Susp design - camber gain?

garage19 - 23/6/08 at 09:28 AM

In a corner do i want the camber gain from suspension geometry to be:

a)Less on the inside wheel?

b)Less on the outside wheel?

c)The same on both wheels?

Thanks,

Doug.

nitram38 - 23/6/08 at 09:48 AM

Doug you need to work out suspension travel in a corner to determine the max camber gain that you want.

Too much can be just as bad as too little.

If you are running a very stiff set up then your camber gain will probably need to be more over a shorter travel.

My MotaLeira has air suspension. It will run at 3" to 6" from the ground so my gain has to be over a longer suspension travel, otherwise I

will wear out my tyres at the 6" height.

Both wheels will have the same suspension arms so one will gain and the other lose.

You need to make models of your suspension arms and pivot them and measure the camber change. You will have to vary the mounting points/length of

arms, until you get what you need.

You can do this with paper and pins or a drawing program.

Here are my trial drawings.

unequal wishbones

Description

up

[img][/img]

rpmagazine - 23/6/08 at 12:33 PM

what is the wheel travel and what is the intended use?

Camber gain in roll is a much discussed issue.

Syd Bridge - 23/6/08 at 12:44 PM

quote:

Originally posted by rpmagazine

what is the wheel travel and what is the intended use?

Camber gain in roll is a much discussed issue.

......and a much misunderstood and misquoted one as well! Too much BS associated with a very simple piece of geometrical exercise, particularly from

the armchair experts.

kb58 - 23/6/08 at 01:04 PM

quote:

Originally posted by Syd Bridge......and a much misunderstood and misquoted one as well! Too much BS associated with a very simple piece

of geometrical exercise, particularly from the armchair experts.

and I though we were past this, the taking shots while offering no substance... sigh.

garage19 - 23/6/08 at 02:57 PM

quote:

Originally posted by rpmagazine

what is the wheel travel and what is the intended use?

Camber gain in roll is a much discussed issue.

Car is a track/fast road use single seater weighing 450ish kg with 13" wheels running sports tyres eg ACB10 or 888s.

nitram38 - 23/6/08 at 05:10 PM

quote:

Originally posted by garage19

quote:

Originally posted by rpmagazine

what is the wheel travel and what is the intended use?

Camber gain in roll is a much discussed issue.

Car is a track/fast road use single seater weighing 450ish kg with 13" wheels running sports tyres eg ACB10 or 888s.

I would suspect the camber gain is mimimal as your suspension travel/body roll will be minimal too.

[Edited on 23/6/2008 by nitram38]

Syd Bridge - 23/6/08 at 07:32 PM

quote:

Originally posted by kb58

quote:

Originally posted by Syd Bridge......and a much misunderstood and misquoted one as well! Too much BS associated with a very simple piece

of geometrical exercise, particularly from the armchair experts.

and I though we were past this, the taking shots while offering no substance... sigh.

Now why does that response not surprise me?

As you sit back in that big comfortable chair, you can rest very much assured that I will NEVER post definitive answers and methods of

my work on any i'net forum, or any public forum for that matter. Just like my peers!

But, some on this forum have benefited from one-to-one already, and will do so ongoing. And to a man, they will not reveal who they are. And for that,

I am eternally grateful. Thanks chaps.

Cheers,

Syd.

nitram38 - 23/6/08 at 07:56 PM

Eh?

Maybe I am a bit naive here, but I thought this forum was here to help other car builders, not to prove how smug we are.......................

If you aren't part of the solution, you are part of the problem.

(I can't remember who said it, but it's true)

kb58 - 24/6/08 at 03:36 AM

quote:

Originally posted by Syd Bridge Now why does that response not surprise me?

Why? Because you've heard it before, on 10/31/07. Since it didn't sink in the last time, here it is again:

quote:

Syd, as I said, I'm all ears - I want to learn - but all I hear is how clueless everyone is. What's with this?:

-"pseudo intellectual discussions"

-"all of you armchair experts"

-"and [what I'm designing] will be travelling quicker than anything you lot will build in your sheds."

Is arrogance the price of knowledge, Syd?

Why allude to being some kind of Suspension Oracle, yet view with distain our attempts at understanding? You won't explain anything, yet insult

our attempts to do so on our own.

Why are you here? I'm disappointed that it's apparently not to educate or enlighten. Answering everything with, "Wow are you guys

wrong", is worse than useless.

Welcome to last year.

[Edited on 6/24/08 by kb58]

Syd Bridge - 24/6/08 at 09:00 AM

And why is it the same two who want me to put specific details on here? So they can make commercial gain from republishing under their own

titles!!!!

Get used to the idea fellas, ...IT JUST AINT GOING TO HAPPEN!!!!  (Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

(Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

Those who I've helped on here, and met me in person, will tell you I'm anything BUT arrogant. I help those who ask politely, and in

confidence. I've also got a pretty good BS sniffer, and have weeded out a few as well!

Cheers,

Syd.

nitram38 - 24/6/08 at 09:45 AM

quote:

Originally posted by Syd Bridge

And why is it the same two who want me to put specific details on here? So they can make commercial gain from republishing under their own

titles!!!!

Get used to the idea fellas, ...IT JUST AINT GOING TO HAPPEN!!!!  (Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

(Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

Those who I've helped on here, and met me in person, will tell you I'm anything BUT arrogant. I help those who ask politely, and in

confidence. I've also got a pretty good BS sniffer, and have weeded out a few as well!

Cheers,

Syd.

Paranoid or What?

As if we are going to go into commercial production of the in's and out's of cambergain!

You can find it in any suspension book, but the idea of a forum is to share knowledge.

It is not as if this knowledge is not already in the public domain.

Syd, I suggest you delete locostbuilders from your shortcuts because you already know everything and have nothing to gain by coming here.

You seem to turn any simple discussion into a war zone.

TheGecko - 24/6/08 at 10:04 AM

I have real difficulty seeing what Syd's contribution is here. He only ever pops in to tell us we all know nothing; that he does; and that he

won't discuss it with us without money changing hands. Well, that sounds like an unregistered trader touting for business to me.

Syd, if you've got a helpful contribution to make then do so. If you're just selling your services, then register as a trader

and advertise them. If you're just here for self-aggrandizement, then buzz off!

On the subject (!) of Doug's original question; I don't know if it can be answered as posed. The goal should be to keep the more heavily

loaded outside wheel more vertical. To do that you need to come up with some estimate of how much chassis roll you'll be dealing with in your

chosen corner and how that, projected through your chosen/designed suspension geometry, is going to affect the final camber of each wheel. The simple

solution, of course, is to keep things both light and stiff so that the actual amounts of movement are all relatively small anyway

What sort of vehicle is this for? [edit] Sorry, missed your second post amongst all the blather. I'd start from the vertical outside wheel and

work back from there. You'll need to know or calculate your roll stiffness to progress things.

Dominic

Disclaimer: I am not a professional suspension engineer nor do I claim to be one. If someone needs advice in my real area of expertise (Oracle

databases and Identity Management/Automated Provisioning systems) I'm happy to offer anything which doesn't breach the Commercial In

Confidence terms my employer expects me to work under (pretty unlikely  ).

).

[Edited on 24/6/2008 by TheGecko]

rpmagazine - 24/6/08 at 10:10 AM

Syd you can rest assured that if you ever write anything original or worthy WRT suspension and that I ever print it I will definitely credit you.

Doug, I have recently had many conversations WRT roll and camber gain.

