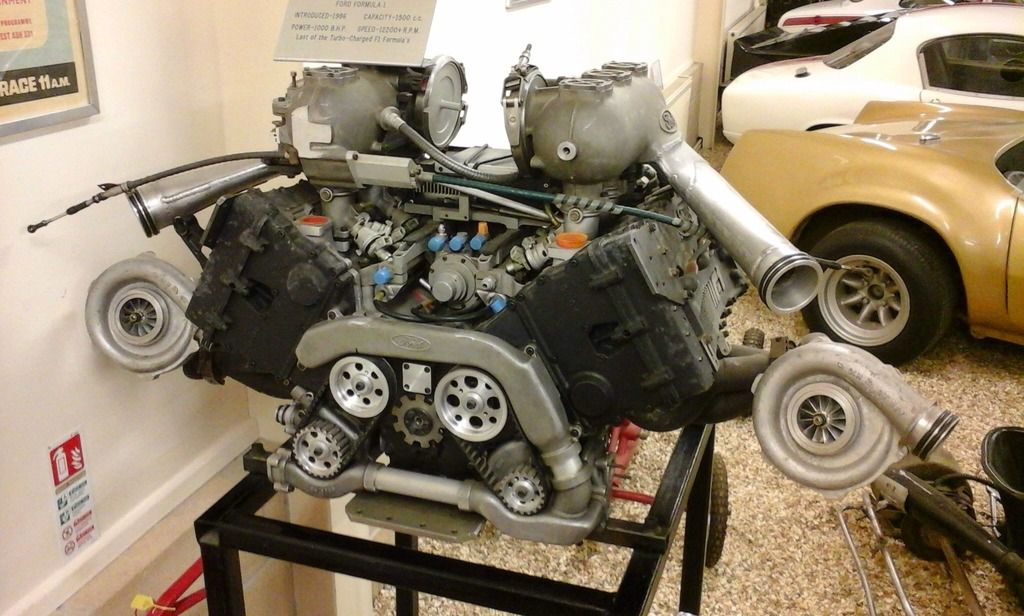

I forgot to mention that I went to the Haynes museum in Saturday and saw this beast, such an inspiration. I was trying to explain to my girlfriend how

rare it was and the best comparison I could think of was 'it's like seeing a unicorn'! She wasn't convinced...

I have an rx8 6 speed box in the shed if you need anything measuring up. If you need a rough bell housing pattern I can always trace it on some card,

scan it in with a scale and send a picture through. General dimension are similar to a ford type 9 and the input shaft has ford diameter and splines

so pinto/Xflow/zetec clutches work.

Remember if you put it in an rx8 emissions will be as produced (rotary engine on v5) at mot time if you plan to put it on the road so will need cats

and injection.

Are you aware of this - https://wmspear.com/Bantam/Albrov8.html Similar type of engine by the looks of it.

Been thinking of other engines this may work for, as I mention, car NA engines don't seem to work out, but audi 1.8t or the new ford 1.0L

Ecoboost (shame it is direct injection to control) might be interesting, but heavy as they have steel blocks.

One thought was two Honda paneuropean v4 end to end with a long drive shaft down the vee. Still only a 2,2L v8 with 220hp, might as well have a 2.3

duratec.

So sports bikes it is, but don't need to tell you.

As for cars, occasionally the tiger hss come up for sale at reasonable prices, these had hewland transaxles, only good for the track though. There was

talk about the doing either the hss or the hs30 with the audi transaxle to cut costs.

[Edited on 19/4/16 by Ugg10]

[Edited on 19/4/16 by Ugg10]

quote:

Originally posted by Ugg10

I have an rx8 6 speed box in the shed if you need anything measuring up. If you need a rough bell housing pattern I can always trace it on some card, scan it in with a scale and send a picture through. General dimension are similar to a ford type 9 and the input shaft has ford diameter and splines so pinto/Xflow/zetec clutches work.

Remember if you put it in an rx8 emissions will be as produced (rotary engine on v5) at mot time if you plan to put it on the road so will need cats and injection.

Are you aware of this - https://wmspear.com/Bantam/Albrov8.html Similar type of engine by the looks of it.

Been thinking of other engines this may work for, as I mention, car NA engines don't seem to work out, but audi 1.8t or the new ford 1.0L Ecoboost (shame it is direct injection to control) might be interesting, but heavy as they have steel blocks.

