A shiny new bonnet!

SPYDER - 23/3/16 at 08:44 PM

The last couple of years has seen a long overdue refurb and update to my Spyder Silverstone.

Firstly, all the glassfibre bits were repainted, including the original bootbox and lid which had been stored for ten years waiting for me to get

round to fitting them.

Then a new, bigger bore exhaust with a proper merge collector, Wideband Lambda and R1 can.

Oh, and a six-speed gearbox conversion which involved making a "reverse remote" to move the lever forward five inches and an Arduino driven

stepper motor to drive the existing cable speedo from the electronic speed sensor.

Follow that up with a throttle body conversion and new Protech shocks.

Phew!

The culmination of this marathon has been the making of a shiny new ally bonnet!

I firstly made the stiffening ribs by hammering them into shape around plywood formers.

Then the holes were put in and swaged using a home made tool. So far, so good.

The main panel was bent around a tapered buck made from a section of very thick plastic pipe.

The louvres were then (very neatly) done by Shapecraft in Hinckley. He only wanted £20! Too cheap! I gave him 30.

A holesaw, a few rivets and some Tigerseal later and it was ready for paint. Lots of etch primer. Lots of flatting down.

Lots more etch primer etc. Then two coats of solid colour two pack, final flat off then two final coats.

I'm pleased with the result, particularly as I am not a sheet metal worker.

Thanks again to Shapecraft and Sean Rowe Bodyworks. And Chris G.

SJ - 23/3/16 at 09:02 PM

Looks great! Using the Arduino sounds interesting.

SPYDER - 23/3/16 at 09:13 PM

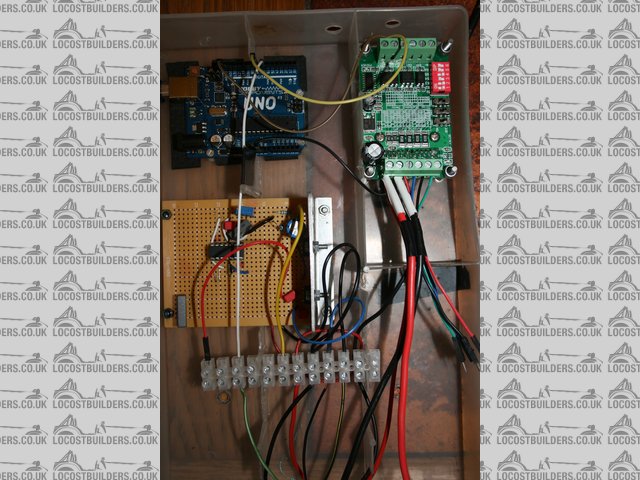

I was determined to keep the existing speedo. Stepper motors dont usually like to do the high revs necessary to drive the speedo directly so I used a

small planetary step up gearbox normally used on RC aircraft to step down the prop speed. I used it in reverse, so to speak. I made the adaptors for

both ends of it on Chris G's lathe. The Arduino takes the pulses from the gearbox and converts them into tones which then pass to a stepper motor

driver board.

I wrote the Arduino code based on a mix of "frequency measuring" and " musical tone" sketches found on the net.

rf900rush - 23/3/16 at 09:47 PM

Is the weight of all that going to slow you down enough not to need the gearbox

On a more serious note are there no some smaller stepper motors that will run fast enough.

My DIY CNC mill motors run fairly fast even on cheap stepper drivers.

Although I do remember having a ETB Speedo that I could beat in my Dax Rush

02GF74 - 28/3/16 at 05:30 PM

Interesting that you got stepper motor going, not really suited to that sort of application

I looked into this but using dc motor and pic but during develipment/callibration i broke the speedo.

The Black Flash - 11/4/16 at 08:49 PM

Damn nice metal work, loving those strengthening ribs