As for your application, you no doubt know there are force based RC's and Geometric RC's. Most of the software packages we can afford use

Geometric RC's and they remain a useful, if admittedly flawed, tool for discussing suspension. Looking at a single axle only, the relationship

between RC and CoG can be summarised (note this is neither a complete description or an accurately described one but it may assist) thus: The distance

between the CoG and RC creates the 'lever' that the roll forces act on and thus the bigger the lever the more 'roll' the car will

likely have at that axle (assuming all other features are the same).

We can mitigate some of these forces by using a sway/anti-roll bar, but we are getting into a more complete discussion and I want to almost stay on

topic!

If we then say "well I'll have them damn close then!" then we run into issues of 'jacking' where instead of rolling the car

will want to lift a wheel.

However it is not just the amount of force but the speed in which the force/roll is reacted. It was suggested to me that I think of RC's as

'fast' reaction and sway bars as 'slow reaction' and advanced dampers somewhere imbetween. This has implications for RC choice for

the type of vehicle (hence my question) and also for the type of control/recovery aspects of a design e.g. if you choose to have high RC's with a

low CoG with your light single seat car you might well get away with it on a track. It is likely that (all other things being equal - AOTBE) this will

mean that your car will be quick to respond to control inputs, but may be too fast at times and is likely to be upset easily by bumps (e.g. you hit a

bump, your hand moves the wheel and your car responds immediately etc).

So what has this got to do with camber gain? Well both not a lot and a bit...you see there is a bit of an interplay - camber gain (really minimising

camber loss) is generally good for steady state cornering and in some cars they add a lot to overcome compliance in the car structure as it flexes

under cornering loads, which is one of the reasons why you see some older racecars such as Escorts with huge amounts of negative static camber on the

front.

The other reason is to keep (mostly) the outside tyre contact patch as uniform as possible with load. In this regard it could be said that we want the

tyre to remain static while the car rolls about it, which is when 'camber gain = roll deg'. not only is this very very hard to predict (it

varies with speed, roll, force etc etc), curiously no manufacturer I discussed this with actually does it! This is partly because negative camber is

only useful when your tyres really need it, which is in high load cornering situations...which for some cars is higher speed (this is where the speed

of roll reaction -CoG/RC etc comes into play) and longer corners. It actually adversely affects longitudinal traction and as such is contraindicated

for braking and start traction. So when you brake heavily and your car dives and you get camber change and then reduced braking effort.

So to too briefly tie the bits together (assume same car and same CoG):

Hillclimbs: you need good longitudinal traction, quick reaction/turn in, minimal roll you could possibly look at higher RC's and less camber

gain.

Sportscar on smooth, high speed track with quick reaction (e.g. exige at Oulton Park): mod RC's and some camber gain...tune camber to keep tyres

happy

Tarmac Rally: Lower RC and possibly less camber gain than above due to road camber changes, need for slower roll reaction and possibly less wheel

camber gain to assist with longitudinal traction - a premium is placed on this due to type of event.

[Edited on 24/6/08 by rpmagazine]

[Edited on 24/6/08 by rpmagazine]

[Edited on 24/6/08 by rpmagazine]

[Edited on 24/6/08 by rpmagazine]

rpmagazine - 24/6/08 at 11:04 AM

Note I've just reread the above and it is a bit of a jumbled mess!...I have a bit more of a think on it.

garage19 - 24/6/08 at 01:01 PM

Thanks for all your input guys.

The chassis should be pretty stiff and suspension movement will be controlled by rod ends rather than rubber/polly bushes so minmal camber gain

required to deal that area.

I guess tyre construction and sidewall strength play a large part in the amount of camber gain required?

Athough i will be using relativly high side wall 13" tyres they will be of the road legal cut slick type eg Toyo 888s so should be pretty stiff

in construction i would imagine?

I have bee playing with an excellent XL spreadsheet for camber change and roll centre location that apparently originated from this forum. Does

anybody know who wrote it?

In my small light car it is currently looking like RC is 1.5 " off the ground with a static ride height of 4". I'm guessing the COG

would be a few inches above that.

Will this make for a un responsive car with slow handling?

pbura - 24/6/08 at 03:31 PM

Doug,

There's a nice old free DOS program called Wishbone that is handy for modeling and is available here:

http://www.locostusa.com/forums/viewtopic.php?t=1438

IIRC, Toyo suggests a camber range of 2.5 to 5 degrees for the R888, which is a wide range and will make your job easier. It would seem that 2.5 as a

static camber would be a little hard on the tires, and I'm interested in others' comments on this.

The roll center height will give you some idea how much load will be transferred via the suspension arms rather than the sprung mass. A very high

roll center, say equal to your CG, would not work well because much of the force would be applied laterally against the outside tire, upsetting

traction. A low roll center causes the load to be transferred through the springs, which is better for traction as these push down on the contact

patch. However, to control body roll you will need more spring, possibly interfering with keeping the tire on the ground. Anti-roll bars

shouldn't be used excessively because they are nothing more than undamped springs.

So, it's a balancing act. A strategy employed by many (assuming you have IRS) is to set the rear roll center height at no more than 3"

because above this jacking forces are excessive in an A-arm suspension. The front is usually a bit lower, like your 1.5"; the reasons for this

are somewhat disputed but most agree it helps with initial turn-in. Then, springs are selected for best tire compliance, and any trimming after that

is done with anti-roll bars and shock settings.

In a solid axle car, the roll centers can be higher. A lot of Locost builders are able to avoid anti-roll bars entirely because of this.

Disclaimer: The above was gained through interested though undisciplined self-study of accessible sources such as Allan Staniforth, Carroll Smith,

and Mark Ortiz, and paying attention to various car builders' experiences. Yes, I am an armchair builder.

[Edited on 24/6/08 by pbura]

mr henderson - 24/6/08 at 04:26 PM

quote:

Originally posted by nitram38

quote:

Originally posted by Syd Bridge

And why is it the same two who want me to put specific details on here? So they can make commercial gain from republishing under their own

titles!!!!

Get used to the idea fellas, ...IT JUST AINT GOING TO HAPPEN!!!!  (Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

(Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

Those who I've helped on here, and met me in person, will tell you I'm anything BUT arrogant. I help those who ask politely, and in

confidence. I've also got a pretty good BS sniffer, and have weeded out a few as well!

Cheers,

Syd.

Paranoid or What?

As if we are going to go into commercial production of the in's and out's of cambergain!

You can find it in any suspension book, but the idea of a forum is to share knowledge.

It is not as if this knowledge is not already in the public domain.

Syd, I suggest you delete locostbuilders from your shortcuts because you already know everything and have nothing to gain by coming here.

You seem to turn any simple discussion into a war zone.

As a disinterested observer, I would have to say that that is a very good answer to Mr Bridge's apparent BS

John

Syd Bridge - 24/6/08 at 08:18 PM

All I've ever tried to do is get these people to let go that horrid 'Roll centre' stuff, and think for themselves.

Seems they can't let go of the fictional rollcentre theory, and work things out from basic principles.

In cornering, cars don't roll about some mythical centre, they roll about the outer contact patches first, and then on it just gets more

complicated.

If any of you grasped the basic principles, you'd wake up to a whole new outlook.

Call me all the names you like, tell me to F off as much as you like. I'm here, I contribute a lot more useful help than many realise, and will

continue to do so.

I just don't ask for open public adulation or approval or thanks, nor do I sprout regurgitated anecdotal information seeking recognition from

others. Quite the opposite. What I give is given freely, but quietly.

