Injection system plumbing sanity check

ianm67 - 20/7/15 at 03:22 PM

Hello chaps,

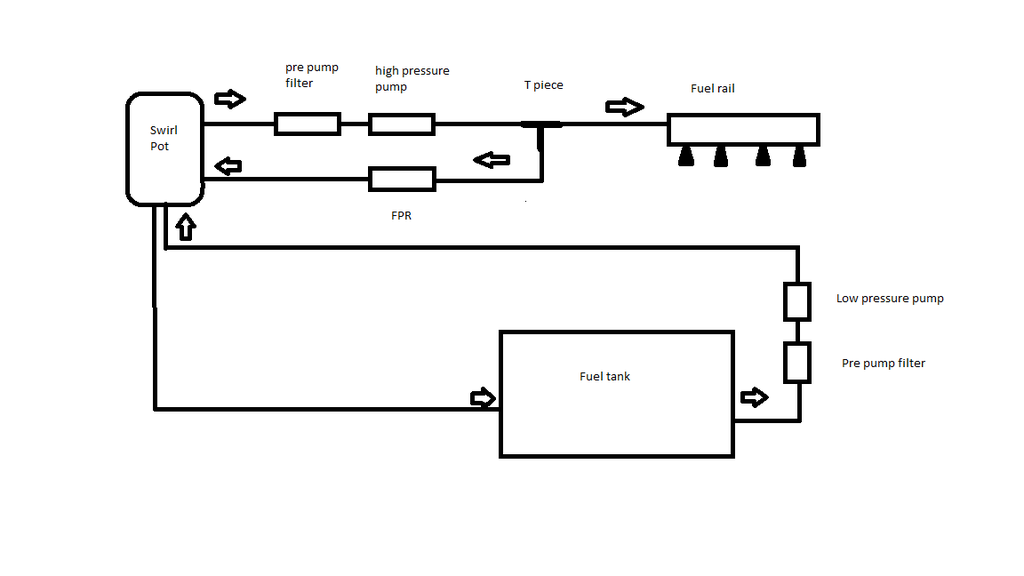

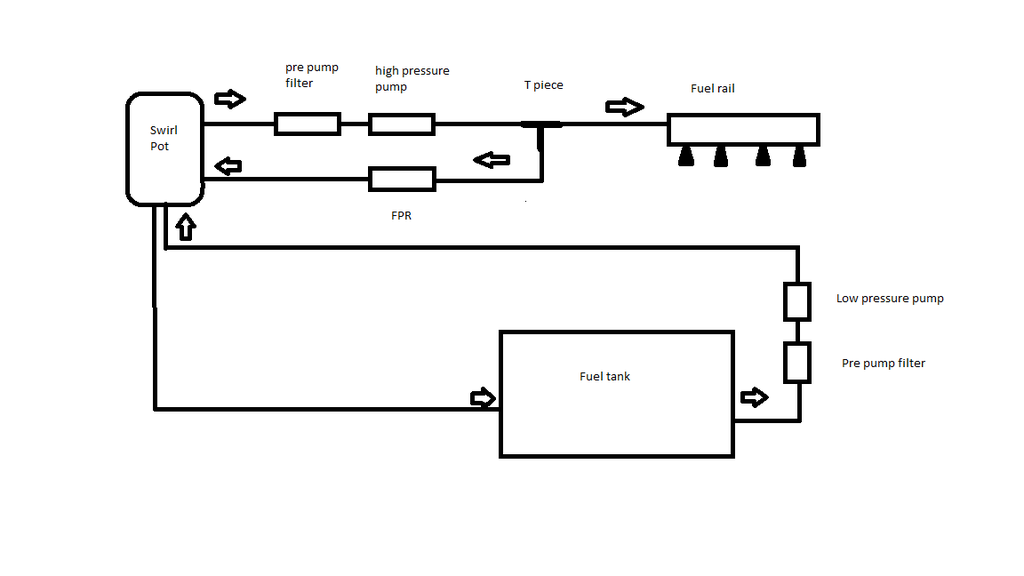

I am going to run a 'dead end' injection set up in my car based around a set of GSXR1000 throttle bodies. The diagram below is how I think

it should all fit together and would appreciate it being sanity checked by the Locost massive.....

