mistergrumpy

|

| posted on 5/5/11 at 06:29 PM |

|

|

Tig Issues

I'm having a problem with my ally welding. I'm trying to weld some 10mmx10mmx6mm cubes to some 6mm plate for the bottom of my chopped sump

and I'm either melting the cubes or manage to get a bit of filler to stick to it but it doesn't want to join to the main plate. I was

thinking something like the heat in the cube will be greater than the plate which will dissipate it quicker maybe.

Can anyone help?

|

|

|

|

|

snakebelly

|

| posted on 5/5/11 at 06:46 PM |

|

|

Had a similar issue recently, turned out it was a material issue, cast Ali to solid billet, managed it in the end but it was a total pig, can you get

a decent run on just the cast sump as a test ?

|

|

|

mistergrumpy

|

| posted on 5/5/11 at 06:57 PM |

|

|

I've not tried yet, the issue so far is ally plate to ally plate.

|

|

|

austin man

|

| posted on 5/5/11 at 07:19 PM |

|

|

have you wire brushed the area and removed all oxidisation , my understanding is that stainless wire brushes are best dor cleaning the area.

Life is like a bowl of fruit, funny how all the weird looking ones are left alone

|

|

|

welderman

|

| posted on 5/5/11 at 07:21 PM |

|

|

Heat is an issue, the larger item will take longer to heat up and the little bit will get hot asap.

Try warming up the area first with the torch and then aim to get the rod and weld onto the little bit.

You can also have a cast part we call monkey metal which will be the crapest alloy going and it might leave some pin holes in your weld.

If your realy realy stuck i could pop over one day

Thank's, Joe

I don't stalk people

http://www.locostbuilders.co.uk/forum/23/viewthread.php?tid=172301

Back on with the Fisher Fury R1

|

|

|

907

|

| posted on 5/5/11 at 07:26 PM |

|

|

You may find it better to weld a longer bar to the sump and then cut it to the height afterwards.

Cheers,

Paul G

|

|

|

mistergrumpy

|

| posted on 5/5/11 at 07:38 PM |

|

|

I don't think its monkey as there's a few done on here already with the same sumps.

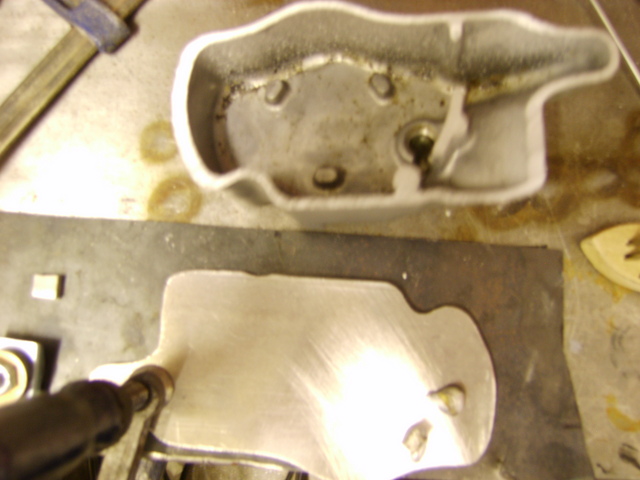

Here's a picture of the bottom of the sump as standard:

Do I really need the lumps in the bottom?

Here's a picture of my effort (I've had to outline the cubes as the camera won't focus):

|

|

|

mistergrumpy

|

| posted on 5/5/11 at 07:41 PM |

|

|

Nice ideas lads, thanks.

Thanks for the offer Joe, I'll give both the ideas a go first then may call for help

|

|

|

welderman

|

| posted on 5/5/11 at 07:46 PM |

|

|

For starters might be better off the bench, the heat transfers though the alloy very quick and cools down, that could be a problem.

Thank's, Joe

I don't stalk people

http://www.locostbuilders.co.uk/forum/23/viewthread.php?tid=172301

Back on with the Fisher Fury R1

|

|

|

mistergrumpy

|

| posted on 5/5/11 at 07:51 PM |

|

|

Cool. Thanks again.

|

|

|

Peteff

|

| posted on 5/5/11 at 10:33 PM |

|

|

If it's to stop the pickup falling off can't you araldite some pieces to the bottom of the pickup instead?

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

mistergrumpy

|

| posted on 6/5/11 at 08:57 AM |

|

|

TBH I don't know why they're there at all. If I don't have to put them in I won't.

|

|

|

Peteff

|

| posted on 6/5/11 at 06:23 PM |

|

|

In the ZX9 sump the oil strainer rests on them, you have to modify it when you cut the sump.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

mistergrumpy

|

| posted on 6/5/11 at 07:32 PM |

|

|

Damn. Cheers Pete, I thought it was retained by the engine block. Job's becoming in depth now.

|

|

|

mistergrumpy

|

| posted on 6/5/11 at 09:05 PM |

|

|

Ha sorted it! I've used a longer piece as per Paul and I've took the base piece off the bench and it occurred to me earlier that

I've still got the thin electrode in so I've switched to the thick one and cranked the amps up and we're on a winner.

Cheers lads.

|

|

|

welderman

|

| posted on 6/5/11 at 09:15 PM |

|

|

Yay happy days

Thank's, Joe

I don't stalk people

http://www.locostbuilders.co.uk/forum/23/viewthread.php?tid=172301

Back on with the Fisher Fury R1

|

|

|

mistergrumpy

|

| posted on 6/5/11 at 09:23 PM |

|

|

Cheers Joe. Was pissing me off slightly. Been trying to cram in as much time on the car as things permit and have a short list of mainly cosmetic

things to do now before I can test out my new clutch improvements.

|

|

|