Oh, and as for touting for business, there are more than one or two on here who I've had to refuse to do work for because of my personal

workload. I've only done one small carbon job this year for a very polite gentleman on this forum, and even he ended up waiting three months! So

no, I'm not looking for more work!! I'm actually trying to divest myself of some.

Cheers,

Syd.

Benonymous - 25/6/08 at 01:46 AM

I remeber reading in the "Race and Rally Car Source Book" that F1 cars have practically no suspension movement. This would greatly simplify

any suspension geometry calculations wouldn't it?

With no movement in the vertical plane you'd only have to concern yourself with roll and as can be observed on a moving F1 car, they have

none!

It's all in the tyres.......

Doug68 - 25/6/08 at 06:18 AM

F1 hmm. If only it were that simple... looking at the picture below clearly there's a lot of camber on the front wheels.

But when they're cornering most of the camber has gone, look at the inside front wheel, clearly somethings moved otherwise there wouldn't be

that gap opening up would there?

And if its not roll thats doing it whats going on?

From my point of view the more I learn about this stuff the more I realize how little I know and how much I've left to learn.

Delinquent - 25/6/08 at 07:55 AM

quote:

But when they're cornering most of the camber has gone, look at the inside front wheel, clearly somethings moved otherwise there

wouldn't be that gap opening up would there?

And if its not roll thats doing it whats going on?

Optical illusion of the camera coupled with tyre distortion giving the car roll (due to weight transfer) around the offside contact patch, the camber

is still there.

The movement of the susp. on modern F1 cars is barely visible to the naked eye, as said they rely almost entirely on the tyre.

[Edited on 25/6/08 by Delinquent]

rpmagazine - 25/6/08 at 09:31 AM

quote:

Originally posted by garage19

Thanks for all your input guys.

The chassis should be pretty stiff and suspension movement will be controlled by rod ends rather than rubber/polly bushes so minmal camber gain

required to deal that area.

I guess tyre construction and sidewall strength play a large part in the amount of camber gain required?

Athough i will be using relativly high side wall 13" tyres they will be of the road legal cut slick type eg Toyo 888s so should be pretty stiff

in construction i would imagine?

I have bee playing with an excellent XL spreadsheet for camber change and roll centre location that apparently originated from this forum. Does

anybody know who wrote it?

In my small light car it is currently looking like RC is 1.5 " off the ground with a static ride height of 4". I'm guessing the COG

would be a few inches above that.

Will this make for a un responsive car with slow handling?

Doug at the end of the day it grip is nearly all about making the tyres happy! You will have a relatively light car and so the sidewall stiffness will

be correspondingly high/per unit weight and you may find that you can run quite low pressures - infact may need to to get the tyres warm on a colder

day.

Compliance and chassis stiffness is perhaps less complex. Rod-ends reduce compliance and also simplify suspension design in a way as none of the cheap

software packages can cope with bush compliance. Also try Greg Locock's SLARK program and try the free demo version of susprog...susprog is

really quite good and easy to use.

I fear I may have mislead you a bit: the responsiveness etc is much more complicated than simple RC's but it is a factor. I think that you are

likely to have so much rubber for the weight and low CoG that your car almost cannot help but be responsive!

rpmagazine - 29/6/08 at 02:13 AM

quote:

Originally posted by Syd Bridge

All I've ever tried to do is get these people to let go that horrid 'Roll centre' stuff, and think for themselves.

Seems they can't let go of the fictional rollcentre theory, and work things out from basic principles.

In cornering, cars don't roll about some mythical centre, they roll about the outer contact patches first, and then on it just gets more

complicated.

If any of you grasped the basic principles, you'd wake up to a whole new outlook.

I might have some sympathy for this position if I were driving a go-kart

What time frame does the road going vehicle with suspension roll on the outside contact patch?

Syd Bridge - 29/6/08 at 10:31 AM

A go-kart is only a car without springs, albeit smaller.

Most things that run with wings today can be interpreted in much the same way.

Check your basic physics and maths, and you should quickly work that out. Maybe??

A simple roll couple of the CoM about the outer contact patch, if you can't work it out yourself.

rpmagazine - 29/6/08 at 10:49 AM

syd, which single seat class with wings has more than 30-40mm total suspension movement in normal operation?

Syd Bridge - 29/6/08 at 02:43 PM

I really don't know if you're deliberately trying to be awkward or what???

What I was trying to say, is that a go-kart is only a car without suspension(whereas in fact, the go-kart suspension is the stiffness of the kart

combined with axle widths), and that single seaters today are pretty much the same as karts. Did I mention suspension movement?

Nothing changes in the dynamic. The first thing any (race) car does on commencing turning, is to roll about the front outer contact patch, then the

front and rear outer, and then things start to complicate.

The prime 'rolling' couple is the CoM about the outer contact patches. No matter how soft or hard the suspension is. Always was, and always

will be. Newtonian physics and all that. I enjoy watching road saloons and sedans of any sort racing, particularly in the corners, and seeing all

this in action. Those big old Jags at Goodwood are like ballerinas, dancing and rolling all over the place.. Give it a try, you might just learn a

thing or two, by thinking about what you are seeing happening in front of your eyes. Take a digi video along, and play it back as slow as possible,

frame by frame. You'll be surprised by what you see. The video is an amazingly powerful diagnostic, and learning, tool when searching for

answers.

How the chassis behaves relative to the suspension is dictated mostly by spring stiffness, wherever they are placed. You can have a single swing axle

each side with the hubs rigidly attached at the outer ends. Attach (stiff)springs from the outside to the chassis as high as possble, and the

behaviour will be different to that when the springs are terminated at a shallow angle, or soft springs. Swing axle lengths become irrelevant, as does

all the fairyland RC stuff.

Does the suspension move the chassis, or the chassis move the suspension?

You gotta decide if the monkey is swinging the elephant by its tail, or the elephant swings the monkey,...so to speak.

And therein lies the dilemma.

Cheers,

Syd.

Edit. Having read all that above, it should now be very obvious to all, that the importance of keeping the CoM as low as possible, can never be

overstated. And thus keeping the rolling moments minimal.

[Edited on 29/6/08 by Syd Bridge]

rpmagazine - 29/6/08 at 11:35 PM

what I am trying to ascertain is why you are relating this information to this discussion and our previous discussions of road/track cars?

Suspension design on a single seat track car places an overall emphasis on factors that have very little to do with cars that require suspension

movement.

FWIW if I were designing another single seat car I would place far less emphasis on what the RC does or where it is...I think we shall have to

continue to disagree.

The available CoM is most often defined not by what is perhaps perceived as 'perfect' or 'ideal' but what we can reasonably

achieve given the available components, the budget and the intended function and what we can construct. I know I can lower the 190kg engine in my car

50mm from where it is, great for CoM. But in doing so I need a new bell housing, gear change mechanism, change to coolant circuit, clutch release

mechanism, a dry sump system. In doing so I would increase my total expenditure considerably and I do not have the flexibility there. So I would need

to give up the option of quality dampers and the engineering in getting them set up correctly. Frankly the dampers are far more important.

[Edited on 29/6/08 by rpmagazine]

[Edited on 30/6/08 by rpmagazine]

[Edited on 30/6/08 by rpmagazine]

cymtriks - 5/7/08 at 09:21 AM

Ok here's my take on this debate we keep hearing between Syd and others.

Point 1

Think of the car as a mass supported by a system of linkages. If this car was supported by very soft (by which I mean a theoretically total softness)

springs then it would be free to move about on its supporting linkages and would move about the geometric roll centres in every direction.