One thought was two Honda paneuropean v4 end to end with a long drive shaft down the vee. Still only a 2,2L v8 with 220hp, might as well have a 2.3 duratec.

So sports bikes it is, but don't need to tell you.

As for cars, occasionally the tiger hss come up for sale at reasonable prices, these had hewland transaxles, only good for the track though.

[Edited on 19/4/16 by Ugg10]

Been doing a bit of googling and had a few brain farts, be interested in your views on this twin bike setup.

So, start with two v-twins, aprilia rsvr Rotax or tl1000r (both around 140 hp), put them spocket to sprocket so they are facing opposite directions.

Inbetween the sprockets put one of these (or similar), possibly with cush drives between the sprocket and gears.

The output gear can then be fixed to the input of a standard diff (bmw e36 2.8, 2.9:1 ratio), plantary type transfer box can also have gearing if

needed. Maybe stick it all in one case and bolt to a frame hokding the engines and the transfer/diff.

There are a couple of autograss class 7 cars using this arrangement but with a chain drive between the two engines and the diff.

I don't think you can remove the sump on these twins like the zx9, leaving the full rotating assembly in tact, but if you could then you could go

down a similar route to you with a bespoke lower section.

No where near as elegant or compact as your solution but could be pretty cheap.

Now, if you could easily extend the drive shaft out of the engine casing the opposite side to the sprocket then you could have the two engines facing

the same way and then put a stock diff inbetween (engines driving the half shafts, output coming out of the prop flange), you then need a second diff

to drive the wheels, gearing between the two diffs could be interesting but this would be more compact.

Both of these not only have two engines but two gearboxes, gears could be sync'd using a powershiter.

[Edited on 20/4/16 by Ugg10]

I like it!

Interestingly Tiger had a pretty well sorted setup from what I've heard, they held the world record for 0-60 at one point. I've always

wondered why they didn't continue with it, so can only assume there just isn't a market for it, or there is more money in selling 100 Zetec

cars than one twin bike engine!

If I had my time again I'd be tempted to have done something like this, although I guess CAD wise it wouldn't have been some challenging.

Yep, the z100, the engines were almost behind eachother and connected to a diff/transfer box developed by zcars (sadly no longer trading) iirc. I

think this diff was more suffusticated as it could cope with each engine running different gears.

Brilliant!

They also made a 4 wheel drive version which must have been insane!

[Edited on 21/4/16 by obr_technology]

Z100WR IIRC. This has the engines facing the forward and backward driving XR4x4/Cosworth diffs. Got a feeling they has some but of electrickery between the two engine acting like a centre diff to make sure the engines did not fight each other too much.

Tiff and a Tiger

Heres a link to Tiff Needle taking about the tiger

Superb! That would have cost me a fraction of what I have in my project!

I was thinking about it driving back from work today, and I suppose I've always wanted to build something like the Ford engine above, and

although mine is very different and doesn't have the God knows how many million budget, it'll look pretty cool once I've got eight

trumpets sucking in loads of air!

[Edited on 21/4/16 by obr_technology]

+1 on the trumpets, got my new (old) dcoe throttle bodies on last weekent plus full radius trumpets., the zetec SE like long runners.

Looking good!

What ECU are you running?

quote:

Originally posted by Ugg10

+1 on the trumpets, got my new (old) dcoe throttle bodies on last weekent plus full radius trumpets., the zetec SE like long runners.

Picked up a sh omex 710 which I have wired up to do sequential injection if needed (cam sensor needed as well), it can also run a fully mapped vct.

Base map at the moment is running batch and off/on/off vct (search jenko on here, he got good results with this method with his zetec SE 1.7 in his

j15). Also plumbed in an innovate lc2 WB Lambda. Will get it mapped later.

This may be worth a read, guy putting in a bike engine v8 into his anglia, he helped me loads getting the ecu sorted, seems to know his stuff.

http://105speed.hyperboards.com/action/view_topic/topic_id/17236

quote:

Originally posted by Ugg10

Picked up a sh omex 710 which I have wired up to do sequential injection if needed (cam sensor needed as well), it can also run a fully mapped vct. Base map at the moment is running batch and off/on/off vct (search jenko on here, he got good results with this method with his zetec SE 1.7 in his j15). Also plumbed in an innovate lc2 WB Lambda. Will get it mapped later.