My next question is based around the FPR...... I want to use one with a fixed rate, the question is should it be 3 bar or 3.5 bar....?

mark chandler - 20/7/15 at 05:37 PM

If you are using a bespoke ECU it will not matter, what are the injectors specified for?

If they can just meet the engines flow requirements at 3bar stick in a 3.5bar unit.

40inches - 20/7/15 at 06:12 PM

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

ianm67 - 20/7/15 at 07:53 PM

quote:

Originally posted by mark chandler

If you are using a bespoke ECU it will not matter, what are the injectors specified for?

If they can just meet the engines flow requirements at 3bar stick in a 3.5bar unit.

Hello Mark,

I am going to be running a Microsquirt. The injector specs are:

Flow Rate (45psi/100%): 230cc/min

I think that 45psi equates to about 3.1 bar so I guess I'll need a 3.5bar FPR?

daviep - 20/7/15 at 08:14 PM

quote:

Originally posted by 40inches

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

I'm confused, he has fitted the FPR at the "T" !

How is yours different?

Cheers

Davie

40inches - 20/7/15 at 08:35 PM

quote:

Originally posted by daviep

quote:

Originally posted by 40inches

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

I'm confused, he has fitted the FPR at the "T" !

How is yours different?

Cheers

Davie

Unless I am seeing it wrong, he has a "T" piece, then the FPR In the return line from the "T" to the swirl pot. I have simply

used the FPR as the "T" piece, that eliminates a couple of connections. I think

Dusty - 20/7/15 at 08:37 PM

I would delete the pre injection pump filter. Fuel in the swirlpot has already been through the pre LP pump filter and HP pumps generally can't

suck for toffee.

Add an injection micro filter after the injection pump. Fuel through the injectors must be super-clean.

daviep - 20/7/15 at 08:42 PM

quote:

Originally posted by 40inches

quote:

Originally posted by daviep

quote:

Originally posted by 40inches

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

I'm confused, he has fitted the FPR at the "T" !

How is yours different?

Cheers

Davie

Unless I am seeing it wrong, he has a "T" piece, then the FPR In the return line from the "T" to the swirl pot. I have simply

used the FPR as the "T" piece, that eliminates a couple of connections. I think

OK but functionally it's the same then.

40inches - 20/7/15 at 08:45 PM

quote:

Originally posted by daviep

quote:

Originally posted by 40inches

quote:

Originally posted by daviep

quote:

Originally posted by 40inches

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

I'm confused, he has fitted the FPR at the "T" !

How is yours different?

Cheers

Davie

Unless I am seeing it wrong, he has a "T" piece, then the FPR In the return line from the "T" to the swirl pot. I have simply

used the FPR as the "T" piece, that eliminates a couple of connections. I think

OK but functionally it's the same then.

Yep! Just neater and less leakage points, in my opinion of course

ianm67 - 20/7/15 at 09:21 PM

quote:

Originally posted by 40inches

I've done almost the same, except I have fitted the FPR at the "T" piece point on your drawing.

Interesting, you must have a FPR with two outlets then? Which one are you using as it would be a little neater....

Toltec - 20/7/15 at 11:21 PM

quote:

Originally posted by ianm67

quote:

Originally posted by mark chandler

If you are using a bespoke ECU it will not matter, what are the injectors specified for?

If they can just meet the engines flow requirements at 3bar stick in a 3.5bar unit.

Hello Mark,

I am going to be running a Microsquirt. The injector specs are:

Flow Rate (45psi/100%): 230cc/min

I think that 45psi equates to about 3.1 bar so I guess I'll need a 3.5bar FPR?