Point 2

Think of the opposite case. Make the springs very stiff or just replace them with rose jointed links. The car's linkages still move but only by

microscopic ammounts. The important thing now is the CoG, the roll centres just drop out of the picture from a practical point of view. The car now

appears to roll about the CoG with the springs just holding it up. The "suspension", in terms of deflection anyway, is now the tire. This is

exactly what I think Syd is describing

Conclusion

In a road car the result will be some way between point 1 and point 2 so the car will tend to roll, in cornering and squat/dive, about a point between

the geometric RC and the CoG. Given the stiffness of a road spring I would expect this point to be closer to the RC for a road car and closer to the

CoG for a race car.

Comments all!

Especially Syd, is this what you've been getting at?

Syd Bridge - 5/7/08 at 09:53 AM

Geez, I'm now convinced I don't write in English!!!  Can someone interpret for me??

Can someone interpret for me??

Did I not say that the car rolls about the outer contact patches, due to the roll couple formed by the CoM trying to go about the contact patch.

Cheers,

Syd.

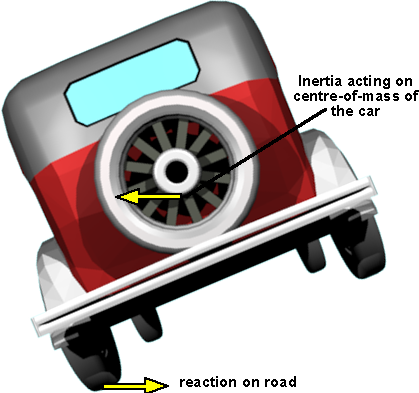

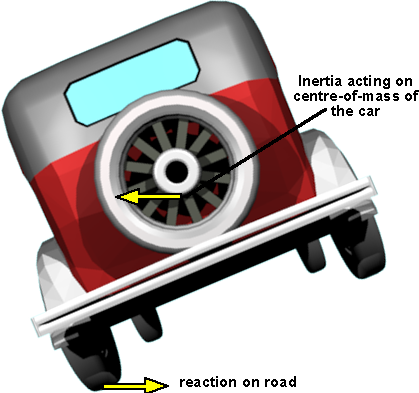

Doug68 - 5/7/08 at 11:28 AM

I think this is the simple point Syd is making...

In theory...

And in practice...

TheGecko - 5/7/08 at 02:39 PM

Nice pictures Doug = I think they do help to illustrate the point.

My take on this:

In pure geometric terms it may be true to say that the roll centre is the point about which the suspension appears to pivot. In practice, as

anyone who's done any roll centre modeling will know, the RC's move all over the place so the car obviously isn't actually rolling

around that point.

In kinematic terms, the fixed point is the contact patch of the outside tyre and everything else moves around that.

The problem is, calculating the geometric roll centre is (relatively) easy whereas calculating the kinematic behaviour is much harder. I'm of

the personal belief that geometric roll centres are still a useful fiction for comparing behaviour of different suspension designs as long as we

don't start believing the car actually rolls around them! I might have a bash at rejigging my RC spreadsheet to work backwards from the outer

contact patch and calculate the position of everything else i.e. chassis roll and both inner and outer camber angles. To do that really requires some

knowledge of roll stiffness, roll couples and the cornering force and their relationship to teh suspension geometry. My 3 semesters of engineering

(from 20 years ago) are now looking pretty shaky! (I eventually completed an IT degree).

Do there exist amateur level tools for doing these calcs?

Dominic

v8kid - 5/7/08 at 05:09 PM

What does it matter?

Surely all we are interested in is making sure the tyres get the best grip possible which means keeping them upright or 1 or 2 degrees negative.

In ultimate terms the outside tyre is the most important and in transition terms the inside tyre is only important while there is significant weight

on it.

Apart from that keep it low keep it central. You can't change the basic laws of physics no matter how fancy the linkages or theory!!

So use one of the loads of free spreadsheeets around and check out that the wheels are always 1 or 2 degrees negative for your range of bump and roll

and Bobs your auntie. Also I'd think it would be handy if the changes in camber were smooth with no sudden changes - would this corelate to the

"roll center migration" I wonder?

Trouble is I find it damn difficult to achieve it and after a few hours of plugging away at a computer get bored and go for a pint

Three nights so far and I still havn't found a suitable compromise between the available chassis mounts and ones that give good camber change -

Its a hard life being a Locoster I'm off for a pint

Ah I should have mentioned we want to have both ends changing by the same ammount so that the oversteer/understeer ballance stays the same. Some cars,

including mine, tend to oversteer more in fast corners so adding a bit of of understeer at the limit makes the driving less tiring.

Now I'm definitly going for that pint

[Edited on 5/7/08 by v8kid]

kb58 - 5/7/08 at 06:44 PM

http://www.2kgt.com/MarkOrtiz/2004_6.pdf

http://www.2kgt.com/MarkOrtiz/2004_8.pdf

cymtriks - 6/7/08 at 08:11 AM

After Syd's last comment here's my revised take on this debate we keep hearing between Syd and others.

Point 1

Think of the car as a mass supported by a system of linkages. If this car was supported by very soft (by which I mean a theoretically total softness)

springs then it would be free to move about on its supporting linkages and would move about the geometric roll centres in every direction. The

important thing, in terms of how much roll occurs, will be the difference between the geometric RC and the CoG.

Point 2

Think of the opposite case. Make the springs very stiff or just replace them with rose jointed links. The car's linkages still move but only by

microscopic ammounts. The important thing now in roll is the height of the CoG above the road, the roll centres just drop out of the picture from a

practical point of view. The car now appears to roll about the outer tyre contact with the springs just holding it up. The "suspension", in

terms of deflection anyway, is now the tire. This is what I think Syd is describing.

HOWEVER....

A search of the internet reveals a few threads on "force based RCs" which, according to people who claim to have modeled these, represent

the true RC.

These are described as being higher than the geometric RC, part way between the geometric RC and the CoG

NEW Conclusions...

In a road car the result will be some way between point 1 and point 2 so the car will tend to roll, in cornering and squat/dive, about a point between

the geometric RC and the tyre contact patch. Given the stiffness of a road spring I would expect this point to be closer to the RC for a road car and

closer to the tyre contact for a race car.

However, as Syd has said, this is the initial event and after this it becomes "complicated" (his words!) so to continue the conclusions

AFTER the initial turn in event and roll about the tyre contact the car settles on its suspension and adopts a stance partly based on the suspensions

geometry, but...

Is this second event controled by the geometric RC, a force based RC or some other contact patch/RC/CoG relationship?

Comments again guys! We may yet figure this out!

rpmagazine - 6/7/08 at 09:39 AM

Geometric RC's and the theories behind them are an old tool to try to understand what happens within a very dynamic event. It is a tool clearly

with flaws, but it has been around a while now as and with any theoretic perspective is has become somewhat reliable and predictive of certain

events...but it is still only a tool.

Force based RC's are used with high end programs that we as mere enthusiasts cannot really access i.e. Adams etc. Agan it is a tool that

manufacturers use and they would not spend millions without some reason, but they do also back it all up with a massive amount of testing and

correlating test results with the programs that they use. This is one area that virtually all enthusiasts fall down on, partly because we don't

have the time/skills/resources but also because we simply want to enjoy what we have created.

What does it matter?...well why do so many go to such trouble to work it all out? I was able through an acquaintance, able to ask some questions of

the designer of the McLaren F1. He answered one of the questions by using the GRC theory and he took it seriously enough.

My concern is that we are treating the contact patches as static things are they simply are not, nor are they fixed points.