This may be worth a read, guy putting in a bike engine v8 into his anglia, he helped me loads getting the ecu sorted, seems to know his stuff.

http://105speed.hyperboards.com/action/view_topic/topic_id/17236

Quick update on the engine, have been messing around with the crank bearing caps. I had planned to get the whole assembly line bored but having taken

a few measurements I don't think I'm far off (0.02mm on a couple of bearings).

As I'm looking at £600 for the line boring I'm going to look at shimming the caps by the 0.02 and seeing what I get.

Please don't get me wrong in that I'm not looking to cut corners, it's just that if I can solve the issue for a few quid then I've

got a lot more to spend on other things (such as a mappable ECU or some forged Pistons! If I can't get the level of accuracy I'm after then

I'll have it all line bored anyway, but would feel stupid spending that kind of money without trying an alternative first.

Good afternoon,

I wanted to give a quick update regarding the project.

Currently the machining which is required is still scheduled for early July.

In the meantime I've got all the technical drawings and models finalised so ready to roll, most of the material is here so just counting down the

days.

I've also worked out that the mx5 or rx8 transmission will provide a rear mounted starter motor. This means that it won't foul the cylinder

heads, which the type 9 bellhousing does. I'm now thinking that when I'm ready for a dyno session I will look around for an MX5 with a

knackered engine so I can stick my engine in there and hopefully be able to do a road test. It's not the lightweight car I'd have liked to

use, but should still be fairly lively.

In light of this I've sold my type 9 transmission, advertised the Sierra diff and a few other bits. This provides a bit more cash for the project

as well as space in the workshop.

quote:

Originally posted by obr_technology

Good afternoon,

I wanted to give a quick update regarding the project.

Currently the machining which is required is still scheduled for early July.

In the meantime I've got all the technical drawings and models finalised so ready to roll, most of the material is here so just counting down the days.

I've also worked out that the mx5 or rx8 transmission will provide a rear mounted starter motor. This means that it won't foul the cylinder heads, which the type 9 bellhousing does. I'm now thinking that when I'm ready for a dyno session I will look around for an MX5 with a knackered engine so I can stick my engine in there and hopefully be able to do a road test. It's not the lightweight car I'd have liked to use, but should still be fairly lively.

In light of this I've sold my type 9 transmission, advertised the Sierra diff and a few other bits. This provides a bit more cash for the project as well as space in the workshop.

Thanks for the info, looks like I'll go for the rx8 box then.

Having had no time to put to the engine recently I've decided to crack on again.

Had a goog day today, took the crankcase to Price brothers in avonmouth to see if I could get a quote on the line boring.

The chap I spoke to seemed keen to help and very knowledgeable so I've left it with them so they can have a proper look.

Also got to have a look at some of the kit which they have which is always nice to see proper engineering kit!

Should have some idea of cost by the beginning of next week.

Popped into Bowden Auto Engineering on the way back through but was all locked up. Depending on whether Price Bros are interested in the work I may

pop in after collecting the crankcase.

Cheers

Olly

Any more progress, really interested to see how this is coming on.

Hope you don't mind me cluttering up you thread, if not let me know and I will delete.

Also, here are a few "ramblings of a madman" having thought about this in the bath and had a few late night, beer infused google sessions, i

came up with the following on a similar theme -

The difficulty (added complication) of the 2 x i4 configuration is that you either have to have them facing the same way and then the exhaust / inlets

clash or have them facing opposite ways and then you need one engine to run an idler to get the correct rotation onto the driveshaft.

I looked at whether you could have two v2 / v4 engines side by side, each canted over opposite ways to make a sort of w4/8 but this makes it very

wide.

Finally I stumbled across what I think may be a reasonable compromise -

The St1300 Honda Paneuropean has a more car like v4 engine:

1,261 cc 90-degree V-4, chain-driven DOHC

Power 117 hp (87 kW) @ 8,000 rpm

Torque 117 N·m (86 lb·ft) @ 6,500 rpm

This sits longitudinally, is shaft driven and interestingly the gearbox seems to sit in the sump under the gearbox. These are extremely tough engines

which regularly are seen in the classified with 100k miles. They are expensive bikes to buy but as they get older and if/when they get dropped the

large amount of fairing will drive economic right offs I think.

