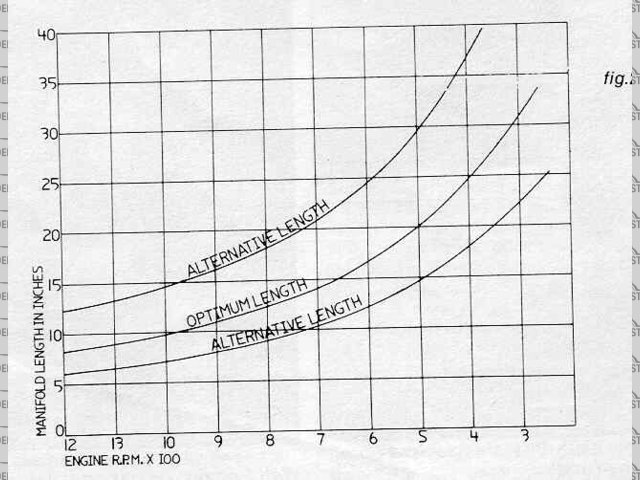

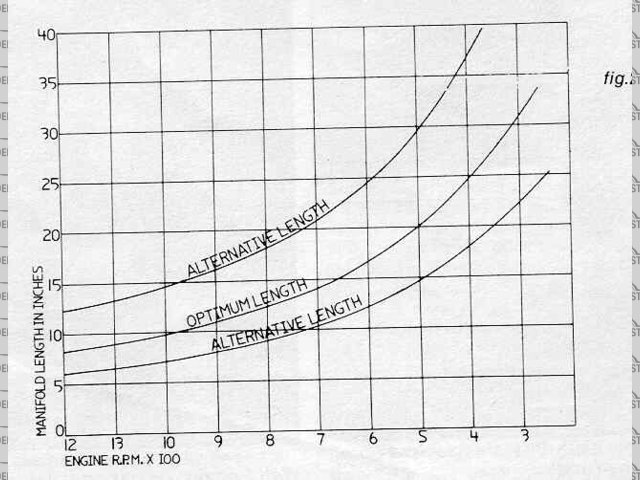

Have you seen the following charts?

I'm building an engine using bike throttle bodies. I want to tune the length of the inlet to create pressure pulses. I have done the

calculations on the overall ideal length, but I am struggling to measure the first section inside the head as it curves. Do I use the length of the

'long' side of the port or do I use the length of the 'short' side of the port. Or do I average the two together? The

difference is about 20mm.

Any advice welcome.

[Edited on 6/6/17 by carboy0]

I wouldn't get hung up over a few mms. Variations in charge temperature and density will likely make a minor mockery of your calcs anyway.

Have you seen the following charts?

The science is deep, I have a set of measurements given to me by a member of Turbosports forum which needed a lot of cam information.

The results he gave me were specific to my engine and gave exhaust and inlet lengths.

If you look at the inlet flow around the valve on a Pinto most of it goes the straighter path over the valve head on the long side of the port so I

would calculate the length using the middle of the port an average of the 2 distances.

Tuning at this level is never about just 1 element so I assume you have fitted bigger valves to a ported head and used waisted stem valves?

Already been done on a flowbench at Emerald. http://www.emeraldm3d.com/articles/emr-adj-length-intake/

Thanks guys, that's really useful stuff and having just read the Dave Walker article, he says just a 4mm difference in length can make a

difference to the torque.

I'm going to use the average of the inside and outside port lengths and make up some different straight inlets in 5mm increments around the

theoretical 3rd order pulse length, and get on a rolling road.

I'll post the results once I have got it all together.

quote:

Originally posted by Myke 2463

Already been done on a flowbench at Emerald. http://www.emeraldm3d.com/articles/emr-adj-length-intake/

Inlet to valve measurement if from intake bell to valve head so you can just extend/reduce trumpet length to get near optimum

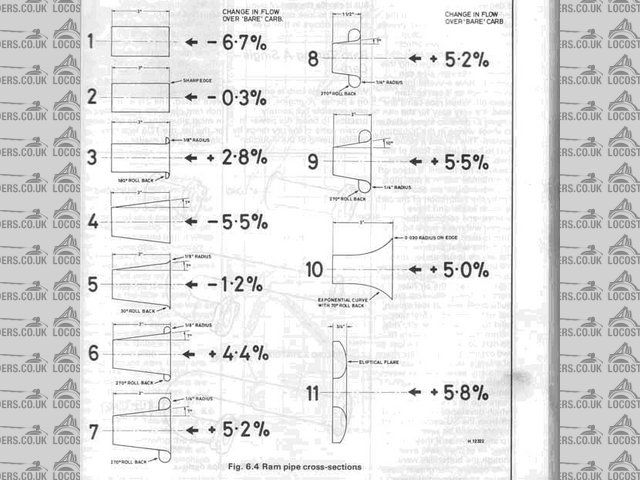

Don't forget rolled ends

I would use the average length in the intake port, but basically fit the longest runner physically possible.