The other aspect to this is that we are discussing a single element of whole a cornering event, with the implication that this is the most significant

element in a vehicles handling and IMO it is not really.

WRT keep it low and central, it is all a balancing act (no pun intended), particularly as to what is possible within our respective skills sets and

finances. A good example is my drive-train: I *can* feasibly lower it 50mm but to do so is a lot of work and would absorb a lot of finances that are

required for say good dampers. So I make the decision based on my set of priorities. I have a total CoG of 432mm which is reasonable and I need the

money to buy dampers so there is no need to change. The dampers will have more of a positive effect than a 12mm OA lower CoG.

[Edited on 6/7/08 by rpmagazine]

[Edited on 6/7/08 by rpmagazine]

kb58 - 6/7/08 at 03:50 PM

quote:

Originally posted by rpmagazineWhat does it matter?...well why do so many go to such trouble to work it all out?

If you spend millions on an F1 team and lose by 0.01 seconds, that's a big deal. For most of us we're happy with getting 80% of the way up

the expense/return curve, before it heads straight up in order to get that last 20% - we just can't afford to go there. However, teaching

ourselves to understand what that last 20% is about is well worth it, though information on force-based roll-centers is not common yet. The articles I

posted are very helpful.

That said, I'm not sure it makes any difference for the majority of us. That is, most of us aren't good enough drivers to even see the lap

time improvement provided by the slightly better suspension. It's like a very small signal improvement in a sea of noise; it's going to be

very difficult to measure.

[Edited on 7/6/08 by kb58]

rpmagazine - 6/7/08 at 10:25 PM

Actually, having spoken to some F1 designers I might suggest that they do not take RC's very seriously given the other priorities such as aero.

Same for CART.

The engineers I know working with Adams etc are all OEM engineers and they have refined their understanding with empirical work too.

The person assisting me (actually he is doing nearly all the work - a choice I made given the information and process is in the public domain) works

with Adams all the time. He noted that his work in Adams seems to constrain the GRC much as we have discussed in the past (he has checked a few times

to satisfy his intellectual curiosity), but it is not an intention but more of a correlation.

v8kid - 7/7/08 at 09:25 AM

Guys,

Whatís with these TLA's? Its just too much effort to follow the argument and decipher the latest three letter acronym. Easy to fall into I

know.

Iím beginning to have some considerable sympathy with Syd he offers an alternative explanation, poses that we should think about it, and gets sniped

at from all quarters.

That would be OK if the counter argument was original but when it runs along the lines of Ė a very important person says so or look at this link to

someone elseís articles - there is not a lot of credibility in that as an original argument now is there?

I freely admit I do not understand the significance of geometric roll centre migration or indeed 50% of Marks articles and since I have a couple of

engineering degrees I am conceited enough to think it isnít stupidity.

The original questions posed were to very well chosen and have made me think. In fact the unasked question made me think more.

I reckon the answers should be Yes positive would be a good idea, No roll plus, Never ever and the unasked question Ė what are the other wheel pair

doing at the same time.

Syd is absolutely correct when we are thinking about one axle, we were the ones who jumped to conclusions. He is also absolutely correct about the

basic physics, what the roll centre myth is doing is trying to give us a way of understanding how the front and rear axles communicate.

Remember the chassis is rigid (hopefully) and the suspension is not (also hopefully). If the roll resistances at each end are different the difference

is transmitted via the chassis. I think Iíll do a Syd here and let you fill in the gaps.

Depending on the arrangement of the wishbones the roll is resisted via the springs ( and very expensive dampers) or the wishbones. That has an affect

on timing only when considered in conjunction with the above.

We also have to bear in mind the original question there is no point in getting the blunt end to communicate the way we want with the sharp end if the

camber is all wrong.

Do you remember the great debate over analogue and digital recording systems? I was suckered and bought a very expensive Lynn Sondeck system. The

engineering was awesome. When after a few years I really listened to CDís I was blown away and sold my analogue system for a much cheaper and better

sounding high street setup. The moral is - the basics source was right in the CD and no amount of gilding the lily on the analogue system could

improve on what was never there in the first place.

Same with the fundamental architecture of the chassis - itís worth the effort to get it right in the first place.

So there it is the thoughts of Chairman V8Kid. Can I ask you a simple question to be answered simply in your own words? ďwhat is the effect of roll

centre migrationĒ (no TLAís)

I donít think anyone knows!

Syd Bridge - 7/7/08 at 10:21 AM

Someone agreeing with me!!!! I better check I'm still alive!

I better check I'm still alive!

Until you lot let go of those cursed 'roll centres', of any flavour, then any hope is lost.

Rollcentres of any type DON'T come into the design process of a road or race car. Anyone telling you that they do, and professing to be a

designer, is pulling your whatever. They may be examined 'after the fact', when the car is up and running, just as an academic exercise, but

they just don't dictate design parameters.

It's all about packaging, but the race car can then be designed for specific behaviour which the road car compromises on, and placement of

critical components can be properly designed in.

Move a spring mount up or down a little, indeed even change spring poundages, and all the GRCs, and even the dynamic, can change appreciably, with

even some very small changes in springs and support placements. It's the big picture, not the fuzzy little one, that counts.

As I put previously, 'does the monkey swing the elephant, or the elephant swing the monkey'?

Cheers,

Syd.

rpmagazine - 7/7/08 at 11:18 AM

V8 and syd, the problem we (us doubters have) is that we have exhaustive literature, tools and well respected professionals constantly working in the

field all noting that the way we have chosen is a reasonable way forward.

On the other hand we have Syd, an essentially anonymous forum member telling us they are all wrong and only he has the truth and that so far it comes

down to 'the car rolls about the outer contact patch and then it gets a lot more complicated'

Apart from the mistrust of an obviously messianic allusion I have not yet seen any theory from syd.

So perhaps this is the time: Run us through the whole 'more complicated' bit of the cornering event and also inform us as to your specific

background so that we can judge the extent of your experience. At the moment all I can see is the links you have to what looks like a ladder chassied

911 replica powered by a cast iron Ford Essex V6.

pbura - 7/7/08 at 11:46 AM

As I understand it, in a symmetrical suspension (one in which the geometric roll center is constrained), the force-based roll center and the geometric

one will be very close. So, it's a decent tool for the home builder to use to estimate spring requirements, etc., in the absence of data

acquisition sensors and racks full of tires, springs, shocks, and antiroll bars.

For the designer, there's no sacrifice involved in centering the GRC. You don't give up camber or Cg. So, I don't understand what all

the fuss is about. Nor Syd's vehemence.

v8kid - 7/7/08 at 03:30 PM

Blimey we are getting a bit heated arenít we? You know its not heresy to question or argue beliefs held by the majority nor do we live in a society

that treats those who differ as outcasts. Do we?

I donít think all well respected engineers do think the same way and there are well respected engineers who question the value of roll centres. Dare I

mention Mitchell? Dixon? Engineers not journalists so their arguments are not as forcefully presented.

So what if we do get the GRC, (now look what youíve done Iíve slipped into TLAís myself) so it does not move. What difference does it make?

How does it affect the cars handling? Specifically what effect does roll centre migration have?

Third time Iíve asked with no answer and thatís because no-one knows. Ė So what difference does it make achieving something if you donít know what you

are achieving?

Jolly good original question by garage19 what? It certainly got me thinking that the only important thing is maximising the tyre grip and balancing

the grip between the ends of the car at all times.

That means the camber has to be appropriate and the roll stiffness has to change the way we want it to with wishbone movement.