So, the idea is that you put two of these end to end to make a 2.5l v8 which will rev to 8k+ and push out around 250hp with a reasonable amount of

torque (for a bike engine). Not startling and no screamer but may be better suited to car road use. Looking at the pictures below there are a couple

of neat areas, the sump come off the bottom of the block and is nicely horizontal to the V and it seems to have a ready made mounting for a drive

shaft down the centre of the V.

So, the sump can be relatively easily made/designed from a rectangular billet of aluminum on a 3 axis mill (probably, designing on the fly in my head)

and a gearbox mounting plate added to the end, a sprocket can be attached to the crank shaft at the rear of each engine, a drive shaft installed

through the two holes on the block with matching sprocket used to connect via chains to the crank shaft sprockets. Add a fly wheel and clutch and off

you go. No lubrication of the drive shaft/chains needed (8k self lubricating bearing are available).

I am sure it is not that simple but on the face of it this looks like a relatively simple way of getting a small capacity (although maybe long), high

revving v8 with reasonable power and torque. Compared to a 2.0l duratec pushing out 250hp this will be relatively lightly stressed and probably a

similar price (assuming you run this with the stock electronics in a dual system) but have a great v8 sound. I would suggest this be mated with an

s2000 box/diff or and audi transaxle.

Any thoughts/ideas welcome.

Hi Ugg,

Like the idea and would have saved me about ten grand!!!

Project is rumbling on, took the crankcase to a couple of machine shops to check the first price I had for line boring and it seems pretty

competitive.

Took it in with the money ready and got a call from them saying they thought it was just the bearing caps which were poorly machined.

I've since measured the caps against my CAD models and there are some serious discrepancies.

I've gone back to the friend who organised the machining for me who is going to see what he can do to, long story but I really should have

checked these a year ago! At the time I got them I was going through a restructure at work so head wasn't really in the project so jumped to the

conclusion that it was the crankcase that was out of line or my CAD models.

Anyway, worst case scenario the shop can still line bore it for me but worth pursuing I think.

Sound like some progress, glad you are getting to the bottom of things.

My thoughts are no where near as elegant or will produce anywhere near the results of your ingenuity. Also they are just thoughts, at least you are

doing something about yours. Maybe when I get the anglia on the road I may look into it further (also got an idea to try and make a CEM engine, google

it, very interesting idea, piston linear rotary combination with very few moving parts).

Did you sort out your idler shaft bearings iirc you were after ones that ran at 26k rpm?

Cheers.

Interesting work. What kind of gearing are you using between cranks that can handle the torque? Do you have harmonic balancing to prevent vibe issues? What gearbox is going on it?

quote:

Originally posted by Ugg10

Sound like some progress, glad you are getting to the bottom of things.

My thoughts are no where near as elegant or will produce anywhere near the results of your ingenuity. Also they are just thoughts, at least you are doing something about yours. Maybe when I get the anglia on the road I may look into it further (also got an idea to try and make a CEM engine, google it, very interesting idea, piston linear rotary combination with very few moving parts).

Did you sort out your idler shaft bearings iirc you were after ones that ran at 26k rpm?

Cheers.

quote:

Originally posted by obr_technology

How's your anglia coming along?

quote:

Originally posted by Ugg10

quote:

Originally posted by obr_technology

How's your anglia coming along?

Nice - functioning bottom end sounds like real progress.

Been a bit slow over the summer due to holidays and family stuff, also had a bit of a mare with the engine.

Engine was running (ish) on a base map, found the front crank seal was leaking so decided to change, easy me thinks. Set to TDC, locked the cams, wedged the flywheel and undid the crank pulley. Found that the cam and crank pulleys have no keyways. Replaced the seal, put the pulley back on and then started the engine, couple of turns, fired and then would not run. Crank pulley had slipped, suspected bent valve. Online manual I was using did not say to replace the crank pulley bolt as it was a stretch one. Put it back together again and runs but not that well. So, rather than sending many hours tracking down the problem which may or may not end up with a new motor (or head off) I spent £90 on a new engine so that is currently being stripped down ready for the swap over. Also decided whilst I am at it to install the RX8 6 Speed box just for the fun of it. So about 6 months behind schedule but most of the rest of the car is ready to go once I have sorted this out.

