scootz

|

| posted on 31/12/17 at 06:20 PM |

|

|

Welding Bolt/ Washer

Evenin'!

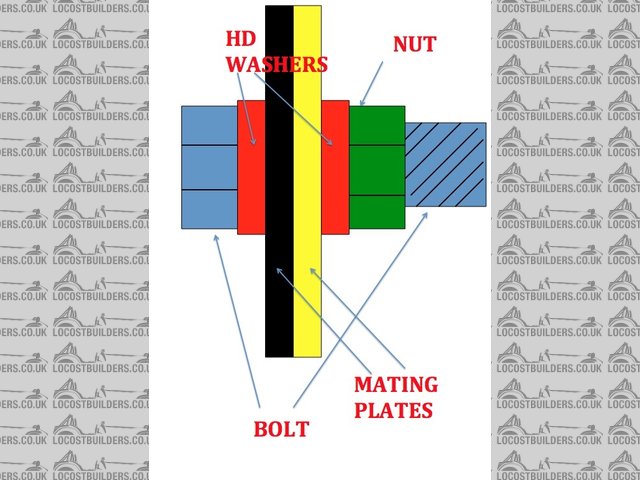

I'm looking to join 2 rectangular plate surfaces together. The outside plate is steel and the inside plate is a high grade Ali.

It will be a stressed joint. Both plate faces are 300mm x 75mm. The Ali plate is 5mm thick and the steel plate is 3mm thick.

I'm using two 12.9 grade bolts (at 12 and 6 o'clock positions), 2 HD oversized washers to spread the load, and 2 HD nuts. Basic drawing

below.

Gaining access to either the nut or the bolt will be a bit of a faff, so I was considering welding the bolt-head and HD washer to the outside mating

surface as this will give me a free hand to work on the 'other side'.

I appreciate this will cause a headache if I strip a thread in future, but other than that inconvenient is there any engineering reason why I

shouldn't weld the bolt and washer to one side?

Cheers.

It's Evolution Baby!

|

|

|

|

|

MikeR

|

| posted on 31/12/17 at 06:50 PM |

|

|

Wouldn't it be better to weld the nut? If you stripped the thread you've got a chance to put an extra nut on it and still use it or tap

out the welded nut o the next size.

|

|

|

scootz

|

| posted on 31/12/17 at 07:16 PM |

|

|

quote:

Originally posted by MikeR

Wouldn't it be better to weld the nut? If you stripped the thread you've got a chance to put an extra nut on it and still use it or tap

out the welded nut o the next size.

Good point... well made!

Yup - that would be easier and 'future proof'.

It's Evolution Baby!

|

|

|

loggyboy

|

| posted on 31/12/17 at 07:39 PM |

|

|

Would it be worth considering some sort of isolation plate to avoid galvonic corrosion?

Mistral Motorsport

|

|

|

scootz

|

| posted on 31/12/17 at 08:02 PM |

|

|

Sorry - should have said that there is a sacrificial 1mm ali shim plate. Also, the steel will be powder coated, the ali is anodised, and I'll

slavver some duralac on as well just to make sure!

It's Evolution Baby!

|

|

|

mcerd1

|

| posted on 31/12/17 at 10:50 PM |

|

|

its also worth saying that welding a 12.9 bolt is a sure way to mess up its heat treatment

how critical is the strength of these bolts / nuts ?

they are probably ways you could make something to hold the nuts / bolts without the need for any welding....

-

|

|

|

scootz

|

| posted on 1/1/18 at 12:22 AM |

|

|

quote:

Originally posted by mcerd1

its also worth saying that welding a 12.9 bolt is a sure way to mess up its heat treatment

how critical is the strength of these bolts / nuts ?

There are probably ways you could make something to hold the nuts / bolts without the need for any welding....

That's what I was wondering - would I be compromising the property of any of the parts by zapping it with heat!

The strength of the bolts is pretty critical - they will be holding the final third of the car on!

I could of course just get on with it and accept that installation / removal will involve a bit of cursing!

It's Evolution Baby!

|

|

|

40inches

|

| posted on 1/1/18 at 01:47 PM |

|

|

Welding on the nut would be best https://www.jhpfasteners.com/weld-fasteners-weld-nuts-c-66_67-l-en.html

|

|

|

scootz

|

| posted on 1/1/18 at 03:15 PM |

|

|

Thanks V much!

It's Evolution Baby!

|

|

|

mcerd1

|

| posted on 1/1/18 at 04:13 PM |

|

|

I was thinking something along the lines of a caged nut as per the link above, that way the nut itself isn't affected by the heat and can be any

grade you like (i.e. grade 12 to match the 12.9 bolt  ) )

-

|

|

|

Theshed

|

| posted on 1/1/18 at 04:20 PM |

|

|

Why not use a nut plate or make something similar?

|

|

|

Slimy38

|

| posted on 1/1/18 at 10:18 PM |

|

|

Don't Lotus glue parts of their cars together? If it's good enough for them to hold their cars together, wouldn't it be good enough

to hold the stack in place? No idea what glue though.

|

|

|

ste

|

| posted on 2/1/18 at 11:14 PM |

|

|

You need an anchor nut.

We use them on aircraft on stressed panels.

They can either be riveted on or bonded on with resin. the nut has some float which helps with alignment.

Let me know what size you need and I could see what ive got hanging around

|

|

|

scootz

|

| posted on 3/1/18 at 12:43 PM |

|

|

Thanks Ste.

2 x M16, and 2 x M12. Let me know what you have and how much you need for them.

Cheers

Scott

It's Evolution Baby!

|

|

|

ste

|

| posted on 3/1/18 at 10:44 PM |

|

|

ah sorry, way too big for what I have. Max M8 is what i have available.

|

|

|

scootz

|

| posted on 4/1/18 at 11:35 AM |

|

|

No probs - thanks anyway for the heads-up... I've found suitable online.

It's Evolution Baby!

|

|

|

02GF74

|

| posted on 4/1/18 at 12:29 PM |

|

|

Google blind bolt and hollowgram bolt. You'll need to do the research as for suitability/strength but these need access from one side to fit.

|

|

|