Now we are expected to believe that roll centres are more than just a measure of the roll stiffness and restraining the movement of the roll centre is

some holy grail to be achieved without regard to camber.

Admittedly the roll center is a very rough approximation and the relative heights of the instantaneous roll centres front to rear do indicate which

way the roll balance is likely to go but we can calculate that from charting the roll stiffness.

For all Syd is berated for not giving detailed explanations I donít see his detractors making any contributions Ė apart from saying it must be so Ďcos

a clever man says so..

So hereís your big chance answer the question.

P.S. Since you ask I have a HND in EEE ( Electrical and Electronic Engineering) , a degree in Mechanical Engineering, and work as a Design Engineer

but I donít think that matters as long as you can structure a good argument. If I recall correctly Cymtricks is no slouch either if I seem to remember

reading a very informative dissertation on chassis design correctly backed up with experimental results.

Syd Bridge - 8/7/08 at 09:09 AM

Mock as you may, Mr. Magazine, but one of those 'ladder chassised 911's' (which are actually space frames if you got close enough to

look) designed and built by an aussie mate of mine, nigh on 20 years ago, would and did kick ten bells out of genuine 911 turbo's of the day

around a circuit, and powered by a measly 200 hp Cosworth(with a cast iron block!), against 300hp+ of the 911. Those cars will still do it today, and

do at track days.

The essence of the superiority is in the suspension. Double wishbones all round and coilovers. And the 'ladder framed grp 911' also was

about 200 kg's lighter.

Then I was fortunate enough to be invited to work alongside some very well known designers, who laughed when I brought up the subject of 'roll

centres'. To a man, they all asked, 'have you been reading Staniforth or something similar?'

It was a couple of sentences by Gordon Murray, whilst writing about the McLaren F1, that made me ask pertinent questions, and as I worked more within

the confined space that these designers operate in, I gathered the answers and the mindset that these fellas operate with.

Today, this small band still keep things close to themselves, and I don't have anywhere near the knowledge they have on the subject.

But, like them, I'm willing to learn and more importantly, to think for myself, and question things that just don't make any sense to me

whatsoever. Like 'roll centres', no sense whatsoever.

Think for yourself, I've given you enough clues to come to your own conclusions.

Cheers,

Syd.

I've heard it said, that sarcasm is the poor friend of anger, or the lowest form of wit. Both fairly sad, in reality.

[Edited on 8/7/08 by Syd Bridge]

rpmagazine - 8/7/08 at 09:33 AM

LOL!

Whilst I think both posts above are quite insightful as I am neither heated or mocking.

I have simply asked for more detail on Syd's theories and asked for some background so I can judge what weight to give to his original theories,

particularly given his habit of openly mocking others as 'armchair experts'. I think it is a perfectly reasonable question to ask, obviously

you do not V8kid and Syd seems slightly outraged!

V8kid you have also mistaken another aspect of my post, I was not asking for formal qualifications as frankly I rate long experience just as highly,

hence the phrasing of my question. Should you wish to make up a defining question I will pass it on and get an answer for you.

As for original thought, I think that most on this forum and I include myself, have enough trouble working accurately with accepted theories that are

known to have a desirable effect.

[Edited on 8/7/08 by rpmagazine]

[Edited on 8/7/08 by rpmagazine]

v8kid - 8/7/08 at 11:39 AM

Eh!

I think thats my case QED then!

Pity it was looking to be a jolly good discussion and I certainly clarified my own thinking although it I didn't think my point would be so

easily accepted.

Cheers all

David

rpmagazine - 8/7/08 at 12:49 PM

you had a point?

I missed it in all the noise, what was it?

mr henderson - 8/7/08 at 12:52 PM

quote:

Originally posted by rpmagazine

you had a point?

I missed it in all the noise, what was it?

I missed it too.

garage19 - 8/7/08 at 03:58 PM

Sooo..... back to the original question...

In the car/application I have previously described would I be way off the mark if i had camber gain that happened to be pretty equal to body roll?

Alan B - 8/7/08 at 04:54 PM

quote:

Originally posted by garage19

Sooo..... back to the original question...

In the car/application I have previously described would I be way off the mark if i had camber gain that happened to be pretty equal to body roll?

That's what I'd be aiming for......

Ringius - 8/7/08 at 09:51 PM

From an arm-chair amateur...

If you compensate fully for body roll, you are likely to sacrifice braking, at least if the car will dive under braking (which it will, more or

less).

The Mazda Miata uses 0.5 degs camber change per 1 deg roll, as does a number of other sportier production cars. These does probably have more

suspension travel than you will have though.

MikeCapon - 10/7/08 at 08:15 AM

This is a really good thread! Fascinating to watch as an interested observer from the comfort of my armchair. Now that the bullets seem to have

stopped flying for a moment can I stick my head out of the trench and ask a simple question.

The basis, or reason for all this debate seems to me to be the supposed difficulty in deciding which factors determine the dynamic behaviour of the

chassis in relation to the road surface and hence how best to design a chassis/suspension system to enable the tyres to best do their job. The

different schools of thought seem to be clutching onto their own theories and simply decrying the others because "You can't prove

it".

Why can't you prove it? Having worked with different datalogging systems and in particular with one very good DA engineer it seems to me that

with just a gyro, 4 suspension pots and IR ride height sensors together with the usual throttle position, brake pressure wheel speeds and steering

angle the behaviour of the chassis could be measured. From here the different theories could be proven or otherwise. The effects of spring changes,

altered pick up points etc could also be compared.

If, as seems likely, no existing theory "fits" the result at least the answer is there and all that remains is to find the equation that

gives that result?

(Pulls head quickly back into trench and prepares coat)

rpmagazine - 10/7/08 at 08:52 AM

I gleaned this from the WWW...so you must take its absolute accuracy with a pinch of salt.

"1st generation MX5 (Miata) The front roll centre was 61mm, the rear 120mm. Camber gain was 0.91 degrees per inch at the front and 0.58 at the

rear.

The new Caterham CSR has RCs at 30mm/65mm front/rear

The Elise roll centres are 30mm/75mm front/rear. The camber gain is 0.31/0.45 degrees per inch front/rear. The effecive swing axle length is about

180inches/110inches front/rear"

Mike of course you can do all of that and more. All of the OEM's do such things...but generally few people who are going to build their own car

have the desire/skill/time/ability to analyse the results. There are simply *so* many variables e.g. slip angles of tyres, which can effectively be

ignored up to .4G but then becomes an issue etc etc. If you have data recording as per the latest Motec dash etc then you can do it...damper rates

etc require higher rates...so it all becomes quite expensive too. It is probably cheaper hiring a professional driver for a couple of days to refine

what you already have?

[Edited on 10/7/08 by rpmagazine]

Syd Bridge - 10/7/08 at 09:25 AM

Roll centres,utter BS, you just can't let them go.

Roll centres,utter BS, you just can't let them go.

I'm not outraged, more like dismayed and disappointed, that an alternative view is put down without good reason. It was taught that the earth was

flat for years, you couldn't go faster than the speed of sound,and the smallest particles were electrons and neutrons,....

I work with DAQ every week, it's the prime development tool, that's how I know.

Cheers,

Syd.

rpmagazine - 10/7/08 at 09:42 AM

Geez syd just let it go and allow us to use the forum to share ideas.

If you have a theory start another thread, in fact I'll go and do it now and you can answer my previous question without derailing this thread.

ravingfool - 10/7/08 at 11:58 AM

Very interesting thread that I will have to read again I think to fully understand all the different ideas as I have absolutely no knowledge of

suspension geometry as such, only a basic grounding in mechanics and I'm not awake enough to deal with it!