Any more ideas as to what you are going to put this engine in? I do like the idea of a Spire GTR with an audi transaxle, mini LMP2 car :-)

And are you going to keep the oem electrics for now i.e. run as 2 separate engines linked or have you though more about ECU's to run both together ?

Hi All,

Just a quick update to say the project is back in motion...

Ive bought this on Thursday so finally have an oil cooler to put in the big pile of bits!

In the meantime our technician has started programming the bearing carriers into the CNC mill.

I've got a bearing to take in so we can test the hole diameter is going to work, a small from what I can see my 62mm bearing will need a 62.04mm

hole for a 'press fit' but want to check it out on a piece of scrap before machining the nice chunk of 7075 alloy.

Will upload some pics of the machining one finished as well as anything else which I get done.

Cheers

Olly

[Edited on 10/2/17 by obr_technology]

Cool, so you found some bearings that run fast enough for the idler shaft then, great news.

nice project, i wish i had your skills

good luck on finding time to finish this one !

quote:

Originally posted by Ugg10

Cool, so you found some bearings that run fast enough for the idler shaft then, great news.

quote:

Originally posted by Gre3D

nice project, i wish i had your skills

good luck on finding time to finish this one !

quote:

Originally posted by obr_technology

quote:

Originally posted by Ugg10

Cool, so you found some bearings that run fast enough for the idler shaft then, great news.

Yes, had some friends round and was chatting to one of them who is a designer at Dyson.

I was chewing over the project with him and he suggested a type of bearing in I'm not familiar with so I've written the name down for when I'm ready!

How's your project coming along?

quote:

Originally posted by Ugg10

quote:

Originally posted by obr_technology

quote:

Originally posted by Ugg10

Cool, so you found some bearings that run fast enough for the idler shaft then, great news.

Yes, had some friends round and was chatting to one of them who is a designer at Dyson.

I was chewing over the project with him and he suggested a type of bearing in I'm not familiar with so I've written the name down for when I'm ready!

How's your project coming along?

Bit slow but got the second engine in, rx8 box in and prop shaft on. However, clutch arm is not in the right position so need to pull the box and make a soaker or extend the arm pivot. Also need to get the engine running better. But I have a deadline for Easter as my garage is being knocked down and need to move the car so best way is to get it legal which means mot.

There is a guy on the 105speedhyperboards forum putting a tkd bike v8 (Yamaha R1 blocks irk, 380hp) in an aglia, nice project.

Here's a link, try this out - http://105speed.hyperboards.com/action/view_topic/topic_id/17236

I think he said that it was used in the back of a pilbeam so hillclimb it was. The Anglia was only 720kg off the ford line so with the iron engine and

box plus interior removed surprisingly it is not much heavier than a seven (well a Larry one with a pinto).

Pictures on here - https://imageshack.com/user/FYB613C

Just to give you an idea of what it looks like

Thanks, typically the link was locked to members but some great pics in the second link.

I get what you are saying about the lightweight Anglia, I'd just always imagined these high revving v8's in tubular chassis with composite

panels such as the radical sr8, SHP RSR escort or Palotov D1. In reality it would still be pretty quick in a saloon car not forgetting it needs to

handle and stop!

Had a great evening with our CNC guy at work.

We wanted to check the bearing fit for some carriers we wanted to mill.

We started with a piece of scrap and used the screen to input the program. As you will see gone are the days of writing lines and lines of code

yourself!:

Here is a pic of setting up the material, using the sensor to set the x, y and z points.

Once programmed and setup the process ran very quickly and we were then able to fit the bearing. We then ran a another cut at 62.04mm which is what my

design table had suggested would provide a press for for this bearing. It was clear that at 62.04mm the bearing was not being sufficiently held so we

will cut the final part at 62.

We the took the bullet of 7075 T6 alloy which I bough about 3 years ago and cut into the required sections for the four bearing carriers, here are

two:

We then loaded up the program which he had done during the day, adjusted the hole size to 62mm and are ready to run the process.

Sadly I got the call to have to head home, so we have stopped but plan to do another night next week.

It was great fun, and CNC programming has come a long way since I last used it.

