pdm

|

| posted on 31/8/09 at 04:11 PM |

|

|

Torquing bolts

Hi all

What is it that dictates a torque setting - is it the type of bolt or what it's securing ?

For instance is the torqued tightness (is that even a proper way of describing it !!) of a steel M10 bolt the same whether its used in say suspension

or the engine ? Or does the same steel m10 bolt need to be torqued tighter dependent on where its beng used ?

Also read that if you use anti-seize lubricant or locking compound you need to adjust the torque - is this true and if so how do you know what to

adjust it by ?

thanks in advance

Paul

|

|

|

|

|

blakep82

|

| posted on 31/8/09 at 04:25 PM |

|

|

there is tables to be found on the internet that list the torque by the diameter of the bolt.

however, not sure if the meterial its bolted to makes a difference.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Jasongray5

|

| posted on 31/8/09 at 04:48 PM |

|

|

if your putting a steel bolt, into ali, then the force you need will be quite small, as it will easily strip the threads!

How hard can it be?

http://www.flickr.com/photos/33261515@N03/sets/72157611049241239/

|

|

|

Angus180

|

| posted on 31/8/09 at 05:09 PM |

|

|

i think its size and mterials, sometimes wet and dry settings are given

|

|

|

Mark G

|

| posted on 31/8/09 at 05:14 PM |

|

|

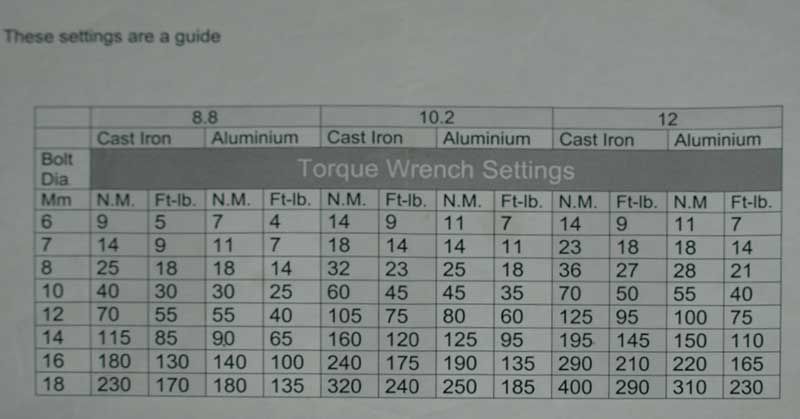

Had this one for years, hope it can be of some help.

|

|

|

pdm

|

| posted on 31/8/09 at 05:50 PM |

|

|

Excellent - thanks to everyone.

One question re the table - are 8.8, 10.2 and 12 different grade/strengths ?

Presumably you therefore use a higher grade when you need a tighter fitting ?

|

|

|

big-vee-twin

|

| posted on 31/8/09 at 06:24 PM |

|

|

Tensile Strength the higher the number the stronger the bolt

Duratec Engine is fitted, MS2 Extra V3 is assembled and tested, engine running, car now built. IVA passed 26/02/2016

http://www.triangleltd.com

|

|

|

MautoK

|

| posted on 31/8/09 at 06:25 PM |

|

|

Depends also on how much the bolt is designed/intended to stretch?

I suspect there will be a significant difference in applied Tq to achive a given clamping force between a, say, 1" full-thread bolt (which

won't/can't stretch) and a 5" long cylinder head bolt with 4" shank and 1" of thread.

John.

He's whittling on a piece of wood. I got a feeling that when he stops whittling, something's gonna happen. (OUATITW/Cheyenne)

|

|

|

Mark G

|

| posted on 31/8/09 at 06:25 PM |

|

|

Its the strength of the metal of the bolt that you're fitting, to put it to perspective. Most 'normal' bolts are 8.8, 10.2 are used

for example in exhaust manifolds and suspension components should all be 12 or above.

|

|

|

pdm

|

| posted on 31/8/09 at 06:34 PM |

|

|

Ok - great. Think that's cleared my thinking.

Thanks all.

|

|

|

flak monkey

|

| posted on 31/8/09 at 06:51 PM |

|

|

The torque dictates the clamping force available.

The max torque for a given grade of bolt into a HT nut will take the bolt to 70% of its UTS, this is when the max clamping force is available.

Obviously in different materials, ther eis a limit to what torque can be use without stripping the threads, and as such the clamping force is reduced

as well.

Take for example a pair of driven flanges bolted together. It is not the bolts which take the load when the falnges are rotated, rather the friction

generated between the faces by the clamping force of the bolts.

David

Sera

http://www.motosera.com

|

|

|

Theshed

|

| posted on 31/8/09 at 09:22 PM |

|

|

STOP STOP STOP - read Engineer to Win or Prepare to Win by Carol Shelby or read all the info on the ARP website. If it really matters - do it right.

|

|

|