But Syd, I would just like to point out that in known history the Earth was never thought to be flat, that is pure myth I'm afraid and as one

opposed to the proliferation of incorrect information being stated as fact, I thought you'd want to know

MikeCapon - 10/7/08 at 04:43 PM

"It's how I think. You look at everything you've done before. You look at other people's work. You feel you can improve and

don't give any secrets away. We do still look at roll centre and geometry, but if I gave you positions or camber change details my opposition

would think I was mental - or they wouldn't believe them."

Tony Southgate

"You cannot reduce the unwanted in a design to zero - you can only hope to minimise what is not good. You can draw the position of the Roll

Centre in static geometry but the dynamic position is a different matter. The point about which a car rolls can be totally modified by altering the

springs, or the weight transfer and the consequent loading on the tyres."

Trevor Harris

I think these two, very credible designers are worth listening to.

Also posted in the other thread.

Dom9 - 16/7/08 at 02:51 PM

Sorry guys, late to this thread as work has picked up recently and i haven't any spare time to work on my own project!

I am, however, reading it with interest! I have always been interested in suspension design and whilst studying at Imperial College for my

undergraduate degree I spent a lot of time doing my own background reading on suspension design, RCs, camber etc etc As I knew it would one day come

in useful.

Truth be told, I have forgotten as lot of it and was hoping to refresh my memory in the coming months before undertaking my chassis design.

I am interested in what Syd is referring to and I agree with a lot of it and have never understood how suspension could be designed around static roll

centres when the sidewalls of tyres deflect and there is a certain amount of slip etc etc. Or perhaps I should say that i could never understand how a

lot of people took roll centres to be the be all and end all when there are so many other dynamic events happening during cornering!

Anyway, my point is, and I am very sorry that I have lost the back issue (if anyone has one; please, please scan my letter), that I wrote a letter to

Race Car Engineering many, many years ago (I want to guess at about July 2001) about the Dax camber compensation suspension.

The month before they had run an article about the Dax system and had not discussed the effect on roll centres in much detail, other than to show it

moves about. Now, it appeared obvious to me that if this system worked (i.e. aided cornering forces), and it was being tested by F1 teams apparently,

then roll centre muct have nothing to do with anything - Which Syd seems to be suggesting!

My letter was not intended to rubbish the camber compensation system but I asked teh question; "we have been told that RC is important for

suspension design, but teh RC is always moving in this system... So what do we think now?" or something like that! (I have no copies and it was 7

years ago).

I never got an answer from the editorial team of the mag, anyone writing in or the designer....

So, it's very interesting here everyone's views on this!

rpmagazine - 17/7/08 at 10:15 AM

I might suggest that you read it again and see who defined GRC's in such a manner. Most of us do not think of them as anything but a tool.

Dom9 - 18/7/08 at 12:34 PM

Sorry rpmagazine - That wasn't intended as a comment towards you or anyone else on this thread... Perhaps a re-read of my post is in order?

It was more an observation about the fact that every book I read (at least 7) about 10 years ago went on and on about roll centres but there appears

to be no updated text 10 years later, unless someone can point me towards one, reflecting this 'new' thinking...

When I was at Lotus I managed to get a copy of their suspension design and ride and handling manual, that was quite interesting I seem to remember...

I must dig it out and see what that says but I think it pretty much followed the other texts I read!

So, feel free to suggest away, where you think it is necessary! I don't think I mentioned anything about the posters on this thread worrying

about roll centres... Did I?

rpmagazine - 19/7/08 at 06:27 AM

Dom9 our issue with GRC's is that they are an accepted if flawed tool. We know that the theory has holes in it e.g. the compliance issue of tyre

flex etc that you mention.

There are other theories 'out there' perhaps much the same as Syd has so briefly alluded to. The 'problem' perhaps is that the GRC

theory gives us the starting point with an somewhat predictable outcome, so syd's shouting it down without providing an alternative is in reality

not helpful.

Milliken is a good read, if somewhat too analytical/mathematical. There is another book that is due for release and I will have a copy soon as part of

the pre-press release. I will post some details when I am allowed to.

[Edited on 19/7/08 by rpmagazine]

Dom9 - 23/7/08 at 03:26 PM

Cheers rpmagazine, I look forward to hearing about it!

rpmagazine - 9/4/09 at 12:02 PM

http://hem.passagen.se/hemipanter/

kb58 - 9/4/09 at 03:44 PM

quote:

Originally posted by rpmagazine

Dom9 our issue with GRC's is that they are an accepted if flawed tool. We know that the theory has holes in it e.g. the compliance issue of tyre

flex etc that you mention. [Edited on 19/7/08 by rpmagazine]

My epiphany with RCs came when I realized the GRC method completely neglects wheel load, always giving both tires equal "voting power"

regardless what the tires are doing.

Consider the case of going round a turn, where 70% vehicle weight is on one tire and 30% on the other; it seems wrong that the 30% tire still has 50%

say in where the RC is. Or, how about taking the same corner at maximum speed where it's common to have essentially zero load on the inside tire.

It can't be right that this useless tires is still dictating RC location.

That's when I started reading up on articles by Ortiz and Mitchell and now look at things very different.

[Edited on 4/10/09 by kb58]

Doug68 - 10/4/09 at 01:24 PM

Not being a stirrer but...

Go on say it: "SydBridge was right after all"

ROFL

Just pulling your chain

From my point of view the more I learn, the more I realise what an amateur I really am.

[Edited on 11/4/09 by Doug68]

cheapracer - 11/4/09 at 02:39 PM

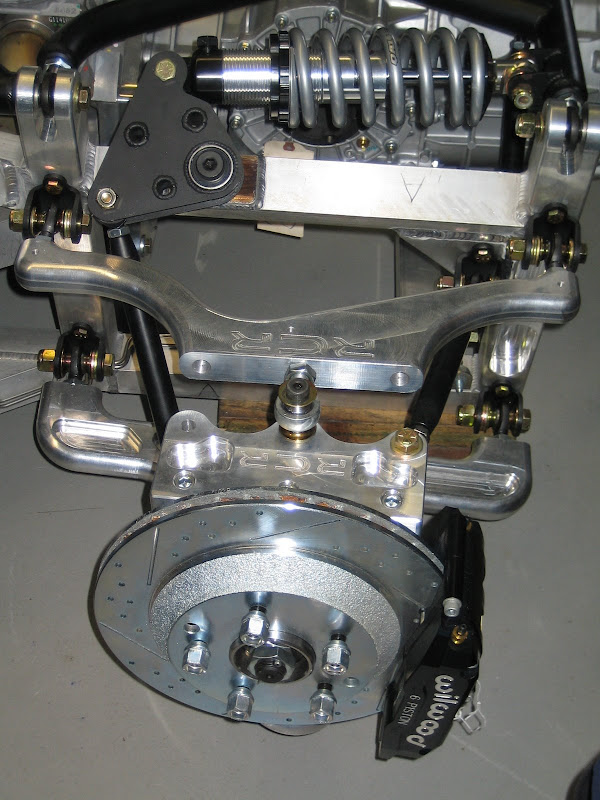

Probably the place to bring this up, this is the RCR SLR Exo car and I have been very supportive of it until I saw the first pictures of it in action

- just have a look at the lovely positive camber on the outside tyres, not to mention the painfully short upper top rear arms causing the inside

negative camber - my point is that beauty doesn't mean function. In this case the top front arms are way too long to give proper camber control,

F1 cars have long top arms and pushrod suspension etc. for aero reasons and mechanical grip is way secondry to that so copying F1 designs for road use

is just silly.