Thanks

Olly

Also managed to get a quick video of cutting the hole for the test piece:

http://i279.photobucket.com/albums/kk143/hornetob/Engine/th_20170216_174241.mp4

I'm still buzzing from this, feel like we are really rolling again now!

[Edited on 18/2/17 by obr_technology]

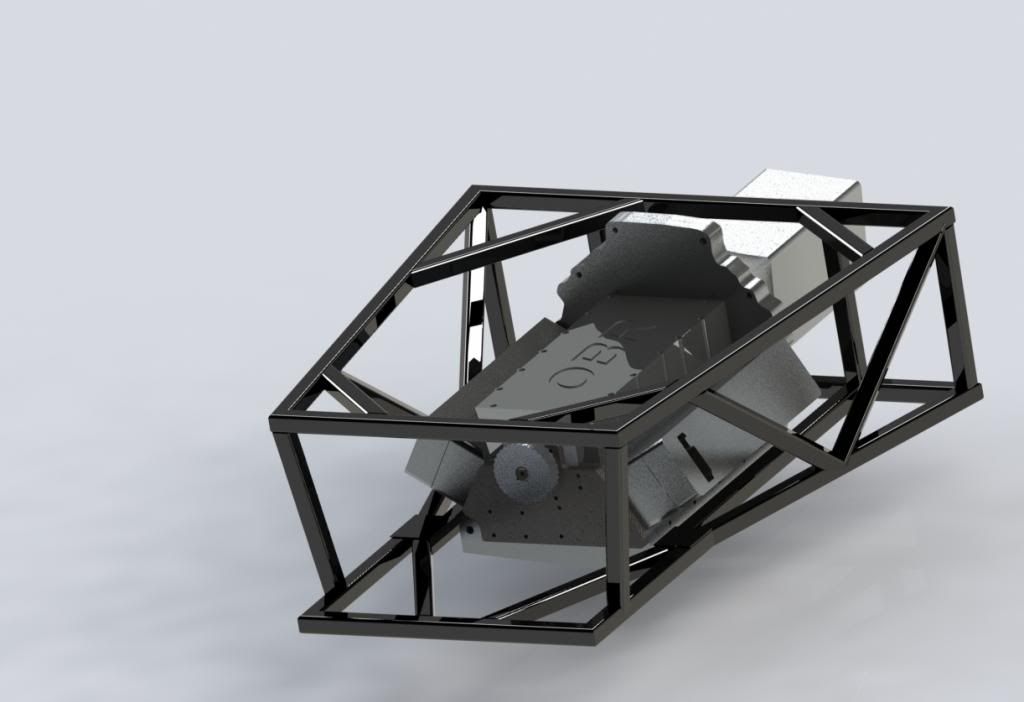

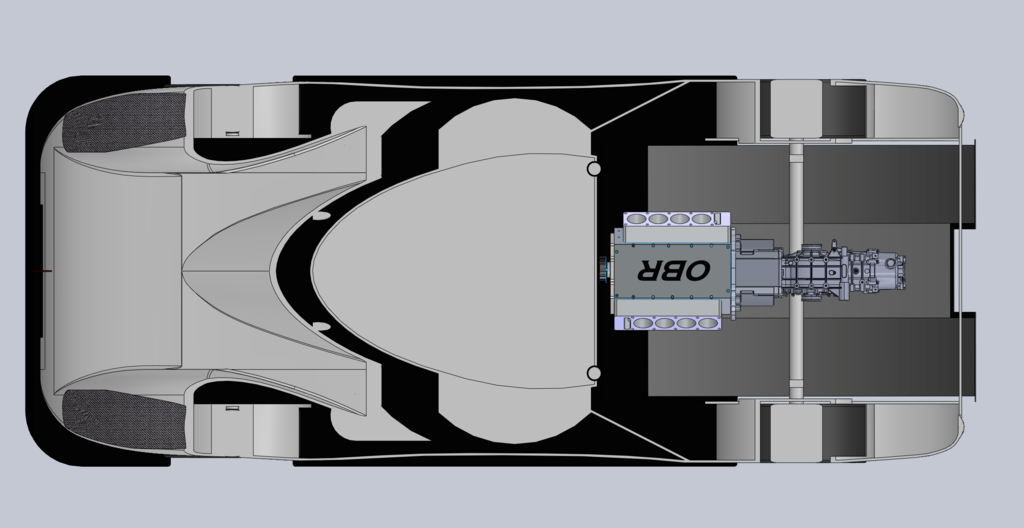

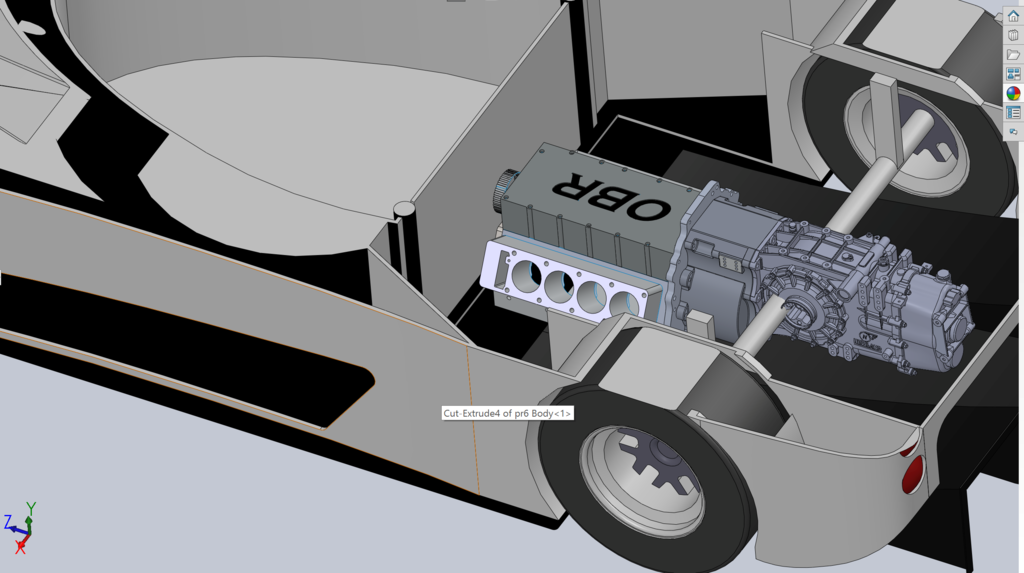

I forgot to mention (I think) that some of my students were looking for a project this year so are modelling/simulating fitting a twin turbo system

onto my engine.

They will do the simulation in Ricardo software and have already modelled the various manifolds they presented as concepts.

The image below shows a mock up of the engine fitted to a Hewland transaxle in the college Radial PR6 (not designed for this type of installation so a

bit of a tight squeeze but you get the idea!)

Before somebody asks, no it doesnt have a solid axle but the students wanted to get an idea of where the wheel centreline was!

[Edited on 21/2/17 by obr_technology]

Progress, great and nice little project for the students, axle and box output bosses don't seem to line up though. Would go well in a spire gtr

as a cost effective test platform (race proven).

I now know why you were interested in the cast stainless manifold thread. An m62 supercharger would fit nicely in the v aswell.

So, when are the kit price and delivery slots going to be released :-)