How much power are you expecting the engine to deliver?

jeffw - 21/7/15 at 05:03 AM

http://atspeedracing.co.uk/products/index.php?main_page=product_info&cPath=8_9&products_id=364&zenid=a44ba7119f7e1ff830c358e9dc19ba87

/>

[Edited on 21/7/15 by jeffw]

ianm67 - 21/7/15 at 05:14 AM

quote:

Originally posted by Toltec

quote:

Originally posted by ianm67

quote:

Originally posted by mark chandler

If you are using a bespoke ECU it will not matter, what are the injectors specified for?

If they can just meet the engines flow requirements at 3bar stick in a 3.5bar unit.

Hello Mark,

I am going to be running a Microsquirt. The injector specs are:

Flow Rate (45psi/100%): 230cc/min

I think that 45psi equates to about 3.1 bar so I guess I'll need a 3.5bar FPR?

How much power are you expecting the engine to deliver?

I'm more interested in torque than headline BHP to be honest, the engine is a standard 2.0 Blacktop with a gas flowed head. 170ish BHP would be

nice.....

[Edited on 21/7/15 by ianm67]

[Edited on 21/7/15 by ianm67]

ianm67 - 21/7/15 at 05:18 AM

quote:

Originally posted by jeffw

http://atspeedracing.co.uk/products/index.php?main_page=product_info&cPath=8_9&products_id=364&zenid=a44ba7119f7e1ff830c358e9dc19ba87

/>

[Edited on 21/7/15 by jeffw]

Thanks Jeff,

That's the one that I have been looking at. Not cheap are they? Works out at almost £100 once delivery and VAT has been added........

IanM

jeffw - 21/7/15 at 07:34 AM

Well....you can buy a Chinese knock-off and risk your engine or....do it once, do it right. Pays your money and takes your chances.

ianm67 - 21/7/15 at 08:14 AM

quote:

Originally posted by jeffw

Well....you can buy a Chinese knock-off and risk your engine or....do it once, do it right. Pays your money and takes your chances.

Wise words.......

adithorp - 21/7/15 at 08:20 AM

You def' need a HP micro filter after the HP pump. I'd leave the HP pre-filter in until its been running a while to catch anything in the

swirl tank from construction, then remove later.

Ask Jeff how he knows about cheap knock offs...

[Edited on 21/7/15 by adithorp]

Toltec - 21/7/15 at 08:38 AM

quote:

Originally posted by ianm67

I'm more interested in torque than headline BHP to be honest, the engine is a standard 2.0 Blacktop with a gas flowed head. 170ish BHP would be

nice.

I think you will be pretty close to the limit of 230cc injectors at that power, going for the 3.5bar fpr to get a bit more flow would probably be

better.

ianm67 - 23/7/15 at 04:04 PM

quote:

Originally posted by Toltec

quote:

Originally posted by ianm67

I'm more interested in torque than headline BHP to be honest, the engine is a standard 2.0 Blacktop with a gas flowed head. 170ish BHP would be

nice.

I think you will be pretty close to the limit of 230cc injectors at that power, going for the 3.5bar fpr to get a bit more flow would probably be

better.

A set of these should sort out any duty cycle / flow constraints:

eBay Item

ianm67 - 29/7/15 at 10:55 AM

Finally found myself a fixed rate FPR at a reasonable price. £65 inc VAT and delivery..... Nice bit of engineering too.....

CorseChris - 3/8/15 at 11:58 AM

Re the injectors and flow, we have some GSXR 600 ITBs on the silvertop Zetec, stock motor, 3 BAR fuel pressure, 220cc/min @ 3 BAR injectors. Engine

makes just a gnats short of 170bhp, duty cycle isn't outrageous. I'd expect a blacktop to make a bit more, so your 10% bigger injectors and

3.5 BAR should be pretty much bang on.

[Edited on 3/8/15 by CorseChris]