[Edited on 11/4/09 by cheapracer]

Rescued attachment SLR4 positive camber.jpg

cheapracer - 11/4/09 at 03:01 PM

..and when I ran the aprox pivot point figures through a simple RC calculator I find that gains positive camber at a rate of around 75% - can't

quite understand why this wasn't figured.

Rescued attachment SLR3 roll 2 degree.jpg

kb58 - 11/4/09 at 04:05 PM

Maybe they felt that straightline traction was more important.

quote:

Originally posted by cheapracer... beauty doesn't mean function....

And something some builders never figure out. Big anti-roll bars would help hide the problem.

Is the car you're selling a market competitor with this one?

[Edited on 4/11/09 by kb58]

Doug68 - 12/4/09 at 05:13 AM

cheapracer, probably a better place to bring this up would be the

forum the picture came from.

RCR has a pretty good rep for building quality vehicles so I'd be surprised if there was not some method to the design. The other thing is that,

as you probably know this was the first day the car was at the track so there's a lot of sorting to do with it generally I am sure.

TheGecko - 13/4/09 at 03:29 AM

I'm not convinced that RCR aren't guilty of choosing style over substance. Here's two shots of the rear suspension of one of their

Coupe's, taken at an open day at their Australian distributor.

To me at least, the flashy, too short, billet top arm would be lighter and simpler as a steel tube construction (although it'd still be too

short). And, feeding the spring loads into the end of that tube where it acts in direct shear on the shank of what looks like a 1/2" rod-end?

Odd - very odd.

Dominic

cheapracer - 13/4/09 at 12:13 PM

Kurt, yep, 0-100-0 may have been on their minds! Roll bars will help but only mask what is basically a wrong design - it gains positive camber from 0

degrees roll on. I guess some thick ones with some static camber to start you off, not going to help you much in the wet though with no compliance and

a dancing inner rear.

FWIW - Don't see them as my competition, In fact I have actively forum supported the SLR, as I do the whole industry, as more sales of this type

of car will only help me - I think this is more a direct Atom competitor and I don't see much change from 40K US on the road for one of these and

the ilk (carbon fibre battery boxes etc.) of those who will undertake one.

I see my direct competitor as MEV actually but hope that general interest in all the mid engined trend thingies including your beast will benefit all

of us with greater spurred interest from John Smith.

Doug, I don't post in that forum, this is but 1 of 4 forums I go to and this is a modern example on offer for this suspension related topic. I

hope something of it helps one of the builders here and to me this is what forums like this are about. I didn't get the pic from that forum, I

got it from another forum - only this picture showing the cars dynamics amongsy many others was removed after another person mentioned about it - as

odd as the ultra short Aarms and the loads put onto the heim joints pictured above as mentioned by Gecko. I already knew about and mentioned those

elsewhere a while back in another forum. With all that torque and the rubber that thing wears I wouldn't want to be booting it up in a bumpy

corner.

Doug you are welcome to bag the crap out of mine soon :-)

Doug68 - 13/4/09 at 12:25 PM

cheaperacer, I don't want to bag the crap out of anyone's work.

Generally unless I think someone's going to hurt themselves or someone else if I can't find anything nice to say then I try to STFU.

cheapracer - 13/4/09 at 04:18 PM

... can't find anything nice to say then I try to STFU.

Thats very good advice for you but umm, you just said that in a very nasty way, lol!

cheapracer - 21/4/09 at 12:27 PM

quote:

Originally posted by cheapracer

FWIW - Don't see them as my competition, In fact I have actively forum supported the SLR, as I do the whole industry,

Well after Fran himself wrote this today I won't be supporting the overpriced and IMO with supporting evidence, suspicious handling SLR anymore.

someone should tell him you can own a Rocket, a Sonic and an Atomic for 1 of his SLR's - oh hang on, I did!

MEV build some cool cars but you must compare apples to apples... I admire what MEV builds for the price and I am not picking on them to be

detrimental or start a flame war.....just using their cars as an example....

kb58 - 21/4/09 at 01:48 PM

quote:

Originally posted by Doug68

Generally unless I think someone's going to hurt themselves ...then I try to STFU.

I've found saying something is often pointless even if well-intended. It often causes said dangerous person to get defensive, coming back with an

"oh yeah, I'll show you," reply, and crash their car anyway...

[Edited on 4/21/09 by kb58]

cheapracer - 21/4/09 at 05:18 PM

quote:

Originally posted by kb58

quote:

I've found saying something is often pointless even if well-intended. It often causes said dangerous person to get defensive, coming back with an

"oh yeah, I'll show you," reply, and crash their car anyway...

[Edited on 4/21/09 by kb58]

Ain't that the truth.

Ain't that the truth.

Kurt I'm confused by your signature, is the mid engine book out or not? Or does that refer to Kimini?

kb58 - 21/4/09 at 06:28 PM

That's the Kimini book. The new one is in the works along with the car.

cheapracer - 22/4/09 at 05:29 AM

quote:

Originally posted by kb58

That's the Kimini book. The new one is in the works along with the car.

Thanks Mate and good luck with it.

Sam_68 - 9/1/10 at 05:21 PM

quote:

Originally posted by Syd Bridge

Rollcentres of any type DON'T come into the design process of a road or race car. Anyone telling you that they do, and professing to be a

designer, is pulling your whatever.

Whilst I have some sympathy for Syd's position (in as much as the geometric roll axis is a myth), I can state absolutely and

categorically that the above statement is incorrect, false, untrue, erroneous, complete-and-utter-tosh, and bollocks.

Whilst (as Syd asserts) cars certainly do not roll about their geometric roll centres, the front and rear roll centres are an important factor in

dictating diagonal weight transfer via the sprung mass when cornering, which in turn has a major influence on understeer/oversteer balance.

The roll centre heights therefore have a major part to play in the basic handling balance of the car, and roll centre movement when

cornering can cause all sorts of nasty issues, since it will result in variations in diagonal weight transfer as the car negotiates the corner.

I know for a fact (having had detailed personal discussions with them), that a number of very emininent race car designers (including a couple

of ex-F1 Chief Designers and several designers of championship winning hillclimb single-seaters) pretty much start off their design from

geometric roll centre positions, whenever they're designing a car with significant suspension compliance (ie. everything apart from

wings-and-slicks circuit single-seaters), with the geometry focusing on minimising roll centre movement throughout the working range, and everything

else - spring rates, tyre widths, ARB rates etc. - developed from there.

In terms of the OP's original question, if you were thinking purely about cornering, you'd actually want the camber agin to be

arranged so that the outside (loaded) wheel progressively went into negative camber as it loads up in the corner, as most tyres generate most

girp with a surprising amount of negative camber, and you pretty much wouldn't care about what the inner wheel was doing, as it progressively

takes less and less of the load as cornering forces increase.

In reality, however, this approach would leave you with unacceptable camber change under pitch (dive and squat) or single-wheel bump, leading to a car

that was squirrelly under braking and had uncertain grip under hard acceleration.

Unless you have active suspension, all supension geometry is a compromise and unfortunately it's up to the individual suspension designer to

choose his own balance of priorities: there's no wrong and right, which is why the discussions frequently get so heated between people who think

that there is...

(Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.

(Well, at least not without a large amount of money involved. This IS my work you

know.) AS you've also been told on the previous occasion.