[Edited on 21/2/17 by Ugg10]

quote:

Originally posted by Ugg10

Progress, great and nice little project for the students, axle and box output bosses don't seem to line up though. Would go well in a spire gtr as a cost effective test platform (race proven).

I now know why you were interested in the cast stainless manifold thread. An m62 supercharger would fit nicely in the v aswell.

So, when are the kit price and delivery slots going to be released :-)

[Edited on 21/2/17 by Ugg10]

More progress on the mill last night, now have all the fronts for the bearing carriers and just need to spend another evening (hopefully next week)

completing the rears.

Pics and more vids to follow.

Hoping this will work:

[flash=425,350]https://youtu.be/7K5CZAPrdWE[/flash]

[Edited on 25/2/17 by obr_technology]

I give up, this will have to do:

https://youtu.be/7K5CZAPrdWE

We've completed the machining of the bearing carriers now, having done 4.

The surface finish could be better, but the crucial dimensions are within tolerance and that is far more important to me!

We've also had the turbo exhaust manifold 3D printed, which the students have then flow tested on our Superflow bench at work.

[Edited on 30/3/17 by obr_technology]

[Edited on 30/3/17 by obr_technology]

with the loss of photobucket I'm going to just use my Facebook page until I can find an easy replacement, please check it out and maybe even give

it a like to stay updated!:

OBR