The 5mm variation can be used to smooth the curve out.

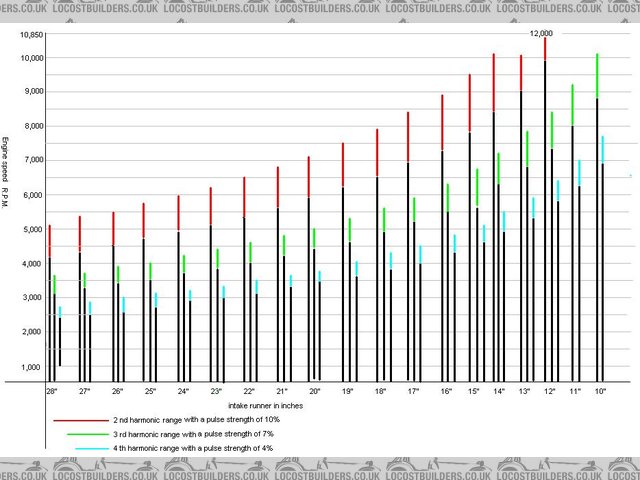

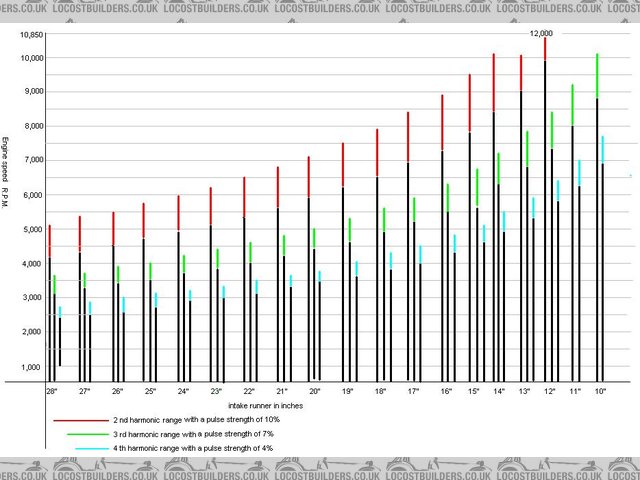

Open the following graphs in seperate tabs and toggle in between to see the differences.

http://www.emeraldm3d.com/media/projects/perfect_flow/50vs80_b.JPG

http://www.emeraldm3d.com/media/projects/perfect_flow/155vs170_b.JPG

The 155mm makes more torque than the 80mm, although the 80mm has a smoother curve. Luckily you can have your cake and eat it. So put 170mm in.

quote:

Originally posted by ettore bugatti

... but basically fit the longest runner physically possible.

Fun, but not quite.

[Edited on 8/6/17 by carboy0]

If you fit the longest runners you can under a typical "7" bonnet they'll be about 14".

Mine are about 14" which, if the diagrams above are to be believed, gives some pulse tuning benefit at around 7k and 5K revs.

Just the areas for peak power and peak torque on many engines.

there's some general rule of thumb dimensions on the Jenvey site as well.

http://www.jenvey.co.uk/faq/general-faq

For my 1.7 Zetec SE (150hp at 7000rpm) looks like I need something like -

35mm butterflies (got 42mm ???)

450mm (18" trumpet inlet to valve distance - interesting this is different to the 14" from the graph earlier in the thread. I am guessing

one is tuned to the 2nd harmonic at approx. 7k rpm and one the third going by the graph.

trumpet inlet to valve distance - interesting this is different to the 14" from the graph earlier in the thread. I am guessing

one is tuned to the 2nd harmonic at approx. 7k rpm and one the third going by the graph.

200mm (8" Valve to butterfly distance

Valve to butterfly distance

Injectors currently in stick position, in head firing at the back of the valve - good for low rpm control and emissions

Will have to get the tape measure out.